22RE Engine Idle Problems

#41

Well ended up fixing my surgeing idle problem by replaceing the idle air control valve. My pickup was idleing high and surgeing with and sometimes without the brakes applied. I figured this out by a test I found on a forum, if you have this problem get your engine warmed up to operateing temp because the test you are about to do is basically doing away with the cold start part of your efi so you want it warm so it will start back up, then shut off the engine, take the duct work off the front of the throttle body and look inside and to the left there is a small hole bout the size of a dime cover it with duct tape but make sure the duct tape is secure and streatched to the outside and underneath the throttle body to make darn sure it wont get sucked into the intake. Then place your duct work back on and start your engine if it just turns over and dies adjust your idle up I found this out the hard way because since it was idleing high I had the idle screw turned all the way down there for it would not start with the tape in place, So after I turned the idle back up it fired right up and ran great. If the tape fixes your problem its the IAC/idle air control valve or the little coolant lines are plugged up going in and out of the iac also could be the little port that the top coolant line is hooked to could also be plugged, it is just up and a lil left of the thermostat housing. Now then I thought id just leave the tape there until I got a new iac well the next morning it would not start cold until I pumped the gas serveral times because once again with the tape in place its basically doing away with the cold start part of your efi. I drove it this way for a day or two and noticed when I replaced the iac and went to take the tape off it started to melt so I wouldnt drive it too long with the tape. On a side note the iac is located right underneath the throttle body. Hope this helps someone out because it took me many hrs of reading and trouble shooting to figure this out before i stumbled across this info. Its late so i hope this makes since. If you have ?s pm me and i will try and explain better. Or do another more informative post when its not so late and im thinking more clear.

Last edited by Kstoy; 04-21-2012 at 12:03 AM.

#42

Registered User

Join Date: Feb 2011

Location: Kent, OH

Posts: 92

Likes: 0

Received 0 Likes

on

0 Posts

I currently have my AAV blocked with duct tape. I found that i got hot and melted too. Ive had to replace it a few times in the past week of driving because of it. But If you put more than just one piece of tape and overlap it and bring it outside where the tubing and clamp go, it doesnt melt and stays in place very well. Also use high quality duct tape. I still check just about everyday to make sure it didnt get sucked up. I will be driving like this for awhile until i can afford a new AAV. Ive checked the hoses and ports for blockage, but im gonna check/clean again soon to see if that helps. A lot of useful info on this thread. I found my answers elsewhere but they all say the same things.

My truck starts right up, just wants idle low(600rpms) for about a minute. So i keep my foot on the throttle at about 1100 rpms for a couple minutes to warm it up like the AAV would do. And then i can let off the throttle and it idles and factory specs. (850 +/- 50 for 4wd 22re).

Hope this helps someone on this old, revived thread! lol

My truck starts right up, just wants idle low(600rpms) for about a minute. So i keep my foot on the throttle at about 1100 rpms for a couple minutes to warm it up like the AAV would do. And then i can let off the throttle and it idles and factory specs. (850 +/- 50 for 4wd 22re).

Hope this helps someone on this old, revived thread! lol

#43

Registered User

MPWarfy, I know it's been a long time since you asked but... I think he means he flushed the water side of the AAV.

See my pic AAV-1717--the first pic you hit when you scroll up from here? The big port in the black plastic is for air. The two smaller metal ones are water. Radiator fluid/water flow through here and the AAV can get really full of gunk and rust--I have seen them packed solid.

So flushing this may solve the AAV/Idle problem for some.

See my pic AAV-1717--the first pic you hit when you scroll up from here? The big port in the black plastic is for air. The two smaller metal ones are water. Radiator fluid/water flow through here and the AAV can get really full of gunk and rust--I have seen them packed solid.

So flushing this may solve the AAV/Idle problem for some.

#44

Registered User

Kstoy and Kros, Thanks for the replies! I have cleaned and replaced my AAV. Still, this might be the issue. I have been trying to hook up with another member to buy one, but we have not had time to meet. I'm gonna swap this thing out just to make sure.

#45

Same surging idle issue plus coolant loss

I have the same surging idle issue accompanied by coolant loss. Is it possible for the AAV valve to allow coolant into the intake? The coolant has to get slightly low for the idle issue to surge.

This is a great and informative thread. Thanks everybody for sharing your knowledge.

This is a great and informative thread. Thanks everybody for sharing your knowledge.

#46

Some insight to add to this issue;

I've had very similar problems but on a freshly rebuilt 22RE, which involved cleaning out the AAV, along with pretty much everything else.

Talking to a local 'Yota guru here he said that another possible cause is simply low coolant believe it or not.

According to him, the Water Temp sensor is tied in to the idle circuit as well. If it doesn't sense the engine warming it will increase the idle to try to boost the water pump and get flow past the sensor. How exactly the brakes come into play I'm not sure.

But long story short, if the AAV checks out, make sure your coolant is topped up and try replacing the water temp sensor.

Hope this helps.

I've had very similar problems but on a freshly rebuilt 22RE, which involved cleaning out the AAV, along with pretty much everything else.

Talking to a local 'Yota guru here he said that another possible cause is simply low coolant believe it or not.

According to him, the Water Temp sensor is tied in to the idle circuit as well. If it doesn't sense the engine warming it will increase the idle to try to boost the water pump and get flow past the sensor. How exactly the brakes come into play I'm not sure.

But long story short, if the AAV checks out, make sure your coolant is topped up and try replacing the water temp sensor.

Hope this helps.

#47

I have the same surging idle issue accompanied by coolant loss. Is it possible for the AAV valve to allow coolant into the intake? The coolant has to get slightly low for the idle issue to surge.

This is a great and informative thread. Thanks everybody for sharing your knowledge.

This is a great and informative thread. Thanks everybody for sharing your knowledge.

#48

Registered User

iTrader: (2)

Join Date: Dec 2009

Location: Pleasanton, CA - SF Bay Area

Posts: 2,159

Likes: 0

Received 7 Likes

on

5 Posts

Holy old thread, Batman!

Thanks for posting this up, especially the photos. I replaced my head recently, hot tanked the intake, and cleaned the injectors, replaced all coolant hoses, etc recently (basically a top end makeover). I adjusted the throttle and TPS per Roger Brown's specs.

"Throttle Stop Screw:The other item that scan affect the TPS adjustment is the Throttle Stop Screw. The stop screw controls the amount of closure for the throttle plate inside the throttle body. It must be set properly BEFORE adjusting the TPS itself. How is this done? The stop screw is set so that the throttle plate is fully closed inside the throttle body, then it is turned in to contact the throttle linkage and then 1/4 turn more before tightening the jam nut to lock it in place. This is done so that the throttle plate is held just barely off fully close to prevent it from sticking inside the throttle body"

HOWEVER....once all that was adjusted to spec, I had terrible cold start idle issues - stumbling, sputtering...around 200 RPMs with it dying often unless it was given gas. Once it warmed up (the motor) it idled great - the only issues were at cold start.

