Fusible Link size for big 3 wiring mod upgrade

#1

Fusible Link size for big 3 wiring mod upgrade

Hi all,

I've been reading every thread on here and out on the web regarding the big 3 wiring mod and regarding fusible links. There seems to be a real lack of information and a lack of understanding regarding fusible links out in the world! Way too much conflicting info out there that has left me fairly confused.

My plan is to upgrade my big 3 wires (on my 88 xtra cab pickup with automatic, 4x4, 22re...pretty much all stock and unmodded except for a lift and an aftermarket alpine head unit) with #4 Carol Super Vu-Tron Orange welding cable (I chose this cable because it is oil-resistant, where most welding cables are apparently not, and there are many warnings on the web to NOT use standard welding cable in under hood applications due to the lack of oil resistance). I also plan on using solid brass marine style terminal clamps as I've heard good things about them.

My main question is regarding the fusible link. My understanding is that the industry standard is to use a fusible link size that is 4 AWG sizes smaller than the wire it is protecting, so in the case of my #4 welding cable, I would normally want a #8 fusible link to protect it. BUT, if I increase the size of the fusible link, do I risk too much load going through it that come cause damage or fire elsewhere, not necessarily to my new #4 wire, but somewhere else down the line? Please forgive me for my still basic knowledge of our electrical system and wiring.

So for those of you who have done this mod, do you

1. keep the stock fusible link (assuming it is in good shape)?

2. replace the stock fusible link with an identical gauge and length fusible link wire (it MUST be fusible link wire and NOT standard wire due to the fire resistant insulation of fusible link wire, which allows the wire to burn up without melting the insulation. and what gauge is the stock fusible link wire to begin with??)?

3. upgrade to a fusible link that is 4 AWG smaller than your new battery cable (would be a #8 fusible link wire in the case of my #4 welding cable)? and if you upgrade to a larger size fusible link, do you still use the same length of the stock fusible link, or do you need a longer or shorter one due to the increase in size??

4. replace with an inline time delay cartridge fuse?

5. replace with an inline spade or other non-time delay fuse (apparently not a great idea)?

6. omit the fusible link entirely?

please let me know how you handled this situation, how it is holding up for you, any lessons you learned along the way, mistakes you made, etc.

thanks for your help! you guys are awesome!

I've been reading every thread on here and out on the web regarding the big 3 wiring mod and regarding fusible links. There seems to be a real lack of information and a lack of understanding regarding fusible links out in the world! Way too much conflicting info out there that has left me fairly confused.

My plan is to upgrade my big 3 wires (on my 88 xtra cab pickup with automatic, 4x4, 22re...pretty much all stock and unmodded except for a lift and an aftermarket alpine head unit) with #4 Carol Super Vu-Tron Orange welding cable (I chose this cable because it is oil-resistant, where most welding cables are apparently not, and there are many warnings on the web to NOT use standard welding cable in under hood applications due to the lack of oil resistance). I also plan on using solid brass marine style terminal clamps as I've heard good things about them.

My main question is regarding the fusible link. My understanding is that the industry standard is to use a fusible link size that is 4 AWG sizes smaller than the wire it is protecting, so in the case of my #4 welding cable, I would normally want a #8 fusible link to protect it. BUT, if I increase the size of the fusible link, do I risk too much load going through it that come cause damage or fire elsewhere, not necessarily to my new #4 wire, but somewhere else down the line? Please forgive me for my still basic knowledge of our electrical system and wiring.

So for those of you who have done this mod, do you

1. keep the stock fusible link (assuming it is in good shape)?

2. replace the stock fusible link with an identical gauge and length fusible link wire (it MUST be fusible link wire and NOT standard wire due to the fire resistant insulation of fusible link wire, which allows the wire to burn up without melting the insulation. and what gauge is the stock fusible link wire to begin with??)?

3. upgrade to a fusible link that is 4 AWG smaller than your new battery cable (would be a #8 fusible link wire in the case of my #4 welding cable)? and if you upgrade to a larger size fusible link, do you still use the same length of the stock fusible link, or do you need a longer or shorter one due to the increase in size??

4. replace with an inline time delay cartridge fuse?

5. replace with an inline spade or other non-time delay fuse (apparently not a great idea)?

6. omit the fusible link entirely?

please let me know how you handled this situation, how it is holding up for you, any lessons you learned along the way, mistakes you made, etc.

thanks for your help! you guys are awesome!

#2

Registered User

iTrader: (1)

Your fusible link rating should be determined by the load on that circuit .

If your upgrading to a 150 amp alternator of course things need to change.

