Hey baby... nice rack!

#1

Hey baby... nice rack!

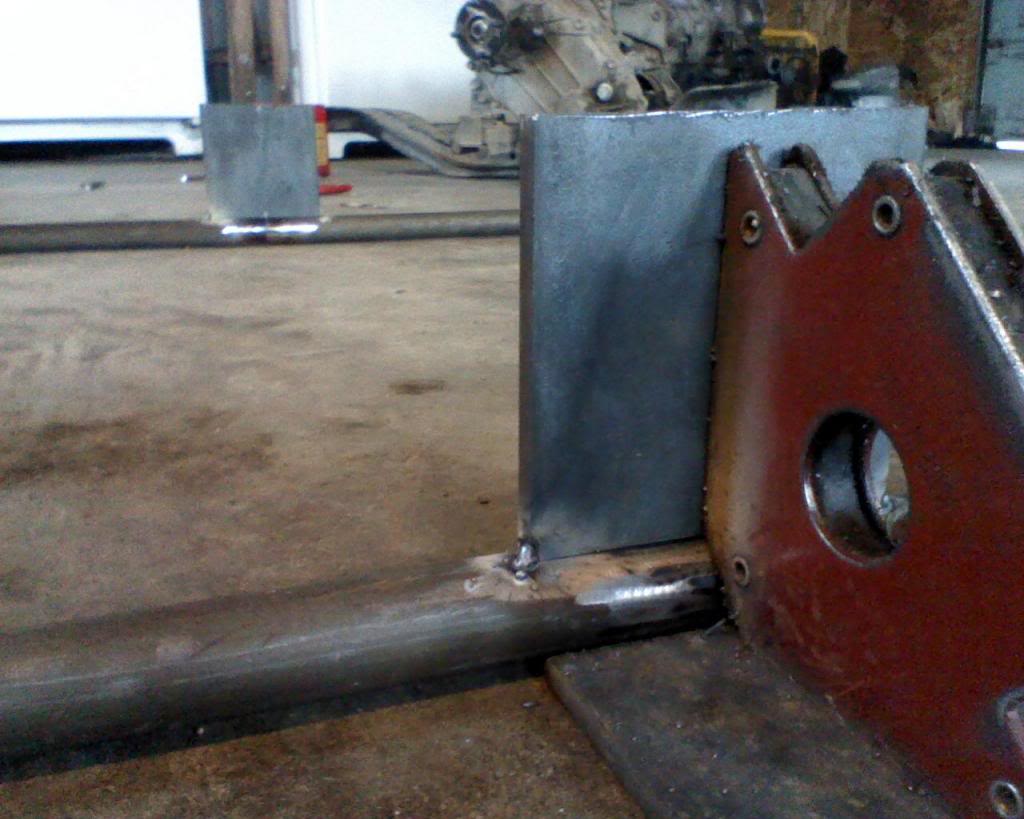

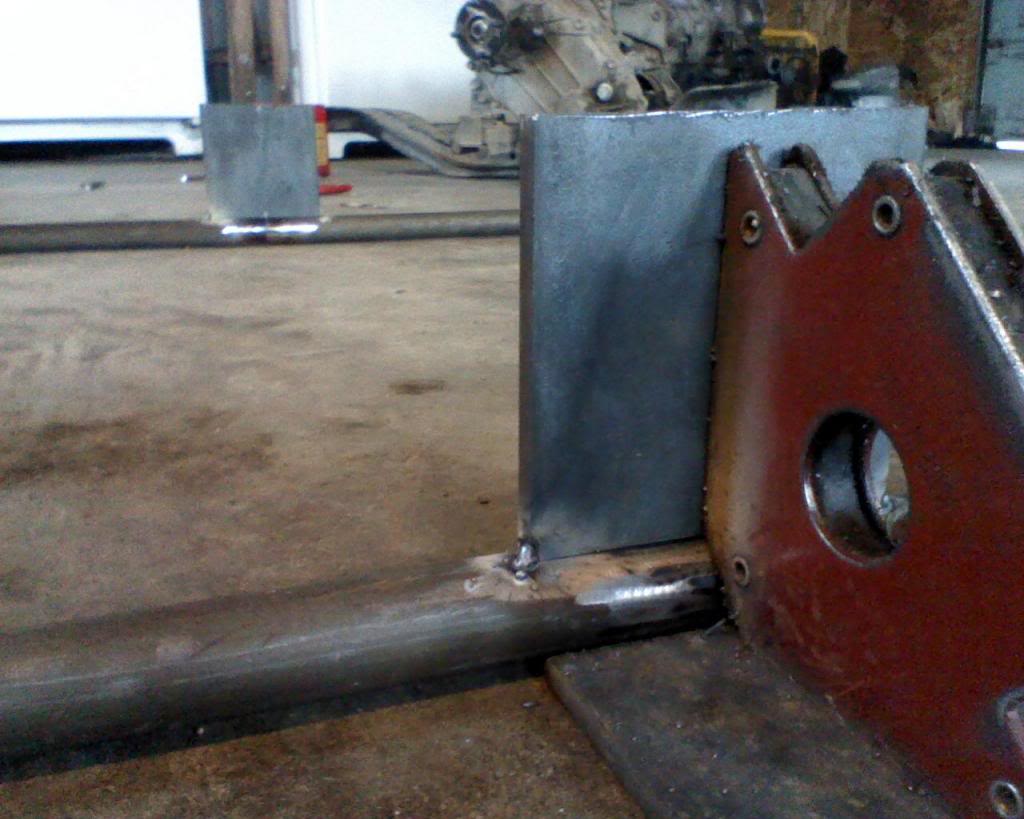

I decided I wanted to try and build my own rack for my runner. So I made up some drawings and took some measurements. Then I went down to the local metal shop and grab some supplies. I went over to a friends house and made some 90's for my little project.

I would post up my thoughts and drawings but I don't want to get made fun of

So I will just try to take photos for each step along the way so you guys get to see the rack build and the end result (Good or Bad)

I would post up my thoughts and drawings but I don't want to get made fun of

So I will just try to take photos for each step along the way so you guys get to see the rack build and the end result (Good or Bad)

#2

Moving Forward...

Well got a lot done today! I only expect maybe one more day to finish...

I had to go back through and make some final cuts and make sure everything was at the right measurement.

Then I laid out the pipe to see how it would fit.

Everything was straighter then I thought it would be and was ready to tack!

Of coarse after tacks on both sides it was time to weld it all up then clean it up with the old grinder.

(Found out how rusty I was at welding... blah )

)

Now time for my 4" tabs to get tacked.

Then Welded.

Now for the little round stock for Pizazz

Next episode comes with more grinding and more welding!

Stay tuned...

I had to go back through and make some final cuts and make sure everything was at the right measurement.