I've made several adjustments in the past month to see if I can get this fixed - adjusting the throttle stop screw to let MORE air in at idle, backing off the dashpot screw 100%, adjusting the large flat head screwdriver idle screw on the TB to let more/less air into the plenum - you name it!

So after all this research I have the feeling something is up with my AAV/IACV. In theory, it's supposed to let MORE air into the plenum when the motor/coolant are cold, then close up and lete LESS air in, once coolant/motor are warmed up - right??

If that's the case, why is my idle LOW when cold, then HIGHER once warmed up?

I'm planning on pulling the TB again, along with the IACV/AAV to crack it open and check it out soon...but wondering if my symptoms point to this part being faulty, and if not, where else to look? What's odd to me is, if the AAV/IACV were not working at all, I wouldn't see ANY change in throttle between cold/warm motor, right???

Thanks for posting this up, especially the photos. I replaced my head recently, hot tanked the intake, and cleaned the injectors, replaced all coolant hoses, etc recently (basically a top end makeover). I adjusted the throttle and TPS per Roger Brown's specs.

"Throttle Stop Screw:The other item that scan affect the TPS adjustment is the Throttle Stop Screw. The stop screw controls the amount of closure for the throttle plate inside the throttle body. It must be set properly BEFORE adjusting the TPS itself. How is this done? The stop screw is set so that the throttle plate is fully closed inside the throttle body, then it is turned in to contact the throttle linkage and then 1/4 turn more before tightening the jam nut to lock it in place. This is done so that the throttle plate is held just barely off fully close to prevent it from sticking inside the throttle body"

HOWEVER....once all that was adjusted to spec, I had terrible cold start idle issues - stumbling, sputtering...around 200 RPMs with it dying often unless it was given gas. Once it warmed up (the motor) it idled great - the only issues were at cold start.

I've made several adjustments in the past month to see if I can get this fixed - adjusting the throttle stop screw to let MORE air in at idle, backing off the dashpot screw 100%, adjusting the large flat head screwdriver idle screw on the TB to let more/less air into the plenum - you name it!

So after all this research I have the feeling something is up with my AAV/IACV. In theory, it's supposed to let MORE air into the plenum when the motor/coolant are cold, then close up and lete LESS air in, once coolant/motor are warmed up - right??

If that's the case, why is my idle LOW when cold, then HIGHER once warmed up?

I'm planning on pulling the TB again, along with the IACV/AAV to crack it open and check it out soon...but wondering if my symptoms point to this part being faulty, and if not, where else to look? What's odd to me is, if the AAV/IACV were not working at all, I wouldn't see ANY change in throttle between cold/warm motor, right???

#49

Registered User

Join Date: May 2012

Location: Lake LA, Mojave DEsert, SoCal

Posts: 2

Received 0 Likes

on

0 Posts

Holy old thread, Batman!

So after all this research I have the feeling something is up with my AAV/IACV. In theory, it's supposed to let MORE air into the plenum when the motor/coolant are cold, then close up and lete LESS air in, once coolant/motor are warmed up - right??

If that's the case, why is my idle LOW when cold, then HIGHER once warmed up?

I'm planning on pulling the TB again, along with the IACV/AAV to crack it open and check it out soon...but wondering if my symptoms point to this part being faulty, and if not, where else to look? What's odd to me is, if the AAV/IACV were not working at all, I wouldn't see ANY change in throttle between cold/warm motor, right???

So after all this research I have the feeling something is up with my AAV/IACV. In theory, it's supposed to let MORE air into the plenum when the motor/coolant are cold, then close up and lete LESS air in, once coolant/motor are warmed up - right??

If that's the case, why is my idle LOW when cold, then HIGHER once warmed up?

I'm planning on pulling the TB again, along with the IACV/AAV to crack it open and check it out soon...but wondering if my symptoms point to this part being faulty, and if not, where else to look? What's odd to me is, if the AAV/IACV were not working at all, I wouldn't see ANY change in throttle between cold/warm motor, right???

The AAV (aka "IACV") allows air to pass at normal operating temp, but closes off at cold temps. Just like in a carburetor the choke butterfly CLOSES when cold to make the air fuel mixture more rich for cold operation, the AAV closing at cold temp reduces the air to richen the mixture.

The AAV works on the temp of the coolant that passes through it, rather than on outside air temp. That way it doesn't matter how warm or cold it is outside, but how warm the engine is.

The 22re also has a cold start fuel injector on the left (towards the cam cover) side of the intake plenum to add fuel when cold also. This is controlled by the coolant temp sensor telling the ECU that the engine is cold.

#50

Registered User

iTrader: (2)

Join Date: Dec 2009

Location: Pleasanton, CA - SF Bay Area

Posts: 2,159

Likes: 0

Received 7 Likes

on

5 Posts

Thanks Richard for the explanation - the way you explain it makes sense, but everything I've read about this valve to date (and now in the FSM) makes me think otherwise - that when motor is cold, it lets more air in to idle up, then once motor is warm, closes the hole to idle down.