As long as all your circuits are protected **** if you want to do away there is no reason not to.

I know of the course of time I have replaced some with in line fuses.

Maybe back in the olden times 10 years ago or so some welding cable was not oil resistant but that has pretty much gone by the wayside .

Maybe you can still special order it.

If your upgrading to a 150 amp alternator of course things need to change.

As long as all your circuits are protected **** if you want to do away there is no reason not to.

I know of the course of time I have replaced some with in line fuses.

Maybe back in the olden times 10 years ago or so some welding cable was not oil resistant but that has pretty much gone by the wayside .

Maybe you can still special order it.

#3

Thanks for the reply Wyoming.  that is good info regarding the welding cable. I found some USA made Flex-A-Prene brand #4 welding cable on fleabay (item #370937699202) for less than $1 a foot that claims oil resistance on the spec sheet on their website.

that is good info regarding the welding cable. I found some USA made Flex-A-Prene brand #4 welding cable on fleabay (item #370937699202) for less than $1 a foot that claims oil resistance on the spec sheet on their website.

regarding the fusible links, I am still a little confused. I kind of get what you are saying regarding protecting the circuit, so maybe it is just trying to reconcile that verses all of the info saying to use 4 AWG smaller than the wire it is protecting. I think I am going to keep the setup utilizing fusible link verses switching to a Maxi Fuse setup that seems to be a safe alternative.

So I guess my main concern is should I upgrade to a 8 AWG fusible link (<12 AWG is hard to find, but I have located some 8 AWG fusible link on fleabay) to protect my new 4 AWG wire, or should I just match whatever the stock AWG fusible link was? So if hypothetically the stock setup was 8 AWG main cable and 12 AWG fusible link, I would run new 4 AWG main cable, and use a new 12 AWG fusible link. I would think that I wouldn't have any issues just replacing with the same gauge of stock link since I wouldn't think that the initial draw on the system wouldn't increase just due to a new 4 AWG main wire, or would it?

My concern with upgrading to an 8 AWG fusible link would be that it would allow more current without burning up, which could fry something else down the line. not nessecarily the new 4 AWG welding cable, because theoretically that should be sufficiently protected by the 4 AWG smaller 8 AWG fusible link.

My concern with keeping the stock fusible link size (let's assume it is 12 AWG for simplicity's sake) is that it may burn/fail too often if the upgraded cable somehow allows a higher than normal startup draw which is now higher than the initial draw when I was running the stock wiring. Is that possible, or will the initial draw remain the same regardless of the increase in the size on my main cable?

So basically, for anyone who has made it through all of my rambling, would you keep the stock fusible link size assuming that the new 4 AWG main cable won't increase the load on the link and cause it to fail under the normal initial draws, OR would you increase the fusible link size to the recommended 8 AWG (4 AWG below the size of the wire it is protecting)?? While I am not an expert in wiring, I would think that the new 4 AWG welding cable shouldn't make a difference in the initial draw being put on the system, so the stock fusible link should be sufficient to handle the initial draw without burning up. As long as this is the case, I am much more comfortable with the smaller stock fusible link to prevent failure/fire somewhere else in the system in the case of a short or other major issue.

Does anyone know the stock AWG size for the battery/ground cables and the stock fusible link AWG size for a 1988 pickup?

that is good info regarding the welding cable. I found some USA made Flex-A-Prene brand #4 welding cable on fleabay (item #370937699202) for less than $1 a foot that claims oil resistance on the spec sheet on their website.

that is good info regarding the welding cable. I found some USA made Flex-A-Prene brand #4 welding cable on fleabay (item #370937699202) for less than $1 a foot that claims oil resistance on the spec sheet on their website.regarding the fusible links, I am still a little confused. I kind of get what you are saying regarding protecting the circuit, so maybe it is just trying to reconcile that verses all of the info saying to use 4 AWG smaller than the wire it is protecting. I think I am going to keep the setup utilizing fusible link verses switching to a Maxi Fuse setup that seems to be a safe alternative.

So I guess my main concern is should I upgrade to a 8 AWG fusible link (<12 AWG is hard to find, but I have located some 8 AWG fusible link on fleabay) to protect my new 4 AWG wire, or should I just match whatever the stock AWG fusible link was? So if hypothetically the stock setup was 8 AWG main cable and 12 AWG fusible link, I would run new 4 AWG main cable, and use a new 12 AWG fusible link. I would think that I wouldn't have any issues just replacing with the same gauge of stock link since I wouldn't think that the initial draw on the system wouldn't increase just due to a new 4 AWG main wire, or would it?

