Code 52 Tech Thread

#141

Registered User

iTrader: (-1)

I didn't read the thread above. Just a quick refresher if it's needed. The knock sensor is a piezoelectric device, this means it generates it's electrical signal and doesn't receive any power from the ECU. They are quite fragile if impacted to heavily they can and will shatter and either provide a smaller signal or not signal at all (sub text don't hit it directly to test it, tap on the block near by)

#142

Registered User

I've recently been blessed with becoming one of the "Code 52" crowd. :-( Very intermittent so far but becoming more frequent.. Regardless, still have a problem somewhere that is going to need addressing.

From the way I read things it can be up to 4 things.

1) the KS itself (original)

2) the KS pigtail wire. (replaced this with a new Toyota one approx. 6 yrs ago when doing a head gasket job)

3) wiring issue from pigtail connector to ECU.

4) ECU (someone mentioned earlier in this thread about finding 3 capacitors in their ECU tied to the KS circuitry which went bad, replaced the caps with success

Cheers

From the way I read things it can be up to 4 things.

1) the KS itself (original)

2) the KS pigtail wire. (replaced this with a new Toyota one approx. 6 yrs ago when doing a head gasket job)

3) wiring issue from pigtail connector to ECU.

4) ECU (someone mentioned earlier in this thread about finding 3 capacitors in their ECU tied to the KS circuitry which went bad, replaced the caps with success

