Re-wiring truck

#1

Registered User

Thread Starter

Re-wiring truck

Hey everyone, I'm in the middle of doing a rebuild on one of my Pickups and while I have the motor out I figured I'd re-wire everything under the hood because when I pulled the motor I noticed a lot of my wires/connectors were very brittle and corroded. Anyone got any pointers for me on how to go about doing this? Any info on where I can possibly just get a whole new wire harness with injector plugs, tps plugs etc?

#4

Toyota sells them for a gazzillion dollars.

I would replace the injector wiring and be done with it

I would replace the injector wiring and be done with it

#7

Registered User

iTrader: (2)

I would just cut and replace the needed wires. Solder and re-crimp with new terminals. All the wire and terminals/connectors can be had pretty cheap online. Even if you have to buy a crimp tool and solder gun it would still be pretty cheap compared to Painless or Toyota replacement.

Trending Topics

#8

#9

Registered User

Thread Starter

Thanks guys I think I'll just cut and splice as you said, after pricing some wire harnesses from painless there is no way in hell I'll be spending $600 on something like this haha

#10

I prefer to twist splices securely, solder then heat shrink. I have both a 30watt and 80watt soldering iron. Wud like to invest in Dremel butane tool someday. Great for soldering or rope cutting when there's no electric power like in the field.

Last edited by RAD4Runner; 12-20-2018 at 05:16 AM.

#11

Registered User

Join Date: Sep 2007

Location: San Francisco East Bay

Posts: 8,250

Likes: 0

Received 820 Likes

on

648 Posts

The injector clips are the most fragile (the plastic locking tab will break, probably due to 25 years of exposure to heat). I recommend that instead of chopping up wires, you replace the part that broke.

I de-pinned the old connecctor bodies, cut off the old pins at the wire crimp, and installed the new pins. It shortens the wire, but only by about 1-2mm, which doesn't matter.

You can get these connectors with "pigtails" already installed, but then you will end up with 12 new crimps and heat-shrink where you once had wire.

Just so you know, soldering is not enough; solder is not mechanically strong. The rest of your harness is only crimped, no solder at all, and it's lasted for 25 years.

You can get these connectors with "pigtails" already installed, but then you will end up with 12 new crimps and heat-shrink where you once had wire.

Just so you know, soldering is not enough; solder is not mechanically strong. The rest of your harness is only crimped, no solder at all, and it's lasted for 25 years.

The following users liked this post:

RAD4Runner (12-20-2018)

#12

Registered User

Join Date: Jul 2012

Location: Northern Colorado

Posts: 1,776

Likes: 0

Received 109 Likes

on

81 Posts

Both crimping and soldering are quite reliable when properly done. Both make a gas-tight (important to maintain electrical integrity) connection that is mechanically quite strong. Note that the only thing holding the connectors and components on the surface-mount ECU board in your truck is solder.

The "properly done" is the issue. Crimps must be done with the proper tool that matches the connector and wire size. No squashing the crimp with pliers and hoping it will hold. By the same token, those blue and red cylindrical crimp connectors you can buy at Walmart are NOT the best way to splice wires for long-term reliability. Crimps are better in the engine compartment where temperatures are high and solder can begin to lose a significant percentage of its strength. But, the primary reason manufacturers use crimps over solder is that crimping is more amenable to high speed automation.

For a solder connection to be reliable, the metals to be joined must be bright and shiny. This can be a problem on old wiring where corrosion has often crept up into the insulation for several inches from the end of the wire, so even if you strip a new end, the wire strands can have dull surfaces that won't bond well to solder. Clean the wires well and then twist them together to maximize bonding area. It's also important to use a big enough iron that can thoroughly heat the joint quickly so that solder flows throughout the joint and bonds everywhere. Heat the joint and let the wire melt the solder - don't drip molten solder onto the joint. Finally, for vehicle work, leaded solder will give you better results. Leaded solder is completely legal in the US for electrical work and is readily available from supply houses. Any solder already in your second gen 4runner is leaded - the automotive industry didn't go ROHS until around 2014. Lead-free solder has problems with brittleness and doesn't handle thermal cycling or vibration nearly as well as leaded, as many laptop owners have found out when their display or processor board quits working due to a cracked surface-mount solder ball. For the same reason, military and space applications still spec leaded solder.

The "properly done" is the issue. Crimps must be done with the proper tool that matches the connector and wire size. No squashing the crimp with pliers and hoping it will hold. By the same token, those blue and red cylindrical crimp connectors you can buy at Walmart are NOT the best way to splice wires for long-term reliability. Crimps are better in the engine compartment where temperatures are high and solder can begin to lose a significant percentage of its strength. But, the primary reason manufacturers use crimps over solder is that crimping is more amenable to high speed automation.