Then I laid out the pipe to see how it would fit.

Everything was straighter then I thought it would be and was ready to tack!

Of coarse after tacks on both sides it was time to weld it all up then clean it up with the old grinder.

(Found out how rusty I was at welding... blah

)

)

Now time for my 4" tabs to get tacked.

Then Welded.

Now for the little round stock for Pizazz

Next episode comes with more grinding and more welding!

Stay tuned...

#6

Registered User

iTrader: (2)

Not to be rude or misleading but your welds look like crap because of the welder you are using. If you were using a better welder you wouldn't have to grind your welds down. I weld for a hobby and its my part time job. My personal welder is a Hobart mig. It uses flux core or argon. When I first started welding (around 15 years old) I used my dads Lincoln. I got really good and enjoyed it. So I went to Walmart and bought one of there century mig welders only to find out that it sucked. There's just not enough amps in those little things to achieve a good bead. So it's not that your rusty its your just trying to use junk IMO. Looks good tho. Anxious to see it finished and its very inspiring.

Trending Topics

#8

Registered User

Join Date: Sep 2008

Location: middle of no where Alaska

Posts: 4,355

Likes: 0

Received 2 Likes

on

2 Posts

Yes, a better machine will wield better results in the hands of an experienced welder, though.

Looks good, but personally I think the rounds are a bit much.

