dropzone's notebook of ideas, links, mods, misc BS

#1

dropzone's notebook of ideas, links, mods, misc BS

**Update 7/10/2017: PHOTOBUCKET CHANGED THEIR TERMS AND WANT $400 A YEAR FOR PIC HOSTING. Some pics in this thread are gone forever***

OK, so I am stealing this idea from another Oregon wheeler 'Mr Stubs'.

the idea comes from a very informative thread on another forum getting gutted when one member had a bad day and deleted some of the best toyota information on the web.

I have tried bookmarking threads, emailing links to myself to save ideas for another day and always loose that info for one reason or another so I am copying Stubs idea and using this thread to store that sort of junk for me to find later.

this is stuff that I have found that may be useful to me, feel free to use the links but as always use at your own risk. we are responsible for the work we do/have done to our trucks.

sources of this stuff comes from all over the web to include: Pirate, TTora, 4x4wire, Ih8ud & vender's websites etc. I will try to give credit where credit is due.

Edit: I guess I will try to organize this thing a little better with a separate section for suspension, engine, general links etc...

OK, so I am stealing this idea from another Oregon wheeler 'Mr Stubs'.

the idea comes from a very informative thread on another forum getting gutted when one member had a bad day and deleted some of the best toyota information on the web.

I have tried bookmarking threads, emailing links to myself to save ideas for another day and always loose that info for one reason or another so I am copying Stubs idea and using this thread to store that sort of junk for me to find later.

this is stuff that I have found that may be useful to me, feel free to use the links but as always use at your own risk. we are responsible for the work we do/have done to our trucks.

sources of this stuff comes from all over the web to include: Pirate, TTora, 4x4wire, Ih8ud & vender's websites etc. I will try to give credit where credit is due.

Edit: I guess I will try to organize this thing a little better with a separate section for suspension, engine, general links etc...

[SIZE="2"]If you have found a company that was great, a link that you feel would be useful or any other Toyota related services please email or PM the info to me and I will add it[/SIZE]

Last edited by dropzone; 07-10-2017 at 11:12 AM.

The following users liked this post:

Seth_PDX (01-23-2021)

#2

increase Power steering fluid reservoir capacity

txzuk1988:

Not sure what the toy factory reservoir capacity is. But I used it stock with a stock mini truck pump for a while. I simply cut the reservoir in half and added some exhaust tubing to make the tank about 8" tall. Here is the 3.5" exhaust pipe I used 409 SS

more reservoir Information:

From Crash:

Power Steering Cavitation--T-G PS pump

possible solutions:

http://www.quadratec.com/products/56112_5000.htm

Not sure what the toy factory reservoir capacity is. But I used it stock with a stock mini truck pump for a while. I simply cut the reservoir in half and added some exhaust tubing to make the tank about 8" tall. Here is the 3.5" exhaust pipe I used 409 SS

more reservoir Information:

From Billavista's paper:

" 3. Reservoirs

3-1. Reservoirs.

A reservoir stores a liquid that is not being used in a hydraulic system. It has many other important functions too:

* It also allows gases to expel and foreign matter to settle out from a liquid.

* It functions as a cooler

* It functions as a "coarse strainer", providing sedimentation of impurities

* It functions as an air and water separator

* It functions as a foundation for pumps etc.

a. Construction. A properly constructed reservoir should be able to dissipate heat from the oil, separate air from the oil, and settle out contaminates that are in it. Reservoirs range in construction from small steel stampings to large cast or fabricated units. The large tanks should be sandblasted after all the welding is completed and then flushed and steam cleaned.

b. Shape. Design features of a reservoir. It should be high and narrow rather than shallow and broad. The oil level should be as high as possible above the opening to a pump's suction line. This prevents the vacuum at the line opening from causing a vortex or whirlpool effect, which would mean that a system is probably taking in air. Aerated oil will not properly transmit power because air is compressible. Aerated oil has a tendency to break down and lose its lubricating ability. To increase the ability of the tank to separate dirt and water, the bottom must be slightly inclined (deepest end opposite the inlet/outlet end). An ordinary cock (without handle) is fitted so that impurities can easily be drained off. Increased separation of the air that is always present in the oil can be obtained by fitting an inclined coarse metal strainer (approx. 25-50 mesh/ inch) by the return line. Both suction and return pipes must be cut diagonally. The ends of the pipes must be located 2-4 times the pipe diameter above the bottom of the tank, partly to avoid foaming at the return line, and partly to prevent air from being drawn into the suction line, especially when the vehicle/vessel heels over to one side.

c. Size. A reservoir must be large enough so that it has a reserve of oil with all the cylinders in a system fully extended. An oil reserve must be high enough to prevent a vortex at the suction line's opening. A reservoir must have sufficient space to hold all the oil when the cylinders are retracted, as well as allow space for expansion when the oil is hot. A common-size reservoir on a mobile machine is a 20- or 30-gallon tank used with a 100- GPM system. Many 10-GPM systems operate with 2- or 3-gallon tanks because these mobile systems operate intermittently, not constantly. For stationary machinery, a rule of thumb is that a reservoirís size should be two to three times a pumpís output per minute. A large size tank is highly desirable for cooling. The large surface areas exposed to the outside air transfer heat from the oil. Also, a large tank helps settle out the contaminates and separates the air by reducing recirculation. If the application is mobile, if there is no cooler built into the system, and provided the tank is located where air circulation is good, ideally the size of the tank should be approx. 2-3 times the capacity of the pump per minute.In our 4x4 systems we are unlikely to be able to achieve such large reservoir capacities as this, but the important lesson is that your reservoirs cannot be too big - it is best to use the largest possible reservoir space and weight restrictions allow."

Further down, it states this:

" f. Line Connections. A pump suction and a tank's return lines should be attached by flanges or by welded heavy-duty couplings. Standard couplings usually are not suitable because they spread when welded. If a suction line is connected at the bottom, a coupling should extend well above the bottom, inside the tank; residual dirt will not get in a suction line when a tank or strainer is cleaned. A return line should discharge near a tank's bottom always below the oil level. A pipe is usually cut at a 45-degree angle and the flow aimed away from a suction line to improve circulation and cooling. A baffle plate is used to separate a suction line from a return line. This causes the return oil to circulate around an outer wall for cooling before it gets to the pump again. A baffle plate should be about two-thirds the height of a tank. The lower corners are cut diagonally to allow circulation. They must be larger in area than a suction line's cross section. Otherwise the oil level between a return and a suction side might be uneven. Baffling also prevents oil from sloshing around when a machine is moving. Many large reservoirs are cross-baffled to provide cooling and prevent sloshing."

From here: http://www.pirate4x4.com/tech/billav...ng/index1.html

Good luck.

Al

" 3. Reservoirs

3-1. Reservoirs.

A reservoir stores a liquid that is not being used in a hydraulic system. It has many other important functions too:

* It also allows gases to expel and foreign matter to settle out from a liquid.

* It functions as a cooler

* It functions as a "coarse strainer", providing sedimentation of impurities

* It functions as an air and water separator

* It functions as a foundation for pumps etc.

a. Construction. A properly constructed reservoir should be able to dissipate heat from the oil, separate air from the oil, and settle out contaminates that are in it. Reservoirs range in construction from small steel stampings to large cast or fabricated units. The large tanks should be sandblasted after all the welding is completed and then flushed and steam cleaned.

b. Shape. Design features of a reservoir. It should be high and narrow rather than shallow and broad. The oil level should be as high as possible above the opening to a pump's suction line. This prevents the vacuum at the line opening from causing a vortex or whirlpool effect, which would mean that a system is probably taking in air. Aerated oil will not properly transmit power because air is compressible. Aerated oil has a tendency to break down and lose its lubricating ability. To increase the ability of the tank to separate dirt and water, the bottom must be slightly inclined (deepest end opposite the inlet/outlet end). An ordinary cock (without handle) is fitted so that impurities can easily be drained off. Increased separation of the air that is always present in the oil can be obtained by fitting an inclined coarse metal strainer (approx. 25-50 mesh/ inch) by the return line. Both suction and return pipes must be cut diagonally. The ends of the pipes must be located 2-4 times the pipe diameter above the bottom of the tank, partly to avoid foaming at the return line, and partly to prevent air from being drawn into the suction line, especially when the vehicle/vessel heels over to one side.

c. Size. A reservoir must be large enough so that it has a reserve of oil with all the cylinders in a system fully extended. An oil reserve must be high enough to prevent a vortex at the suction line's opening. A reservoir must have sufficient space to hold all the oil when the cylinders are retracted, as well as allow space for expansion when the oil is hot. A common-size reservoir on a mobile machine is a 20- or 30-gallon tank used with a 100- GPM system. Many 10-GPM systems operate with 2- or 3-gallon tanks because these mobile systems operate intermittently, not constantly. For stationary machinery, a rule of thumb is that a reservoirís size should be two to three times a pumpís output per minute. A large size tank is highly desirable for cooling. The large surface areas exposed to the outside air transfer heat from the oil. Also, a large tank helps settle out the contaminates and separates the air by reducing recirculation. If the application is mobile, if there is no cooler built into the system, and provided the tank is located where air circulation is good, ideally the size of the tank should be approx. 2-3 times the capacity of the pump per minute.In our 4x4 systems we are unlikely to be able to achieve such large reservoir capacities as this, but the important lesson is that your reservoirs cannot be too big - it is best to use the largest possible reservoir space and weight restrictions allow."

Further down, it states this:

" f. Line Connections. A pump suction and a tank's return lines should be attached by flanges or by welded heavy-duty couplings. Standard couplings usually are not suitable because they spread when welded. If a suction line is connected at the bottom, a coupling should extend well above the bottom, inside the tank; residual dirt will not get in a suction line when a tank or strainer is cleaned. A return line should discharge near a tank's bottom always below the oil level. A pipe is usually cut at a 45-degree angle and the flow aimed away from a suction line to improve circulation and cooling. A baffle plate is used to separate a suction line from a return line. This causes the return oil to circulate around an outer wall for cooling before it gets to the pump again. A baffle plate should be about two-thirds the height of a tank. The lower corners are cut diagonally to allow circulation. They must be larger in area than a suction line's cross section. Otherwise the oil level between a return and a suction side might be uneven. Baffling also prevents oil from sloshing around when a machine is moving. Many large reservoirs are cross-baffled to provide cooling and prevent sloshing."

