Weber Tech/Tuning for newbies and tuning

#1

Registered User

Thread Starter

Join Date: Jan 2011

Location: Twentynine Palms, CA

Posts: 351

Likes: 0

Received 0 Likes

on

0 Posts

Weber Tech/Tuning for everyone

Welcome to the Weber Tech thread....hopefully a sticky

Welcome to the Weber Tech thread....hopefully a sticky

Ok first off thank you to all of the members who know what the heck they're doing with Weber carburetors. I will try to mention your quotes by name but if my keyboard malfunctions after I throw it out the window....well I apologize.

I've been killing myself and others have too over running either the 32/36 or the 38 Weber. I know that the DCOE is a completely different animal but there are those who run those as well....so your input would be greatly appreciated.

I'll start it off with some very useful info that I have dug up and good points to start with for people new to Weber carbs on their 20/22r.

1.If you don't have a Weber but want one. Order from www.redlineweber.com or www.LCengineering.com. Those two retailers I know to have legit Weber parts. If there are others I would be happy to add them....but I am adding information I know to be correct.

2. If you don't know what jets are this is what they are. They control the flow of fuel/air where they will mix and atomize....to be blown up in your cylinders. There are many different sizes but each carb has their own jets. Sizing is dependent on what performance modifications you have done, elevation (above 6500ft), humidity, ethanol content or type of fuel, etc.

Both LC Engineering and Redline have jets and jet kits available. Go to their site and read up on them. Redline has some very good information. If you are curious what ships with a Weber carburetor LC Engineering lists it with the type of Carburetor on their pages.

2.There are other parts recommended to make the Weber work right for you. This can be argued on and by all means if you want to run them without these parts go ahead but this is what I know to help.

A. You are going to end up pretty much de-smogging your engine from what I understand. If you want to keep passing smog there are those who have done it but please

B. A fuel regulator is highly recommended. I have heard good things about the Holley FPR (fuel pressure regulator) and the Weber FPR. The one apparently from Summit is junk....as are many others. If you have experience with a bad one please list it....or a good one again....please list it.

C. Fuel Pressure gauge....will help with reading how much pressure exactly you have going through your line into the Weber.

D. A jet kit(s) for your Weber. They are entirely necessary for correctly tuning your engine.

E. A one piece adapter for your Weber or you can go all out and get an Offenhauser intake manifold. The two piece that ships with your Weber is junk!!

3. Now that you have a Weber 32/36 or 38 the tuning on these is different so hopefully there will be seperate sections for this later. For the most part I am trying to keep it generalized so you understand how this thing actually works.

A. Adjusting float level is as simple as taking the top of the carburetor off, flipping it upside down on a level surface and bending the tab up or down so that the floats rest 3/8" to 7/16" above the top of the carb.

4. Modification for 32/36.

A. If you want to do the vent mod it is extremely easy to accomplish with some JB weld and 3/8" copper pipe. Here is the link for it.

http://board.marlincrawler.com/index.php?topic=46859.0

B. Sync Link for Weber 32/36

Here is a very interesting thread for synchronizing the 32/36 so that both the butterflies open at the same time.

https://www.yotatech.com/forums/f114...talled-225236/

And now on to the information I have found on Yotatech. I just want to compile it so that you don't have to dig so much for it.

Input borrowed from Trevorthetrekker:

Hey buddy, got your PM.

First off, the number one thing you can do to better match your Weber to your 22R is to ensure that you have no vacuum leaks. The stock adapter plates which come with the Redline 38 / 22R kit are complete crap.

Rating: Negative 5 stars out of five.

Who sells CAST IRON ADAPTER PLATES, with threaded rods as studs!? No matter the quality of gasket or RTV that you throw on there, they will never seal properly. Maybe for like two minutes, but as soon as the engine heats up, the plates expand, the studs move, and now you have an air leak. No thanks.

This is mostly important because as you tune your engine, it will be changing temperature, and as temperature changes, so does the severity of your vacuum leaks. You could be getting a huge leak when you first start, only to have it seal up once you're up to temperature. Or vice versa, you could have no leaks at startup, only to have a huge one at temp. This can be a huge nuisance and is definitely something to take into considerations.

I have seen threads on here where people have machined the plates down properly, then added real locking studs. This is fine if you're on a budget, but if you already splurged on the Weber 38, just spend the $250 to get the matching Offenhauser intake manifold: http://www.lceperformance.com/Downdr...-p/1032060.htm

Words can't describe the performance increase I have seen from bolting on this manifold. I now see why people love them so dearly.

NOW, that you don't have any nasty vacuum leaks...

The Weber carbs can be a beech to tune, but as long as you know the tricks, they will run better than stock.

The main thing you need to know is that you MUST stay in the range of needle adjustment that Weber specifies in the manual. Here is a quote from the Weber tuning website which is a MANDATORY read if you want it to run right. Don't just read it; understand it:

If the mixture screw is more than 1 1/2 turns out turns then the Idle jet is too lean (too small). When the mixture screw is ½ turn or less, then the Idle jet is too rich (too large). These assumptions are based on the fact that the speed screw setting is not opened more than 1/2 turn in.