#9

Registered User

Join Date: Jul 2012

Location: Seattle, WA

Posts: 416

Likes: 0

Received 0 Likes

on

0 Posts

Not to be rude or misleading but your welds look like crap because of the welder you are using. If you were using a better welder you wouldn't have to grind your welds down. I weld for a hobby and its my part time job. My personal welder is a Hobart mig. It uses flux core or argon. When I first started welding (around 15 years old) I used my dads Lincoln. I got really good and enjoyed it. So I went to Walmart and bought one of there century mig welders only to find out that it sucked. There's just not enough amps in those little things to achieve a good bead. So it's not that your rusty its your just trying to use junk IMO. Looks good tho. Anxious to see it finished and its very inspiring.

. But yeah, a nice machine helps a lot, we have Miller Synchrowaves at my work and they do a pretty damn good job. I've also used an Areowave, those are REALLY nice. Those aren't really machines for the hobbyist though cause they're big $$$.

. But yeah, a nice machine helps a lot, we have Miller Synchrowaves at my work and they do a pretty damn good job. I've also used an Areowave, those are REALLY nice. Those aren't really machines for the hobbyist though cause they're big $$$.The rack looks good though, I like the design, and keeping it cheap too! Keep at it.

Last edited by B-Fake; 01-18-2013 at 08:13 PM.

#10

Yea I had to switch to my arc welder about half way through cause this cheap one I have just isn't cutting it. I think its too cheap for cheap lol. I have it on max heat setting and it barely penetrates this stuff. But I haven't done any serious welding for a few years as well. But my grinder should help that hahaha.

#13

Registered User

Join Date: Sep 2008

Location: middle of no where Alaska

Posts: 4,355

Likes: 0

Received 2 Likes

on

2 Posts

Yea I had to switch to my arc welder about half way through cause this cheap one I have just isn't cutting it. I think its too cheap for cheap lol. I have it on max heat setting and it barely penetrates this stuff. But I haven't done any serious welding for a few years as well. But my grinder should help that hahaha.

But I guess if your Stick is working for you, keep with it. Whats the wall thickness of the tube? Judging by your cost so far, I am assuming HREW? So it should weld easily. Also, I think the 1/4" plates are a little over-kill

But I guess if your Stick is working for you, keep with it. Whats the wall thickness of the tube? Judging by your cost so far, I am assuming HREW? So it should weld easily. Also, I think the 1/4" plates are a little over-kill

I think its a good design, just aesthetically, to me, the extra rounds are not pleasing

I expect your final product to change my opinion, though.

I expect your final product to change my opinion, though.

Last edited by toyota4x4907; 01-18-2013 at 08:42 PM.

#15

The plates are over kill they were supposed to be 1/8 but When I got my 5 foot section from the guy i noticed it was 1/4.  Soooo being the nice gentleman that I am, I kept my mouth shut and decided to work with it.

Soooo being the nice gentleman that I am, I kept my mouth shut and decided to work with it.

As far as the heat goes I only have 2 settings on that thing Low or Max and low just wasn't penetrating at all it just sat on top So I went on with the max setting at about 4 speed.

Soooo being the nice gentleman that I am, I kept my mouth shut and decided to work with it.

Soooo being the nice gentleman that I am, I kept my mouth shut and decided to work with it.

As far as the heat goes I only have 2 settings on that thing Low or Max and low just wasn't penetrating at all it just sat on top So I went on with the max setting at about 4 speed.

#19

Registered User

Join Date: Sep 2008

Location: middle of no where Alaska

Posts: 4,355

Likes: 0

Received 2 Likes

on

2 Posts

The plates are over kill they were supposed to be 1/8 but When I got my 5 foot section from the guy i noticed it was 1/4.  Soooo being the nice gentleman that I am, I kept my mouth shut and decided to work with it.

Soooo being the nice gentleman that I am, I kept my mouth shut and decided to work with it.

As far as the heat goes I only have 2 settings on that thing Low or Max and low just wasn't penetrating at all it just sat on top So I went on with the max setting at about 4 speed.

Soooo being the nice gentleman that I am, I kept my mouth shut and decided to work with it.

Soooo being the nice gentleman that I am, I kept my mouth shut and decided to work with it.

As far as the heat goes I only have 2 settings on that thing Low or Max and low just wasn't penetrating at all it just sat on top So I went on with the max setting at about 4 speed.