From here: http://www.pirate4x4.com/tech/billav...ng/index1.html

Good luck.

Al

Ok, there is one thing that you really need ... some way to keep the p/s fluid temp down. Since I am going to tap the steering box for hydro assist, that will help with keeping the temps down a little, but a cooler is still needed. Unfortunately there is just NO room down low (You always need to make sure your reservior is the highest point or fluid will drain back and overfill the res.) to mount the cooler easily. I finally ended up mouting it to the battery tray...

I just finished building my truck and installed the TG Power steering pump, resevoir, and cooler. I tapped my own PS box and used a 6" stroke 1 1/2" PSC Ram. I am using royal purple synthetic PS fluid. I bled everything real well and the system was working good. I took it for a ride today and the steering got progressivly worse. I had it ideling and opened the resevoir to see a small vortex drawing air occasionally. With the truck off the large resy is filled up to the welded seam. Does anyone have any suggestions or experience with this? I've read about this issue with stock resevoirs but the problem went away when the installed a larger one or increased capacity. Thanks

Last edited by dropzone; 05-28-2009 at 12:00 AM.

#3

Mounting Box for High steer and Steering Box Info

The IFS box mount is pretty simple. Cut the fender well so you can easily access the PS box area like shown in my pictures posted already and then push the box all the way forward until it is on the core. Angle it so the holes line up on the frame in the center and then test fit your mounting plates. Tack weld and test fit again to make sure the pitman arm clears and weld out.

what you don't want to have happen when you install your high steer:

Power steering box rebuilding:

http://web.archive.org/web/200503220.../taco/box.html

will aad some more info on steering box stuff here--

great link on rebuilding your steering box: http://web.archive.org/web/200503220.../taco/box.html

tapping your box for hydro assist http://board.marlincrawler.com/index.php?topic=10579.0

just in case you take a steering box apart too far--great write up

Found this on ttora in this thread:

http://ttora.com/forum/showthread.php?t=146872

Well, this is my first technical post so I will try to put this together in a way that should be pretty simple to follow;

Earlier today I tore apart an '87 Toyota IFS steering box from a 4Runner to start tapping the case for hydro assist stearing. Well, I was blessed with the opportunity to experience the frustration of many before me who have experienced the miss hap of pulling the worm gear from its piston and the 43 bearings (yes, I counted) snugged away inside pour out to their freedom. Thankfully I had the shaft pointed up and the bearing fell into its own housing.

**Just as a note, if you are seperating your steering box for hydro assist plumbing, you DO NOT have to pull the worm shaft out!! Once you've backed out the 10mm hex centering shaft cover, pull it out with channel locks if it doesn't want to come the rest of the way out, a spring will follow and behind that is the centering shaft which must come out or your piston won't slide out. This is where I screwed up and didn't realize the shaft was still in there, so I pulled the worm gear to see what was wrong and got myself in a pickle.**

So here are the puzzle pieces; Worm gear with spline shaft, Worm gear piston, and 43 bearings.

This tube acts as a channel that the bearings travel through while the piston rides up and down on the shaft. It has to be removed with a phillip's head screwdriver and it will come out rather easily and is split down the middle;

cont...

Earlier today I tore apart an '87 Toyota IFS steering box from a 4Runner to start tapping the case for hydro assist stearing. Well, I was blessed with the opportunity to experience the frustration of many before me who have experienced the miss hap of pulling the worm gear from its piston and the 43 bearings (yes, I counted) snugged away inside pour out to their freedom. Thankfully I had the shaft pointed up and the bearing fell into its own housing.

**Just as a note, if you are seperating your steering box for hydro assist plumbing, you DO NOT have to pull the worm shaft out!! Once you've backed out the 10mm hex centering shaft cover, pull it out with channel locks if it doesn't want to come the rest of the way out, a spring will follow and behind that is the centering shaft which must come out or your piston won't slide out. This is where I screwed up and didn't realize the shaft was still in there, so I pulled the worm gear to see what was wrong and got myself in a pickle.**

So here are the puzzle pieces; Worm gear with spline shaft, Worm gear piston, and 43 bearings.

This tube acts as a channel that the bearings travel through while the piston rides up and down on the shaft. It has to be removed with a phillip's head screwdriver and it will come out rather easily and is split down the middle;

cont...

Next, thread the shaft back into the piston until the threads start to appear at the at the lower port for the tube. You won't be able to get the bearings back in with the shaft all the way home as you need to work it in and let gravity help you a little bit to get the bearings settled in;

I used the tang end of a file to help push the bearings in and found that turning the shaft back n forth a little helped sit them in.

Make sure the bearings sit "down" into the shaft and don't ride up to the top of the piston or they'll start plopping out. And, don't let them ride down into the piston past the lower port or they will find their way into the bottom of the piston and you'll have to back the shaft out and start over!

Here you can see that there are as many bearings now in side that are going to fit. BUT, there are quite a few left over, exactly enough to fit inside the tube.

How am I going to get them to stay inside the tube with out them going all over when I pick it up to put it back in place on the piston...?

cont...

I used the tang end of a file to help push the bearings in and found that turning the shaft back n forth a little helped sit them in.

Make sure the bearings sit "down" into the shaft and don't ride up to the top of the piston or they'll start plopping out. And, don't let them ride down into the piston past the lower port or they will find their way into the bottom of the piston and you'll have to back the shaft out and start over!

Here you can see that there are as many bearings now in side that are going to fit. BUT, there are quite a few left over, exactly enough to fit inside the tube.

How am I going to get them to stay inside the tube with out them going all over when I pick it up to put it back in place on the piston...?

cont...

VASELINE!!

I didn't want to use gear lube cause I figured it would be too thick and maybe end up with a fluid flow issue. I'm guessing the vaseline is light enough that it'll liquify pretty quick and blend in with the power steering fluid pretty easily. And, I probably didn't have to use as much as I did either. Some at each end of the tube would have worked just as well. I tried this once without the vaseline and the bearings spilled uncontrollably and jammed up the ports so that I could not sink the tube so I had to fish the bearings out to try again;

After the tube is in place, put the strap over it and put the screws in. Test the travel of the shaft a couple of times and if it feels like it is riding well, tighten the screws the rest of the way. You cannot afford to have them backing out;

Easiest way I found to see if the bearings were sitting well was to let gravity do it's work. I pulled the shaft out some of the way (NOT TOO MUCH OR YOU"LL LOSE THE BEARINGS AGAIN) and just let the weight of it pull itself down onto the piston. If it rides down without binding or stalling you've completed the task;

http://yfrog.us/jpwormgearbearings011z

Yer back in buisness!!

I didn't want to use gear lube cause I figured it would be too thick and maybe end up with a fluid flow issue. I'm guessing the vaseline is light enough that it'll liquify pretty quick and blend in with the power steering fluid pretty easily. And, I probably didn't have to use as much as I did either. Some at each end of the tube would have worked just as well. I tried this once without the vaseline and the bearings spilled uncontrollably and jammed up the ports so that I could not sink the tube so I had to fish the bearings out to try again;

After the tube is in place, put the strap over it and put the screws in. Test the travel of the shaft a couple of times and if it feels like it is riding well, tighten the screws the rest of the way. You cannot afford to have them backing out;

Easiest way I found to see if the bearings were sitting well was to let gravity do it's work. I pulled the shaft out some of the way (NOT TOO MUCH OR YOU"LL LOSE THE BEARINGS AGAIN) and just let the weight of it pull itself down onto the piston. If it rides down without binding or stalling you've completed the task;

http://yfrog.us/jpwormgearbearings011z

Yer back in buisness!!

Pitman Arms - Dimension of other arms

http://www.pirate4x4.com/forum/showthread.php?t=593367

http://www.pirate4x4.com/forum/showthread.php?t=294202

Pitman Arm Removal / Swap - How to

http://www.pirate4x4.com/forum/showthread.php?t=511091

[Power Steering Box - Info

How to rebuild it

http://web.archive.org/web/200503220.../taco/box.html

Steering Box rebuild kit PN 04455-35080

http://www.pirate4x4.com/forum/showthread.php?t=587519

How to Tap it for Hydro Assist

http://www.wildyoats.com/hydraulic_assist_tech.htm

http://board.marlincrawler.com/index.php?topic=10579.0

Power Steering Box Location, Moving it Forward by Bones

Since this has been on numerous threads, I may as well post it here. Here's an IFS steering box moved as far forward as I could (2.5"~) and hacked the radiator support to boot. Ref: http://www.pirate4x4.com/forum/showt...t=steering+box

More pictures of mounting the power steering IFS boxes here:

http://www.pirate4x4.com/forum/showthread.php?t=587517

http://www.pirate4x4.com/forum/showthread.php?t=424669

Power steering box identification

http://www.pirate4x4.com/forum/showthread.php?t=587515

Power Steering Box AN-Fittings

http://www.pirate4x4.com/forum/showthread.php?t=617050

High Pressure Port - 16 x 1.5 MM Inverted Flare to #6 JIC Male adapter, Toyota - 'PSC Motorsports' #PSC-SF06 or 'Summit Racing' #EAR-9919DFJERL

Low Pressure Port - 17 x 1.5 MM Inverted Flare to #6 JIC Male adapter, Toyota - 'PSC Motorsports' #PSC-SF07

Power Steering Flush

http://www.pirate4x4.com/forum/showthread.php?t=588900

Power Steering Hose Part Numbers- Stock Application-

Stock power steering high pressure hose PN's:

'85 4WD NAPA: NPS73354 $27.99

VATO Zone: 71260 $25.99

'83 4WD VATO Zone: 71171 $25.99

Schucks: 71171 $37.93

The difference's between the two are the '83 has a 45 degree bend and long stem into the box and a 90 degree bend on the pump end and the '85 has a short 90 on the box side and two oposing 90's on the pump side

Power Steering Pump Mod - Removing the restrictor plate

http://www.pirate4x4.com/forum/showt...hreadid=167299

http://board.marlincrawler.com/index.php?topic=10579.0

Power Steering Pump - High Flow TC style mounting

http://www.pirate4x4.com/forum/showthread.php?t=571624

http://www.pirate4x4.com/forum/showthread.php?t=630765

Power Steering Reservior

www.Speedwaymotors.com has a power steering resivoir that is a perfect fit for this set up. $24.95

It is P/N 91032876-STD-10. It has a -6 inlet and a -10 outlet.

this fits the power steering pump inlet well.