For a solder connection to be reliable, the metals to be joined must be bright and shiny. This can be a problem on old wiring where corrosion has often crept up into the insulation for several inches from the end of the wire, so even if you strip a new end, the wire strands can have dull surfaces that won't bond well to solder. Clean the wires well and then twist them together to maximize bonding area. It's also important to use a big enough iron that can thoroughly heat the joint quickly so that solder flows throughout the joint and bonds everywhere. Heat the joint and let the wire melt the solder - don't drip molten solder onto the joint. Finally, for vehicle work, leaded solder will give you better results. Leaded solder is completely legal in the US for electrical work and is readily available from supply houses. Any solder already in your second gen 4runner is leaded - the automotive industry didn't go ROHS until around 2014. Lead-free solder has problems with brittleness and doesn't handle thermal cycling or vibration nearly as well as leaded, as many laptop owners have found out when their display or processor board quits working due to a cracked surface-mount solder ball. For the same reason, military and space applications still spec leaded solder.

The following 2 users liked this post by RJR:

old87yota (12-20-2018),

RAD4Runner (12-20-2018)

#13

hose blue and red cylindrical crimp connectors you can buy at Walmart are NOT the best way to splice wires for long-term reliability. ...

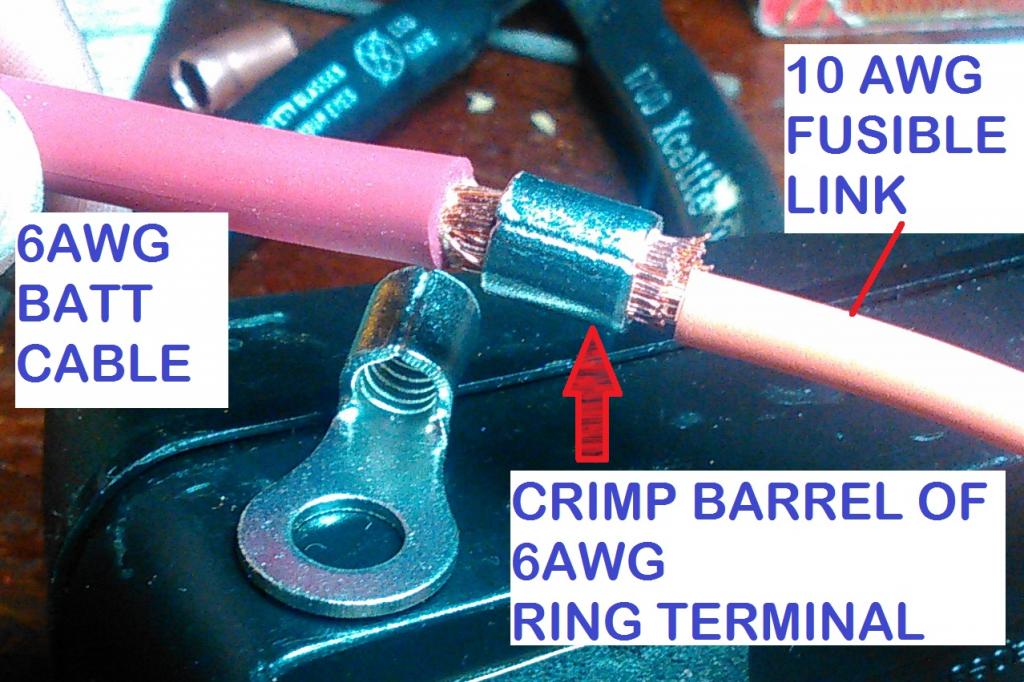

I like to parallel crimp then solder to fill in voids and increase contact area and corrosion-resistance, especially if near the battery. When I could not find the right-size parallel crimp...

#14

Registered User

The "properly done" is the issue. Crimps must be done with the proper tool that matches the connector and wire size. No squashing the crimp with pliers and hoping it will hold. By the same token, those blue and red cylindrical crimp connectors you can buy at Walmart are NOT the best way to splice wires for long-term reliability.

If you are set on using butt style connectors, the only ones I will use are the ones with heat shrink and adhesive built in (not the hard plastic, brightly colored ones), of course using the correct crimping tool.

Thread

Thread Starter

Forum

Replies

Last Post

zerokelvin

Newbie Tech Section

14

07-02-2018 08:37 PM

yamahabanshee350

General Electrical & Lighting Related Topics

3

12-09-2011 06:40 PM

Dailydriver2

General Electrical & Lighting Related Topics

3

12-16-2005 04:12 PM

Vinman

95.5-2004 Tacomas & 96-2002 4Runners

6

11-01-2005 12:13 PM