(http://www.redlineweber.com/html/Tec...as_tunning.htm)

What they don't tell you, and you need to know, is that if your mixture screw is more than 1.5 turns out, fuel will actually be DRIPPING past your mixture screws, instead of being atomized through the ports. This leads to very inaccurate fuel metering, where it will be hard to tell if you're running too rich or too lean, since the mixture will be continuously changing.

Along with that, the speed screw setting is just as equally as sensitive. If the speed screw is adjusted more than 1.5 turns in, then the throttle plate / butterfly valve will move away from the transition ports in the venturi. This means that not only is there fuel coming from the idle port, but also the transition ports, so now you have even more fuel dumping into your carb.

When I first got my 38, I didn't really understand this, and I just kept backing out the screws since she was lean, until she ran somewhat OK, but I was still disappointed. Finally after READING and UNDERSTANDING the instructions, I realized I needed a jet kit. After enrichening the jets and re-tuning, she runs better than ever.

BUY A JET KIT: http://www.lceperformance.com/Weber-...-p/1035006.htm

These are way too expensive and should come standard with the carbs, as they are absolutely essential to proper operation. The jets that come with the carbs are ALWAYS too lean. This is mainly because they engineered the Weber carbs before they started messing with our fuel supply. Fuels nowadays run much more lean than they did 10 years ago.

Another thing I have noticed that has helped during this long quest of tuning my 38/22R is to advance the timing. Right now if I remember correctly, I'm around 5 degrees advanced. She still runs the same around 10, but as soon as I put her back to zero, she runs pretty rough. I have seen the same for other people with Webers; that they need to advance the timing a bit.

One last reminder about Webers: get a good fuel pressure regulator and a fuel pressure gauge, and stay under 3 psi! Any more pressure, the fuel will be forced past your float needle, which will overfill your bowl, which will mean you're running rich yet again.

In conclusion, note that Webers con be finicky if you don't know their flaws. However once you understand what every part does, and how they all affect each other, Webers can be the simplest, best performing and most reliable carburetors for the 22R.

No vacuum leaks, proper jets, proper tuning, proper timing, proper fuel pressure. All errors in these areas are due to operator error. For those who say that Webers suck... You're doing it to yourself.

I can't stress enough; READ AND UNDERSTAND the tuning guide:

http://www.redlineweber.com/html/Tec...as_tunning.htm

This can definitely be some confusing stuff if you're new to tinkering, so don't beat yourself up over it. Just take the time to understand, and you'll be set!

Good luck, and feel free to ask any questions!

First off, the number one thing you can do to better match your Weber to your 22R is to ensure that you have no vacuum leaks. The stock adapter plates which come with the Redline 38 / 22R kit are complete crap.

Rating: Negative 5 stars out of five.

Who sells CAST IRON ADAPTER PLATES, with threaded rods as studs!? No matter the quality of gasket or RTV that you throw on there, they will never seal properly. Maybe for like two minutes, but as soon as the engine heats up, the plates expand, the studs move, and now you have an air leak. No thanks.

This is mostly important because as you tune your engine, it will be changing temperature, and as temperature changes, so does the severity of your vacuum leaks. You could be getting a huge leak when you first start, only to have it seal up once you're up to temperature. Or vice versa, you could have no leaks at startup, only to have a huge one at temp. This can be a huge nuisance and is definitely something to take into considerations.

I have seen threads on here where people have machined the plates down properly, then added real locking studs. This is fine if you're on a budget, but if you already splurged on the Weber 38, just spend the $250 to get the matching Offenhauser intake manifold: http://www.lceperformance.com/Downdr...-p/1032060.htm

Words can't describe the performance increase I have seen from bolting on this manifold. I now see why people love them so dearly.

NOW, that you don't have any nasty vacuum leaks...

The Weber carbs can be a beech to tune, but as long as you know the tricks, they will run better than stock.

The main thing you need to know is that you MUST stay in the range of needle adjustment that Weber specifies in the manual. Here is a quote from the Weber tuning website which is a MANDATORY read if you want it to run right. Don't just read it; understand it:

If the mixture screw is more than 1 1/2 turns out turns then the Idle jet is too lean (too small). When the mixture screw is ½ turn or less, then the Idle jet is too rich (too large). These assumptions are based on the fact that the speed screw setting is not opened more than 1/2 turn in.

(http://www.redlineweber.com/html/Tec...as_tunning.htm)

What they don't tell you, and you need to know, is that if your mixture screw is more than 1.5 turns out, fuel will actually be DRIPPING past your mixture screws, instead of being atomized through the ports. This leads to very inaccurate fuel metering, where it will be hard to tell if you're running too rich or too lean, since the mixture will be continuously changing.

Along with that, the speed screw setting is just as equally as sensitive. If the speed screw is adjusted more than 1.5 turns in, then the throttle plate / butterfly valve will move away from the transition ports in the venturi. This means that not only is there fuel coming from the idle port, but also the transition ports, so now you have even more fuel dumping into your carb.

When I first got my 38, I didn't really understand this, and I just kept backing out the screws since she was lean, until she ran somewhat OK, but I was still disappointed. Finally after READING and UNDERSTANDING the instructions, I realized I needed a jet kit. After enrichening the jets and re-tuning, she runs better than ever.