Tripling the size of the Toyota power steering reservoir

http://www.pirate4x4.com/forum/showthread.php?t=579700

http://www.pirate4x4.com/forum/showthread.php?t=593367

http://www.pirate4x4.com/forum/showthread.php?t=294202

Pitman Arm Removal / Swap - How to

http://www.pirate4x4.com/forum/showthread.php?t=511091

[Power Steering Box - Info

How to rebuild it

http://web.archive.org/web/200503220.../taco/box.html

Steering Box rebuild kit PN 04455-35080

http://www.pirate4x4.com/forum/showthread.php?t=587519

How to Tap it for Hydro Assist

http://www.wildyoats.com/hydraulic_assist_tech.htm

http://board.marlincrawler.com/index.php?topic=10579.0

Power Steering Box Location, Moving it Forward by Bones

Since this has been on numerous threads, I may as well post it here. Here's an IFS steering box moved as far forward as I could (2.5"~) and hacked the radiator support to boot. Ref: http://www.pirate4x4.com/forum/showt...t=steering+box

More pictures of mounting the power steering IFS boxes here:

http://www.pirate4x4.com/forum/showthread.php?t=587517

http://www.pirate4x4.com/forum/showthread.php?t=424669

Power steering box identification

http://www.pirate4x4.com/forum/showthread.php?t=587515

Power Steering Box AN-Fittings

http://www.pirate4x4.com/forum/showthread.php?t=617050

High Pressure Port - 16 x 1.5 MM Inverted Flare to #6 JIC Male adapter, Toyota - 'PSC Motorsports' #PSC-SF06 or 'Summit Racing' #EAR-9919DFJERL

Low Pressure Port - 17 x 1.5 MM Inverted Flare to #6 JIC Male adapter, Toyota - 'PSC Motorsports' #PSC-SF07

Power Steering Flush

http://www.pirate4x4.com/forum/showthread.php?t=588900

Power Steering Hose Part Numbers- Stock Application-

Stock power steering high pressure hose PN's:

'85 4WD NAPA: NPS73354 $27.99

VATO Zone: 71260 $25.99

'83 4WD VATO Zone: 71171 $25.99

Schucks: 71171 $37.93

The difference's between the two are the '83 has a 45 degree bend and long stem into the box and a 90 degree bend on the pump end and the '85 has a short 90 on the box side and two oposing 90's on the pump side

Power Steering Pump Mod - Removing the restrictor plate

http://www.pirate4x4.com/forum/showt...hreadid=167299

http://board.marlincrawler.com/index.php?topic=10579.0

Power Steering Pump - High Flow TC style mounting

http://www.pirate4x4.com/forum/showthread.php?t=571624

http://www.pirate4x4.com/forum/showthread.php?t=630765

Power Steering Reservior

www.Speedwaymotors.com has a power steering resivoir that is a perfect fit for this set up. $24.95

It is P/N 91032876-STD-10. It has a -6 inlet and a -10 outlet.

this fits the power steering pump inlet well.

Tripling the size of the Toyota power steering reservoir

http://www.pirate4x4.com/forum/showthread.php?t=579700

Last edited by dropzone; 12-09-2011 at 05:18 AM.

#5

thread links

Google for TOyota Websites

Flat Bed Pics:

http://www.pirate4x4.com/forum/showt...ferrerid=89727

Toyota Front Bumper pics

http://pirate4x4.com/forum/showthrea...t=front+bumper

Great info On color schemes etc:

Toyota Reference.com

SR-5 Info

SR-5.com

Service Manual Links:

http://ncttora.com/fsm/index.html

4Crawler Off Road Toyota CHeap Tricks

Rear Disk Conversion Links/Help:

http://www.pirate4x4.com/forum/showt...ferrerid=89727

--Proportioning Valve http://www.pirate4x4.com/forum/showt...ferrerid=89727

--Dave'z Offroad Performance Rear Disk Conversion kit:

http://www.davezoffroadperformance.c...c.php?f=3&t=52

Steering Box Rebuilding:

http://www.pirate4x4.com/forum/showt...ferrerid=89727

Power Steering Pump Rebuilding

http://www.toy4x4.net/ps/index.htm

Axle Info

Axle info - Toyota

Toyota Mini Truck Front Axle Identification

79-80 no gusset

81-83 short gusset (to u-bolts)

84-85 long gusset (past u-bolts)

Stock Toyota front axle measurements for comparison:

55.5" wide, 29" spring perch centers, '79-85 Toyota trucks and 4runners, SA Hubs

58.25" wide, 29" spring perch centers, '79-85 Toyota trucks and 4runners, IFS Hubs

63.5" wide, (set up for coil springs) 90-97 FJ80 and FZJ80 Landcruisers

'86-95 IFS front end is about 58.5" wide

'93-98 T100 IFS front end is about 65" wide

Toyota Rear Axle Widths:

55" wide, '79-85 4wd trucks/4runners - 6 Lug

58" wide, '86-95 4wd trucks/4runners - 6 Lug

56" wide, '79-95 2wd Trucks - 5 Lug

60.75" wide, '95.5-up Tacomas/4runners

66.75" wide, '93-98 T100 trucks

Identifying Toyota Third Members:

http://home.4x4wire.com/erik/diffs/

Find your factory Gear Ratio using your VIN

http://www.brian894x4.com/Gearratiosanddiffs.html

More Differential Information:

"LPH" (Long Pinion Head) vs "SPH" (Short Pinion Head). by Drew Persson

http://www.pirate4x4.com/forum/showt...23#post1478223

Myth Settled: 8.4, V6, 4cyl, ALL 8" - by Brian Ellinger

http://www.pirate4x4.com/forum/showt...hreadid=228681

Pluging ABS sensor hole in late model diffs

http://www.pirate4x4.com/forum/showthread.php?t=587522

Toyota 4 pinoin 6 cylinder 8" diff (30 spline)

http://www.4crawler.com/4x4/Images/Diff6cyl.jpg

Toyota Land cruiser high pinion 8" diff (30 spline)

http://www.4crawler.com/4x4/Images/DiffHP.jpg

Toyota 4 pinion 6 cylinder 8" 3rd from a '96-00? 4Runner (30 spline)

http://www.pirate4x4.com/forum/attac...&postid=436184

Differential Mounting Differences Between Different 3rd Members

http://www.pirate4x4.com/forum/showt...52#post5331552

ID Toyota Mini Truck axles

79-80 no gusset

81-83 short gusset (to u-bolts)

84-85 long gusset (past u-bolts)

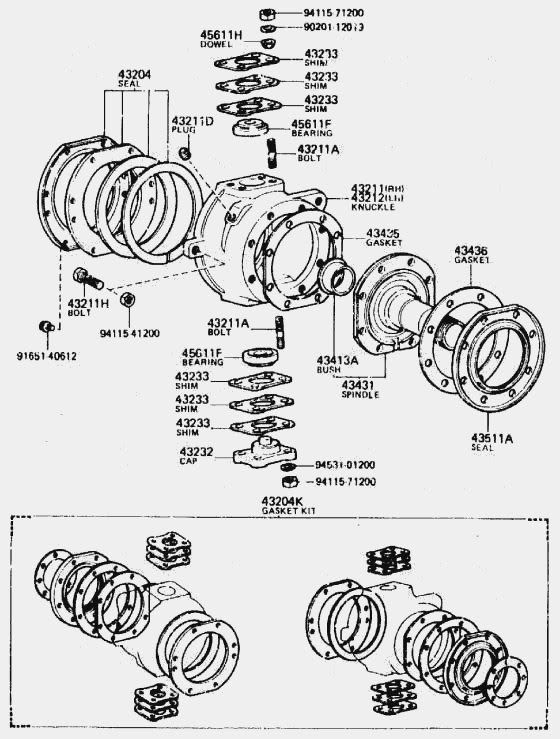

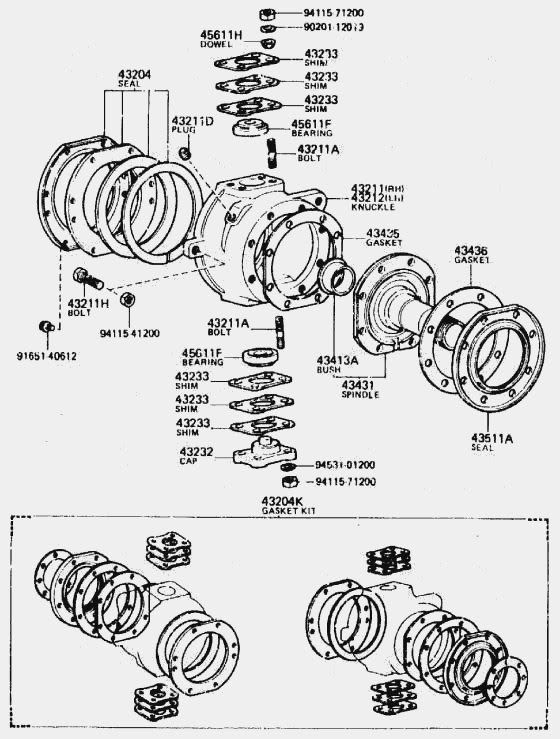

Rebuilding Front Straight Axle:

http://www.birfield.com/~morgan/tech/axle/

http://www.4crawler.com/4x4/CheapTri...eRebuild.shtml

http://www.lukemiller.org/toys/1985_...t_axle_FSM.pdf

Rebuilding Aisin Manual Hubs:

