Rear bumper brackets on aftermarket swingout

#42

Contributing Member

Thread Starter

iTrader: (3)

Update, 06OCT09

Ok, well today I dropped the bumper off to get the main bracketry burned on and hopefully will get it back tomorrow. Then, I'll gusset and paint and be done with it for now.

#44

Contributing Member

Thread Starter

iTrader: (3)

Update, 11OCT09

I finally got out and started cutting gussets to reenforce the brackets. I had to bolt everything together though because the steel plates have a nice bend in them. So, I'll have to tack the gussets in place while it's attached to the truck. <sigh>

#45

Contributing Member

Thread Starter

iTrader: (3)

Update, 12OCT09

Ok, well today I got to weld on the brackets after I tacked them on while the bumper was fully mounted on the truck. This thing is getting heavier and heavier! LOL!! It was a real pain putting it up by myself.  I know for a fact that the thermo protection circuit works great on my little 110v welder...twice.

I know for a fact that the thermo protection circuit works great on my little 110v welder...twice.  Next, I have to box in the gussets and then box in the frame brackets and I'll be able to paint it.

Next, I have to box in the gussets and then box in the frame brackets and I'll be able to paint it.

I know for a fact that the thermo protection circuit works great on my little 110v welder...twice.

I know for a fact that the thermo protection circuit works great on my little 110v welder...twice.  Next, I have to box in the gussets and then box in the frame brackets and I'll be able to paint it.

Next, I have to box in the gussets and then box in the frame brackets and I'll be able to paint it.

#46

Contributing Member

Thread Starter

iTrader: (3)

Update, 18OCT09

Today I finished cutting out all the rest of the pieces I need to box all the brackets in. I laid all the pieces in spot and then began to tack everything together. Wouldn't you know it, I ran out of wire!! LOL!!!  So, I had the old wire that came with the pawn shop welder and man was that stuff crap. Grrrrrrrrrrrrrr. Needless to say, I had to go get some more Lincoln wire. Hopefully I'll get some time this week to burn this stuff in and then paint it and I'll be DONE!!! Well...with THAT project anyways!!!!!

So, I had the old wire that came with the pawn shop welder and man was that stuff crap. Grrrrrrrrrrrrrr. Needless to say, I had to go get some more Lincoln wire. Hopefully I'll get some time this week to burn this stuff in and then paint it and I'll be DONE!!! Well...with THAT project anyways!!!!!

So, I had the old wire that came with the pawn shop welder and man was that stuff crap. Grrrrrrrrrrrrrr. Needless to say, I had to go get some more Lincoln wire. Hopefully I'll get some time this week to burn this stuff in and then paint it and I'll be DONE!!! Well...with THAT project anyways!!!!!

So, I had the old wire that came with the pawn shop welder and man was that stuff crap. Grrrrrrrrrrrrrr. Needless to say, I had to go get some more Lincoln wire. Hopefully I'll get some time this week to burn this stuff in and then paint it and I'll be DONE!!! Well...with THAT project anyways!!!!!

#47

Contributing Member

Thread Starter

iTrader: (3)

Update, 22OCT09

Today I finally got everything done!!! Finished welding in my gussets, filled in the holes and etched primered and painted everything!! Hopefully this weekend I'll be able to remount everything and be done. Still have to make some mud flap studs but I haven't even pick up the rubber matting I need for that.

So, what do ya'll think???

So, what do ya'll think???

#49

Registered User

Join Date: Feb 2007

Location: Sierra Nevada's or the Deserts of Las Vegas

Posts: 2,203

Likes: 0

Received 0 Likes

on

0 Posts

Lookin good! You gunna cut off those ubolt threads up top? Otherwise your bumpstop won't do much...you probably realize that, just throwin it out there!

#50

Contributing Member

Thread Starter

iTrader: (3)

Now that I have to get the grinder out, I'll zip those down to a couple of threads above the nut. Good lookin out, I appreciate it!

Now that I have to get the grinder out, I'll zip those down to a couple of threads above the nut. Good lookin out, I appreciate it!

#51

Contributing Member

Thread Starter

iTrader: (3)

Update, 31OCT09

Happy Halloween!!

Today I ground down the frame brackets and installed everything. It's all done now. The true test will be under compression/jacking/recovery but I'm confident that this new set up will work better that before.