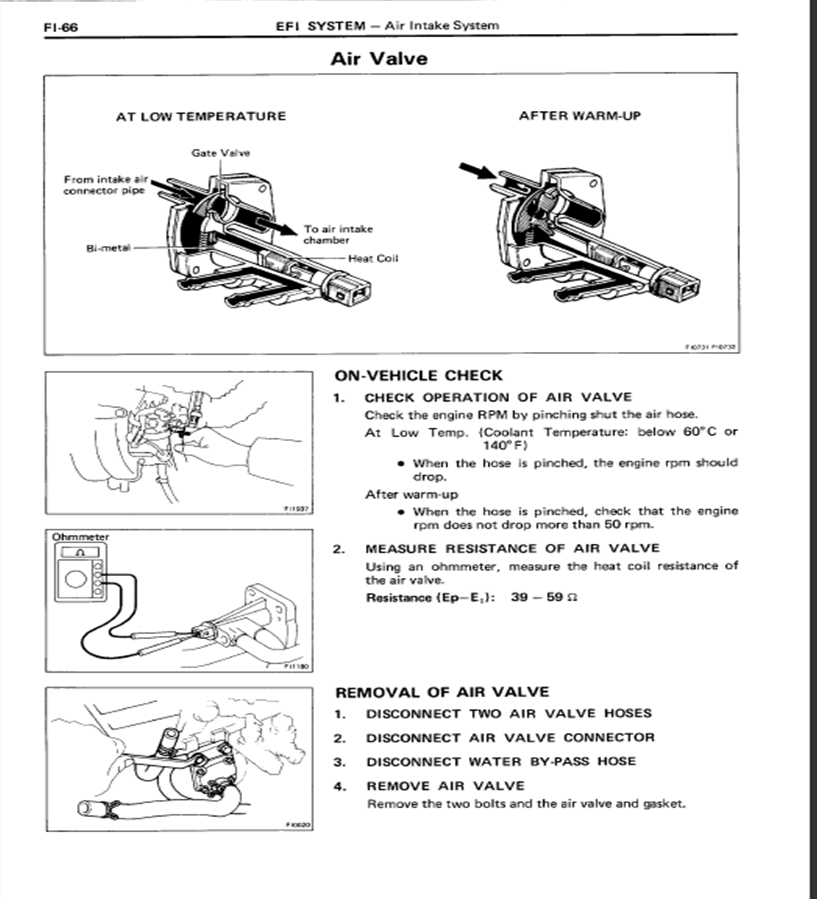

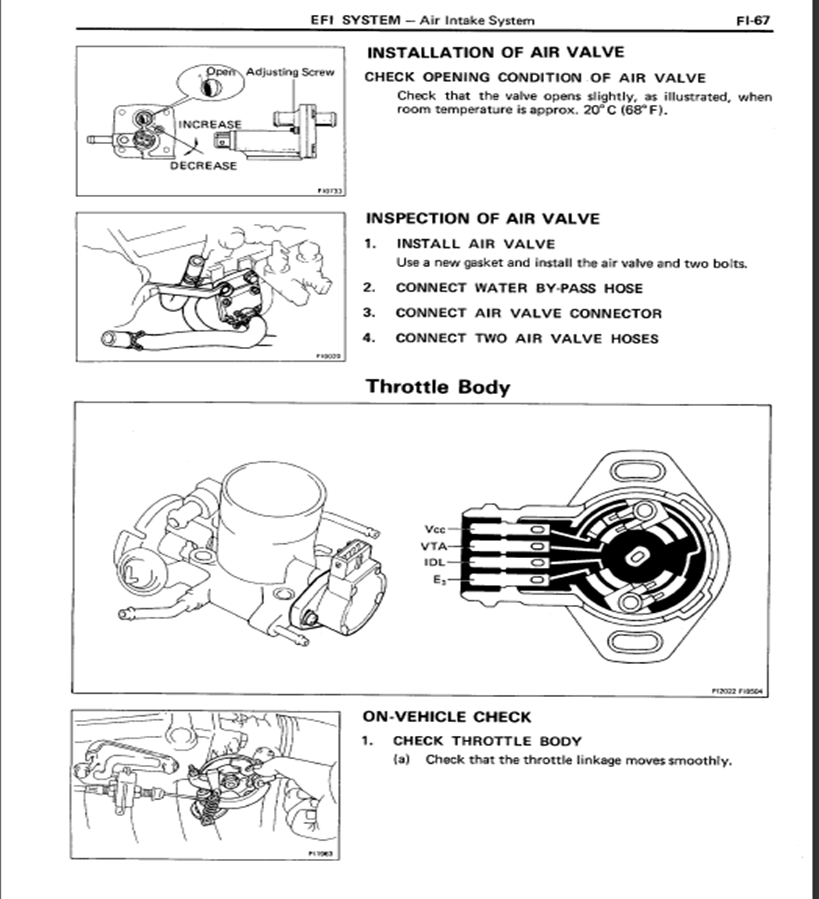

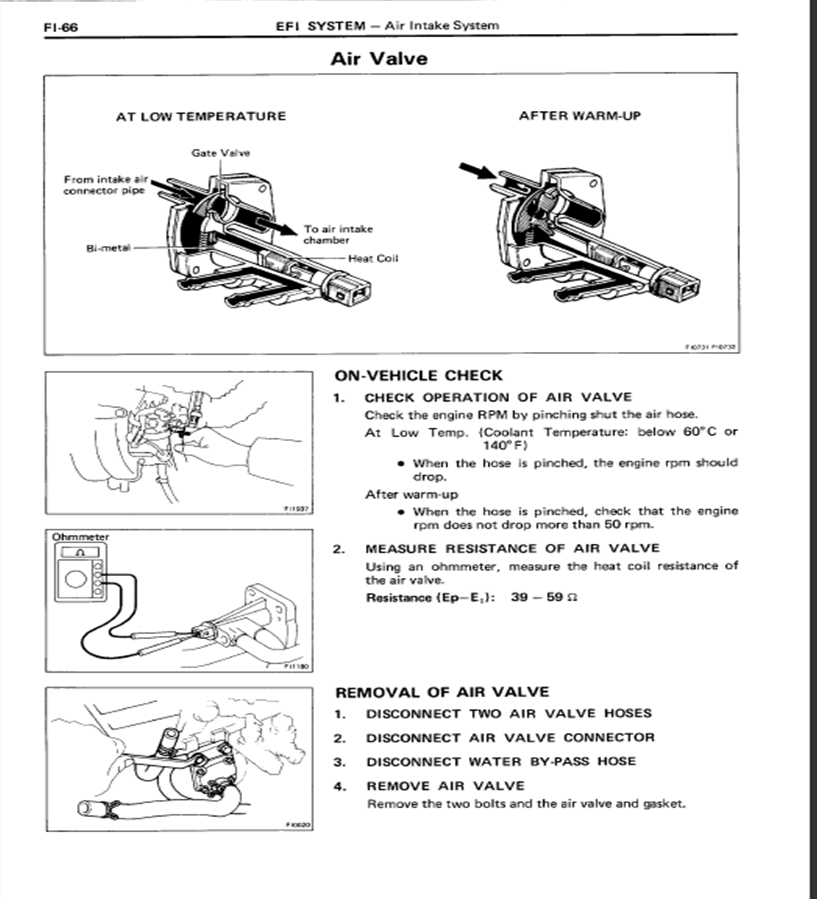

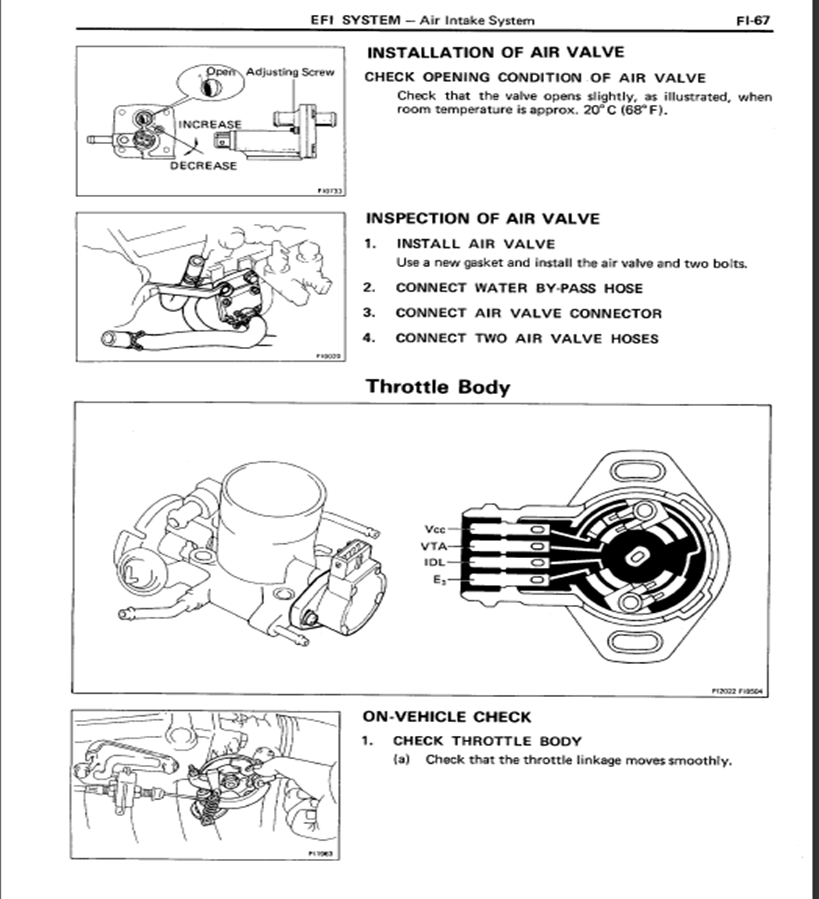

I found this in the FSM today:

the tests the FSM recommends seem to bolster this as well - when you pinch the air hose when starting cold, idle should drop (meaning that when cold, the valve is letting more air into the motor, giving it a higher idle, right??).

There is also an adjustment screw on the back of this sucker it looks like - when I get some time I'm going to drain coolant, remove this guy, and and take apart to see if anything is blocking movement of the parts inside, and then start adjusting the screw....

None of this, even if I am right, explains why my engine idles higher when warm versus when cold, does it?

I found this in the FSM today:

the tests the FSM recommends seem to bolster this as well - when you pinch the air hose when starting cold, idle should drop (meaning that when cold, the valve is letting more air into the motor, giving it a higher idle, right??).

There is also an adjustment screw on the back of this sucker it looks like - when I get some time I'm going to drain coolant, remove this guy, and and take apart to see if anything is blocking movement of the parts inside, and then start adjusting the screw....

None of this, even if I am right, explains why my engine idles higher when warm versus when cold, does it?

#51

Registered User

Phil - I'm with you, I believe the IACV should be open allowing more air in when cold, and closed when warm, cutting off the extra air. I think yours could be stuck OPEN. And what I think that would mean is that when you let it warm up and set the idle, you are setting the idle screw to adjust idle for the normal throttle butterfly position plus the extra air coming in from the IACV being stuck open---in other words probably turning adjusting the idle pretty far down. At cold, the engine is expecting "extra" air, but not getting any "extra". In other words, your cold idle point is artificially lower than it should be. It won't cost you anything to check it. Mine had a broken tab which I think made it closed all the time, so I bought a used one from eBay and verified that it moved by putting it in the freezer and then letting it warm up to FL temperature. Also, I see you did some head work, have you adjusted your valves recently?

