A lesson learned (pics)

#1

Registered User

Thread Starter

A lesson learned (pics)

So for all of those would be "im going to change my timing belt, can i do this" people. Let this be a lesson of one SMALL thing to get right

ALWAYS, ALWAYS make shure you have the crank pully seated on the key. (edit as a result of not being seated right the pully had a slight wobble to it that didnt show up right away)OH i torqued im crank bolt down alright, but it seems to have done nothing but drive the key into the side of the pulley, not the keyway!

what happens you ask?

THIS

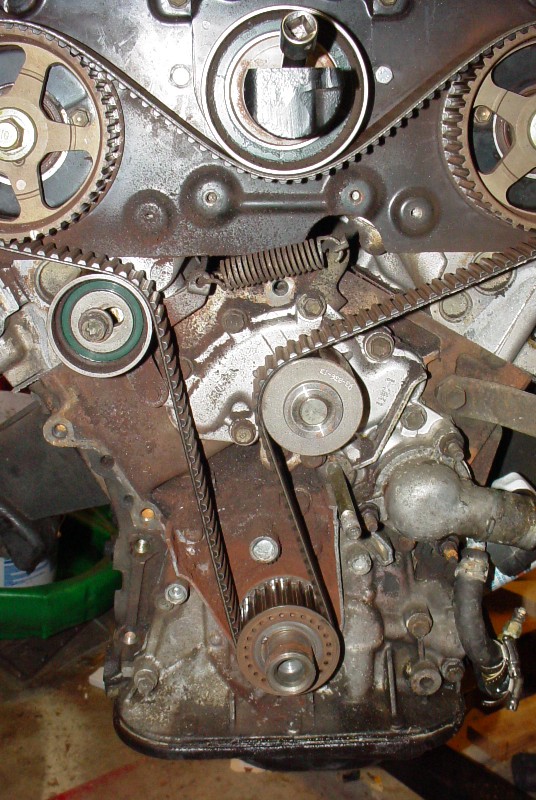

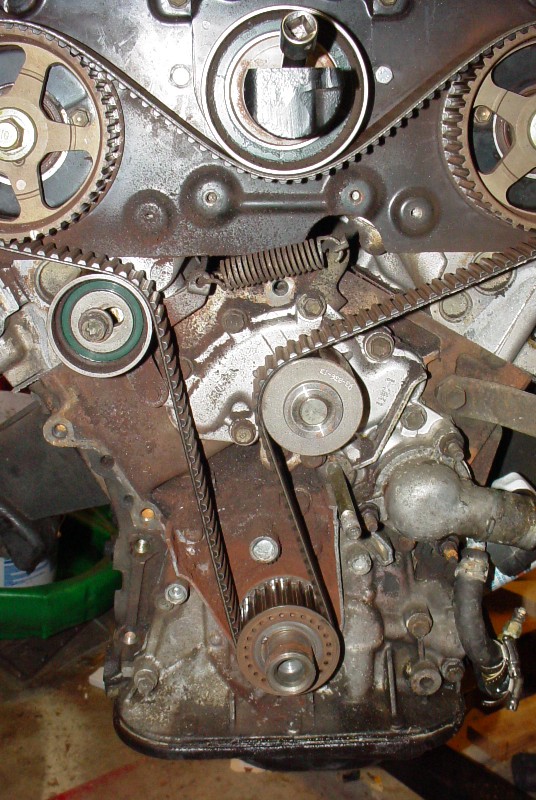

the plate that is supposed to keep the belt from migrateing to far forward rides back 1/8" which lets the belt rub up against the fan bracket.