Today I ground down the frame brackets and installed everything. It's all done now. The true test will be under compression/jacking/recovery but I'm confident that this new set up will work better that before.

#52

Contributing Member

Thread Starter

iTrader: (3)

Update, 01NOV09

Ok, well, here's the results of my project:

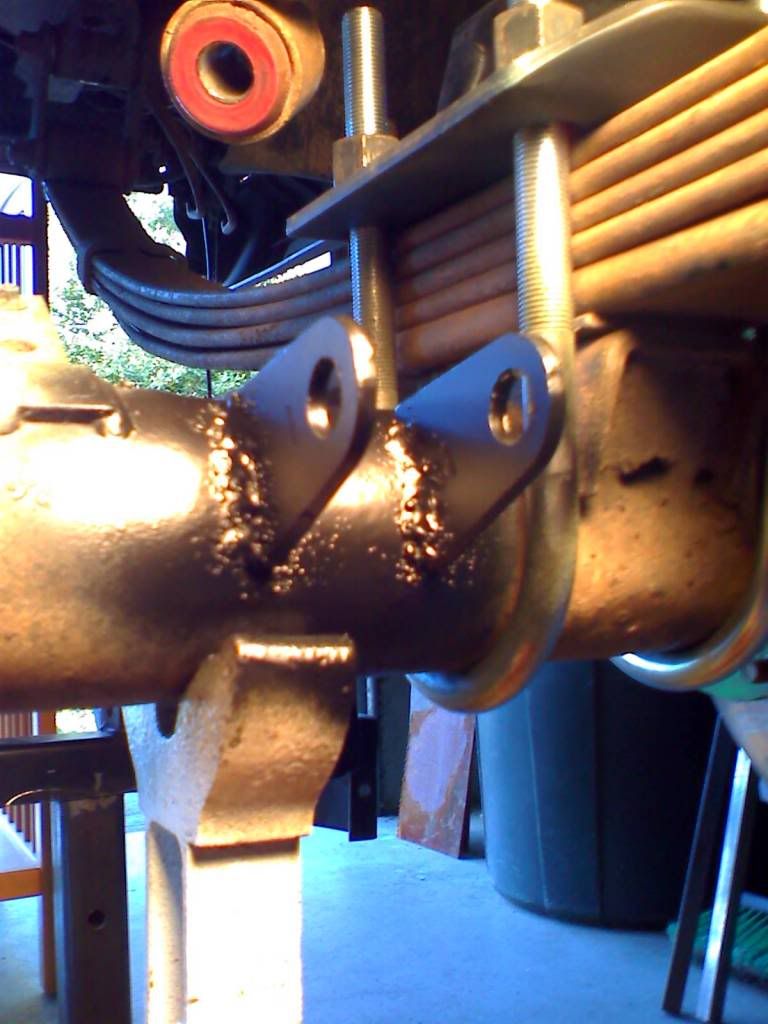

Here's a shot of the new bumper brackets. As you can see my shackles are NO WHERE near making any kind of contact with those brackets. Success!!! That is actually the farthest my shackles have moved in years! LOL!!!

Bad news: my shocks are now stopping my axle due to full compression of the shock itself because I raised the mount when I installed the flip kit.

So, the question is: should I install a bumpstop extension???? I think I would rather have a shock be at full compression rather than extension, but really what do I know??

It's probably a good thing though that my shocks are stopping the articulation. Due to the wheels I have and their shallow backspacing I am actually rubbing against those plastic trim pieces behind the rear tire(honestly who still has those things anyways... ). I don't imagine they are going to last much longer. Also, my rear tires are ALMOST rubbing the frame rails now too. This is not a surprise to me, as I was aware of this when I went with these rims. I may also consider moving the axle forward a smidge to center it in the wheel wheel. I could also put some wheel spacers on too(atleast 1").

). I don't imagine they are going to last much longer. Also, my rear tires are ALMOST rubbing the frame rails now too. This is not a surprise to me, as I was aware of this when I went with these rims. I may also consider moving the axle forward a smidge to center it in the wheel wheel. I could also put some wheel spacers on too(atleast 1").

Ironically, the front end has about 1-2" of compression/extension to go before bumpstops are contacted and thats with a swaybar on!! LOL!!

So, whattya all think??

Here's a shot of the new bumper brackets. As you can see my shackles are NO WHERE near making any kind of contact with those brackets. Success!!! That is actually the farthest my shackles have moved in years! LOL!!!