BUY A JET KIT: http://www.lceperformance.com/Weber-...-p/1035006.htm

These are way too expensive and should come standard with the carbs, as they are absolutely essential to proper operation. The jets that come with the carbs are ALWAYS too lean. This is mainly because they engineered the Weber carbs before they started messing with our fuel supply. Fuels nowadays run much more lean than they did 10 years ago.

Another thing I have noticed that has helped during this long quest of tuning my 38/22R is to advance the timing. Right now if I remember correctly, I'm around 5 degrees advanced. She still runs the same around 10, but as soon as I put her back to zero, she runs pretty rough. I have seen the same for other people with Webers; that they need to advance the timing a bit.

One last reminder about Webers: get a good fuel pressure regulator and a fuel pressure gauge, and stay under 3 psi! Any more pressure, the fuel will be forced past your float needle, which will overfill your bowl, which will mean you're running rich yet again.

In conclusion, note that Webers con be finicky if you don't know their flaws. However once you understand what every part does, and how they all affect each other, Webers can be the simplest, best performing and most reliable carburetors for the 22R.

No vacuum leaks, proper jets, proper tuning, proper timing, proper fuel pressure. All errors in these areas are due to operator error. For those who say that Webers suck... You're doing it to yourself.

I can't stress enough; READ AND UNDERSTAND the tuning guide:

http://www.redlineweber.com/html/Tec...as_tunning.htm

This can definitely be some confusing stuff if you're new to tinkering, so don't beat yourself up over it. Just take the time to understand, and you'll be set!

Good luck, and feel free to ask any questions!

Originally Posted by xxxtreme22r

Someone please sticky this.

NOTE: This ONLY goes for the 32/36 DGV/DGEV/DGAV etc series of carburetors not the 38.

This procedure assumes no modifications have been done internally to the carburetor. Including but not limited to primary and secondary main jets, air corrector jets.

It also assumes you have no vacuum leaks ANYWHERE including the popular two-piece adapter that typically comes with the kits. I HIGHLY suggest using the Transdapt 1 piece adapter. Others have had decent results with the LCE spiral adapter as well, even though that is also a two-piece unit. Easy way to test for vacuum leaks at the adapter is to spray carb cleaner in and around the entire base of the carburetor. If a change in idle (usually a stumble) is noticed then the adapter is leaking air into the engine and needs to be fixed before any accurate tune is achieved.

Other common areas for vacuum leaks are Valve cover gasket, oil pan gasket and timing cover gaskets.

Carburetor Set Up and Lean Best Idle Adjustment

Base line Settings

Speed Screw 1 to 11/2 turns

Mixture Screw 2 turns

Your settings with engine running

Speed Screw ____________

Mixture Screw ___________

It is important to follow all linkage and lever installation instructions. The number one and two reasons for tuning errors are improper linkage installations and over tightened linkage nut, causing a binding in linkage assembly.

CALIBRATIONS MAY VARY DUE TO REGIONAL FUELS AND STATE OF ENGINE TUNE AND PERFORMANCE. POOR RUNNING QUALITY DOES NOT MEAN A DEFECT IN THE CARBURETOR. AN ADVANTAGE OF THE WEBER CARBURETOR IS ITS EASE OF ADJUSTMENT AND TUNING.

SET UP ADJUSTMENTS

Start set up by confirming carb base line settings. Do not depend on the factory delivered settings. Check them before the carb is installed.

All settings are done with choke disengaged or warmed up so that the choke is fully opened and disengaged. This is done on automatic choke carburetors by first opening the choke butterfly by hand and inserting a wood block or wedge of some kind to hold open while the linkage is cycled (linkage operated through its full movement ) to clear the choke cam. (You will hear a metallic click as the cam is released. You can check the fast Idle screw under the choke assembly to confirm that it is not in contact with the choke fast idle cam.)

Set the Idle stop screw (speed screw see fig 1) by backing out the Idle speed screw until it is not in contact with the throttle stop lever. Cycle the linkage again to be sure that the linkage comes to close without any assistance. (Checking for linkage bind) Now bring screw back into contact with the lever and continue to open or screwing in 1 turn no more than 11/2 turns.

Set the mixture screw (see Fig 1) by first screwing in until the screw stops, bottoms out.

DO NOT FORCE OR BIND AS THIS WILL CAUSE DAMAGE TO THE SCREW AND IT’S SEAT IN THE BODY OF CARBURETOR.

Back out the screw 2 full turns.

TUNING

BE SURE TO FOLLOW THE NEXT INSTRUCTIONS IN THE PROPER SEQUENCE, DEVIATION WILL CAUSE THE CARBURETOR TO NOT FUNCTION TO ITS IDEAL SPECIFICATIONS AND MAY NOT PROVIDE THE PERFORMANCE AND FUEL ECONOMY AS DESIGNED.

Start the engine, the engine will run very slowly more like a tractor. As long as the engine stays running idle speed is not important at this point.

The first thing to do is not set up the idle speed, but to set the Idle mixture screw to lean best idle setting. First, turn in the mixture screw until the engine dies or runs worse, then back out the screw (recommend turning ¼ to ½ turn at a time). The engine should pick up speed and begin to smooth out. Back out ½ turn more, or until the screw does nothing or runs worse then turn back to the point where it ran its best.