Cheers

#143

Registered User

Join Date: Dec 2015

Location: Washington

Posts: 17

Likes: 0

Received 0 Likes

on

0 Posts

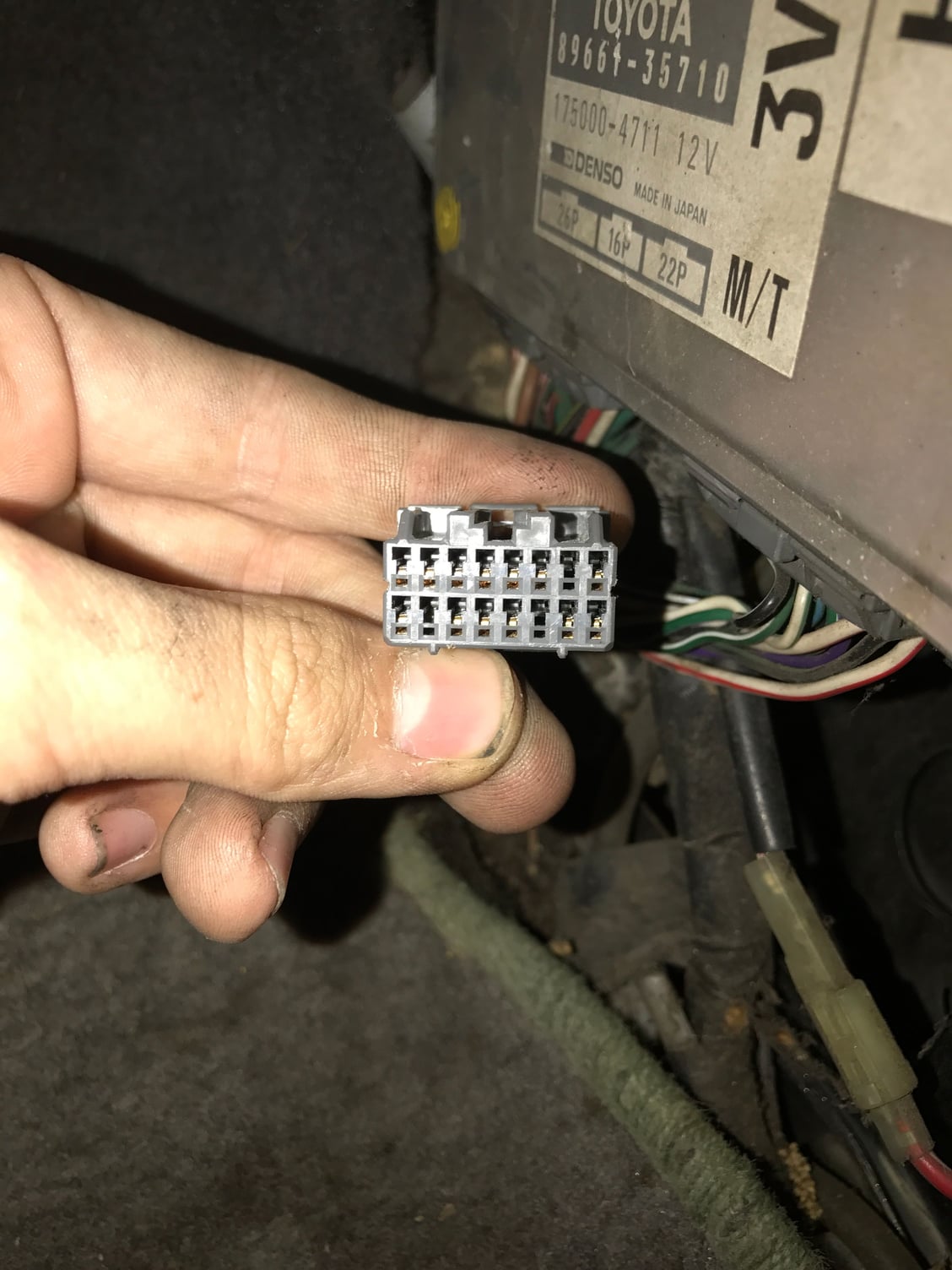

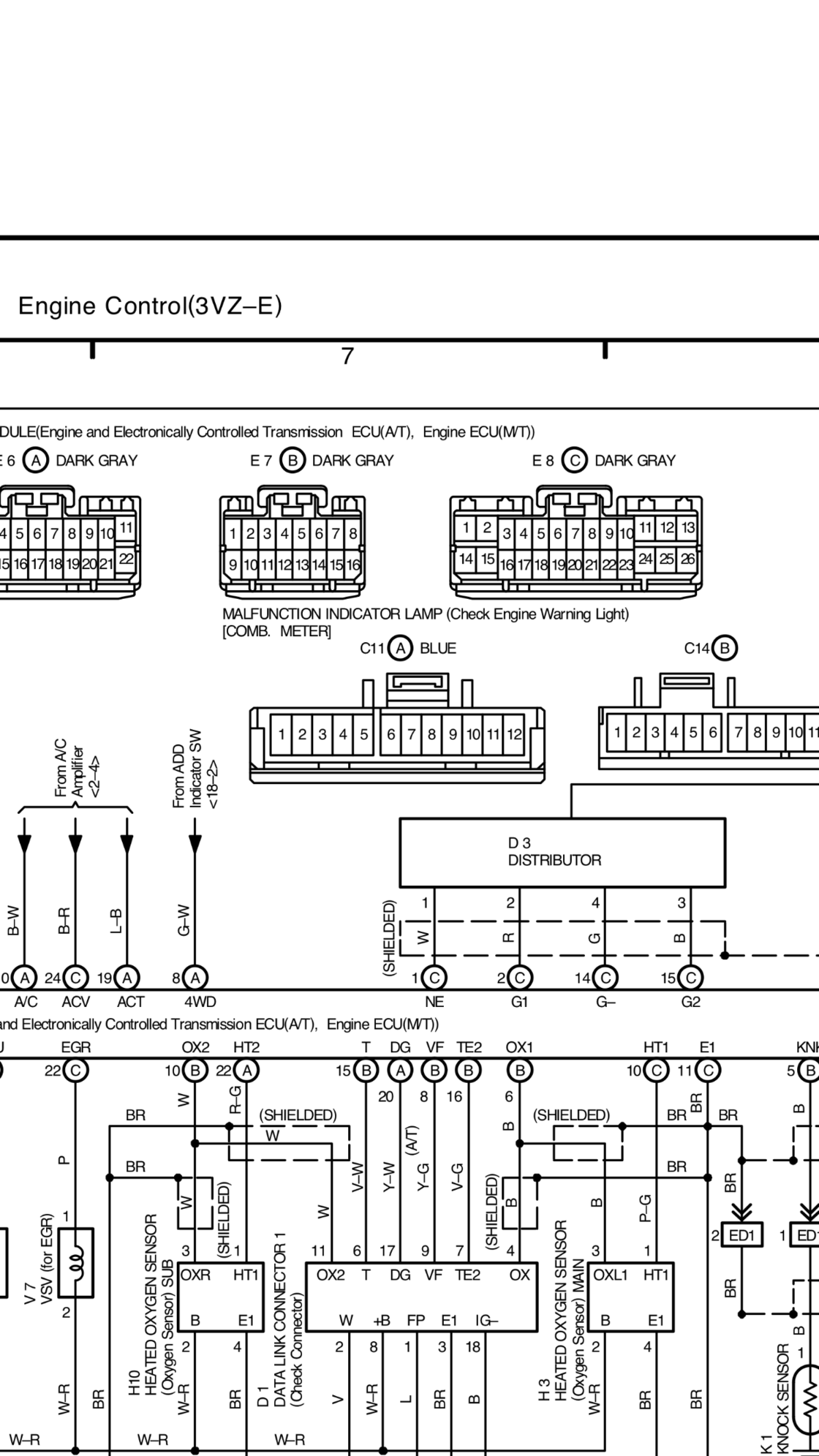

So I've been trying to diagnose my code 52 as well, on my 94 pickup 3vze M/T. I just ordered a new denso knk sensor and sub-harness so that should be here shortly. Am I right in reading this diagram that pin 5 on the B connector is the KNK sensor, even on a M/T vehicle? I was testing plug B pin 4 with my multimeter earlier as that is the wire my diagram was showing... Are the A/T and M/T pinouts different? Really need to get this darn 52 tracked down, I'm prepared to rewire the whole circuit with rg-58 a/u if need be.

#148

Registered User

Join Date: Dec 2015

Location: Washington

Posts: 17

Likes: 0

Received 0 Likes

on

0 Posts

I'll have to look tomorrow when it's daylight again. I pulled the throttle body so I could get to the plug for the knock sensor, both wires insulation was cracked at the harness plug.... almost would say the ground and signal wires were touching.

#149

Registered User

Join Date: Jan 2015

Location: These slippery people Gonna see you through

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

shield had voltage on it so I am replacing the line..

I did do the other no no tried a cheve sensor so I am going back to Toyota.

You did say it a closed system so no other input to knock ?

I did do the other no no tried a cheve sensor so I am going back to Toyota.

You did say it a closed system so no other input to knock ?

#150

The shielding is grounded. If you check it against a positive terminal you will get positive voltage. If you check it against ground, you should get no voltage. If you get voltage, there is a short. I'm 99.99% sure about this from when I chased my own code 51 crap.

#151