https://www.yotatech.com/forums/f116...ferrerid=12218

Power Steering Cooler Recommendations

http://www.tacomaterritory.com/forum...teering+cooler

Suspension links

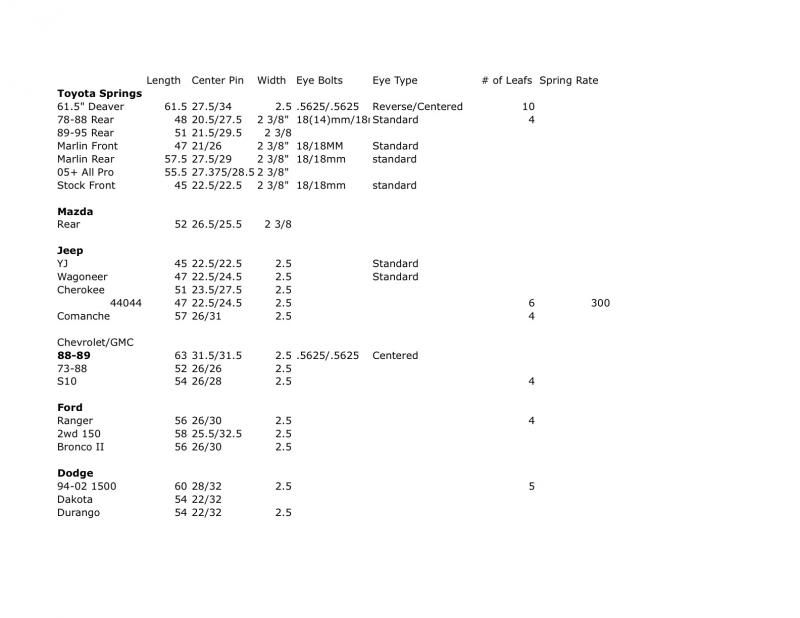

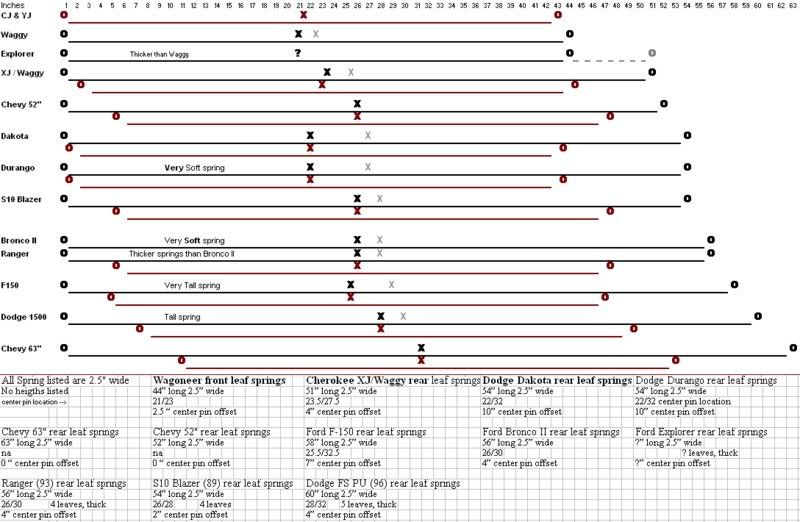

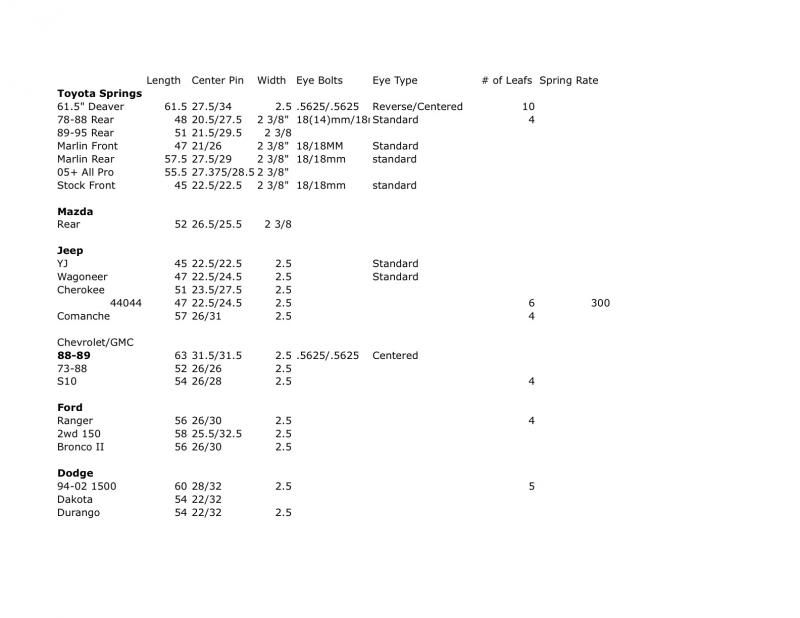

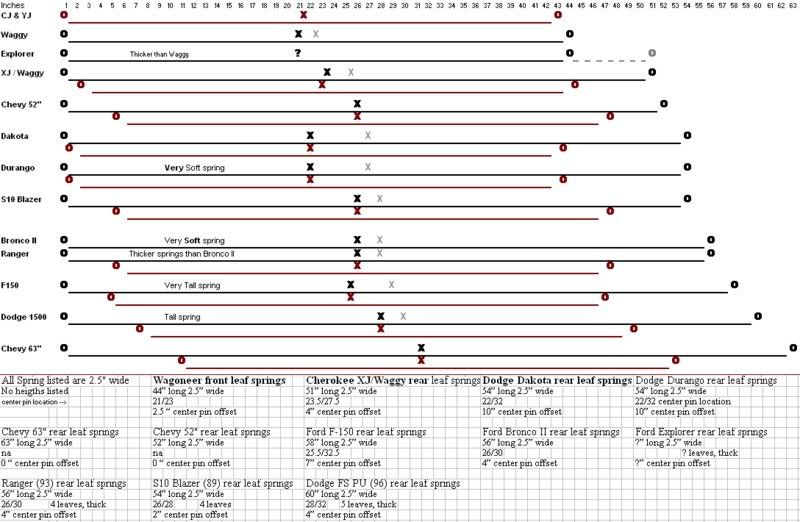

Toyota Rear Springs up front (RUF)

http://pirate4x4.com/forum/showthrea...&highlight=faq

63" Chevy Spring Conversions: http://pirate4x4.com/forum/showthrea...ight=chevy+faq

Transfer Case Info

Trail-Gears TC Videos:

t-case: http://www.trail-gear.com/videos/toy-tcase.wmv

Dual case: http://www.trail-gear.com/videos/toydualcase.wmv

Transmission and other Transfer case info: http://www.4x4wire.com/toyota/faq/parts/

Marlin transmission info: http://marlincrawler.com/transmission/rebuilt-complete

4.7 gear install (Kiwi found something the pro's were not aware of )

)

pretty cool when Marlin's kid notices your fix:

Rear Differential Breather Extension:

https://www.yotatech.com/forums/f129...her-mod-75747/

TTORA FAQ and TOyota Knowledge Base LINK: http://www.ttora.com/wiki/index.php/Main_Page

IH8Mud's Toyota TAQ: http://forum.ih8mud.com/79-95-toyota...questions.html

YotaTech tech Write Ups

Roger Browns AKA 4Crawlers info (some great stuff) he covers just about anything you can think of

4Runner: http://www.4crawler.com/4Runner.shtml

Cheap Tricks: http://www.4crawler.com/4x4/CheapTri...#MODIFICATION$

Drive Shaft Info

General DS info

Building a Square Front Driveshaft

Flat Bed Pics:

http://www.pirate4x4.com/forum/showt...ferrerid=89727

Toyota Front Bumper pics

http://pirate4x4.com/forum/showthrea...t=front+bumper

Great info On color schemes etc:

Toyota Reference.com

SR-5 Info

SR-5.com

Service Manual Links:

http://ncttora.com/fsm/index.html

4Crawler Off Road Toyota CHeap Tricks

Rear Disk Conversion Links/Help:

http://www.pirate4x4.com/forum/showt...ferrerid=89727

--Proportioning Valve http://www.pirate4x4.com/forum/showt...ferrerid=89727

--Dave'z Offroad Performance Rear Disk Conversion kit:

http://www.davezoffroadperformance.c...c.php?f=3&t=52

Steering Box Rebuilding:

http://www.pirate4x4.com/forum/showt...ferrerid=89727

Power Steering Pump Rebuilding

http://www.toy4x4.net/ps/index.htm

Axle Info

Axle info - Toyota

Toyota Mini Truck Front Axle Identification

79-80 no gusset

81-83 short gusset (to u-bolts)

84-85 long gusset (past u-bolts)

Stock Toyota front axle measurements for comparison:

55.5" wide, 29" spring perch centers, '79-85 Toyota trucks and 4runners, SA Hubs

58.25" wide, 29" spring perch centers, '79-85 Toyota trucks and 4runners, IFS Hubs

63.5" wide, (set up for coil springs) 90-97 FJ80 and FZJ80 Landcruisers

'86-95 IFS front end is about 58.5" wide

'93-98 T100 IFS front end is about 65" wide

Toyota Rear Axle Widths:

55" wide, '79-85 4wd trucks/4runners - 6 Lug

58" wide, '86-95 4wd trucks/4runners - 6 Lug

56" wide, '79-95 2wd Trucks - 5 Lug

60.75" wide, '95.5-up Tacomas/4runners

66.75" wide, '93-98 T100 trucks

Identifying Toyota Third Members:

http://home.4x4wire.com/erik/diffs/

Find your factory Gear Ratio using your VIN

http://www.brian894x4.com/Gearratiosanddiffs.html

More Differential Information:

"LPH" (Long Pinion Head) vs "SPH" (Short Pinion Head). by Drew Persson

http://www.pirate4x4.com/forum/showt...23#post1478223

Myth Settled: 8.4, V6, 4cyl, ALL 8" - by Brian Ellinger

http://www.pirate4x4.com/forum/showt...hreadid=228681

Pluging ABS sensor hole in late model diffs

http://www.pirate4x4.com/forum/showthread.php?t=587522

Toyota 4 pinoin 6 cylinder 8" diff (30 spline)

http://www.4crawler.com/4x4/Images/Diff6cyl.jpg

Toyota Land cruiser high pinion 8" diff (30 spline)

http://www.4crawler.com/4x4/Images/DiffHP.jpg

Toyota 4 pinion 6 cylinder 8" 3rd from a '96-00? 4Runner (30 spline)

http://www.pirate4x4.com/forum/attac...&postid=436184

Differential Mounting Differences Between Different 3rd Members

http://www.pirate4x4.com/forum/showt...52#post5331552

ID Toyota Mini Truck axles

79-80 no gusset

81-83 short gusset (to u-bolts)

84-85 long gusset (past u-bolts)

Rebuilding Front Straight Axle:

http://www.birfield.com/~morgan/tech/axle/

http://www.4crawler.com/4x4/CheapTri...eRebuild.shtml

http://www.lukemiller.org/toys/1985_...t_axle_FSM.pdf

Rebuilding Aisin Manual Hubs:

https://www.yotatech.com/forums/f116...ferrerid=12218

Power Steering Cooler Recommendations

http://www.tacomaterritory.com/forum...teering+cooler

Suspension links

Toyota Rear Springs up front (RUF)

http://pirate4x4.com/forum/showthrea...&highlight=faq

63" Chevy Spring Conversions: http://pirate4x4.com/forum/showthrea...ight=chevy+faq

Transfer Case Info

Trail-Gears TC Videos:

t-case: http://www.trail-gear.com/videos/toy-tcase.wmv

Dual case: http://www.trail-gear.com/videos/toydualcase.wmv

Transmission and other Transfer case info: http://www.4x4wire.com/toyota/faq/parts/

Marlin transmission info: http://marlincrawler.com/transmission/rebuilt-complete

4.7 gear install (Kiwi found something the pro's were not aware of

)

)So, I put some 4.7 gears in My single, forward shift, T-case yesterday. I've worked on lots of New Process cases but never a toyota case, so I actually read the directions..........that was My downfall.