Use your ear, not a scope or tuning instruments at this point. You want to tune the engine by sound. Adjust to best, fastest and smoothest running point.

Now that the mixture screw is at its best running location, you can adjust the Idle speed the screw. The screw will be sensitive and should only take ¼ to ½ turns to achieve the idle speed you like.

Check and set idle to your driving preference. Put the car in gear and apply slight load, (AC on) and set the Idle as you like it. Don’t set it too high, as this will cause causes excessive clutch and brake wear. The Idle only needs to be 7 to 900 RPM with light load or AC on.

Recheck timing and vacuum hook ups. Recheck mixture screw to lean best idle again. If all is still best and smoothest idle then confirm and note the final settings.

To confirm settings with the engine running. Start by screwing in the mixture screw and count the number of turns it takes to bottom out and note if the engine dies. If Idle Mixture screws are with in ½ turn of base line setting then all is well and have fun. Also check the speed screw and note how many total turns from initial contact. You may have opened (turned in) the speed screw. Your final setting should be under 2 full turns. Reset the screws (back in) to the best final settings (Per your notes) and go on a test drive and have fun. If the settings are other than described then you may want to recalibrate the Idle circuit (low speed circuit) to your engines needs. This is done by following the rule of thumb BELOW.

Simple Rules for low speed calibration

If the mixture screw is more than 2 1/2 turns out turns then the Idle jet is too lean (too Small). When the mixture screw is less than 11/2 then the Idle jet is too rich (too large). These assumptions are based on the fact that the speed screw setting is not opened more than 11/2 turns. If the speed screw has to be opened 2 or more turns then this is also an indication of a lean condition usually requiring greater change. At times it may appear to be showing signs of richness or flooding it is really a lean condition. See pictures and notes in the tech 2 article supplied in the kit instructions, view and please understand the need to keep throttle plate as near to closed as possible so as not to prematurely expose the transition holes. This is what causes the visible rich condition, and confirms the need to increase the jet size.

JET KITS are available if needed.

EXAMPLE: With the speed screw set at no more than (1 1/2) turns in after contact with the stop lever; and the best idle occurring with the mixture screw set at 3 turns from bottom, indicates the need for a larger Idle jet. Achieving the best idle at under 2 turns indicates the need for a smaller idle jet.

The secret to understanding the critical nature of the carburetor set up and the advantages of a WEBER over other carburetors is the Idle circuit. Referred to as the low speed circuit by Weber, this circuit is responsible for 80% of the driving operation. This is the reason that the Weber should give a fuel economy improvement over most factory carbs along with significant performance gains. In the worst case you should not see a significant fuel economy loss over stock, while improving HP & Drivability.

The Weber Carburetor is a sequentially timed device to the motor like the distributor. Time taken in the setup will provide more fun later.

weber carb tuning:

Float setting

http://board.marlincrawler.com/index.php?topic=62976.0

˟

trouble shooting guide:

http://www.webercarbsdirect.com/v/vs...ng%20Guide.pdf

˟

carb adjustment guide:

http://www.cjclub.co.il/files/Weber3236adjust.pdf

˟

jetting:

http://www.bmw2002faq.com/content/view/62/32/

˟

parts diagram/exploded view:

http://www.redlineweber.com/html/Tec..._breakdown.htm

Ok now after you have read or sorted through all of that information you should be able to figure it out. MAKE SURE YOU LOOK FOR VACUUM LEAKS!!

Remember that you are completely changing a very important piece of your engine. Write down what you change and keep notes on questions to ask. It will help you sort through everything and troubleshoot problems. This is kind of an exact science....but with gernades. Close will get the engine to run....perfection will make it purr.

Best of luck and for the gurus please add any info I have left out. I will try to update this as I sort through my own troubles. This stuff has helped me a lot....the least I can do is try and help some others in their quest to keep it old school.

Semper Fi.

Kryptoroxx

Last edited by KryptoRoxx; 11-09-2012 at 12:41 PM. Reason: WORK IN PROGRESS!!

#3

Registered User

Thread Starter

Join Date: Jan 2011

Location: Twentynine Palms, CA

Posts: 351

Likes: 0

Received 0 Likes

on

0 Posts

I've noticed that as well. I hope that people will take the time to reading it. Those pieces I posted helped me a lot in tuning. I wish I knew a little more about side drafts and the 38 to help others out. Yotatech has the best info on the Weber's afaik.

#4

Registered User

Well, I'm honored you linked my sync-link thread. Unfortunately, I more than likely won't be adding any more tech to that thread, sold my '83 a couple weeks ago.

I also hope this ends up helping people with their issues, mostly with the cast adapter, of course. Thanks Krypto!

I also hope this ends up helping people with their issues, mostly with the cast adapter, of course. Thanks Krypto!

#7

Registered User

iTrader: (1)

I like this thread a lot here is some info I have:

I bought my weber dges from carbs unlimited, as long as it is from redline as it seems to be the authorised distributor, you should be ok.

Here is a link that talks about fake and real webers:

http://genuineweber.blogspot.ca/

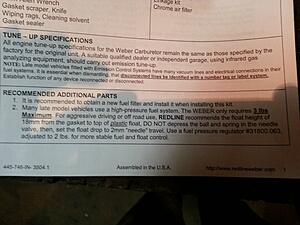

Here is what weber says about the regulator vs no regulator debate.