My concern with upgrading to an 8 AWG fusible link would be that it would allow more current without burning up, which could fry something else down the line. not nessecarily the new 4 AWG welding cable, because theoretically that should be sufficiently protected by the 4 AWG smaller 8 AWG fusible link.

My concern with keeping the stock fusible link size (let's assume it is 12 AWG for simplicity's sake) is that it may burn/fail too often if the upgraded cable somehow allows a higher than normal startup draw which is now higher than the initial draw when I was running the stock wiring. Is that possible, or will the initial draw remain the same regardless of the increase in the size on my main cable?

So basically, for anyone who has made it through all of my rambling, would you keep the stock fusible link size assuming that the new 4 AWG main cable won't increase the load on the link and cause it to fail under the normal initial draws, OR would you increase the fusible link size to the recommended 8 AWG (4 AWG below the size of the wire it is protecting)?? While I am not an expert in wiring, I would think that the new 4 AWG welding cable shouldn't make a difference in the initial draw being put on the system, so the stock fusible link should be sufficient to handle the initial draw without burning up. As long as this is the case, I am much more comfortable with the smaller stock fusible link to prevent failure/fire somewhere else in the system in the case of a short or other major issue.

Does anyone know the stock AWG size for the battery/ground cables and the stock fusible link AWG size for a 1988 pickup?

#4

Registered User

iTrader: (1)

I am pretty sure Japan never used AWG wire sizes in there specs I could be wrong

I am pretty sure Japan never used AWG wire sizes in there specs I could be wrongAs long as you have not really changed the electrical system you will be fine with the old fusible link

As it gets confusing when people throw around terms that can mean anything!!

The Big 3 can mean different things to everyone.

You would be replacing the wire from the B terminal of the alternator to the fuse block

Crimp on lugs both ends make sure the lugs will attach to both ends being able to fit where they need to. Before making the cable.

If your planning to do it this way !!! ** No need to mess with any fusible links Fuses or anything.

The positive cable from the battery to the starter I use #1 welding cable for that one. Pretty straight forward .

The grounds are simple I run one to the engine block one to the inner fender. One to the frame because I like a good ground at the rear of vehicle.

I end up using odd lengths of welding cable not much use for pieces 2' to 4' long.

I hope this clears up your questions.

#5

yes, thank you Wyoming, you have been very helpful! do you the use #1 welding cable for the grounds and for the alternator to fuse block as well, or do you use a different size, or is it just based on what excess random pieces you have laying around at the time?

also, I know some people use #4, some use #1, and some even use 1/0. why did you choose #1 vs say #4? do you have a lot of accessories in your trucks where you feel #4 would be too small? I assume #4 is probably overkill itself for my stock truck, even if I added some extra lights??

and where on the frame did you put the extra ground? assuming you have to drill and tap it? I have never really done that before either, so would I maybe drill and tap for a 5/16" machine screw, use a 3/8" lug on the end of the ground, and then attach the lug to the frame with a 5/16" machine screw and some red or blue loc-tite? should I be using loc-tite for all of my ground to frame/chassis/block connections after cleaning paint/corrosion etc off the connection point? I've also heard of people using no-ox-id to prevent corrosion and oxidation of the ground connections. could I just put a little Loctite on the threads, and then no-ox-id on the frame and screw head?

after this I will quit bugging you! promise!

promise!

also, I know some people use #4, some use #1, and some even use 1/0. why did you choose #1 vs say #4? do you have a lot of accessories in your trucks where you feel #4 would be too small? I assume #4 is probably overkill itself for my stock truck, even if I added some extra lights??

and where on the frame did you put the extra ground? assuming you have to drill and tap it? I have never really done that before either, so would I maybe drill and tap for a 5/16" machine screw, use a 3/8" lug on the end of the ground, and then attach the lug to the frame with a 5/16" machine screw and some red or blue loc-tite? should I be using loc-tite for all of my ground to frame/chassis/block connections after cleaning paint/corrosion etc off the connection point? I've also heard of people using no-ox-id to prevent corrosion and oxidation of the ground connections. could I just put a little Loctite on the threads, and then no-ox-id on the frame and screw head?

after this I will quit bugging you!

promise!

promise!

#6

Registered User

iTrader: (1)

When I replace the the Alternator B terminal wire if it has the stock alternator I just use 8 Gauge wire the size from the factory.

Which now being brand new works just fine and bolts into the fuse block without any problems

No need to drill and tap any holes I go right to the front tie downs all these vehicles.

About the only added power drains would be the winch in a receiver mount that gets moved vehicle to vehicle

The ground cables most often just what I have laying around.