When you read the directions, You dont really watch what's going on because You're depending on the step by step directions to guide You, plus looking at the cool pictures.

So I clearanced the case for the new oversized gear. I fit the gear in place and all looked good

I also clearanced the shift fork/dog for Low gear, just like the pictures tell You to do.

I put the whole thing back together, and thats when I found out that as soon as I put the case in low gear on the bench, that it locked up.

So, of course I just added some more force to fix the problem . Well, when I did that it would make a ty noise and then would jump out of low gear. WTF.

. Well, when I did that it would make a ty noise and then would jump out of low gear. WTF.

I pull the whole thing apart to trace the problem down. And now for the stupid part.

The directions say to clearance the low gear shift fork down, but they dont tell You to grind the roll pin for that fork down, or dont drive it all the way home. Because if You dont shorten that roll pin or do drive it down all the way........Guess what?

It then hits the in new oversized gear and locks Your Up!

This is the pin in question after shortening it.

In low gear, after the fix.

I hope this helps some other Noob, do it right the First time.

Kiwi

When you read the directions, You dont really watch what's going on because You're depending on the step by step directions to guide You, plus looking at the cool pictures.

So I clearanced the case for the new oversized gear. I fit the gear in place and all looked good

I also clearanced the shift fork/dog for Low gear, just like the pictures tell You to do.

I put the whole thing back together, and thats when I found out that as soon as I put the case in low gear on the bench, that it locked up.

So, of course I just added some more force to fix the problem

. Well, when I did that it would make a ty noise and then would jump out of low gear. WTF.

. Well, when I did that it would make a ty noise and then would jump out of low gear. WTF.I pull the whole thing apart to trace the problem down. And now for the stupid part.

The directions say to clearance the low gear shift fork down, but they dont tell You to grind the roll pin for that fork down, or dont drive it all the way home. Because if You dont shorten that roll pin or do drive it down all the way........Guess what?

It then hits the in new oversized gear and locks Your Up!

This is the pin in question after shortening it.

In low gear, after the fix.

I hope this helps some other Noob, do it right the First time.

Kiwi

Kiwipushrod,

I noticed you are installing TG gears but the same applies with our instructions in that the former employee who made the guide left that part out!

So I have updated step 49 of our installer to include this required info

http://www.marlincrawler.com/tech/gu...1-gear-install

Thanks for the tip!

Mike

I noticed you are installing TG gears but the same applies with our instructions in that the former employee who made the guide left that part out!

So I have updated step 49 of our installer to include this required info

http://www.marlincrawler.com/tech/gu...1-gear-install

Thanks for the tip!

Mike

Rear Differential Breather Extension:

https://www.yotatech.com/forums/f129...her-mod-75747/

TTORA FAQ and TOyota Knowledge Base LINK: http://www.ttora.com/wiki/index.php/Main_Page

IH8Mud's Toyota TAQ: http://forum.ih8mud.com/79-95-toyota...questions.html

YotaTech tech Write Ups

Roger Browns AKA 4Crawlers info (some great stuff) he covers just about anything you can think of

4Runner: http://www.4crawler.com/4Runner.shtml

Cheap Tricks: http://www.4crawler.com/4x4/CheapTri...#MODIFICATION$

Drive Shaft Info

General DS info

Building a Square Front Driveshaft

Last edited by dropzone; 06-07-2016 at 03:49 PM. Reason: fixed, added some links

#6

WInch Info

I could go on for hours about this subject, so I will keep this short.

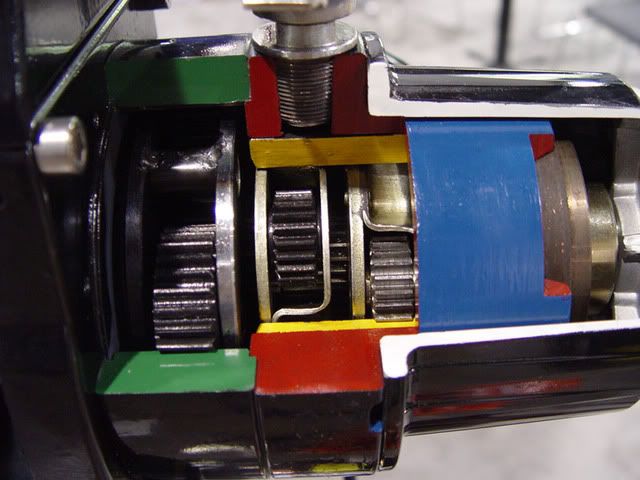

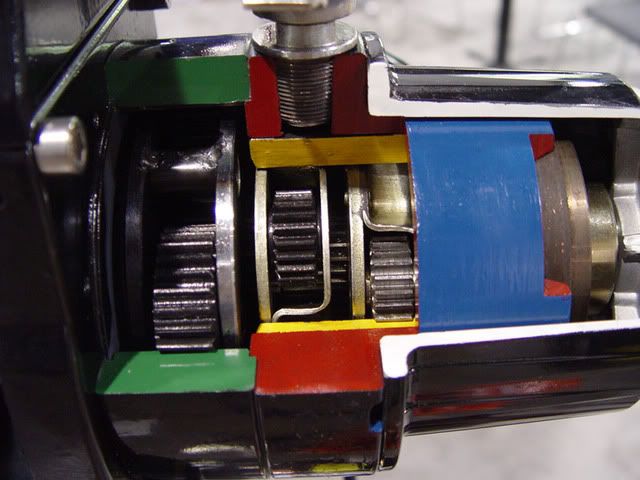

First, there are 3 basic types of winches:

Planetary:

Spur Gear:

Worm Gear:

Planetary winches are a great option for the recreational 4x4 enthusiast. They are relatively affordable, and perform well under occasional use. Although the quality varies the greatest among this sector.

The other types of winches are Spur Gear, and Worm Gear winches. These are industrial winches. If your going to use your winch 5, 10, 50 times a day, buy a Spur or Worm Drive winch. Also notice that I showed pictures of almost every winch in this market. The Ramsey shown is almost identical to what you will find on almost every flat bed wrecking truck on the road today. The Superwinch Husky is an offroad recovery worm drive winch. Then, we all know the Warn 8274. Worm drive winches are also the only winches which are designed to power a load out.

As I mentioned, the big difference comes in the Planetary gear winches.

The largest issues with these winches come from poor build quality. Its very common to have 1 or 2 85 amp solenoids going to a 400 amp motor. Thus, the solenoids will melt. Also, the motors do not have a long duty cycle. Heat becomes a killer for these winches. Planetary drive winches use a brake to hold the load in place. Normally it does not work very well. When you power out, the brake engages, and is always pushing against the winch. Guess, what, this creates heat.

For those who like to run synthetic winch line, this heat will melt the winchline. Most winches (warn's, milemarker's, ramsey's, etc) have the brake under the winch drum. This means as you power out the winch will heat up, and melt the winch line. While most have sidestepped this issue by using fireline, it still is a problem. The only manufacturer who has an external brake, is superwinch, in their EP series winches:

Another issue with synthetic winchline is it is very slick, thus causing it to slide in-between the underlaying layers on the winch drum. With steel cable, it is very easy to spool the cable, so it is nice and tight, avoiding this issue. Even with with best spool job, synthetic winchline will slip in-between the lower layers. This causes a very hard side-load on the winch:

On the Warn winches, it will cause the casting of the winch to snap off at the cross bars. I wish I had a good photo of when one broke on my co-worker in Maine. It made a bad situation worse.

Next is going into rating. Some manufacturers rate the winches at their stall speed and some rate their winches at their working load. So, YES one manufacturer can call a winch a 8,000, and some could call it 10,000.

I don't know if you can tell, but I have had to use ALOT of winches, and prefer Superwinch. They just seem to be built better. I have also had a lot of problems with Warn Winches. But this could also be because I have used 10 warn winches to every other winch out there. I personally feel, if you want a REALLY good winch, you should suck it up and buy a worm, or spur drive winch. I love the superwinch husky, but its stupid expensive. The Warn 8274 is awesome, but so fast, it can get unsafe. I ended up picking up a Ramsey re12000 for my current truck, because they are priced right, and short of some bad solenoids (easy to swap in superwinch solenoids), are really good winches.

Let me know what else you would like to know.

First, there are 3 basic types of winches:

Planetary:

Spur Gear:

Worm Gear:

Planetary winches are a great option for the recreational 4x4 enthusiast. They are relatively affordable, and perform well under occasional use. Although the quality varies the greatest among this sector.

The other types of winches are Spur Gear, and Worm Gear winches. These are industrial winches. If your going to use your winch 5, 10, 50 times a day, buy a Spur or Worm Drive winch. Also notice that I showed pictures of almost every winch in this market. The Ramsey shown is almost identical to what you will find on almost every flat bed wrecking truck on the road today. The Superwinch Husky is an offroad recovery worm drive winch. Then, we all know the Warn 8274. Worm drive winches are also the only winches which are designed to power a load out.

As I mentioned, the big difference comes in the Planetary gear winches.

