Broken Oil pressure switch question

#1

Broken Oil pressure switch question

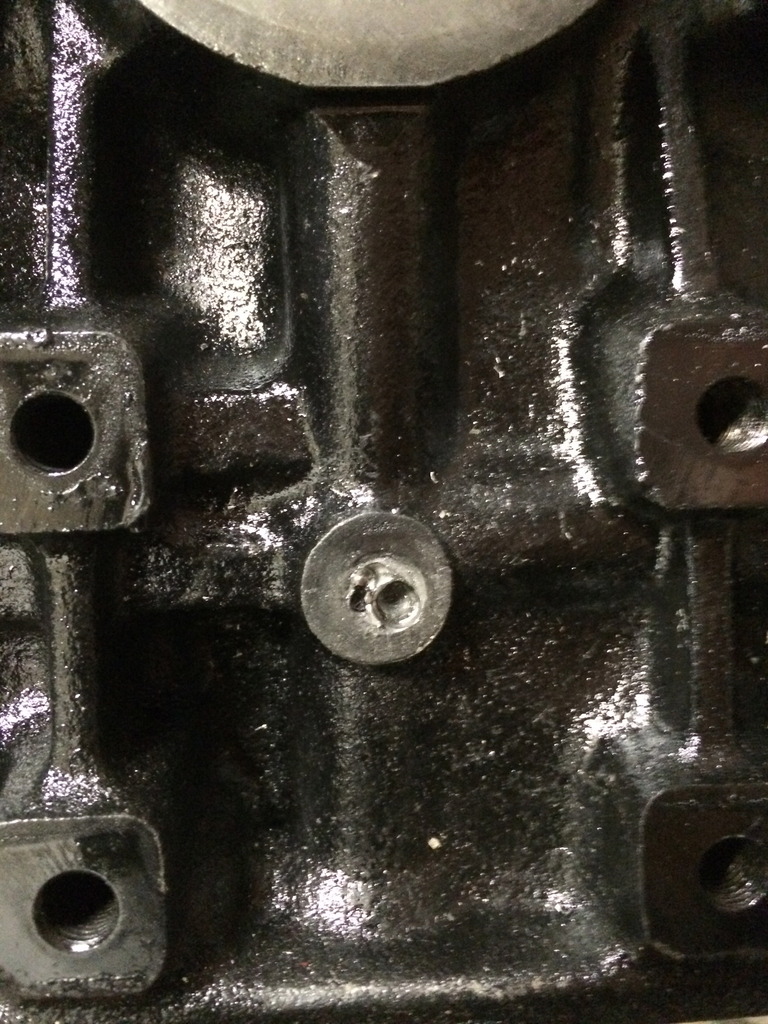

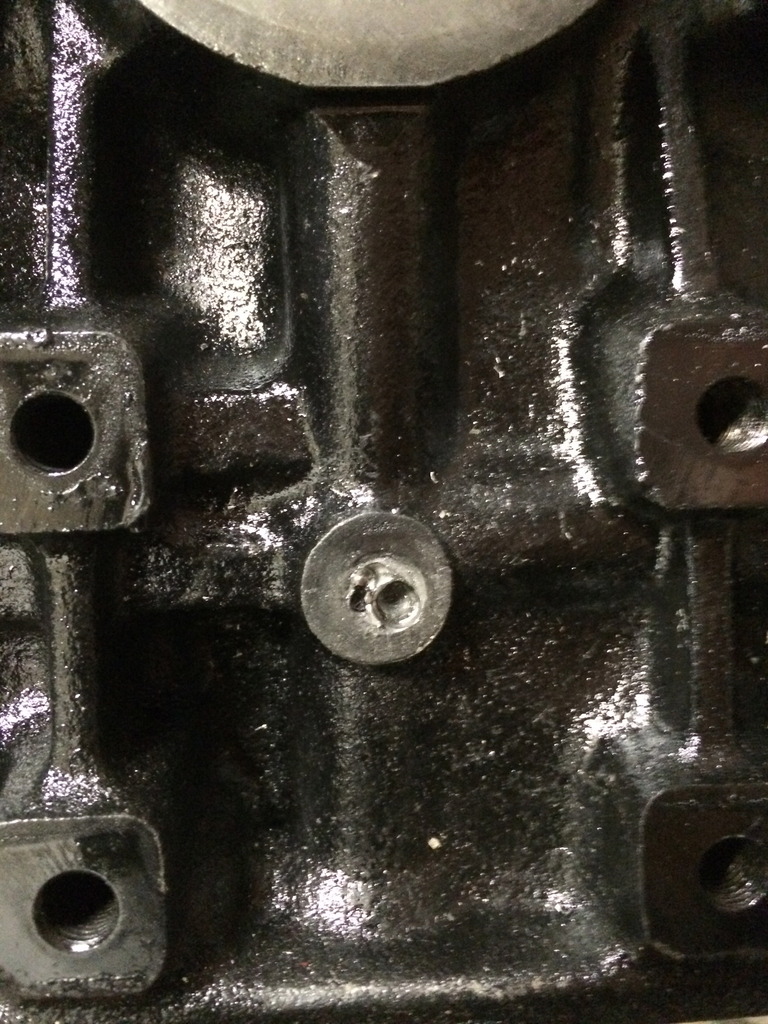

Hey guys I accdentally snapped my oil pressure switch and then tried to remove it with a thread extractor which broke

So then I couldnt get my center punch centered and messed it all up.

Can I weld it shut and relocate the switch? There is a plug in my block (circled in pic) can I move the switch there?

Thanks

So then I couldnt get my center punch centered and messed it all up.

Can I weld it shut and relocate the switch? There is a plug in my block (circled in pic) can I move the switch there?

Thanks

#2

Super Moderator

Staff

iTrader: (1)

Join Date: Aug 2008

Location: Anderson Missouri

Posts: 11,788

Likes: 0

Received 21 Likes

on

19 Posts

You probably used one of those swirled extractors and they are brittle and will snap easily, done the same thing myself. Those should be outlawed. Teh square extractor is more forgiving.

What I did was put a washer and a nut over the broken extractor and welded the nut to it and it came out.

What I did was put a washer and a nut over the broken extractor and welded the nut to it and it came out.

#3

Registered User

Join Date: Sep 2007

Location: San Francisco East Bay

Posts: 8,254

Likes: 0

Received 822 Likes

on

649 Posts

Xylicon recently posted about using that port for a second sender. https://www.yotatech.com/forums/f116...l-port-287580/ Note that the port is "inside" the motor mount, which limits the amount of space (but didn't hurt Xylicon's efforts).