Feel free to ask questions!!

long day time for bed!!!

Which now being brand new works just fine and bolts into the fuse block without any problems

No need to drill and tap any holes I go right to the front tie downs all these vehicles.

About the only added power drains would be the winch in a receiver mount that gets moved vehicle to vehicle

The ground cables most often just what I have laying around.

Feel free to ask questions!!

long day time for bed!!!

#7

My 2 cents...

One quick suggestion:

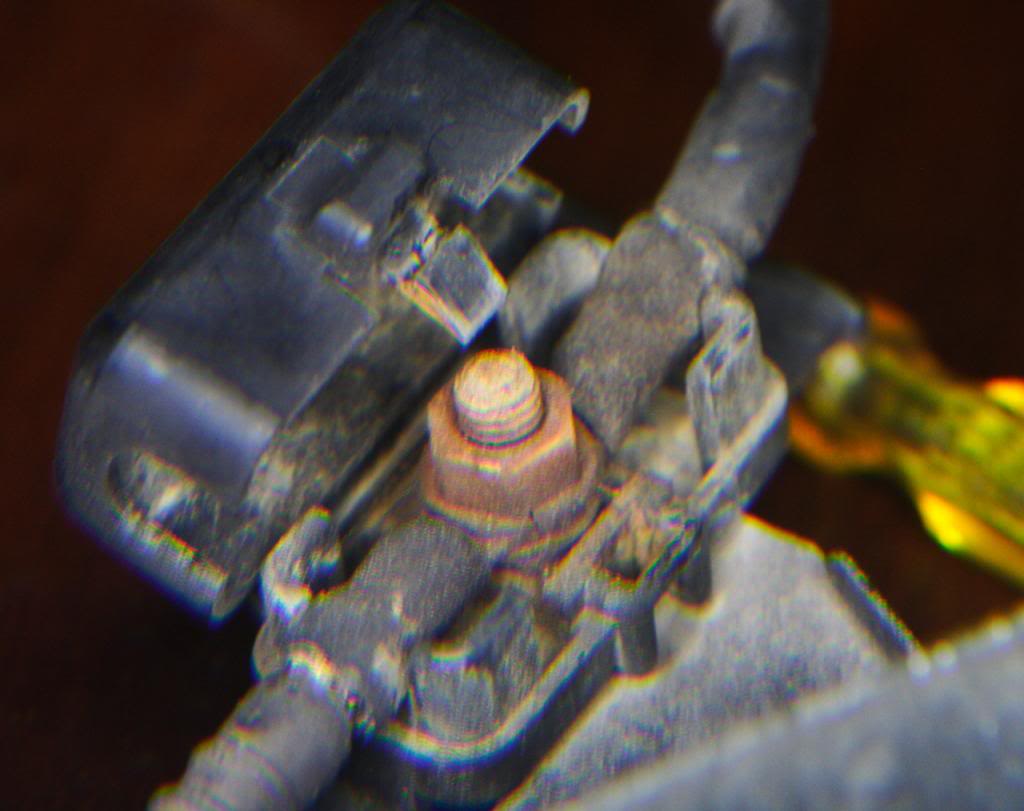

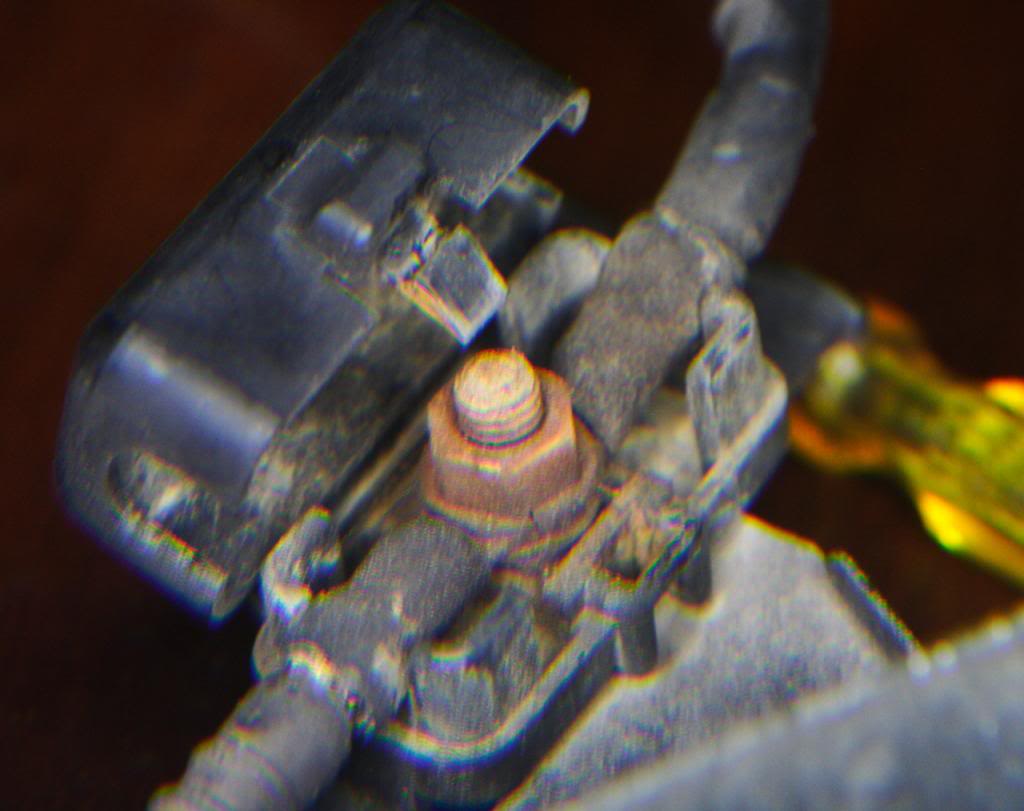

If replacing B (alt to Batt) wire, get rid of this, that at first glance looks some ferrite choke for cleaning power.

it is not a choke. It is a tap that takes up space, and for the last 27 years no one probably ever used. That space could be used for headlight/aux light relays instead.

It is a potential place for corrosion which would get in the way between alt and all circuits.

Also, if I were to upgrade charging circuit wiring, I would use new B wire rated for new higher-capacity alternator like you would^^^, but wire it this way.

If replacing B (alt to Batt) wire, get rid of this, that at first glance looks some ferrite choke for cleaning power.

it is not a choke. It is a tap that takes up space, and for the last 27 years no one probably ever used. That space could be used for headlight/aux light relays instead.

It is a potential place for corrosion which would get in the way between alt and all circuits.

Also, if I were to upgrade charging circuit wiring, I would use new B wire rated for new higher-capacity alternator like you would^^^, but wire it this way.

Last edited by RAD4Runner; 12-12-2013 at 05:41 PM.

Trending Topics

#8

Registered User

iTrader: (1)

I have done a few like that but I also pull out the old wire for the B terminal because it is pretty much dead from being cooked for 20 years.

I have done a few like that but I also pull out the old wire for the B terminal because it is pretty much dead from being cooked for 20 years.The ones I just replaced the stock wire is for the little old lady now younger then me .

