Slider Step Idea

#1

Registered User

Thread Starter

Slider Step Idea

So I plan on getting the SS 7.2 lift on this summer. I should gain 3 to 3.5" of lift. My wife/kids already complain that it is difficult to get in the truck after I removed the running boards, and the lift will make it worse. I want to get a set of the 4xInnovations sliders, but want to make them more step friendly.

My idea is this: take some 3/4 No. 9 flattened expanded metal sheet, and cut it into pieces to fit between the slider rails. Weld it into place about a 1/4" below the top surface of the sliders. This would "fill" in the openings to provide more step surface, but not look too bulky by filling it in with a solid plate.

For those not familiar with flattened expanded metal sheet:

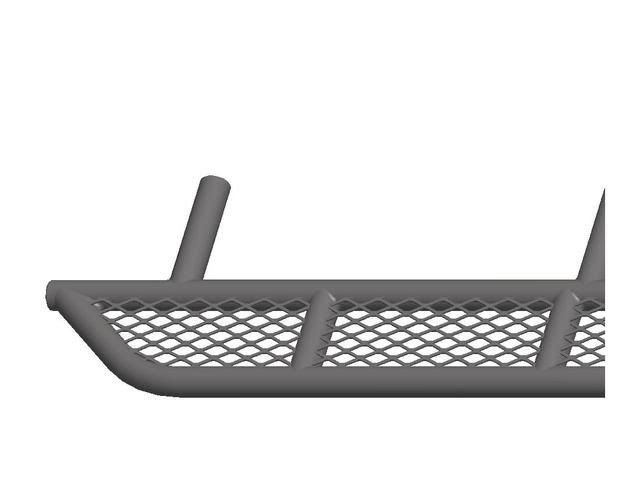

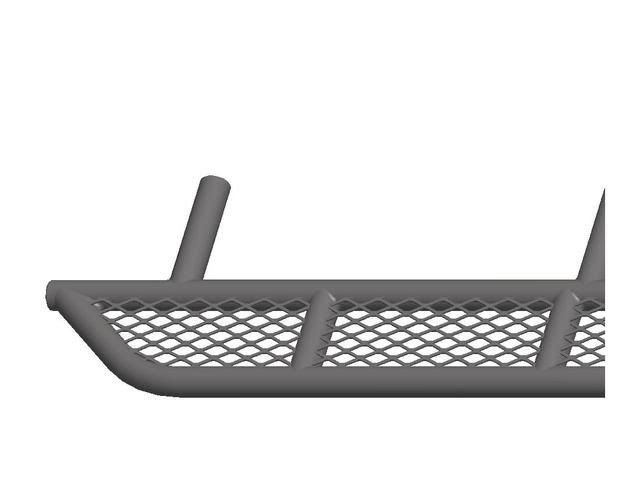

I mocked it up in CAD to see what it would look like:

Close-up of front end:

Close-up of back end:

I would mount the slider/steps low on the frame and with little or no tilt angle, just straight outward. This would also give more protection to body panels from kicked up stones from the tires (similar to the running boards I took off). I would probably Herculiner the whole thing.

So, what I am asking is: Has anyone done anything like this, or seen it done? Will it work?

My concerns are: How difficult would this be to weld? Would the openings make any whistling noises on the highway?

What do you think?

My idea is this: take some 3/4 No. 9 flattened expanded metal sheet, and cut it into pieces to fit between the slider rails. Weld it into place about a 1/4" below the top surface of the sliders. This would "fill" in the openings to provide more step surface, but not look too bulky by filling it in with a solid plate.

For those not familiar with flattened expanded metal sheet:

I mocked it up in CAD to see what it would look like:

Close-up of front end:

Close-up of back end:

I would mount the slider/steps low on the frame and with little or no tilt angle, just straight outward. This would also give more protection to body panels from kicked up stones from the tires (similar to the running boards I took off). I would probably Herculiner the whole thing.

So, what I am asking is: Has anyone done anything like this, or seen it done? Will it work?

My concerns are: How difficult would this be to weld? Would the openings make any whistling noises on the highway?

What do you think?

#2

Registered User

Join Date: Jan 2007

Location: Lewiston Idaho

Posts: 396

Likes: 0

Received 0 Likes

on

0 Posts

I thought of the same thing. My only fears were that they would fill up with mud or snow but mounting them streight out wouldent look bad that is what i did on mine.

#4

I have got 4xinnovations sliders (purchased thru wab fab) on my '81, can't go wrong with them. They are shipped with out the legs attached so you can tilt them anyway you like. Plus when you install them, keep they 1/2" or so away from your rockers--they will flex with the frame and periodically make a loud thump if placed too close.

