MasterFlow & SuperFlow air compressor MF-1050 & MV-50

#42

All good info. I just won an eBay auction for a 1050 so I'm waiting to try it out! I'm thinking about getting a set of Staun Tyre Deflators (http://www.4x4rockshop.com/Scripts/p...?idproduct=337) to put in the bag with the compressor for trail days. I don't plan on hard mounting this thing. I planning on saving up more cash to do an Oasis or Extreme Aire for the hard mount so I can run tools. That's not going to happen for a while though!

Oasis:

http://www.oasisoffroad.com/p3.html

Extreme Aire:

http://www.extremeoutback.com/index....d=6495971.3356

Oasis:

http://www.oasisoffroad.com/p3.html

Extreme Aire:

http://www.extremeoutback.com/index....d=6495971.3356

#43

Contributing Member

Join Date: Jul 2006

Location: Humboldt County, CA

Posts: 284

Likes: 0

Received 0 Likes

on

0 Posts

Sorry about the thread hijack.

Thanks

#44

smear grease on the tap, run it in part way, then remove it clean the debri, repeat the process, till it's done. Or keep it face down so when you tap the shavings fall out......

#45

I have no idea if they ship to Spain or not, but it's worth a shot to try!

#46

Registered User

Join Date: Jul 2004

Location: Barcelona (Spain)

Posts: 917

Likes: 0

Received 0 Likes

on

0 Posts

I can try...

I've found locally a 65 liters/minute 150psi max for 56$... It's chinese, don't know what to do... For so little money I can try it but also if it fails I've lost 60$ for spend in another better...

David

I've found locally a 65 liters/minute 150psi max for 56$... It's chinese, don't know what to do... For so little money I can try it but also if it fails I've lost 60$ for spend in another better...

David

#47

True, but if it works then you saved yourself $100 or more!

I know I plan on doing a better setup hard mounted to the truck, but I'm looking at $1000 or more for that. The Oasis, which I would LOVE to have, is $1200-$1300 by itself. So if $60 gets me by until then.....

I know I plan on doing a better setup hard mounted to the truck, but I'm looking at $1000 or more for that. The Oasis, which I would LOVE to have, is $1200-$1300 by itself. So if $60 gets me by until then.....

#48

Contributing Member

I just got one of these compressors, and I want to use it for a small onboard air \ air locker setup. I have a 1/4-18 NPT tap. Do I need to drill the hole out then run the tap through? What about the metal particles and shavings, how do you get them out of the compressor? Basically, how do I do this?

I drilled the hole with a drill bit first but I forget which size, whatever the tap calls for; it didn't end up taking out much material, if any. Then I tapped the hole, being careful to chase the threads several times. By doing this you can use any standard 1/4-18 NPT fitting in there! I put a right angle on mine, and then added a standard air hose chuck.

I think it would be a good idea to attach the extension I have in there to the handle somehow, to help stiffen it in the case of bumps.

I'm going for an on-board air system too, and I'm probably dumping the air-chuck idea in favor of a hose fitting and some hard plastic tube, since I will be hard-mounting one or hopefully two of these compressors under my chassis (with switches on the dash to control them), and will have the air chuck come up by one of my rear wheel wells to attach a hose to. Intersetingly, the air filter's threaded hole apperas to already be 1/4-18 NPT, or very close to it. I will chase the threads with a tap to be sure, and then the compressors will have a breather that goes into the engine compartment, so they don't suck in any water or mud.

If you want to use this compressor with an air locker (ARB I assume) make sure you get a pressure switch from Viair to shut the compressor on at 85psi / off at 105psi.

Should be pretty slick

Last edited by mastacox; 02-22-2007 at 05:38 AM.

#49

That looks like a good plan! For a fraction of the cost I've been looking at!

Quick question tho, how will those hold up to water? I've found very little specs on them compared with other brands. I'm thinking occasional splashing might be ok, but I'd be afraid to submerge it. Or even splash it after it heats up to 150* or so filling a tank/tire/etc. I was planning on putting mine under the hood somewhere to help protect from water.

Quick question tho, how will those hold up to water? I've found very little specs on them compared with other brands. I'm thinking occasional splashing might be ok, but I'd be afraid to submerge it. Or even splash it after it heats up to 150* or so filling a tank/tire/etc. I was planning on putting mine under the hood somewhere to help protect from water.

#50

I hate to wake up this thread, but my search led me to the excellent info posted here and I am quite interested in purchasing a Q-Industries compressor.

Does anyone know what the CFM or Liter Per Minute is for the newer Q89 ?

It seems like the duty cycle of that unit is about 25 minutes.

What is the duty cycle of the MF-1050 (Tsunami) unit?

Also, I noticed there is also a Master Flow Q-Maxx unit? Does anyone have any info on that one?