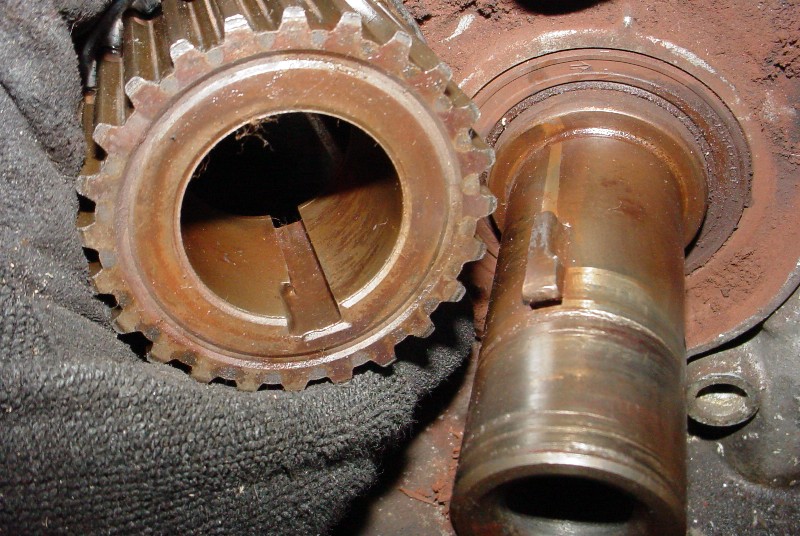

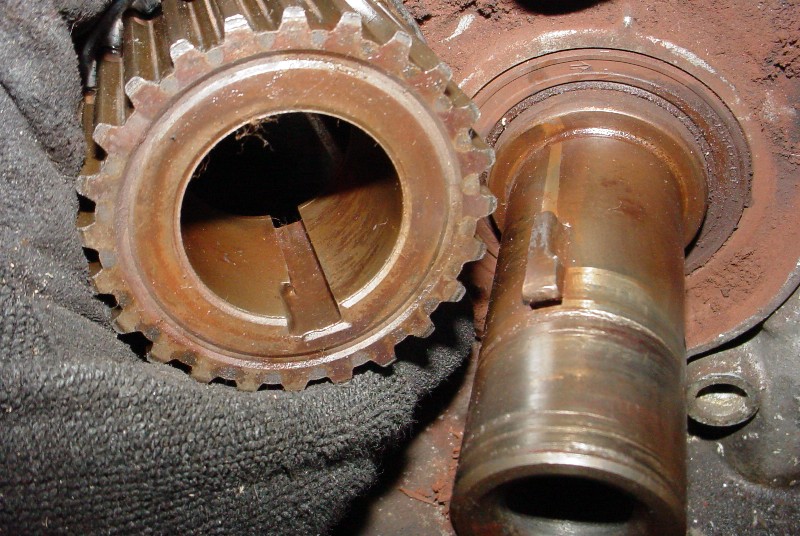

Then with no 180lflbs pressing on the crank gear, its free to wobble around on the key giveing you this!

THen your timming goes all to hell, the motor doesnt want to run right, and you decide to rebuild the motor because its got a wicked tick and loss of power.

http://www.snjschmidt.com/pics/motor/bad_tb.mpg (ya i know the lighting is bad, perhaps someone with some movie editing softwere can lighten it up, )

SO class what have we learned....

ALWAYS, ALWAYS make shure you have the crank pully seated on the key. (edit as a result of not being seated right the pully had a slight wobble to it that didnt show up right away)OH i torqued im crank bolt down alright, but it seems to have done nothing but drive the key into the side of the pulley, not the keyway!

what happens you ask?

THIS

the plate that is supposed to keep the belt from migrateing to far forward rides back 1/8" which lets the belt rub up against the fan bracket.

Then with no 180lflbs pressing on the crank gear, its free to wobble around on the key giveing you this!

THen your timming goes all to hell, the motor doesnt want to run right, and you decide to rebuild the motor because its got a wicked tick and loss of power.

http://www.snjschmidt.com/pics/motor/bad_tb.mpg (ya i know the lighting is bad, perhaps someone with some movie editing softwere can lighten it up, )

SO class what have we learned....

Last edited by snap-on; 07-07-2006 at 08:01 PM.

#5

Registered User

Originally Posted by snap-on

the upper water inlet makes a great place to keep your socket on a 3" extension?

just cuz its tight dont mean its right

Last edited by surf4runner; 01-14-2006 at 10:43 AM.