Reviving this thread after a bit it seems! I was having a CEL for a week and a bit before I was able to deal with it today. I have codes 43 and 52. Thanks to this thread I figured it was the knock sensor or its wiring and where it was and. Since we did an oil change at the same time it was easy to get a wrench in there to undo the knock sensor. However when I went to pull the connector off the knock sensor, the female plug just came right off the sensor, leaving it in two pieces. I unscrewed the knock sensor and this is what I have now. We have a theory: a small coolant leak from a pipe up above has been dripping coolant on it for a while, causing whatever that pink stuff is to corrode. My question is, is that black/dark brown fluid supposed to be on the inside of the sensor? The interior of the sensor and the plug were coated in it. It's not connected to the oil pan in any ways, but it is near the oil filter and oil sensor so perhaps a very messy oil filter changed splashed oil all over it? Would that corrode it and make it fall apart? Or would it be the coolant corroding that adhesive or whatever it is....Anyways, super happy I don't have to chase a wiring issue, and once I get a new sensor this should be an easy fix (crossing my fingers).

Last edited by weirdchylde; 01-26-2018 at 04:49 PM.

#152

V6 Knock Sensor Discontinued

Toyota told me the knock sensor pigtail is discontinued for my 95 4 Runner. The dealer suggested the junk yard but I'm hesitant to put in an old part. Are there any aftermarket sources?

TIA

Brian

TIA

Brian

#153

1988 4Runner 22RE

This is my first tech question. I chose this thread b/c it seems to be the most comprehensive Code 52 thread Iíve seen after reading dozens. I have a 1988 4Runner 22RE which was rebuilt by a local machine shop a couple years ago. Code 52 just popped up and I need some help trouble shooting...

Although the basic function of the KS and purpose of Code 52 is the same for the 22RE and 3VZ, Iíve determined the trouble shooting may be different. For example, thereís a lot of talk about replacing a ďpig tailĒ. Iíve come to the conclusion that this is specific to the 3VZ while the 22RE is a single wire between the KS and ECU.