Last edited by coryc85; 07-08-2013 at 01:29 PM.

#52

Registered User

iTrader: (2)

Join Date: Dec 2009

Location: Pleasanton, CA - SF Bay Area

Posts: 2,159

Likes: 0

Received 7 Likes

on

5 Posts

Thanks Corey - that theory makes sense to me and I'm really excited to pull this thing and test it out.

I did replace the head (Street RV with 268* cam installed from ENGNBLDR) recently with a HG replacement, and cleaned all the injectors (witchhunter), and added a CAI (I also did the 82 supra AFM but the vance was sticking and throwing codes so I went back to stock AFM and the CAI.....different story and not part of this problem I don't think).

I did adjust the valves at 500 miles after Head insteall, along with oil change and head bolt torquing, as recommended.

Motor runs well otherwise - it's just this cold idle thing that's giving me grief.

I removed the IACV during this, and cleaned the outside with a wire brush and rag - maybe something fell into an opening during this? I'll find out!

Will let you know how this goes - hope to get to it this week.

I did replace the head (Street RV with 268* cam installed from ENGNBLDR) recently with a HG replacement, and cleaned all the injectors (witchhunter), and added a CAI (I also did the 82 supra AFM but the vance was sticking and throwing codes so I went back to stock AFM and the CAI.....different story and not part of this problem I don't think).

I did adjust the valves at 500 miles after Head insteall, along with oil change and head bolt torquing, as recommended.

Motor runs well otherwise - it's just this cold idle thing that's giving me grief.

I removed the IACV during this, and cleaned the outside with a wire brush and rag - maybe something fell into an opening during this? I'll find out!

Will let you know how this goes - hope to get to it this week.

#53

Registered User

iTrader: (2)

Join Date: Dec 2009

Location: Pleasanton, CA - SF Bay Area

Posts: 2,159

Likes: 0

Received 7 Likes

on

5 Posts

OK, so last night I changed my oil, drained the coolant, and removed the TB and IACV to look inside.

I tested the resistance on the plug in the back and got a big fat "0" - that doesn't seem right. but, to be honest, I don't know what the resistance number means or what this tells the ECU.

