3.0 rebuild begins

#21

Registered User

Thread Starter

top ring stuck on this piston

All the rings are stuck on this piston

ready to take to the machine shop

cleaning off the gunk while waiting on the engine parts at the machine shop.

#22

Registered User

Thread Starter

Has anyone run across a ball bearing plug in the oil galley that was leaking? If so, what what was your solution. Mine is leaking at the rear block galley.

#24

Registered User

Thread Starter

because of this water circulation was restricted on the back side of number 6. Found a build up of crud packed between the cylinder wall and freeze plug.

#26

Registered User

Thread Starter

this the ball bearing in the rear oil galley

Hard to see but it is/was leaking. rear of block

this is a shot of the front oil galley with its ball bearing. I have read about them in the toyota manuals but this is a first for me.

#28

Registered User

Thread Starter

Yes the block is going to the machine shop for cleaning and new freeze plugs. The procedure for getting the ball bearings out is crazy. localized heating until they fall out! Correct me if i read it wrong. Regardless more reading required.

#29

Registered User

Must have been a cost/time cutting measure to use these. If one leaks, I'd be afraid it'd leak again, even if it was reset.

Don't know why it wouldn't be possible to drill and tap for a tapered thread plug with female allen top then grind, or mill it flush after setting it.

Don't know why it wouldn't be possible to drill and tap for a tapered thread plug with female allen top then grind, or mill it flush after setting it.

#30

Registered User

Thread Starter

I want to replace them with pipe plugs. But have to get them out first with out messing up the block. Thot it was in the FSM but now i think i read it online somewhere. The one that is leaking is the rear and I only want to do it once. Those are the only ones i have found, hope there arent any more!!

#31

Registered User

Thread Starter

I found an article from enginebuildermag about removing the ball bearing. It is saying about the same thing i have seen else where.

(From Enginebuildermag.com) ( Toyota and some other manufacturers utilize a ball bearing to cap off oil galleys instead of a pipe plug. These should always be removed to ensure that the oil galleys are cleaned of any contaminants.

To remove the ball, heat it cherry red with a TIG welder, then cool it with water; the ball will then fall out. Drive the other end out with a rod from the opposite end. To replace, use sealer and install new balls which are available from several different suppliers that sell standard balls for ball bearings. So far, the balls used have been standard sizes.)

(From Enginebuildermag.com) ( Toyota and some other manufacturers utilize a ball bearing to cap off oil galleys instead of a pipe plug. These should always be removed to ensure that the oil galleys are cleaned of any contaminants.

To remove the ball, heat it cherry red with a TIG welder, then cool it with water; the ball will then fall out. Drive the other end out with a rod from the opposite end. To replace, use sealer and install new balls which are available from several different suppliers that sell standard balls for ball bearings. So far, the balls used have been standard sizes.)

#32

Registered User

Thread Starter

Got the engine parts in the machine shop. I decided to have the block bored because of a couple of pistons were scraping the cylinder walls to the point they might not hone out. Mains are good, crank will be polished. I decided to NOT have the ball bearings removed from the oil galley. I am going to use epoxy around the edge of the ball to hopefully stop the leak/seep. Wont know about the heads for a few days. The cams might be able to be polished. I have a week or so wait for them to get to it, this shop is really busy. Time to do some parts cleaning.

#34

Registered User

Thread Starter

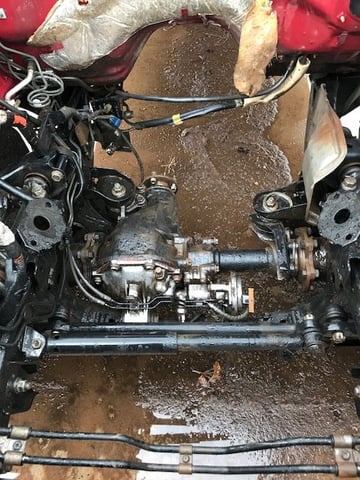

Just a little bit of dirt and grime

Started pressure washing the engine bay

We are in a drought here in Texas. I got half way done washing and the bottom fell out of the clouds for the rest for the day. that's just nuts!!

Transmission clean

All cleaned up

#35

Registered User

Join Date: Jan 2011

Location: exo-reality -wave if you see me; Front Range, CO

Posts: 652

Received 93 Likes

on

73 Posts

Looking good. Nice truck.

You must live around the "Slow-deatha" or Midland area.

IF you go without having them knock that ball plug out, -maybe- try JB weld to seal around it. I'd probably try to get that ball out though.

I get kinda paranoid about thinkin' what kind of crap is plugged backup behind it, Nowhutahmean Vern?

And after seeing that water jacket outlet plug up above? Yucko. Good luck.

You must live around the "Slow-deatha" or Midland area.

IF you go without having them knock that ball plug out, -maybe- try JB weld to seal around it. I'd probably try to get that ball out though.

I get kinda paranoid about thinkin' what kind of crap is plugged backup behind it, Nowhutahmean Vern?

And after seeing that water jacket outlet plug up above? Yucko. Good luck.

#37

Registered User

Thread Starter

Coopster, I will have the oil galleys all cleaned out before it goes back together. I'm in Lubbock, the only difference between Midland/Lubbock area would be the oil field smell. YUCK.

#38

Registered User

Thread Starter

Anyone know of some good deals on the injector nozzle holders

I got some new injectors but they did not come with the seals for the electrical connectors. Im thinking orings , anyone know a size. been looking not found yet.

replaced the transmission screen. the old one was not too bad for over 125,000 miles.

Last edited by amamike91; 08-26-2018 at 07:46 AM.

#39

Registered User

Thread Starter

Back from the machine shop ready to put back together.

Gift wrapped.

I'm ready to get started, Block was bored .50 mm over. Crank was polished, std/std. Heads were surfaced, new valve guides and new cams. The rods were checked and honed.

Just replaced all the power steering hoses. All new vacuum lines and wire looming is next on the list. Replacing the output shaft seals on the transfer case. And the list goes on.