#6

Registered User

Join Date: Jan 2006

Location: houston,tx

Posts: 32

Likes: 0

Received 0 Likes

on

0 Posts

whats the correct way to check

newb here,hey snap on,

what would be the best way to double check to see if the crank pulley is fully seated, i'm about to embark on this madness but didn't know there would be some "free play" once you put the crankshaft pulley back on.

thanks for this board I'm building my confidence up to do this!

what would be the best way to double check to see if the crank pulley is fully seated, i'm about to embark on this madness but didn't know there would be some "free play" once you put the crankshaft pulley back on.

thanks for this board I'm building my confidence up to do this!

#7

Contributing Member

Originally Posted by snap-on

SO class what have we learned....

j/k

(thanks, by the way, I'm doing my 3.4 first time myself next month..)

Last edited by habanero; 01-19-2006 at 03:44 AM.

Trending Topics

#8

Registered User

Join Date: May 2004

Location: 100 miles offshore as much as possible, & Springfield Oregon USA

Posts: 3,291

Likes: 0

Received 0 Likes

on

0 Posts

Seems like it would have taken a huge amount of effort to crank that bolt down and crush that key into the pulley like that. First rule of wrenching is that if it resists, find out why, don't just use a longer bar? (Once saw a guy totally bust a manual transmission, the new engine didn't have a deep enough hole machined in the crank and he just kept tightening down the bellhousing bolts, cussing all the time about how hard it was to pull it together - till it shattered.)

But thanks for the tip - it could save someone some grief.

But thanks for the tip - it could save someone some grief.

#9

Contributing Member

Originally Posted by Flamedx4

Seems like it would have taken a huge amount of effort to crank that bolt down and crush that key into the pulley like that. First rule of wrenching is that if it resists, find out why, don't just use a longer bar? (Once saw a guy totally bust a manual transmission, the new engine didn't have a deep enough hole machined in the crank and he just kept tightening down the bellhousing bolts, cussing all the time about how hard it was to pull it together - till it shattered.)

But thanks for the tip - it could save someone some grief.

But thanks for the tip - it could save someone some grief.

this is espeicaly true with yotas..if it doesnt fit on right before you bolt/screw it down....you did somethign wrong somewhere.

#12

Registered User

Thread Starter

Originally Posted by Flamedx4

Seems like it would have taken a huge amount of effort to crank that bolt down and crush that key into the pulley like that.

The key wasnt crushed flat by any means. I put my the torque wrench on it, and when i got to 180 it clicked and i thought i was done.

as for the best way to double check that the pulley is seated right, look at the end of the pulley when you think its on all the way. The distance between the end of the pulley (were the bolt flange mounts) and the end of the crank is only about 1/8" max when fully seated correctly. NOT 1/4-3/16!

Ill post a pic showing a propertly seated crank pulley. (something i learned myself.)

#13

Registered User

Join Date: Jan 2006

Location: houston,tx

Posts: 32

Likes: 0

Received 0 Likes

on

0 Posts

almost to that point

thanks snap on,

i'll have to remember that, if i can just get this p.s. pulley off so I can take off the crankshaft pulley, but everytime i try to remove one of the four bolts the pulley wants to move and I'm all paranoid about keeping the notch on TDC, i know some use an impact on the crankshaft pulley but what about those p.s. bolts? how do you keep the crank from moving without the sst tool? hey thanks for this board I wouldn't even have the cajones to get this far.

i'll have to remember that, if i can just get this p.s. pulley off so I can take off the crankshaft pulley, but everytime i try to remove one of the four bolts the pulley wants to move and I'm all paranoid about keeping the notch on TDC, i know some use an impact on the crankshaft pulley but what about those p.s. bolts? how do you keep the crank from moving without the sst tool? hey thanks for this board I wouldn't even have the cajones to get this far.

#14

Originally Posted by radrav4

thanks snap on,

i'll have to remember that, if i can just get this p.s. pulley off so I can take off the crankshaft pulley, but everytime i try to remove one of the four bolts the pulley wants to move and I'm all paranoid about keeping the notch on TDC, i know some use an impact on the crankshaft pulley but what about those p.s. bolts? how do you keep the crank from moving without the sst tool? hey thanks for this board I wouldn't even have the cajones to get this far.

i'll have to remember that, if i can just get this p.s. pulley off so I can take off the crankshaft pulley, but everytime i try to remove one of the four bolts the pulley wants to move and I'm all paranoid about keeping the notch on TDC, i know some use an impact on the crankshaft pulley but what about those p.s. bolts? how do you keep the crank from moving without the sst tool? hey thanks for this board I wouldn't even have the cajones to get this far.