Screw extractors, even the "square" ones, are designed to be very hard and therefore brittle. Using one is always risky; once you're broken it off you cannot drill it out (the extractor is harder than the drill). The weld-on-the-nut method described by Terrys87 does work, but requires some welding talent. (Enough of which I don't think I have.)

Screw extractors, even the "square" ones, are designed to be very hard and therefore brittle. Using one is always risky; once you're broken it off you cannot drill it out (the extractor is harder than the drill). The weld-on-the-nut method described by Terrys87 does work, but requires some welding talent. (Enough of which I don't think I have.)

Last edited by scope103; 03-27-2015 at 07:24 AM.

#4

Xylicon recently posted about using that port for a second sender. https://www.yotatech.com/forums/f116...l-port-287580/ Note that the port is "inside" the motor mount, which limits the amount of space (but didn't hurt Xylicon's efforts).

Screw extractors, even the "square" ones, are designed to be very hard and therefore brittle. Using one is always risky; once you're broken it off you cannot drill it out (the extractor is harder than the drill). The weld-on-the-nut method described by Terrys87 does work, but requires some welding talent. (Enough of which I don't think I have.)

Screw extractors, even the "square" ones, are designed to be very hard and therefore brittle. Using one is always risky; once you're broken it off you cannot drill it out (the extractor is harder than the drill). The weld-on-the-nut method described by Terrys87 does work, but requires some welding talent. (Enough of which I don't think I have.)

Thread

Thread Starter

Forum

Replies

Last Post

GreatLakesGuy

The Classifieds GraveYard

8

09-04-2015 09:27 AM

skoti89

Offroad Tech

3

07-08-2015 12:05 AM