I guess it can run on the mecanical fuel pump but probably not at its best, if you run an electric pump you have no choice.

this is what he is talking about

Now I have a couple of questions that I hope can be answered to help others aswell, can someone explain the tuning of air correction jets and what is their connection with idle and main?

Also, the weber 38 that I have has no fuel return line, I run a holley electric pump with a holley fpr, I haven't started tuning yet (tomorrow), is this normal or will this stress the pump? It puts out 7psi stock.

thanks

I bought my weber dges from carbs unlimited, as long as it is from redline as it seems to be the authorised distributor, you should be ok.

Here is a link that talks about fake and real webers:

http://genuineweber.blogspot.ca/

Here is what weber says about the regulator vs no regulator debate.

I guess it can run on the mecanical fuel pump but probably not at its best, if you run an electric pump you have no choice.

What they don't tell you, and you need to know, is that if your mixture screw is more than 1.5 turns out, fuel will actually be DRIPPING past your mixture screws, instead of being atomized through the ports. This leads to very inaccurate fuel metering, where it will be hard to tell if you're running too rich or too lean, since the mixture will be continuously changing.

Along with that, the speed screw setting is just as equally as sensitive. If the speed screw is adjusted more than 1.5 turns in, then the throttle plate / butterfly valve will move away from the transition ports in the venturi. This means that not only is there fuel coming from the idle port, but also the transition ports, so now you have even more fuel dumping into your carb.

Along with that, the speed screw setting is just as equally as sensitive. If the speed screw is adjusted more than 1.5 turns in, then the throttle plate / butterfly valve will move away from the transition ports in the venturi. This means that not only is there fuel coming from the idle port, but also the transition ports, so now you have even more fuel dumping into your carb.

Now I have a couple of questions that I hope can be answered to help others aswell, can someone explain the tuning of air correction jets and what is their connection with idle and main?

Also, the weber 38 that I have has no fuel return line, I run a holley electric pump with a holley fpr, I haven't started tuning yet (tomorrow), is this normal or will this stress the pump? It puts out 7psi stock.

thanks

Trending Topics

#8

Registered User

Join Date: May 2012

Location: Portland, OR

Posts: 68

Likes: 0

Received 0 Likes

on

0 Posts

From what I recall, the idle circuit is it's own circuit, and tuning is done independently. With my 38, I haven't noticed a change in idle performance after tuning my air jets.

Haven't seen a real procedure for tuning the air jets, basically just change jets until you feel the most power at full throttle. This could probably be most accurately done with an accelerometer and/or dyno runs.

Haven't seen a real procedure for tuning the air jets, basically just change jets until you feel the most power at full throttle. This could probably be most accurately done with an accelerometer and/or dyno runs.

#9

Registered User

Gillesdetrail, Trevor is right about the air correctors, they don't affect idle at all. They just help to atomize the fuel from the primary and secondary main jets. When I was reading up on tuning the 32/36's a majority of the info out on the internets was for BMW 2002's. They recommended a separation of 50 between the size of the mains and the air correctors. I don't remember exactly what mine was after I got done tuning, but I don't think they were 50 from the mains. My final jetting is in that sync link thread, as is most of my knowledge I've forgotten since I haven't messed with a weber for awhile. What I do know is no matter what any of the sellers tell you, they don't put different jets in for your application. Every one I've seen opened up for the first time has the standard jets, only difference is between the manual choke or automatic choke. 1 jet is different. 22r's don't really flow that much air, they're kind of tractor motors, so even though I was at 4,000' to 9,000' elevation, I had to get richer jets. The idle circuit is also the main fuel supply until at least 2500 to 3000 rpm on a 22r, as well. I don't think a 22r revs enough to benefit from changes to the air correctors unless you have a pretty high dollar motor from someone like LCE. Other rule of thumb I saw most everywhere concerning the jets: if you change 1 jet(any of them) 1 size, change them ALL 1 size. That was universal across all the different makes that had forums with people posting weber tech.

Hope I helped rather than confused you, but have fun. When you get it dialed in, tuning is very rewarding, and will someday become a lost art.

Hope I helped rather than confused you, but have fun. When you get it dialed in, tuning is very rewarding, and will someday become a lost art.

#12

Registered User

First of all, good thread!

I'll add what I know from personal experience with Webers.

I used to run a 32/36 DGEV. Started with the Redline plate adaptor then went to an Offy dual plane manifold. I cannot stress enough how big a difference this made. I'm sure that the 38 with the single plane is good, but with the 32/36 the dual plane is the only way to go. I saw great improvements in throttle response, some power gain and improvement in fuel economy. The smaller primary runner keeps the velocity up for better atomization, ect. when you're just in the primary barrel. Worked great and was well worth the money, even for the budget builder.

Now for DCOE's:

If you aren't punched out, bigger valves, mid to nasty cam, and headers; don't waste the money. These are ment for getting after it, not economy. You will need to get an electric fuel pump and a FPR. The manifold won't fit with the stock pump and these carbs like 1.5 to 1psi. Also, there is no port for vac advance for the dizzy, I got a mechanical advance distributor from LCE and it's great, but, it's an other expence to take into account.