#15

Registered User

Join Date: Aug 2003

Location: Richmond VA

Posts: 106

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by radrav4

thanks snap on,

i'll have to remember that, if i can just get this p.s. pulley off so I can take off the crankshaft pulley, but everytime i try to remove one of the four bolts the pulley wants to move and I'm all paranoid about keeping the notch on TDC, i know some use an impact on the crankshaft pulley but what about those p.s. bolts? how do you keep the crank from moving without the sst tool? hey thanks for this board I wouldn't even have the cajones to get this far.

i'll have to remember that, if i can just get this p.s. pulley off so I can take off the crankshaft pulley, but everytime i try to remove one of the four bolts the pulley wants to move and I'm all paranoid about keeping the notch on TDC, i know some use an impact on the crankshaft pulley but what about those p.s. bolts? how do you keep the crank from moving without the sst tool? hey thanks for this board I wouldn't even have the cajones to get this far.

Also, I just used a 3/8" ratchet and socket to remove the PS pulley.

#16

I'm at that point now in getting my engine put back together from the HG replacement... I didn't take the lower crankshaft timing gear off, but I did remove the harmonic balancer pulley...

When you say crankshaft pulley are you referring to the lower timing gear on the crankshaft? I didn't remove that.

I'm not entirely sure what to look for, to make sure I have it mounted right.

When you say crankshaft pulley are you referring to the lower timing gear on the crankshaft? I didn't remove that.

I'm not entirely sure what to look for, to make sure I have it mounted right.

#17

the lesson learned is the money you will be spending to fix that mess you could of payed a toyota tech to the job right the first time. but thats how everyone learns is by messing it up your self then you will never forget the mistake you made.

#18

Registered User

Join Date: Jan 2005

Location: Youfalla, Al

Posts: 399

Likes: 0

Received 0 Likes

on

0 Posts

I would glady pay a toyota tech(cash on th side) to replace my wife timing belt on her 3.4L(I could do it but I am lazy). There is no way in hell, I would let a stealership touch my vehicle again. I had the steering rod relay recall done, they tried to tell me I needed about $600 work on the pitman and idler arms(both had been replaced a little over a year ago). Then I would need my wheel bearings repacked(not replaced) for then nice sum of $540. I laughed and told them all that had been done a year ago! They told me that is must not have been done by a toyota dealership and they didn't use toyota parts. I said it was done by Toyota and they used toyota parts(I had reciepts). He there was no way a Toyota service dept would use inferior parts and need this stuff replaced, only after 1 year. I said, "Really, your dam service dept is the one who got the parts and done all the repair work a year a ago for 650 dollars!" Long story short, I told them where to stick it and went had it checked and aligned at a real hitw service station!

Last edited by trx125; 05-29-2006 at 08:58 AM.

#19

^^^^ Wow!!!

I had the rely rod recall done on mine, and some of them parts you noted that they said need replaced, they replaced them at no charge to me.

When I got it back I have a pretty much new steering setup. Minus pitman arm I think, I think they said they just put all new bushings, but I got a new idler arm.

Although the local Toyota dealer here Rocks!!! If I had the money I wouldn't hesitate to take my yota down there an have them do some work. Dealerships are just like any autoshop though, gotta watch out for the bastards that'll take every penny away from you they can.

I had the rely rod recall done on mine, and some of them parts you noted that they said need replaced, they replaced them at no charge to me.

When I got it back I have a pretty much new steering setup. Minus pitman arm I think, I think they said they just put all new bushings, but I got a new idler arm.

Although the local Toyota dealer here Rocks!!! If I had the money I wouldn't hesitate to take my yota down there an have them do some work. Dealerships are just like any autoshop though, gotta watch out for the bastards that'll take every penny away from you they can.

Last edited by Chuki; 05-29-2006 at 11:21 AM.

#20

alot of it is just finding a tech that u trust and like and knows what they are doing and stay w/ that person weather it be an independent or a dealer ship. not all dealer techs are out to rip u off. and if your off roading as much as some of you do it may have needed all that stuff that soon.