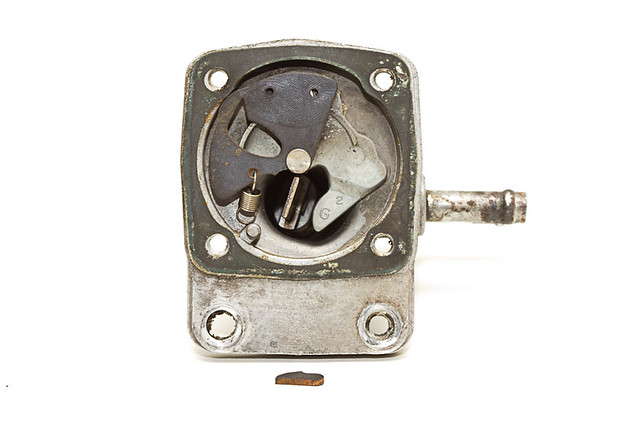

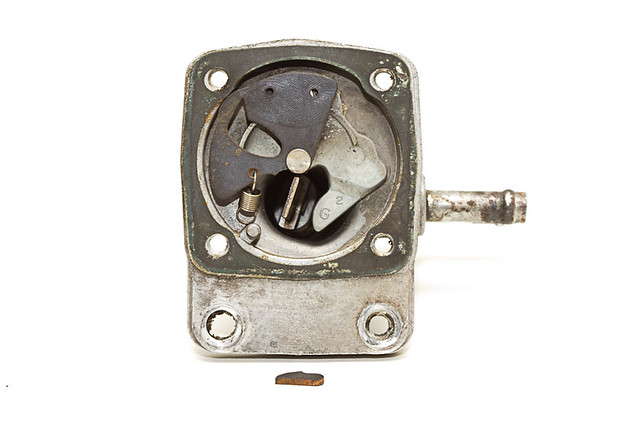

Then I opened it up. As a reminder, here is Morton's opened up, with the broken tab:

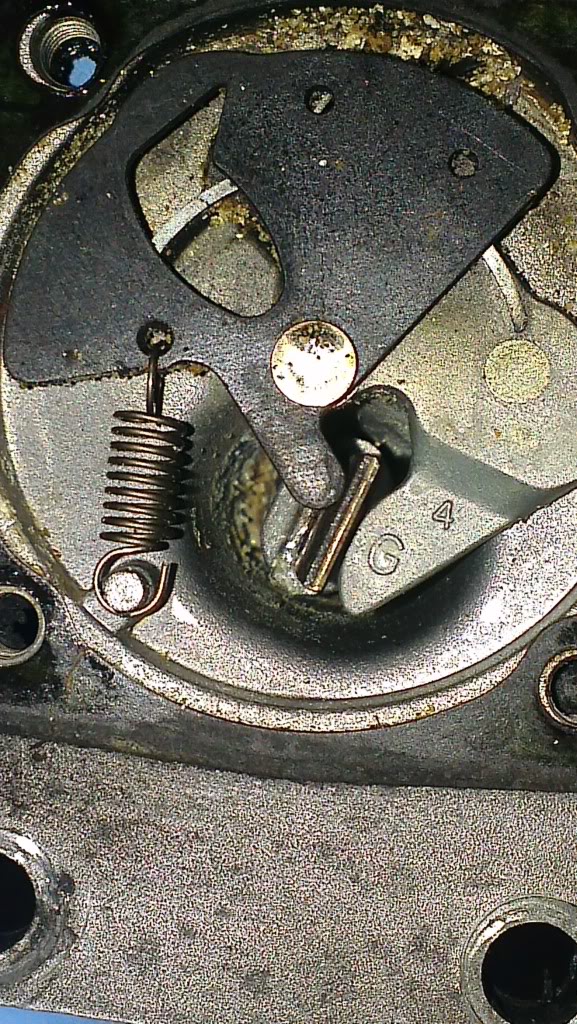

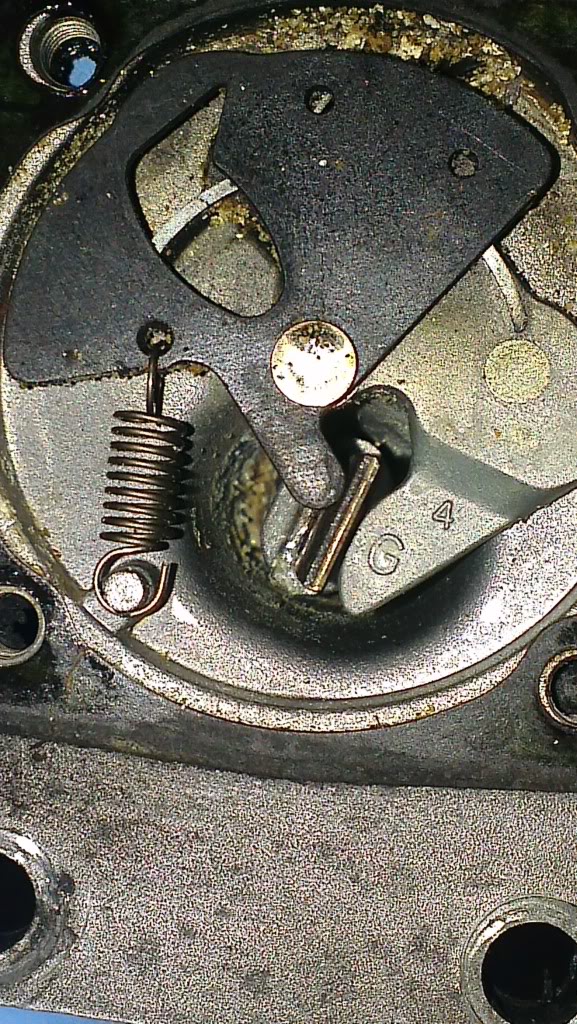

Here is mine (note, the spring was attached, just not in this photo):