1. Test circuit. My wire harness appears to be in good shape. Tested circuit between ECU connector and KS connector and has good continuity. I started exploring the issue of the shielded ground wire after all the research here. I donít see any visible evidence of braided shielded / coax type ground wire on my harness. Not on the KS side or ECU. It is a single insulated wire, that has a loose soft plastic sleeve around the wire on the KS side. On the ECU side it appears to be a single insulated wire clearly visible for a couple inches after coming out of the harness. As a test, i slipped a couple inches of a copper jumper wire between the loose sleeve and the inner wire then tested continuity to ground on the KS side. Nothing / Inconclusive. Either the braided line in there is not properly grounded, I didnít go far enough With jumper to reach it, or its not there at all. Does the 22RE have a shielded ground wire? I would think so based on what Iíve read and If so, were does it go to ground so I can find it. Iíve seen posts where it says it is ground at the ECU but I just donít see how thatís possible on my harness.

2. Since the circuit tested good continuity, and I wasnít getting anywhere testing ground, I figured Iíd replace the KS to rule that out. There seems to be pretty strong consensus that this has to be an OEM Toyota KS. My dealer says theyíre discontinued as do many of the Online Toyota parts stores. I also read several threads where switching years is not good (ie using 89 KS with an 88 ECU) so Iíve been a little reluctant to buy an unknown used one on EBay. Weíre searching local junk yards but no luck yet on an 8822RE 4Runner. I assume an 8822RE pickup would work but am uncertain if another Yota model same engine / same year is OK. Iíd appreciate yallís thoughts. In the event, this doesnít work...I have not seen one thread where someone recommends the best aftermarket alternative. I was going to go Rockauto over the local parts shops. But I would love to hear yíall opinion. Thx

This is my first tech question. I chose this thread b/c it seems to be the most comprehensive Code 52 thread Iíve seen after reading dozens. I have a 1988 4Runner 22RE which was rebuilt by a local machine shop a couple years ago. Code 52 just popped up and I need some help trouble shooting...

Although the basic function of the KS and purpose of Code 52 is the same for the 22RE and 3VZ, Iíve determined the trouble shooting may be different. For example, thereís a lot of talk about replacing a ďpig tailĒ. Iíve come to the conclusion that this is specific to the 3VZ while the 22RE is a single wire between the KS and ECU.

1. Test circuit. My wire harness appears to be in good shape. Tested circuit between ECU connector and KS connector and has good continuity. I started exploring the issue of the shielded ground wire after all the research here. I donít see any visible evidence of braided shielded / coax type ground wire on my harness. Not on the KS side or ECU. It is a single insulated wire, that has a loose soft plastic sleeve around the wire on the KS side. On the ECU side it appears to be a single insulated wire clearly visible for a couple inches after coming out of the harness. As a test, i slipped a couple inches of a copper jumper wire between the loose sleeve and the inner wire then tested continuity to ground on the KS side. Nothing / Inconclusive. Either the braided line in there is not properly grounded, I didnít go far enough With jumper to reach it, or its not there at all. Does the 22RE have a shielded ground wire? I would think so based on what Iíve read and If so, were does it go to ground so I can find it. Iíve seen posts where it says it is ground at the ECU but I just donít see how thatís possible on my harness.

2. Since the circuit tested good continuity, and I wasnít getting anywhere testing ground, I figured Iíd replace the KS to rule that out. There seems to be pretty strong consensus that this has to be an OEM Toyota KS. My dealer says theyíre discontinued as do many of the Online Toyota parts stores. I also read several threads where switching years is not good (ie using 89 KS with an 88 ECU) so Iíve been a little reluctant to buy an unknown used one on EBay. Weíre searching local junk yards but no luck yet on an 8822RE 4Runner. I assume an 8822RE pickup would work but am uncertain if another Yota model same engine / same year is OK. Iíd appreciate yallís thoughts. In the event, this doesnít work...I have not seen one thread where someone recommends the best aftermarket alternative. I was going to go Rockauto over the local parts shops. But I would love to hear yíall opinion. Thx

Last edited by Toyogator00; 06-07-2020 at 07:01 AM. Reason: Add vehicle at top of post

#154

Toyogator, the shielding works when grounded on one end of the wire only. According to my electrical engineer friend noone understands ground loops but they can cause a problem. I did not understand 3xactly how you tested with the multimeter. You are supposed to get 12 volt positive between the shielding and pos terminal. You shouldn't get any continuity for the signal wire to anything, unplug the KS. This is what I remember.