For tuning, the procedures are very similar to the 32/36's but you have to sync the carbs (more or less like syncing the multiple carbs on motorcycles, or so I've heard). This is a little painful the first time, but really not that bad. People will gripe and say these are fussy, hard to tune, hard to keep in tune, ect. They are liars or don't know what they're doing. I tweak my tune about every year (not jetting or anything, just mild tune up). It only takes me about 15-20 min. I may have lost a tiny amount to grunt right off of idle (going from 32/36 w/offy dual plane) but more power through the rest of the powerband and definately gained a decent amount at the top end. Fuel economy went down but part of that is because these are so good it's hard to keep your foot out of it. I'll answer any more specifics about the DCOE's if people want to know or the DCOE Guru on here (Suncomb) might chime in with his thoughts. All in all, weber makes a great carb. BTW, check the body on an Edelbrock 4 barrel, you might just see an underlined W.

I'll add what I know from personal experience with Webers.

I used to run a 32/36 DGEV. Started with the Redline plate adaptor then went to an Offy dual plane manifold. I cannot stress enough how big a difference this made. I'm sure that the 38 with the single plane is good, but with the 32/36 the dual plane is the only way to go. I saw great improvements in throttle response, some power gain and improvement in fuel economy. The smaller primary runner keeps the velocity up for better atomization, ect. when you're just in the primary barrel. Worked great and was well worth the money, even for the budget builder.

Now for DCOE's:

If you aren't punched out, bigger valves, mid to nasty cam, and headers; don't waste the money. These are ment for getting after it, not economy. You will need to get an electric fuel pump and a FPR. The manifold won't fit with the stock pump and these carbs like 1.5 to 1psi. Also, there is no port for vac advance for the dizzy, I got a mechanical advance distributor from LCE and it's great, but, it's an other expence to take into account.

For tuning, the procedures are very similar to the 32/36's but you have to sync the carbs (more or less like syncing the multiple carbs on motorcycles, or so I've heard). This is a little painful the first time, but really not that bad. People will gripe and say these are fussy, hard to tune, hard to keep in tune, ect. They are liars or don't know what they're doing. I tweak my tune about every year (not jetting or anything, just mild tune up). It only takes me about 15-20 min. I may have lost a tiny amount to grunt right off of idle (going from 32/36 w/offy dual plane) but more power through the rest of the powerband and definately gained a decent amount at the top end. Fuel economy went down but part of that is because these are so good it's hard to keep your foot out of it. I'll answer any more specifics about the DCOE's if people want to know or the DCOE Guru on here (Suncomb) might chime in with his thoughts. All in all, weber makes a great carb. BTW, check the body on an Edelbrock 4 barrel, you might just see an underlined W.

#13

Registered User

iTrader: (1)

Join Date: Feb 2013

Location: baton rouge,louisiana

Posts: 447

Likes: 0

Received 0 Likes

on

0 Posts

Bingle did you say you need to run a elec pump with the offy intake for the 32/36. Im running real rich as I smell strong gas smell and black soot coming from exhaust and I sprayed around the base of carb and I guess I havs leaks cause it stumbled bad and I have the spiral adapter on already. Maybe the vac leak is the cause for my rich condition but Im saving for a offy intake. The spiral adapters from lc must not be worth a crap either

#14

Registered User

No, Offy intake for the 32/36 works with the stock fuel pump. I had to go to electric with the 45DCOE manifold.

Don't know what to say about the spiral adaptor. I've never heard anything negitive about them. Try sealing it up again? Make sure the mating surfaces are clean, gasget, maybe a thin skiff of rtv, torque down in criss cross pattern. Maybe the machinist had a bad day and you got a lemon. Check the surfaces to make sure they're all flat? Good luck.

Don't know what to say about the spiral adaptor. I've never heard anything negitive about them. Try sealing it up again? Make sure the mating surfaces are clean, gasget, maybe a thin skiff of rtv, torque down in criss cross pattern. Maybe the machinist had a bad day and you got a lemon. Check the surfaces to make sure they're all flat? Good luck.

#15

Registered User

As a side note for those of you who are concidering an offy intake. Fron LCE's website:

Warning: Single plane manifold uses an 8 bolt water plate(under manifold)

Warning: Dual plane manifold uses an 11 bolt water plate(under manifold)

Warning: Both single and dual plane manifolds require an 81-83 style thermostat housing

I believe the 11 bolt plate is from the early 22r's and the 8 bolt is the later style. I used my '81's plate on the dual plane.

Warning: Single plane manifold uses an 8 bolt water plate(under manifold)

Warning: Dual plane manifold uses an 11 bolt water plate(under manifold)

Warning: Both single and dual plane manifolds require an 81-83 style thermostat housing

I believe the 11 bolt plate is from the early 22r's and the 8 bolt is the later style. I used my '81's plate on the dual plane.

#16

Registered User

iTrader: (1)

A dual plane intake manifold will give you better low-end torque versus a single. This is better for street/truck use IMO. I run a stock 20R intake at the moment, though I keep my eyes peeled for a used dual-plane Offy.