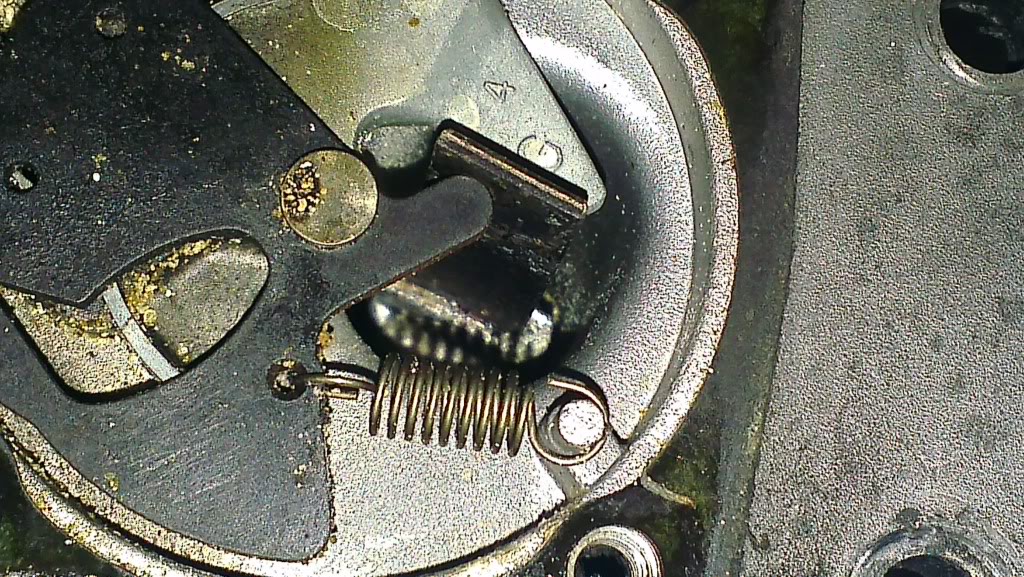

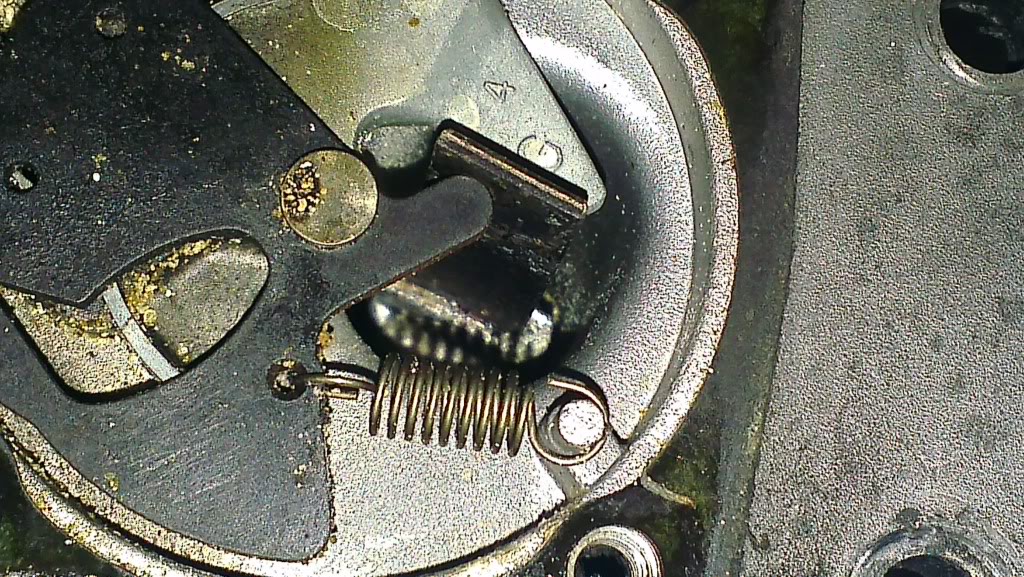

Closed:

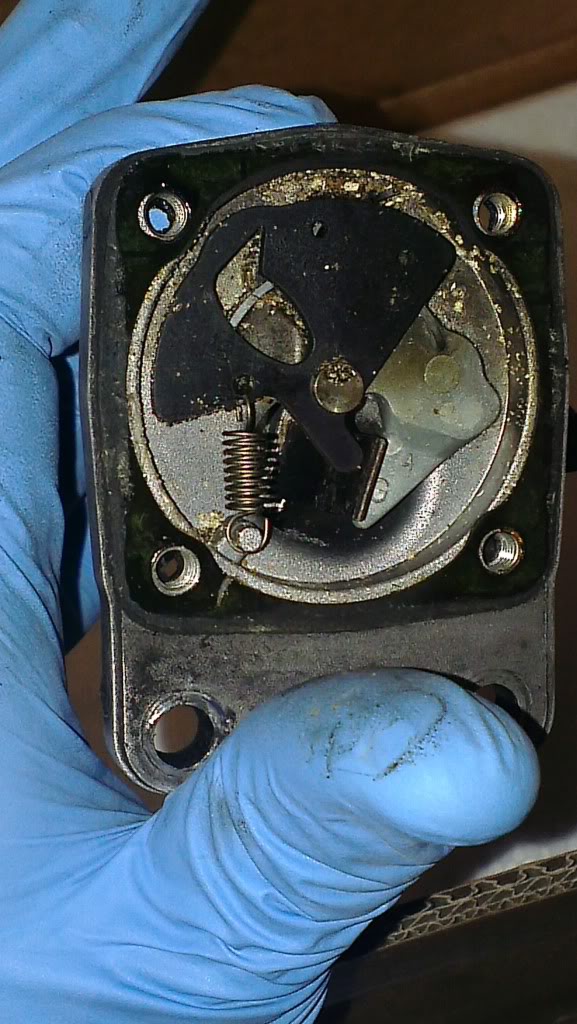

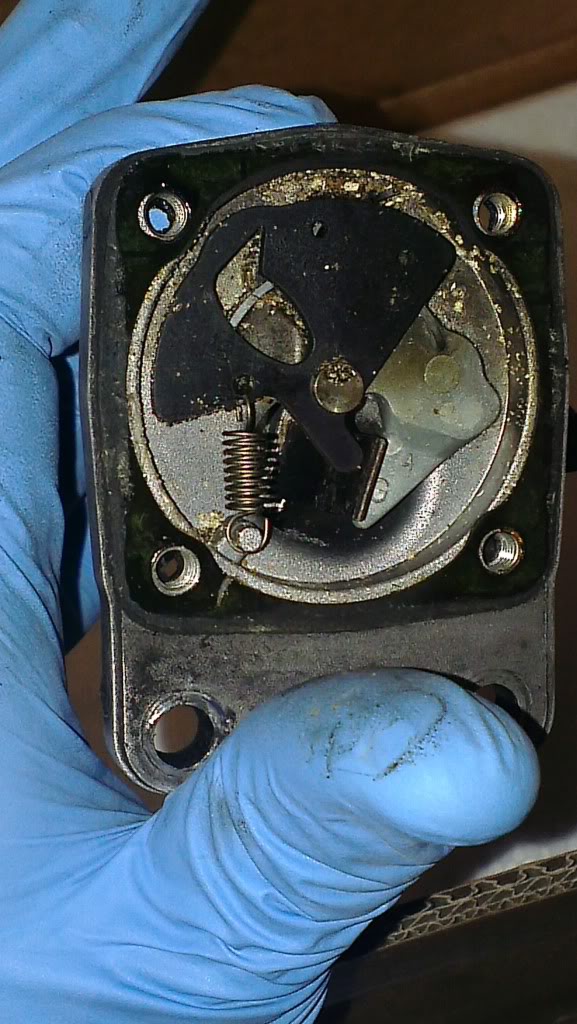

Open (I'm pushing the disc with my thumb, against the spring):

There was a bunch of grainy stuff inside, what looked like sand (!)....I was able to blow it out with my mouth....just some quick, targeted huffs and puffs....but it didn't seem to be hindering the operation/movement of the parts inside:

So, here is how I THINK it's supposed to work:

The bi metal tab that sticks out just to the right of the spring (and flush against the edge of the 1/3 of a disc piece that's mounted to the spring) should, when the motor is COLD, push to the left, applying pressure to the spring and rotatined the disc clockwise so that it opens the air passage. The coolant that runs through the opposite side of the valve makes the bi metal tab move slowly to the right as the coolant temperature rises, allowing the spring the pull the disc counter clockwise, thus closing the air passage. This creates higher idle (more air) when motor is started cold, and lower idle (less air) when motor warms up - it's all based on coolant temperature.