Thanks in advance.

Does anyone know what the CFM or Liter Per Minute is for the newer Q89 ?

It seems like the duty cycle of that unit is about 25 minutes.

What is the duty cycle of the MF-1050 (Tsunami) unit?

Also, I noticed there is also a Master Flow Q-Maxx unit? Does anyone have any info on that one?

Thanks in advance.

#55

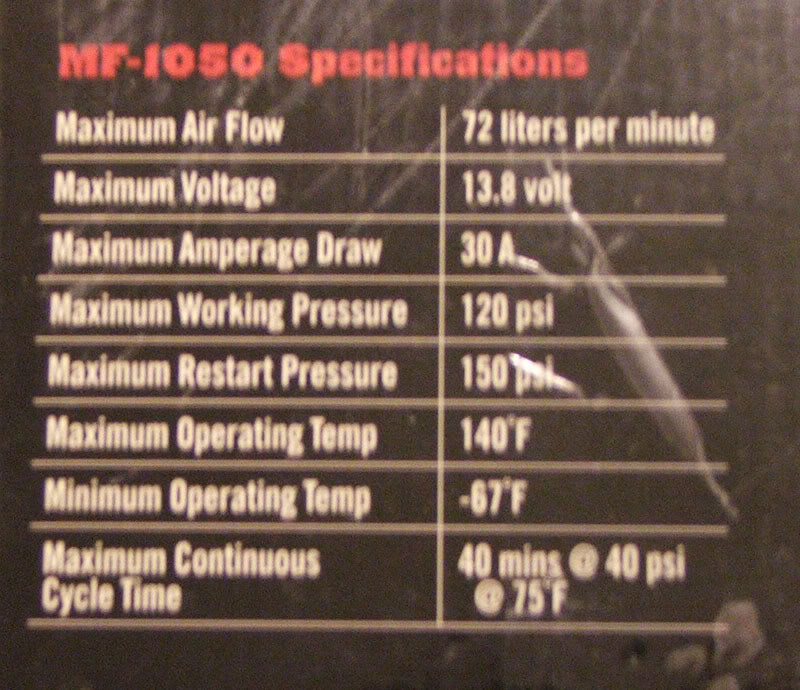

1. The MV50 was the first original model. It had a flow rate of 72LPM which was printed both on the shipping box and the label sticker on the compressor.

2. The MF-1050 became the 2nd generation model that looked identical to the MV50. However, while it listed a flow rate of 72LPM on the shipping box, the label sticker on the compressor stated 50LPM.

3. The Q-Maxx or MF-1052 is the current model. The is probably what you saw at Costco. This particular model does not show flow rate information on the shipping box or the label sticker on the body. I don't know why they stopped listing it?

4. The is also another model called the Q-89, which also has been seen in Costco. But the price is out of this league, costing 3 times as much. It is a dual cylinder pump.

The Company that manufactures these compressors has been very evasive in providing information about their products. In the dozen or so emails I have sent to them, they state that all 3 models are comparable (not identical). Perhaps the oldest model did produce a very high flow rate but due manufacturing costs, they are now only producing 50LPM models? There is no way to be sure.

If anyone has access to the MV50 and the MF-1050/52 , perhaps they could better inform us as to which has a better flow rate. Sorry to be persistant, but I own an Import 4x4 shop in NYC, and a lot of customers have been asking about compressors and I want to provide them the best product.

2. The MF-1050 became the 2nd generation model that looked identical to the MV50. However, while it listed a flow rate of 72LPM on the shipping box, the label sticker on the compressor stated 50LPM.

3. The Q-Maxx or MF-1052 is the current model. The is probably what you saw at Costco. This particular model does not show flow rate information on the shipping box or the label sticker on the body. I don't know why they stopped listing it?

4. The is also another model called the Q-89, which also has been seen in Costco. But the price is out of this league, costing 3 times as much. It is a dual cylinder pump.

The Company that manufactures these compressors has been very evasive in providing information about their products. In the dozen or so emails I have sent to them, they state that all 3 models are comparable (not identical). Perhaps the oldest model did produce a very high flow rate but due manufacturing costs, they are now only producing 50LPM models? There is no way to be sure.

If anyone has access to the MV50 and the MF-1050/52 , perhaps they could better inform us as to which has a better flow rate. Sorry to be persistant, but I own an Import 4x4 shop in NYC, and a lot of customers have been asking about compressors and I want to provide them the best product.

Last edited by Titus Pullo; 03-18-2007 at 06:51 PM.