Bad news: my shocks are now stopping my axle due to full compression of the shock itself because I raised the mount when I installed the flip kit.

So, the question is: should I install a bumpstop extension???? I think I would rather have a shock be at full compression rather than extension, but really what do I know??

It's probably a good thing though that my shocks are stopping the articulation. Due to the wheels I have and their shallow backspacing I am actually rubbing against those plastic trim pieces behind the rear tire(honestly who still has those things anyways...

). I don't imagine they are going to last much longer. Also, my rear tires are ALMOST rubbing the frame rails now too. This is not a surprise to me, as I was aware of this when I went with these rims. I may also consider moving the axle forward a smidge to center it in the wheel wheel. I could also put some wheel spacers on too(atleast 1").

). I don't imagine they are going to last much longer. Also, my rear tires are ALMOST rubbing the frame rails now too. This is not a surprise to me, as I was aware of this when I went with these rims. I may also consider moving the axle forward a smidge to center it in the wheel wheel. I could also put some wheel spacers on too(atleast 1").

Ironically, the front end has about 1-2" of compression/extension to go before bumpstops are contacted and thats with a swaybar on!! LOL!!

So, whattya all think??

#53

Registered User

iTrader: (1)

Join Date: Aug 2006

Location: Ft Collins, CO

Posts: 3,477

Likes: 0

Received 0 Likes

on

0 Posts

Move the shock mounts lower. You want more compression than what is showing. You could easly move them so the shock bolt is just under the axle tube. That is where I mount them on all of the rigs that leave the shop.

I would also consider a 5" long shackle. It will increase the flex quite a bit to be honest with you.

I would also consider a 5" long shackle. It will increase the flex quite a bit to be honest with you.

Last edited by ScottyC; 11-01-2009 at 04:59 PM.

#54

Contributing Member

Thread Starter

iTrader: (3)

Move the shock mounts lower. You want more compression than what is showing. You could easly move them so the shock bolt is just under the axle tube. That is where I mount them on all of the rigs that leave the shop.

I would also consider a 5" long shackle. It will increase the flex quite a bit to be honest with you.

I would also consider a 5" long shackle. It will increase the flex quite a bit to be honest with you.

#57

Contributing Member

iTrader: (3)

I found with the stock rear shock mounts, there was no way to get a shock sized to fit, it was either too short under extension or too long under compression with any sort of suspension flex (fine for stock springs):

- http://www.4crawler.com/4x4/4R_suspe...shtml#R-Shocks

- http://www.4crawler.com/4x4/4R_suspe...shtml#R-Shocks

#58

Contributing Member

Thread Starter

iTrader: (3)

I found with the stock rear shock mounts, there was no way to get a shock sized to fit, it was either too short under extension or too long under compression with any sort of suspension flex (fine for stock springs):

- http://www.4crawler.com/4x4/4R_suspe...shtml#R-Shocks

- http://www.4crawler.com/4x4/4R_suspe...shtml#R-Shocks

Now, am I going to damage my shocks?

Last edited by BigBluePile; 11-04-2009 at 04:00 PM.

#59

Contributing Member

Thread Starter

iTrader: (3)

Update, 14DEC09

Ok, well, its completed and here's the results...geez all this 'cause of stupid bumper brackets...sheesh. LOL!!!

So, recap then pics:

4Crawler rear bumper bracket kit

TG ubolt flip kit/bumpstops

TG 1.5" wheel spacers x4

TG 5" greaseable rear shackles

Locally sourced shock mount tabs/bolts

Now, I have to do something with the backside of the wheel well and I can get some more "squat" out of the rear axle. I'm contemplating some axle relocation plates to move the axle forward a little.

Any thoughts??

The front actually has another smidgen to go before bumpstops become compressed. Not too shabby and WAY better than what I had before!!!!

So, recap then pics:

4Crawler rear bumper bracket kit

TG ubolt flip kit/bumpstops

TG 1.5" wheel spacers x4

TG 5" greaseable rear shackles

Locally sourced shock mount tabs/bolts

Now, I have to do something with the backside of the wheel well and I can get some more "squat" out of the rear axle. I'm contemplating some axle relocation plates to move the axle forward a little.

Any thoughts??

The front actually has another smidgen to go before bumpstops become compressed. Not too shabby and WAY better than what I had before!!!!