It all comes down to just how many extra goodies one is trying to run off the stock alternator

#9

Registered User

iTrader: (1)

Hey 88 check out this. Good info there. I am doing a GM alternator swap in my 94 4Runner. I called the guy here and bought this. I am doing the big 3 upgrade. I am going to replace the fusible link with a 4 or 6 gauge wire.

Like Wyoming stated, when you choose a fuse for the cable, you don't want the fuse rating to be higher than the maximum current carrying spec of the gauge of wire you are using. In fact, the dude at the place I bought that alternator said to get a fuse that was 85% (I Think) of the max current capacity of the 2 gauge AWG wire I am using because I had enough left from my F350. It's Ancor cable - good stuff. I saw ratings of around 185 amps to around 215 amps for the 2 gauge cable, so the size of the mega fuse I went with was 175 amp. You want the fuse to be the weakest part of the wire but don't put in too small of a fuse that will limit the amperage of the circuit. You want the fuse to blow before the wire melts and starts a fire possibly....

Good info here. When I do the swap, I am going to post a thread...

Like Wyoming stated, when you choose a fuse for the cable, you don't want the fuse rating to be higher than the maximum current carrying spec of the gauge of wire you are using. In fact, the dude at the place I bought that alternator said to get a fuse that was 85% (I Think) of the max current capacity of the 2 gauge AWG wire I am using because I had enough left from my F350. It's Ancor cable - good stuff. I saw ratings of around 185 amps to around 215 amps for the 2 gauge cable, so the size of the mega fuse I went with was 175 amp. You want the fuse to be the weakest part of the wire but don't put in too small of a fuse that will limit the amperage of the circuit. You want the fuse to blow before the wire melts and starts a fire possibly....

Good info here. When I do the swap, I am going to post a thread...

Thread

Thread Starter

Forum

Replies

Last Post

icentropy

86-95 Trucks & 4Runners

10

07-11-2015 07:21 AM