The largest issues with these winches come from poor build quality. Its very common to have 1 or 2 85 amp solenoids going to a 400 amp motor. Thus, the solenoids will melt. Also, the motors do not have a long duty cycle. Heat becomes a killer for these winches. Planetary drive winches use a brake to hold the load in place. Normally it does not work very well. When you power out, the brake engages, and is always pushing against the winch. Guess, what, this creates heat.

For those who like to run synthetic winch line, this heat will melt the winchline. Most winches (warn's, milemarker's, ramsey's, etc) have the brake under the winch drum. This means as you power out the winch will heat up, and melt the winch line. While most have sidestepped this issue by using fireline, it still is a problem. The only manufacturer who has an external brake, is superwinch, in their EP series winches:

Another issue with synthetic winchline is it is very slick, thus causing it to slide in-between the underlaying layers on the winch drum. With steel cable, it is very easy to spool the cable, so it is nice and tight, avoiding this issue. Even with with best spool job, synthetic winchline will slip in-between the lower layers. This causes a very hard side-load on the winch:

On the Warn winches, it will cause the casting of the winch to snap off at the cross bars. I wish I had a good photo of when one broke on my co-worker in Maine. It made a bad situation worse.

Next is going into rating. Some manufacturers rate the winches at their stall speed and some rate their winches at their working load. So, YES one manufacturer can call a winch a 8,000, and some could call it 10,000.

I don't know if you can tell, but I have had to use ALOT of winches, and prefer Superwinch. They just seem to be built better. I have also had a lot of problems with Warn Winches. But this could also be because I have used 10 warn winches to every other winch out there. I personally feel, if you want a REALLY good winch, you should suck it up and buy a worm, or spur drive winch. I love the superwinch husky, but its stupid expensive. The Warn 8274 is awesome, but so fast, it can get unsafe. I ended up picking up a Ramsey re12000 for my current truck, because they are priced right, and short of some bad solenoids (easy to swap in superwinch solenoids), are really good winches.

Let me know what else you would like to know.

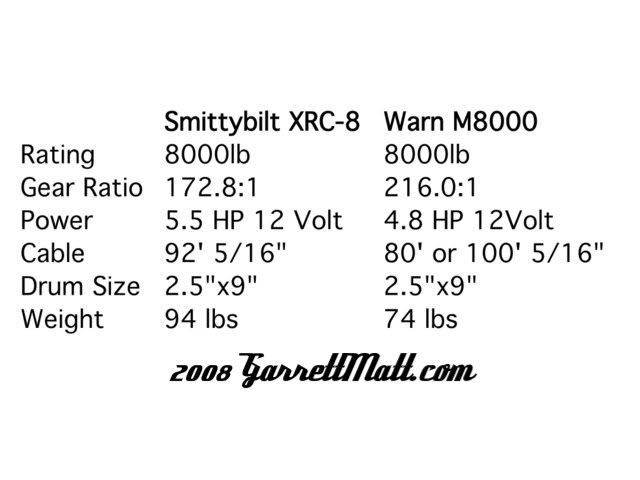

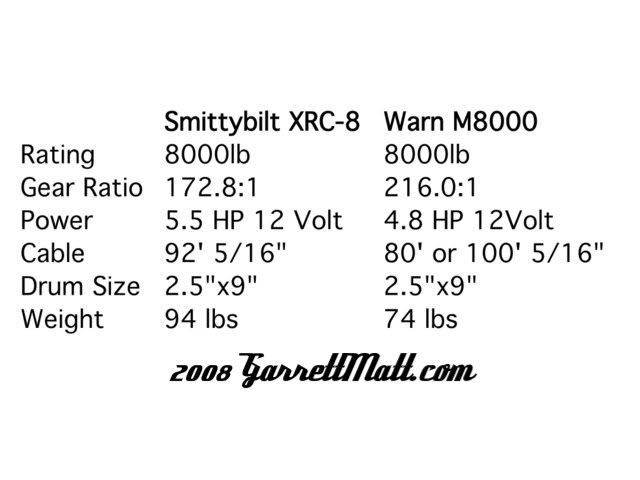

Ha ha. I was hoping you wouldn't ask about the Smittybilt winch. Its one of the few I have NOT used. Although, when you look at the specs next to a warn, it makes any educated buyers wonder why they would want the warn:

See, the specifications on the Smittybult are better! More hp, with less gearing means a faster winch, which does not slow down as much under hard pulls. Warn put in a lower hp motor, and increased the gearing to get the same 8000lb rating out of it.

Also remember the size of the drum acts as a gear too. While not an issue with the 2 winches in question, it becomes something to look at when comparing other winches on the market. Just think: Torque=ForcexDistance So the farther the cable is from the center of the pivot (the drum) the less torque is applied through the winch cable. Thus, less pulling power.

So the smaller the drum of the winch, the more torque you get out of the winch cable. The larger the drum, the less torque out of the winch, but the faster the speed. This also works the other way around. The more wraps on the winch drum, the less power a winch can exert. This will easily drop the pulling power of your 8000lb winch to 4500lbs.

Moving onto the Chicago Electric winch. This is one I have used. After using other winches, this thing feels like it is straight out of 1945. When it gets a load on it, the winch moves SLOW. It also makes so much noise you think that it is un-oiled and the gears are about to seize up. One thing I really don't like about the winch is that the passenger side of the winch spins with the drum. I'm not a big fan of external parts to the winch moving. Its one more chance to get fingers caught up and pinched.

One winch I have been impressed by (for the price) is the milemarker SE9500C:

My buddy Max runs one on his Jeep. What I like the most about this winch is it has a thermal cutout switch. So when the winch gets hot, it shuts down. Keeps dummies like me from frying a substantial chunk of change. I wish more winches has this feature.

Hydraulic winches are awesome. They will pull a house down. But they are not well suited for vehicle recovery. A vehicle needs to be running for the winch to work. There are quite a few situations where it is safer to have the vehicle off, or it is rolled over, and needs to be winched back up. This task is not possible with a hydraulic winch. For our purposes, the electric winch is the only way to go.

Winch looks good! Having 4 crossbars should help quite a bit supporting a synthetic winchline. Just remember, try your best never to power out, and keep as few wraps on the drum as possible to help prevent any side loading to the winch. Synthetic line needs about 10 wraps on a bare drum before you can winch off of it. I'd try my best to keep it there as much as possible. One easy way to help with this is to have 70' of winchline on the drum, and carry a 50' winch extension line with you.

One other point I should mention is ALWAYS ALWAYS ALWAYS wear gloves when winching. Even with synthetic line. Steel cable will get burs in it, and poke your hand. Synthetic line picks up outside elements as it is dragged across the ground. A small stick doesn't seem too bad until it is gouged into your hand!

Also make sure to wear a glove that will fall off easily. If a winch cable were to catch your glove, you want the glove to easily come off of your hand so your hand is not sucked into the winch. This is especially important with the warn 8274 and its 74 ft/min line-speed.

I suggest using a rappelling glove. I use PMI's. And if I can find the PMI heavy-duty gloves, I buy those.

As you can see rappelling gloves have an extra layer across your palm to help keep your hands safe. Thick enough to help protect, but still thin enough to allow movement. Perfect for recreational winching.

Again, if there is anything anyone would like to know, post up!

See, the specifications on the Smittybult are better! More hp, with less gearing means a faster winch, which does not slow down as much under hard pulls. Warn put in a lower hp motor, and increased the gearing to get the same 8000lb rating out of it.

Also remember the size of the drum acts as a gear too. While not an issue with the 2 winches in question, it becomes something to look at when comparing other winches on the market. Just think: Torque=ForcexDistance So the farther the cable is from the center of the pivot (the drum) the less torque is applied through the winch cable. Thus, less pulling power.

So the smaller the drum of the winch, the more torque you get out of the winch cable. The larger the drum, the less torque out of the winch, but the faster the speed. This also works the other way around. The more wraps on the winch drum, the less power a winch can exert. This will easily drop the pulling power of your 8000lb winch to 4500lbs.

Moving onto the Chicago Electric winch. This is one I have used. After using other winches, this thing feels like it is straight out of 1945. When it gets a load on it, the winch moves SLOW. It also makes so much noise you think that it is un-oiled and the gears are about to seize up. One thing I really don't like about the winch is that the passenger side of the winch spins with the drum. I'm not a big fan of external parts to the winch moving. Its one more chance to get fingers caught up and pinched.

One winch I have been impressed by (for the price) is the milemarker SE9500C:

My buddy Max runs one on his Jeep. What I like the most about this winch is it has a thermal cutout switch. So when the winch gets hot, it shuts down. Keeps dummies like me from frying a substantial chunk of change. I wish more winches has this feature.

Hydraulic winches are awesome. They will pull a house down. But they are not well suited for vehicle recovery. A vehicle needs to be running for the winch to work. There are quite a few situations where it is safer to have the vehicle off, or it is rolled over, and needs to be winched back up. This task is not possible with a hydraulic winch. For our purposes, the electric winch is the only way to go.

Winch looks good! Having 4 crossbars should help quite a bit supporting a synthetic winchline. Just remember, try your best never to power out, and keep as few wraps on the drum as possible to help prevent any side loading to the winch. Synthetic line needs about 10 wraps on a bare drum before you can winch off of it. I'd try my best to keep it there as much as possible. One easy way to help with this is to have 70' of winchline on the drum, and carry a 50' winch extension line with you.

One other point I should mention is ALWAYS ALWAYS ALWAYS wear gloves when winching. Even with synthetic line. Steel cable will get burs in it, and poke your hand. Synthetic line picks up outside elements as it is dragged across the ground. A small stick doesn't seem too bad until it is gouged into your hand!

Also make sure to wear a glove that will fall off easily. If a winch cable were to catch your glove, you want the glove to easily come off of your hand so your hand is not sucked into the winch. This is especially important with the warn 8274 and its 74 ft/min line-speed.

I suggest using a rappelling glove. I use PMI's. And if I can find the PMI heavy-duty gloves, I buy those.

As you can see rappelling gloves have an extra layer across your palm to help keep your hands safe. Thick enough to help protect, but still thin enough to allow movement. Perfect for recreational winching.

Again, if there is anything anyone would like to know, post up!

WINCH LINE

What winchline you have, and how long is completely dependent on what your surroundings are like.

Here are some questions to ask yourself.

1) How far away is the nearest winchpoint where I wheel?