I think the expanded metal is a great idea. A couple of times my wife has tweaked an ankle (stupid high heels) getting in/out of my trucks due to the open sliders. Noise I don't feel would be an issue. I don't notice noise related to the sliders on either of my trucks, but of course I run MT's on both so most noise is a tire related issue to me...

edit: nice job on the CAD, wish I had access to a program like that...my skills with MS paint make it look like my 2 year old neice did the drawings...

I think the expanded metal is a great idea. A couple of times my wife has tweaked an ankle (stupid high heels) getting in/out of my trucks due to the open sliders. Noise I don't feel would be an issue. I don't notice noise related to the sliders on either of my trucks, but of course I run MT's on both so most noise is a tire related issue to me...

edit: nice job on the CAD, wish I had access to a program like that...my skills with MS paint make it look like my 2 year old neice did the drawings...

Last edited by dropzone; 02-21-2008 at 09:08 AM.

#6

Registered User

Thread Starter

Thanks for the input so far.

I was thinking that the holes would keep it from filling with mud/snow, rather than if it was a solid plate. If they did plug up, it would be easy to hose them out.

Feel free! Let me know how it works out.

Well, I am a designer. So i've run CAD 40+ hours a week, for the last 15 years. I've gotten pretty good at it.

Keep the comments coming!

My only fears were that they would fill up with mud or snow

I might steal the idea from you when I get sliders

nice job on the CAD, wish I had access to a program like that

Keep the comments coming!

#7

Registered User

Join Date: Nov 2006

Location: Clayton, IN

Posts: 73

Likes: 0

Received 0 Likes

on

0 Posts

i dunno if all of you put gussets on the top or bottom of the legs on ur sliders but when i put mine on they flexed a little bit up and down then i put just a little gusset like 1.5 x2.5 triangle gusset on the top and there rigid as hell i think its the best to do if ur gonna be using them to full potential. thats my opinion.

Trending Topics

#10

Registered User

Join Date: Apr 2005

Location: Godfrey, Illinois

Posts: 940

Likes: 0

Received 0 Likes

on

0 Posts

#12

Contributing Member

Join Date: Jan 2006

Location: Summit County, Colorado

Posts: 899

Likes: 0

Received 0 Likes

on

0 Posts

Based on my experience with both flat and angled expanded, I would recommend the angled. It would give more "bite" as a step, and it would be more resistant to dishing when weight is applied to it. The flat will deform more easily, and you'll end up with the expanded bowing downward between its supports.

All in all, a very good idea, though.

All in all, a very good idea, though.

#13

I just got my sliders in yesterday and was also considering doing this. The only problems I could see is that if you install the slider with little or no tilt angle and put it out wide enough to use it as a step, it might make it little harder to get through tighter trails. Also, what are the odds of coming down on a rock directly between the rails of the sliders on the sheet metal? I've never had a set of sliders or came down on my rocker panels so I wouldn't know.

But other then those, I love the idea.

But other then those, I love the idea.

#14

Registered User

iTrader: (1)

It all depends on how hard you wheel. I wheeled for years and years before even installing rock sliders, so it's all relative. Worse case scenario is I mess one up and it costs me some time to cut out a new one and burn it in.

My rocksliders are mounted so close to the body that anything passing through the voids in the rocksliders would probably damage my body, so I'd rather the inserts took the hit.

My rocksliders are mounted so close to the body that anything passing through the voids in the rocksliders would probably damage my body, so I'd rather the inserts took the hit.

#15

Registered User

Thread Starter

OK, so here is my latest design:

It would be 1/8" thick steel, and I could easily cut out the diagonal slots myself. I will probably try to mock it up with some PVC pipe and cardboard to see how it would look.

Should be easier to weld, stronger, provide more protection, and whistle less. What do you think?

It would be 1/8" thick steel, and I could easily cut out the diagonal slots myself. I will probably try to mock it up with some PVC pipe and cardboard to see how it would look.

Should be easier to weld, stronger, provide more protection, and whistle less. What do you think?

#16

Registered User

OK, so here is my latest design:

It would be 1/8" thick steel, and I could easily cut out the diagonal slots myself. I will probably try to mock it up with some PVC pipe and cardboard to see how it would look.

Should be easier to weld, stronger, provide more protection, and whistle less. What do you think?

It would be 1/8" thick steel, and I could easily cut out the diagonal slots myself. I will probably try to mock it up with some PVC pipe and cardboard to see how it would look.

Should be easier to weld, stronger, provide more protection, and whistle less. What do you think?

#17

I like the new design, if they were on the market I probably would buy one. But one other thing I considered, if you'll mount these flat with no angle, do you still want to keep the kick outs? It'll make it wider then if it was angled, plus I've heard sliders with kickouts make it harder to get into the back doors of lifted 4runners.

#20

Registered User

Join Date: Dec 2007

Location: North Carolina

Posts: 139

Likes: 0

Received 0 Likes

on

0 Posts

I am thinking of doing this to some sliders my friend has...except I thought about using diamond plate. Instead of welding it in between the tubes..welding it directly on top.