Mine was stuck closed.

I heated up some boiling water and poured a little into the inlet/outlet pipe on the opposite side of the valve to see if it would move the bi metal piece - NOTHING happened. I even tried this with the spring disconnected - same result. I can't tell if the bi metal tab is supposed to move left right, or actually rotated CW/CCW - I tried pushing the tab left and right to bend it where it was keeping the passage open, but it would just return to its previous (closed) position. Boiling water did nothing to make the bi metal tab move whatsoever.

So, my conclusion is that my IACV bi metal piece just stopped working and my valve is permanently closed at all temperatures. This leads to a really rough/low idle cold, and if I want to raise the cold idle, it will translate into a higher idle when warm (1100 RPMS at least). I guess I need to start shopping for a new IAVC - are they ONLY OEM or are there aftermarket ones?

I tested the resistance on the plug in the back and got a big fat "0" - that doesn't seem right. but, to be honest, I don't know what the resistance number means or what this tells the ECU.

Then I opened it up. As a reminder, here is Morton's opened up, with the broken tab:

Here is mine (note, the spring was attached, just not in this photo):

Closed:

Open (I'm pushing the disc with my thumb, against the spring):

There was a bunch of grainy stuff inside, what looked like sand (!)....I was able to blow it out with my mouth....just some quick, targeted huffs and puffs....but it didn't seem to be hindering the operation/movement of the parts inside:

So, here is how I THINK it's supposed to work:

The bi metal tab that sticks out just to the right of the spring (and flush against the edge of the 1/3 of a disc piece that's mounted to the spring) should, when the motor is COLD, push to the left, applying pressure to the spring and rotatined the disc clockwise so that it opens the air passage. The coolant that runs through the opposite side of the valve makes the bi metal tab move slowly to the right as the coolant temperature rises, allowing the spring the pull the disc counter clockwise, thus closing the air passage. This creates higher idle (more air) when motor is started cold, and lower idle (less air) when motor warms up - it's all based on coolant temperature.

Mine was stuck closed.

I heated up some boiling water and poured a little into the inlet/outlet pipe on the opposite side of the valve to see if it would move the bi metal piece - NOTHING happened. I even tried this with the spring disconnected - same result. I can't tell if the bi metal tab is supposed to move left right, or actually rotated CW/CCW - I tried pushing the tab left and right to bend it where it was keeping the passage open, but it would just return to its previous (closed) position. Boiling water did nothing to make the bi metal tab move whatsoever.

So, my conclusion is that my IACV bi metal piece just stopped working and my valve is permanently closed at all temperatures. This leads to a really rough/low idle cold, and if I want to raise the cold idle, it will translate into a higher idle when warm (1100 RPMS at least). I guess I need to start shopping for a new IAVC - are they ONLY OEM or are there aftermarket ones?

#54

Registered User

Philbert - that's some good investigating there. Sounds like my theory was completely backwards, yours was stuck closed not open like I thought. Weird though, you wouldn't think that bi-metal piece would ever fail, but I guess so. I found a replacement on eBay, the guy said he would send me another one if that one did not work. To test mine, I just put it in the freezer for a while, took it out, saw it was open, let it warm up to nice South FL temps for a while and it closed. Here is the link to where I tested my coil and the valve https://www.yotatech.com/forums/f199...l#post51856443

#55

Registered User

iTrader: (2)

Join Date: Dec 2009

Location: Pleasanton, CA - SF Bay Area

Posts: 2,159

Likes: 0

Received 7 Likes

on

5 Posts

Thanks Corey!

I have one on order from a guy on CL...should be here soon.

You had to put it in freezer to open up - that sounds extreme? Mine was fully closed at room temp in CA (65*), as well as pouring boiling water into the bypass - nothing moving on the bimetal part at all...

I'll play with it a little before installing, and will make sure I have a handy socket to adjust the nut on the back if I need to adjust it while installed in the truck...stand by!

I have one on order from a guy on CL...should be here soon.

You had to put it in freezer to open up - that sounds extreme? Mine was fully closed at room temp in CA (65*), as well as pouring boiling water into the bypass - nothing moving on the bimetal part at all...

I'll play with it a little before installing, and will make sure I have a handy socket to adjust the nut on the back if I need to adjust it while installed in the truck...stand by!

#57

Registered User

iTrader: (2)

Join Date: Dec 2009

Location: Pleasanton, CA - SF Bay Area

Posts: 2,159

Likes: 0

Received 7 Likes

on

5 Posts

Yeah, mine had all that crap in it...guess the good news was that it wasn't getting through to the motor....

With bimetal, not sure how careful you have to be when cleaning - maybe just use pressurized air to get anything out of there?

Will report back once I have the new part.....

#58

Registered User

Phil....

The bimetal piece in the valve is not sensitive to cleaners like sensors are. There is an electrical heater coil down in the valve, so I wouldn't spray anything in it. Just swab the inner body and gate/spring assembly with a rag with some cleaner on it if you really need to. TB cleaner, for example. Then, blow it dry.

The AAV's spring loaded gate opens and closes by movement of the bimetal element, as you know. The element is heated by voltage supplied from the circuit open relay and surrounding air temperature and coolant temp. The element works like any bimetal element in a household thermostat that controls your central air unit. So, it is sensitive to ambient temps! Just not as sensitive as central air thermostat. Since it's made of two different types of metal (steel and brass, I believe) and each type of metal expands/contracts at different rates, it will straighten/remain straight when cold but warp/deflect when heated. Note, these are sustained temp. Minor variations in temp for quick periods won't effect it much if at all.

So, what usually goes bad in the AAV is either the heated coil winding burning out (valve gate won't close) or the bimetal element loses resilience due to metal fatigue (valve gate won't open). By losing resilience I mean that gate maintains constant pressure against the element by way of the spring and, due to this pressure, eventually remains deflected/unable to straighten out and open the gate. Thermal wax type valves on later engines are a different story since the design is entirely different.