2) Will my winchline rub on anything?

For simplicity of this argument, lets focus on steel cable vs. synthetic.

Question #1 refers to the length of your cable. The wheeler who enjoys going through the Southern California Desert is going to need a much longer cable than someone who spends their time in Rousch Creek.

The goal is to have 5 wraps with steel cable, or 10 with synthetic when you start your pull. I round it up to 10' longer than your average pull. So lets say your from PA, and most of your pulls are 20-40' long. I would tell you to run a 50' winchline.

But if you are from Southern California, the anchor may be 100-200 feet away. So this person may need 150' of cable on the drum, plus a winch extension line (or 2).

But if you run synthetic line, you can easily shorten the winch-line to make sure you get those 10 wraps on the drum... more on that below.

Onto question #2. will my winchline rub on anything?

If you answered yes to this question, do not run synthetic line. Tree branches, rocks, and other environmental factors can easily damage a synthetic line and cause it to snap very very easily.

Are the most abrasive conditions your winchline will see be sand? Or are you going to be extra careful with the winchline to make sure it never rubs a rock? Then synthetic will be a great choice.

Remember, having synthetic line is much safer than steel line. Synthetic line does not stretch line steel. Steel will stretch about 15%, and if it were to snap, it take out anything in its path. This is where I want to add a very cool photo of a winchline that went through a land rover discovery, but I can't fine the photo. I would love it if someone could post that photo up for me.

An interesting thing to think about, is a synthetic line is easily damaged by the outside environment, but is not damaged by itself. A steel cable is not easily damaged by the outside environment, but is easily damaged by itself. For example, when you spool a steel cable, it is easy to kink the line, putting in a stress point, and weakening it. Leave it like that for too long, and it can fail.

If synthetic line snaps, you will most likely get a bruise. Although the biggest advantage I see, is how much easier it is to run a synthetic cable up a hill.

To the average user, who is clueless about winches, manufacturers have found that 100' of steel cable is the best choice. It is abrasion resistant, and is a good length to attach to the nearest winch anchor. This is why almost every winch you see on the market today has around 100' of steel cable on it.

To the question about fire wire. All winchlines should be able to withstand some heat from the bare drum. Otherwise, the line can melt, and thus, fail. So if you have a planetary winch, make sure the wrap around the drum is some kind of high temperature line.

Here is a trick I learned from Bill Burke about shortening winch lines, and winch extension lines. Just make a daisy chain. It does not hurt the winchline, and gives you the ability to tailor the length of the line to fit your pull:

Step 1: Flip the thimble through the screw pin d-shackle making a loop.

Step 2: Pull loop back with your right hand, leaving the single cable in your left hand.

Step 3: Cross line in left hand through the loop, and switch the old loop to your right hand, and the single cable to your left hand.

Step 4: Pull on the single cable with your right hand to create a new loop. The single cable is now in your left hand again. Repeat this action to shorten the winchline as necessary.

Step 5: When the winch line is at the appropriate length, stick a bunch through the loop in your right hand and pull back with your left hand to close the loop. I use a hitch pin as a bung, but most anything solid will work. I have even used a rolled up newspaper before.

Step 6: Give the winchline a good tug, to make sure everything is good and tight. Now your ready to winch.

Here are some questions to ask yourself.

1) How far away is the nearest winchpoint where I wheel?

2) Will my winchline rub on anything?

For simplicity of this argument, lets focus on steel cable vs. synthetic.

Question #1 refers to the length of your cable. The wheeler who enjoys going through the Southern California Desert is going to need a much longer cable than someone who spends their time in Rousch Creek.

The goal is to have 5 wraps with steel cable, or 10 with synthetic when you start your pull. I round it up to 10' longer than your average pull. So lets say your from PA, and most of your pulls are 20-40' long. I would tell you to run a 50' winchline.

But if you are from Southern California, the anchor may be 100-200 feet away. So this person may need 150' of cable on the drum, plus a winch extension line (or 2).

But if you run synthetic line, you can easily shorten the winch-line to make sure you get those 10 wraps on the drum... more on that below.

Onto question #2. will my winchline rub on anything?

If you answered yes to this question, do not run synthetic line. Tree branches, rocks, and other environmental factors can easily damage a synthetic line and cause it to snap very very easily.

Are the most abrasive conditions your winchline will see be sand? Or are you going to be extra careful with the winchline to make sure it never rubs a rock? Then synthetic will be a great choice.

Remember, having synthetic line is much safer than steel line. Synthetic line does not stretch line steel. Steel will stretch about 15%, and if it were to snap, it take out anything in its path. This is where I want to add a very cool photo of a winchline that went through a land rover discovery, but I can't fine the photo. I would love it if someone could post that photo up for me.

An interesting thing to think about, is a synthetic line is easily damaged by the outside environment, but is not damaged by itself. A steel cable is not easily damaged by the outside environment, but is easily damaged by itself. For example, when you spool a steel cable, it is easy to kink the line, putting in a stress point, and weakening it. Leave it like that for too long, and it can fail.

If synthetic line snaps, you will most likely get a bruise. Although the biggest advantage I see, is how much easier it is to run a synthetic cable up a hill.

To the average user, who is clueless about winches, manufacturers have found that 100' of steel cable is the best choice. It is abrasion resistant, and is a good length to attach to the nearest winch anchor. This is why almost every winch you see on the market today has around 100' of steel cable on it.

To the question about fire wire. All winchlines should be able to withstand some heat from the bare drum. Otherwise, the line can melt, and thus, fail. So if you have a planetary winch, make sure the wrap around the drum is some kind of high temperature line.

Here is a trick I learned from Bill Burke about shortening winch lines, and winch extension lines. Just make a daisy chain. It does not hurt the winchline, and gives you the ability to tailor the length of the line to fit your pull:

Step 1: Flip the thimble through the screw pin d-shackle making a loop.

Step 2: Pull loop back with your right hand, leaving the single cable in your left hand.

Step 3: Cross line in left hand through the loop, and switch the old loop to your right hand, and the single cable to your left hand.

Step 4: Pull on the single cable with your right hand to create a new loop. The single cable is now in your left hand again. Repeat this action to shorten the winchline as necessary.

Step 5: When the winch line is at the appropriate length, stick a bunch through the loop in your right hand and pull back with your left hand to close the loop. I use a hitch pin as a bung, but most anything solid will work. I have even used a rolled up newspaper before.

Step 6: Give the winchline a good tug, to make sure everything is good and tight. Now your ready to winch.

When you do a winch pull with the motor, the motor is taking the load. If you pull on the cable by moving the truck when the winch is off, then the brake is taking the load, which might not be good for it, especially when it gets shock loaded.

Pulling on the cable with the truck is a lot more likely to cause a shock load, and shock loads can be several times that of a normal winch pull. This could cause a failure somewhere (probably the cable). That's why yank straps are better for pulling with the vehicle- they stretch to absorb and reduce some of the shock load, and they have higher pull ratings. If you were in low-low and very careful not to yank and cause a shock load, I'm sure it would be ok though.

And don't combine a winch with a yank strap either. I did that dragging OOP's out of Fordyce once. When the cable (rope) broke, the yank strap shot his winch hook at my rig. Luckily it went under my rig instead of into it. Lesson learned! :eek: I should have known better though...

Pulling on the cable with the truck is a lot more likely to cause a shock load, and shock loads can be several times that of a normal winch pull. This could cause a failure somewhere (probably the cable). That's why yank straps are better for pulling with the vehicle- they stretch to absorb and reduce some of the shock load, and they have higher pull ratings. If you were in low-low and very careful not to yank and cause a shock load, I'm sure it would be ok though.

And don't combine a winch with a yank strap either. I did that dragging OOP's out of Fordyce once. When the cable (rope) broke, the yank strap shot his winch hook at my rig. Luckily it went under my rig instead of into it. Lesson learned! :eek: I should have known better though...

If you read Eriks he told you why not to use a tow strap, you want to use winch rope.

Here are a couple of threads by Scott at Rockstomper on spliceing and putting loops in winch rope.

http://www.pirate4x4.com/forum/showt...hreadid=177074

http://www.pirate4x4.com/forum/showt...hreadid=177344

Here are a couple of threads by Scott at Rockstomper on spliceing and putting loops in winch rope.

http://www.pirate4x4.com/forum/showt...hreadid=177074

http://www.pirate4x4.com/forum/showt...hreadid=177344

Someone gave me the link once to ones from autozone for $15 a piece. I tried to find them, with no luck.

Although, seriously consider wiring in a Superwinch S3 Solenoid, or another manufacturer's sealed solenoid box. The S3 is the solenoid which is in the EP series and husky series winches. I believe the T-Max Boomer box is the same kind of solenoid setup. If it is sealed, the contacts do not get corroded, thus, they have less resistance, and are less likely to fail. Plus, most of these newer sealed solenoids are designed as a 450 amp solenoid, instead of running 2 85 amp solenoids in parallel.

Your solenoid box, with a bad solenoid, and the control plug taken out is worth around $50. It goes back to everything with Warn stamped on it being worth gold. The S3 solenoid is $120. So your out $70, but have a FAR more reliable solenoid setup.

Although, seriously consider wiring in a Superwinch S3 Solenoid, or another manufacturer's sealed solenoid box. The S3 is the solenoid which is in the EP series and husky series winches. I believe the T-Max Boomer box is the same kind of solenoid setup. If it is sealed, the contacts do not get corroded, thus, they have less resistance, and are less likely to fail. Plus, most of these newer sealed solenoids are designed as a 450 amp solenoid, instead of running 2 85 amp solenoids in parallel.

Your solenoid box, with a bad solenoid, and the control plug taken out is worth around $50. It goes back to everything with Warn stamped on it being worth gold. The S3 solenoid is $120. So your out $70, but have a FAR more reliable solenoid setup.

Recovery 101 LINK

http://www.pirate4x4.com/tech/billav...ery/index.html

Winches From Hell Test Comparison: cheap Vs expensive winchs in real world situations

Last edited by dropzone; 05-01-2009 at 12:23 AM. Reason: added a link

#7

Registered User

When I find good stuff, I print it so I have a copy.