#155

Toyogator, the shielding works when grounded on one end of the wire only. According to my electrical engineer friend noone understands ground loops but they can cause a problem. I did not understand 3xactly how you tested with the multimeter. You are supposed to get 12 volt positive between the shielding and pos terminal. You shouldn't get any continuity for the signal wire to anything, unplug the KS. This is what I remember.

#156

On the 3vze, if i remember correctly, the ks had a 2nd wire which was grounding to the block through the ks. So on the ecu side the shielding just ends near The termination point.

Does your ks connector have 2 pins?

For the continuity test you did, you should check resistance. A good wire will be well under 1ohm. You could have very high resistance but still have continuity.

Does your ks connector have 2 pins?

For the continuity test you did, you should check resistance. A good wire will be well under 1ohm. You could have very high resistance but still have continuity.

#157

Thanks Gevo, that all makes sense if the 3VZ has a second pin. As far as I can tell... My KS is a single pin / single signal wire for the 22RE. No evidence of shielding wire. That was kinda to basis of the question. A lot of threads discuss wiring being vast majority of the code 52 issues, then go onto working through the shielding in detail since the harsh conditions damage that ďpigtailĒ. However, trouble shooting recommendations for 3vzís and 22REís seem to get crossed up in a lot of threads. Since I canít find any evidence of shielded wire, it begs the question...Does the 88 22RE have a two pin shielded wire or an unshielded single pin signal wire. I would assume based on my research that if the 3vz KS required shielding to limit interference in the signal, the same would apply to a 22re KS. However, I canít find any thread that states this conclusively for the 22RE. I would just like to rule out definitively if the 22re has shielding and if so, how can I get to it to test it. If not, I can move on to replacing the KS. But Iíd still be appreciative if someone could advise the best after market solution since Toyota has discontinued the 1988 OEM KS. Thanks again

#158

I am sure eventually someone with a 22re can chime in. One last thing I have to say is, after completely replacing my wire my code 52 still didn't go away. I used good quality shielded wire. It went away when i installed a new KS.

#159

Registered User

Join Date: Sep 2007

Location: San Francisco East Bay

Posts: 8,252

Likes: 0

Received 820 Likes

on

648 Posts

I don't have a 22re, but I do have part of a 1989 EWD. This does show the Knock Sensor connected to the ECM with shielded wire. As Toyogator suspected, there appears to be no connector between the sensor and the ECM (unlike the 3VZE).

On the 3VZE, the shield is grounded "at" the ECM, but it doesn't come all the way through to the connector. Instead the shield, and a number of other grounds, are spliced somewhere near the ECM (and presumably reach a body ground). As Gevo points out, the shield is grounded only at one end (not the sensor end). Presumably to avoid what audio guys call ground-loops. (Digital guys do this to avoid "ground bounce.")

Shielded wire doesn't look that different from the outside; maybe a little fatter than you'd expect. If there's a chance that your sensor wire was replaced with "ordinary" wire, I would think that would cause a problem. (Just look at the ECM connector. Anyone who is going to go to the trouble to make a professional factory-like repair would use the correct wire, so if it looks factory-like at the connector, the shield probably starts (and is grounded at) only a few inches away.)

On the 3VZE, the shield is grounded "at" the ECM, but it doesn't come all the way through to the connector. Instead the shield, and a number of other grounds, are spliced somewhere near the ECM (and presumably reach a body ground). As Gevo points out, the shield is grounded only at one end (not the sensor end). Presumably to avoid what audio guys call ground-loops. (Digital guys do this to avoid "ground bounce.")

Shielded wire doesn't look that different from the outside; maybe a little fatter than you'd expect. If there's a chance that your sensor wire was replaced with "ordinary" wire, I would think that would cause a problem. (Just look at the ECM connector. Anyone who is going to go to the trouble to make a professional factory-like repair would use the correct wire, so if it looks factory-like at the connector, the shield probably starts (and is grounded at) only a few inches away.)

#160

Thank you Scope103...Iíll check for the ground connection a couple inches from the ECM as you suggested. Iím pretty sure this is the factory / original harness. Iím still curious if anyone has an opinion on the best 88 22RE after market KS option if an OEM can not be found. e.g. Rockauto sells a manufacturer WVE 5s2301 and an NTK id0201. A mechanic buddy of mine suggested trying an ACDelco. This sounds like heresy, but if OEM is not available, someone has to have a ďnext best optionĒ. Sounds like thereís consensus that oreillys, Napa, and autozone replacements should be avoided based on prior posts.