There is no advantage IMO to using an aftermarket single-plane intake on a 20R head other than the carb bolt pattern, so no spacer is needed reducing chance for vacuum leaks. The stock 22R intake sucks due to the single runner (realistically fine for most applications), so it's likely any aftermarket intake is a benefit.

As far as carb tuning I'd like to add something I don't think has been covered; the reason for Weber's stated idle speed settings has a lot to do with the use of vacuum advance. If the throttle plate is opened too far it not only makes idle adjustment difficult but it allows vacuum to the baseplate, engaging your vacuum advance. You'll notice that 22R's running much over .450 lift on the cam or anything over 220-225 degrees on the duration probably aren't running a vacuum advance anymore because of this.

When cam sizes are increased significantly the engine needs more fuel/air. To accomodate this you must crack the throttle plate open further at low engine speed OR use a bigger carb (i.e. Holley 2bbl or sidedrafts). Most of you won't run into this problem since you're into trucks. Race cars trying to make top-end power are going to be running .500+ lift cams and side-draft setups.

The guidelines listed here are fantastic, but when you begin modifying engines things change. Anyone stroking/boring or adding a large cam might find that the baseline Weber settings here will have to be tweaked somewhat on top of re-cruving the distributor and eliminating the vacuum advance. I realize for the vast majority of people on this site this information won't apply since most of us don't care about upper RPM power as much as down low thus are not running high-lift cams. Just be aware that more than any other bit in an N/A engine, camshaft changes have a huge effect on carb tuning. Every time lift and duration are increased so is the demand for air/fuel.

I think I read on here that pretty much all Weber's will need to be jetted richer for stock engines. I have found this to be true, and have found that even a .020 overbore can cause a Weber on the exact same engine with the exact same performance parts to suddenly run a bit lean. These small engines are much more tempermental than big V8's or inline six cylinders.

There is no advantage IMO to using an aftermarket single-plane intake on a 20R head other than the carb bolt pattern, so no spacer is needed reducing chance for vacuum leaks. The stock 22R intake sucks due to the single runner (realistically fine for most applications), so it's likely any aftermarket intake is a benefit.

As far as carb tuning I'd like to add something I don't think has been covered; the reason for Weber's stated idle speed settings has a lot to do with the use of vacuum advance. If the throttle plate is opened too far it not only makes idle adjustment difficult but it allows vacuum to the baseplate, engaging your vacuum advance. You'll notice that 22R's running much over .450 lift on the cam or anything over 220-225 degrees on the duration probably aren't running a vacuum advance anymore because of this.

When cam sizes are increased significantly the engine needs more fuel/air. To accomodate this you must crack the throttle plate open further at low engine speed OR use a bigger carb (i.e. Holley 2bbl or sidedrafts). Most of you won't run into this problem since you're into trucks. Race cars trying to make top-end power are going to be running .500+ lift cams and side-draft setups.

The guidelines listed here are fantastic, but when you begin modifying engines things change. Anyone stroking/boring or adding a large cam might find that the baseline Weber settings here will have to be tweaked somewhat on top of re-cruving the distributor and eliminating the vacuum advance. I realize for the vast majority of people on this site this information won't apply since most of us don't care about upper RPM power as much as down low thus are not running high-lift cams. Just be aware that more than any other bit in an N/A engine, camshaft changes have a huge effect on carb tuning. Every time lift and duration are increased so is the demand for air/fuel.

I think I read on here that pretty much all Weber's will need to be jetted richer for stock engines. I have found this to be true, and have found that even a .020 overbore can cause a Weber on the exact same engine with the exact same performance parts to suddenly run a bit lean. These small engines are much more tempermental than big V8's or inline six cylinders.

#17

Registered User

iTrader: (1)

No, Offy intake for the 32/36 works with the stock fuel pump. I had to go to electric with the 45DCOE manifold.

Don't know what to say about the spiral adaptor. I've never heard anything negitive about them. Try sealing it up again? Make sure the mating surfaces are clean, gasget, maybe a thin skiff of rtv, torque down in criss cross pattern. Maybe the machinist had a bad day and you got a lemon. Check the surfaces to make sure they're all flat? Good luck.

Don't know what to say about the spiral adaptor. I've never heard anything negitive about them. Try sealing it up again? Make sure the mating surfaces are clean, gasget, maybe a thin skiff of rtv, torque down in criss cross pattern. Maybe the machinist had a bad day and you got a lemon. Check the surfaces to make sure they're all flat? Good luck.

Find a known, flat surface. Use this surface to make sure your adaptor is true and flat. If it isn't true, either replace it or do some barnyard surfacing.

Don't pay a machinist to surface your intake manifold, exhaust manifold or other potentially warped bolt-on bits. Find some flat concrete and apply even pressure to whatever you're surfacing while doing a figure-eight pattern. If it's warped bad, use a mildly rougher surface and move to a smooth surface when getting close to flat again. On an intake, exhaust manifold, carb adaptor a slightly rougher sealing surface isn't going to matter if you have good gaskets. It takes some sweat on a very warped piece, but it's free and you can have a friend help. I have used this method with a 100% success rate for years.

Obviously you don't want to try this with a cylinder head. Manifolds and adaptors, however, are no problem. If it's flat already, let it be. Also make sure when working on the intake side not to over-tighten bolts and studs. Especially on carbs and adaptors.