But this makes it difficult to reproduce or keep digitally. I wish a forum thread could be cut and pasted onto a word doc. (I've tried unsuccessfully to do this, forums must do something different so you can't do this)

THanks, Phil

But this makes it difficult to reproduce or keep digitally. I wish a forum thread could be cut and pasted onto a word doc. (I've tried unsuccessfully to do this, forums must do something different so you can't do this)

THanks, Phil

Trending Topics

#8

Gear Calculators

Here are a couple of gear calculators that you can you to figure real world rpm's with assorted gears and tire sizes:

http://www.4lo.com/calc/gearratio.htm

this one has a ton of optionss:

http://www.grimmjeeper.com/gears.html

http://www.4lo.com/calc/gearratio.htm

this one has a ton of optionss:

http://www.grimmjeeper.com/gears.html

#9

Alternator upgrades/Electrical info

Toyota Electrical 101

good source for electrical stuff: http://order.waytekwire.com

Toyota High Output Alternator INfo http://www.ttora.com/forum/showthrea...eferrerid=8874

Wiring Chart (amps to gauge size)

Cool Aux Fuse box kit; http://dogbytecomputer.com/blue-sea-...ative-bus.html

1981 Toyota Truck Wiring Diagram

http://s119.photobucket.com/albums/o...ruck%20wiring/

1st Gen ('81) Vacuum Diagrams: http://s119.photobucket.com/albums/o...acuum%20lines/

22R(RE) alternator upgrades (borrowed from this thread http://pirate4x4.com/forum/showthread.php?t=587456)

GM alternator to 22RE conversion:

Basic Diagram for wiring Aux Light with a relay

Compliments of Elton:

click to enlarge, than when open, click again to enlarge one more time

good source for electrical stuff: http://order.waytekwire.com

Toyota High Output Alternator INfo http://www.ttora.com/forum/showthrea...eferrerid=8874

Wiring Chart (amps to gauge size)

Cool Aux Fuse box kit; http://dogbytecomputer.com/blue-sea-...ative-bus.html

1981 Toyota Truck Wiring Diagram

http://s119.photobucket.com/albums/o...ruck%20wiring/

1st Gen ('81) Vacuum Diagrams: http://s119.photobucket.com/albums/o...acuum%20lines/

22R(RE) alternator upgrades (borrowed from this thread http://pirate4x4.com/forum/showthread.php?t=587456)

I did this mod on my 82 Pick-up and it works great!

The early 22R's pre 84.5's run the 40 Amp externally regulated alternators.

While the 85+ 22R's have the 60 Amp internally regulated alternators.

Comparison photo, the early model alt is considerably larger.

The lower engine/alternator mounts are different, sorry I don't have pics of them. But the older 40amp alternator is mounted in a "female" fashion, while the older mounted in a "male" fashion. The upper mount/adjustment point are the same on both alternators/engines.

The wiring harness from the alternators to the fenderwell plugs are also different. They both are wired differently and have different plug patterns. The only mod necessary is on the fenderwell wiring:

-Carefully remove the 'cover' on the top of the plug(no pic again!)

-Pry the wires out the back of the plug

-Eliminate the external regulator with wiring, LEAVE enough wire to splice into the alternator connection.

-Simple color coordination here, just line up the colors with the coresponding color on the "new" alternator harness. yellow-yellow red-red black-black white-white

-You will have a extra yellow wire after you splice the new connector, I just spliced it into the other yellow wire. PIC

I just ran a 8Ga wire from the white to my ammeter with a 60 amp inline fuse to the battery.

Parts needed for swap:

-Motor/Alternator mount from later 85+ 22R with internally regulated alternator

-Alternator wire harness from alternator to fenderwell plug

-Internally regulated alternator

The early 22R's pre 84.5's run the 40 Amp externally regulated alternators.

While the 85+ 22R's have the 60 Amp internally regulated alternators.

Comparison photo, the early model alt is considerably larger.

The lower engine/alternator mounts are different, sorry I don't have pics of them. But the older 40amp alternator is mounted in a "female" fashion, while the older mounted in a "male" fashion. The upper mount/adjustment point are the same on both alternators/engines.

The wiring harness from the alternators to the fenderwell plugs are also different. They both are wired differently and have different plug patterns. The only mod necessary is on the fenderwell wiring:

-Carefully remove the 'cover' on the top of the plug(no pic again!)

-Pry the wires out the back of the plug

-Eliminate the external regulator with wiring, LEAVE enough wire to splice into the alternator connection.

-Simple color coordination here, just line up the colors with the coresponding color on the "new" alternator harness. yellow-yellow red-red black-black white-white

-You will have a extra yellow wire after you splice the new connector, I just spliced it into the other yellow wire. PIC

I just ran a 8Ga wire from the white to my ammeter with a 60 amp inline fuse to the battery.

Parts needed for swap:

-Motor/Alternator mount from later 85+ 22R with internally regulated alternator

-Alternator wire harness from alternator to fenderwell plug

-Internally regulated alternator

90 supra runs a 80 amp alternator and it is a plug and play.

Yep. The late 80's Corolla, Supra, Cressida and Mini trucks all ran the same physical size Alternator. The Supra and Cressida got 80 ampers and the rest got 60 amp.

Might have to swap the pully but that would be it. Somethign weird is the early 90's 4Runner got a 70 amp on the 22RE's and it has a different plug.

Yep. The late 80's Corolla, Supra, Cressida and Mini trucks all ran the same physical size Alternator. The Supra and Cressida got 80 ampers and the rest got 60 amp.

Might have to swap the pully but that would be it. Somethign weird is the early 90's 4Runner got a 70 amp on the 22RE's and it has a different plug.

ended up going with a gm type 140 amp powermaster... and one of aaron's skookum bolt on passenger side GM alt brackets:

aaron518@charter.net

The alternator is one wire capable - I wired it up 3 wire for better performance. Review the mad electric link for more info:

http://www.madelectrical.com/electri...hreewire.shtml

Good Links:

aaron518@charter.net

The alternator is one wire capable - I wired it up 3 wire for better performance. Review the mad electric link for more info:

http://www.madelectrical.com/electri...hreewire.shtml

Good Links:

22RE Alternator Upgrades / Tech useful links:

http://www.4x4wire.com/toyota/tech/alternator/

http://mralternator.com/alternators/toyota.html

http://www.4crawler.com/4x4/CheapTri...er/index.shtml

11-22 added the following:

http://www.off-road.com/toyota/tech/100alt/

ORC writeup on adding GM alternator to Toyota V6

http://www.madelectrical.com/electri...elcoremy.shtml

Good writeup on the GM 10si and 12si alternators.

http://www.densoaftermarket.com/prod...121&aaia=25688

Good pic of the stock Denso alternator

http://www.premierpowerwelder.com/specs/PP155.html Geezey peezey this one has got the bling factor all to hell - $900!?!

http://www.mobi-arc.com/pricing.htm (Go all the way to near the bottom). Note the Powermaster reference, but no pricing information.

http://www.powermastermotorsports.com/toyota.html

another high-priced alternative

more good sites:

http://www.home.earthlink.net/~twopapa/bigalt.htm

http://www.csupomona.edu/~cdcabrera/gm1wire.htm

http://www.pirate4x4.com/forum/showthread.php?t=47624

This appears to be the best writeup available:

http://www.rocketcityrockcrawlers.co...lt_upgrade.htm

http://www.4x4wire.com/toyota/tech/alternator/

http://mralternator.com/alternators/toyota.html

http://www.4crawler.com/4x4/CheapTri...er/index.shtml

11-22 added the following:

http://www.off-road.com/toyota/tech/100alt/

ORC writeup on adding GM alternator to Toyota V6

http://www.madelectrical.com/electri...elcoremy.shtml

Good writeup on the GM 10si and 12si alternators.

http://www.densoaftermarket.com/prod...121&aaia=25688

Good pic of the stock Denso alternator

http://www.premierpowerwelder.com/specs/PP155.html Geezey peezey this one has got the bling factor all to hell - $900!?!

http://www.mobi-arc.com/pricing.htm (Go all the way to near the bottom). Note the Powermaster reference, but no pricing information.

http://www.powermastermotorsports.com/toyota.html

another high-priced alternative

more good sites:

http://www.home.earthlink.net/~twopapa/bigalt.htm

http://www.csupomona.edu/~cdcabrera/gm1wire.htm

http://www.pirate4x4.com/forum/showthread.php?t=47624

This appears to be the best writeup available:

http://www.rocketcityrockcrawlers.co...lt_upgrade.htm

Compliments of Elton:

click to enlarge, than when open, click again to enlarge one more time

Last edited by dropzone; 04-26-2009 at 12:42 AM. Reason: found some alternator stuff

#10

Registered User

what does the extra fluid capacity give you?

#11

Brake Master Cylinder/Booster Upgrades

somethings I have been reading about the 1" MC (I have one to install too) is that the brakes will feel worse after the swap because the ratio is different unless you convert to a dual diaphram master cylinder (86-87 turbo truck or 88 V-6 4runner, T100's or something like that)

with the stock first gen booster and 1" MC the pedal may feel like it is stiffer and go closer to the floor. here is the MC thread I was reading:

http://www.pirate4x4.com/forum/showthread.php?t=763888

booster links:

http://home.4x4wire.com/erik/4runner/brakes/

http://www.pirate4x4.com/forum/showt...ferrerid=89727

Load Sensing Proportional Valve: LSPV --more to follow

Removal: http://4x4spot.com/proportioning.htm

http://www.off-road.com/trucks4x4/ar....jsp?id=186295

Rebuilding Brake Calipers (good detailed writeup)

http://www.pirate4x4.com/forum/showthread.php?t=770289

Turbo/Dual Diaprahm Brake Booster Upgrade

with the stock first gen booster and 1" MC the pedal may feel like it is stiffer and go closer to the floor. here is the MC thread I was reading:

http://www.pirate4x4.com/forum/showthread.php?t=763888

Sounds like you have the opposite problem I have.

I swapped in the bigger Calipers and now the pedal is too soft and goes to the floor.

Basically, your Master Cyl is too big for the stock 85 calipers. Just replacing one part of the brake system does not always make the brakes better. You have to keep the 'system' working together. Too hard of a pedal means the master is too big. Too soft means it is too small.

Here is the general rundown of how it should be setup.

13/16" master with 4 cyl (2 small/2 large piston) calipers and 79-85 drum brakes

7/8" master with 4 cyl (2 small/2 large piston) calipers and 86-95 drum brakes