EFI designs work quite differently than carb'd systems. Carb'd systems enrichen the fuel mix by limiting air supplied to the intake. However, EFI systems allow for a lot more air making the warm up cycle more efficient hastening the needed time to reach operating temps. What controls additional fuel needed during the warm up cycle is the coolant temp sensor. When temps are cold, the voltage signal from the sensor to the ECU is low signaling low engine temps. The ECU then, in this case, holds the injectors open longer during their pulse (known as injector duration) causing the fuel enriched condition. As the temps rise, the voltage rises and the duration is then shortened. During cold operation/warm up cycle, this is coupled by the associated higher RPM's of a normal cold idle. Since the distributor RPM signal controls injector pulsation (ie, faster during higher RPM's) there is, again, an enriched condition..... as would be during RPM's of acceleration or when under load at normal operating temps.

The cold start injector system is only operational when the key is in the start position and the motor is being cranked. The injector is controlled by the signal from the timing switch (on or off) that is also sensitive to coolant temps. However, if the coolant is above a certain temp (forget what that is exactly....it's in the manuals), the signal from the key/STA position will not ground at the time switch to cause the injector to pulse. Problems with the cold start system is usually due to the heated coils/contacts in the time switch burning out and losing the ability to ground the STA signal. This failure can easily be bypassed by simply grounding the switch to the battery with a remote wire when necessary. I've done this with toggle switch in the cab until I could get a new time switch.

You guys can read more about this at autoshop101.com under technical articles:

Air induction: http://autoshop101.com/forms/h21.pdf

Input sensors: http://autoshop101.com/forms/h24.pdf

Hopefully all this makes sense. If not and/or you have questions, lemme know.

The bimetal piece in the valve is not sensitive to cleaners like sensors are. There is an electrical heater coil down in the valve, so I wouldn't spray anything in it. Just swab the inner body and gate/spring assembly with a rag with some cleaner on it if you really need to. TB cleaner, for example. Then, blow it dry.

The AAV's spring loaded gate opens and closes by movement of the bimetal element, as you know. The element is heated by voltage supplied from the circuit open relay and surrounding air temperature and coolant temp. The element works like any bimetal element in a household thermostat that controls your central air unit. So, it is sensitive to ambient temps! Just not as sensitive as central air thermostat. Since it's made of two different types of metal (steel and brass, I believe) and each type of metal expands/contracts at different rates, it will straighten/remain straight when cold but warp/deflect when heated. Note, these are sustained temp. Minor variations in temp for quick periods won't effect it much if at all.

So, what usually goes bad in the AAV is either the heated coil winding burning out (valve gate won't close) or the bimetal element loses resilience due to metal fatigue (valve gate won't open). By losing resilience I mean that gate maintains constant pressure against the element by way of the spring and, due to this pressure, eventually remains deflected/unable to straighten out and open the gate. Thermal wax type valves on later engines are a different story since the design is entirely different.

Philbert...You have that backwards!

The AAV (aka "IACV") allows air to pass at normal operating temp, but closes off at cold temps. Just like in a carburetor the choke butterfly CLOSES when cold to make the air fuel mixture more rich for cold operation, the AAV closing at cold temp reduces the air to richen the mixture.

The AAV works on the temp of the coolant that passes through it, rather than on outside air temp. That way it doesn't matter how warm or cold it is outside, but how warm the engine is.

The 22re also has a cold start fuel injector on the left (towards the cam cover) side of the intake plenum to add fuel when cold also. This is controlled by the coolant temp sensor telling the ECU that the engine is cold.

The AAV (aka "IACV") allows air to pass at normal operating temp, but closes off at cold temps. Just like in a carburetor the choke butterfly CLOSES when cold to make the air fuel mixture more rich for cold operation, the AAV closing at cold temp reduces the air to richen the mixture.

The AAV works on the temp of the coolant that passes through it, rather than on outside air temp. That way it doesn't matter how warm or cold it is outside, but how warm the engine is.

The 22re also has a cold start fuel injector on the left (towards the cam cover) side of the intake plenum to add fuel when cold also. This is controlled by the coolant temp sensor telling the ECU that the engine is cold.

The cold start injector system is only operational when the key is in the start position and the motor is being cranked. The injector is controlled by the signal from the timing switch (on or off) that is also sensitive to coolant temps. However, if the coolant is above a certain temp (forget what that is exactly....it's in the manuals), the signal from the key/STA position will not ground at the time switch to cause the injector to pulse. Problems with the cold start system is usually due to the heated coils/contacts in the time switch burning out and losing the ability to ground the STA signal. This failure can easily be bypassed by simply grounding the switch to the battery with a remote wire when necessary. I've done this with toggle switch in the cab until I could get a new time switch.

You guys can read more about this at autoshop101.com under technical articles:

Air induction: http://autoshop101.com/forms/h21.pdf

Input sensors: http://autoshop101.com/forms/h24.pdf

Hopefully all this makes sense. If not and/or you have questions, lemme know.

Last edited by thook; 07-29-2013 at 08:34 AM.

#59

Registered User

iTrader: (2)

Join Date: Dec 2009

Location: Pleasanton, CA - SF Bay Area

Posts: 2,159

Likes: 0

Received 7 Likes

on

5 Posts

Matthew - awesome post, and thanks for the link to that article!

I installed a replacement (read: used and working) IACV yesterday on the truck, adjsuted my TPS and TB, and put it all back together and started it up.

Idled high, around 1000-1100 RPM, then settled down to around 750 RPM once at 180*. It was about 80* out so I wanted to check it starting even colder. This morning, I started it and it was about 60* and same thing: idled high and then evened out around 750 once warm.

I think this was the culprit.

Not sure if I mentioned it above but the coil have zero continuity on my old, stuck-closed IACV, and the bimetal piece wasn't moving at all, even with boiling water going through the bypass - it was 100% dead. This newer once had about 50 ohms resistance on the coil (within spec) and did move with hot water (slowly).

Learned a heck of a lot with this exercise, thanks everyone, especially THook, for helping me understand it!

Phil

I installed a replacement (read: used and working) IACV yesterday on the truck, adjsuted my TPS and TB, and put it all back together and started it up.

Idled high, around 1000-1100 RPM, then settled down to around 750 RPM once at 180*. It was about 80* out so I wanted to check it starting even colder. This morning, I started it and it was about 60* and same thing: idled high and then evened out around 750 once warm.

I think this was the culprit.

Not sure if I mentioned it above but the coil have zero continuity on my old, stuck-closed IACV, and the bimetal piece wasn't moving at all, even with boiling water going through the bypass - it was 100% dead. This newer once had about 50 ohms resistance on the coil (within spec) and did move with hot water (slowly).

Learned a heck of a lot with this exercise, thanks everyone, especially THook, for helping me understand it!

Phil

.

.