#56

^I noticed the same thing trying to find specs. The Q89 would have a higher flow I would assume since it's a dual cylinder, but I have been unable to find any relevant specs on it to justify the $150+ price tag. I bought the MF-1050 for ~$50 on eBay figuring it'll be enough for now. As it is I will have to lengthen the power cables as they do not reach the passenger side rear tire on my 06 DC Tacoma. Also, the screw on valve is nice in that it stays in place while inflating and can air down the tire. However, the air down feature is finicky. If you don't hold the hose straight and put tension on it, then it tends to let air out while you're trying to pump it in. I'm thinking of replacing that part myself and just get a set of preset air down valves as I'm more likely to put air in than let it out. But for $50 I guess I can't complain. $20-$30 cig plug compressors would take me half an hour or more to fill a tire. (assuming they don't blow a fuse in the process)

Edit:

Oh, and it seems like the valve doesn't push the valve stem in enough to open it up all the way, and has to force air passed the semi closed stem valve. When I first used it I had to turn the compressor on and off getting close to the pressure I wanted as it would read about 5PSI higher when running than when I turned it off for a few seconds. At one point it rose to around 75-80PSI from 30PSI in a few seconds. So a better inflator is definitely going on when I find one that will work. Maybe one that clamps on as my cold fingers seemed to let quite a bit out trying to unscrew from the valve stem.

Edit:

Oh, and it seems like the valve doesn't push the valve stem in enough to open it up all the way, and has to force air passed the semi closed stem valve. When I first used it I had to turn the compressor on and off getting close to the pressure I wanted as it would read about 5PSI higher when running than when I turned it off for a few seconds. At one point it rose to around 75-80PSI from 30PSI in a few seconds. So a better inflator is definitely going on when I find one that will work. Maybe one that clamps on as my cold fingers seemed to let quite a bit out trying to unscrew from the valve stem.

Last edited by piercedtiger; 03-19-2007 at 04:32 AM.

#57

Registered User

Join Date: Oct 2004

Location: Chandler AZ

Posts: 38

Likes: 0

Received 0 Likes

on

0 Posts

...

If anyone has access to the MV50 and the MF-1050/52 , perhaps they could better inform us as to which has a better flow rate. Sorry to be persistant, but I own an Import 4x4 shop in NYC, and a lot of customers have been asking about compressors and I want to provide them the best product.

If anyone has access to the MV50 and the MF-1050/52 , perhaps they could better inform us as to which has a better flow rate. Sorry to be persistant, but I own an Import 4x4 shop in NYC, and a lot of customers have been asking about compressors and I want to provide them the best product.

I just put 37's on the LX

and thinking of moving to a truck mounted air setup. Looking at the Puma unit, mounting the pump inside and the tank underneath.

and thinking of moving to a truck mounted air setup. Looking at the Puma unit, mounting the pump inside and the tank underneath. http://cgi.ebay.com/ebaymotors/PUMA-...spagenameZWDVW

#58

Registered User

Join Date: Oct 2004

Location: Chandler AZ

Posts: 38

Likes: 0

Received 0 Likes

on

0 Posts

...

Edit:

Oh, and it seems like the valve doesn't push the valve stem in enough to open it up all the way, and has to force air passed the semi closed stem valve. When I first used it I had to turn the compressor on and off getting close to the pressure I wanted as it would read about 5PSI higher when running than when I turned it off for a few seconds. At one point it rose to around 75-80PSI from 30PSI in a few seconds. So a better inflator is definitely going on when I find one that will work. Maybe one that clamps on as my cold fingers seemed to let quite a bit out trying to unscrew from the valve stem.

Edit:

Oh, and it seems like the valve doesn't push the valve stem in enough to open it up all the way, and has to force air passed the semi closed stem valve. When I first used it I had to turn the compressor on and off getting close to the pressure I wanted as it would read about 5PSI higher when running than when I turned it off for a few seconds. At one point it rose to around 75-80PSI from 30PSI in a few seconds. So a better inflator is definitely going on when I find one that will work. Maybe one that clamps on as my cold fingers seemed to let quite a bit out trying to unscrew from the valve stem.

Be careful of your choices if you change any of the fittings. These compressors don't have any shutoff or blow off protection, so all fittings must be free flow, vented type. If the more common sealed type fittings are used and the pump is left running even for a few seconds very high pressures can be produced blowing lines, fittings, heads, etc off with high velocity!

#59

Registered User

Join Date: Oct 2004

Location: Chandler AZ

Posts: 38

Likes: 0

Received 0 Likes

on

0 Posts

From our limited testing the dual makes less volume than two singles and costs more. So I don't see the point, with two singles if one takes a dump you can still air up with the other.

#60

I also have the official reason why there are 2 different air flow rates listed on the MF-1050. This is the Company's response:

"The flow rate from the cylinder for the MF-1050 is 72 LPM. The flow rate from the end of the hose is 50 LPM".

It took me a lot of persistance to finally get that answer from them. But that's just the way I am

Nobody would ship me one to Spain with USPS?

Nobody would ship me one to Spain with USPS?