#18

A dual plane intake manifold will give you better low-end torque versus a single. This is better for street/truck use IMO. I run a stock 20R intake at the moment, though I keep my eyes peeled for a used dual-plane Offy.

There is no advantage IMO to using an aftermarket single-plane intake on a 20R head other than the carb bolt pattern, so no spacer is needed reducing chance for vacuum leaks. The stock 22R intake sucks due to the single runner (realistically fine for most applications), so it's likely any aftermarket intake is a benefit.

As far as carb tuning I'd like to add something I don't think has been covered; the reason for Weber's stated idle speed settings has a lot to do with the use of vacuum advance. If the throttle plate is opened too far it not only makes idle adjustment difficult but it allows vacuum to the baseplate, engaging your vacuum advance. You'll notice that 22R's running much over .450 lift on the cam or anything over 220-225 degrees on the duration probably aren't running a vacuum advance anymore because of this.

When cam sizes are increased significantly the engine needs more fuel/air. To accomodate this you must crack the throttle plate open further at low engine speed OR use a bigger carb (i.e. Holley 2bbl or sidedrafts). Most of you won't run into this problem since you're into trucks. Race cars trying to make top-end power are going to be running .500+ lift cams and side-draft setups.

The guidelines listed here are fantastic, but when you begin modifying engines things change. Anyone stroking/boring or adding a large cam might find that the baseline Weber settings here will have to be tweaked somewhat on top of re-cruving the distributor and eliminating the vacuum advance. I realize for the vast majority of people on this site this information won't apply since most of us don't care about upper RPM power as much as down low thus are not running high-lift cams. Just be aware that more than any other bit in an N/A engine, camshaft changes have a huge effect on carb tuning. Every time lift and duration are increased so is the demand for air/fuel.

I think I read on here that pretty much all Weber's will need to be jetted richer for stock engines. I have found this to be true, and have found that even a .020 overbore can cause a Weber on the exact same engine with the exact same performance parts to suddenly run a bit lean. These small engines are much more tempermental than big V8's or inline six cylinders.

There is no advantage IMO to using an aftermarket single-plane intake on a 20R head other than the carb bolt pattern, so no spacer is needed reducing chance for vacuum leaks. The stock 22R intake sucks due to the single runner (realistically fine for most applications), so it's likely any aftermarket intake is a benefit.

As far as carb tuning I'd like to add something I don't think has been covered; the reason for Weber's stated idle speed settings has a lot to do with the use of vacuum advance. If the throttle plate is opened too far it not only makes idle adjustment difficult but it allows vacuum to the baseplate, engaging your vacuum advance. You'll notice that 22R's running much over .450 lift on the cam or anything over 220-225 degrees on the duration probably aren't running a vacuum advance anymore because of this.

When cam sizes are increased significantly the engine needs more fuel/air. To accomodate this you must crack the throttle plate open further at low engine speed OR use a bigger carb (i.e. Holley 2bbl or sidedrafts). Most of you won't run into this problem since you're into trucks. Race cars trying to make top-end power are going to be running .500+ lift cams and side-draft setups.

The guidelines listed here are fantastic, but when you begin modifying engines things change. Anyone stroking/boring or adding a large cam might find that the baseline Weber settings here will have to be tweaked somewhat on top of re-cruving the distributor and eliminating the vacuum advance. I realize for the vast majority of people on this site this information won't apply since most of us don't care about upper RPM power as much as down low thus are not running high-lift cams. Just be aware that more than any other bit in an N/A engine, camshaft changes have a huge effect on carb tuning. Every time lift and duration are increased so is the demand for air/fuel.

I think I read on here that pretty much all Weber's will need to be jetted richer for stock engines. I have found this to be true, and have found that even a .020 overbore can cause a Weber on the exact same engine with the exact same performance parts to suddenly run a bit lean. These small engines are much more tempermental than big V8's or inline six cylinders.

I can confirm that bit about running lean, atleast for me.

I just put my weber 32/36 back on my 20 over, with streetrv head, engnbldr 268c cam, os valves, and 2.25" exhaust. It runs incredibly lean. I purchased a afm gauge just to be sure. The only time it doesn't run lean is during wot which oddly enough it seems to be a notch or two above stoich.

I had the same issue a few years back prior to the rebuild only it was less pronounced with everything stock. (just having the afm screw out more than ideal)

I'm at about sea level.

I've got a rejet kit coming in today

I'll start with the idle jets, then just see what happens from there

Last edited by Soul_keeper; 07-23-2014 at 10:41 AM.

#19

Registered User

iTrader: (1)

Maybe a 38 would be better for your setup? I'm happy I chose my weber 38 even though I did a lot of research and most people exept 1 or 2 said the 38 was too much carb for a 22r even if modded. I have a worn out bottom end, 20r ported head, oversized valves, thorley 4-2-1 header and it runs good with the jets it came with, mixture screws turned 1.5, from 0 to 3/4 pedal it's smooth and peppy, but from 3/4 to full throttle I can feel it loose power, so I'm guessing my main jets are a little too small, I too will need to buy a jet kit as soon as I can. I think I also need to adjust float level because if I'm at redline for more than 2-3 seconds the floats seem to empty and the engine cuts out for a second before I shift.