ScubaFab Tacoma rear bumper

#1

Registered User

Thread Starter

ScubaFab Tacoma rear bumper

Figured I'd just start this rather then adding pictures to the "my truck got rear ended thread"

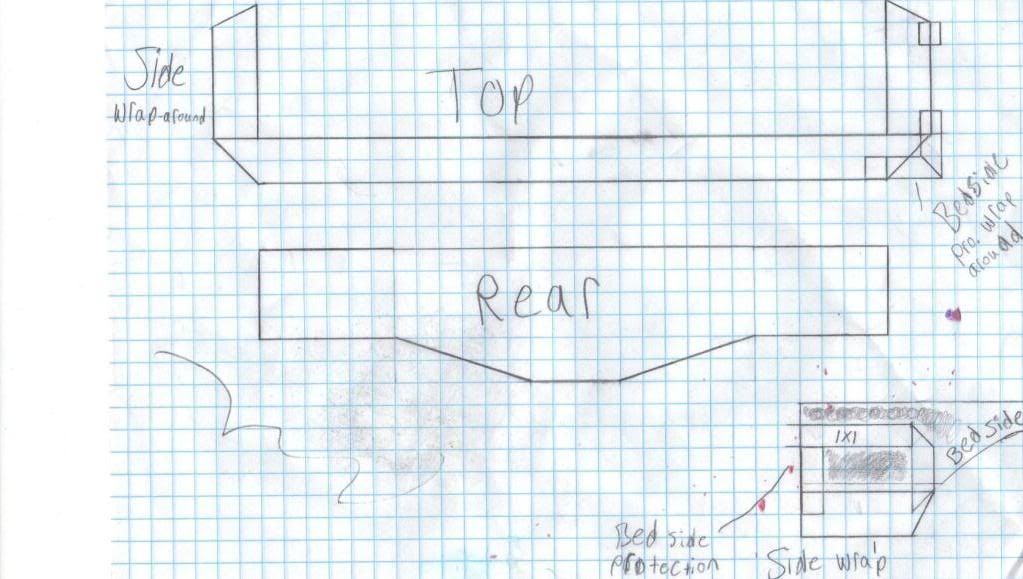

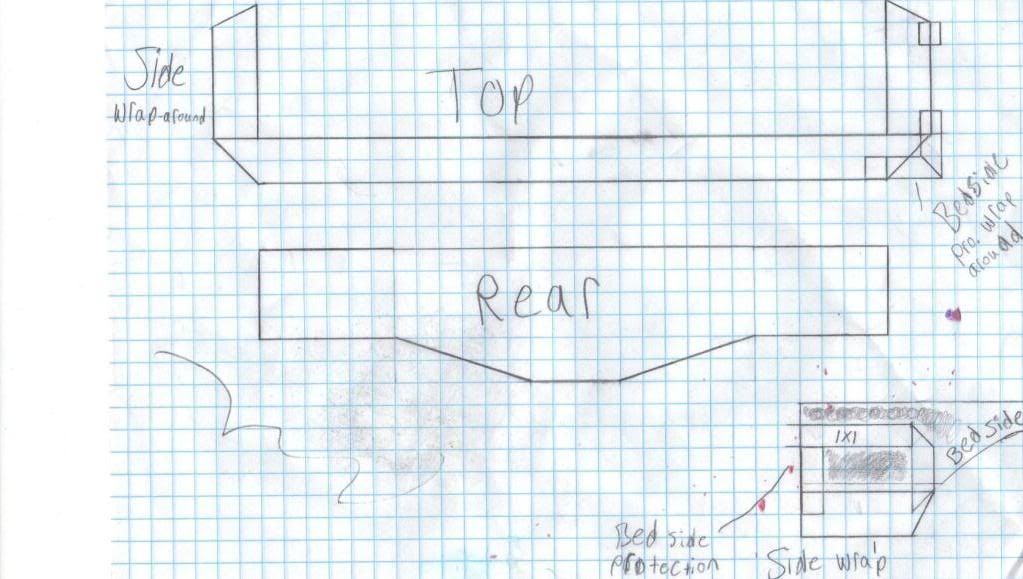

Plans : 4X2 for the main body, 2X2 for fender wrap around, 1.5X1.5 for the bed side and tail light protection. All of it is in the 3/16th's-1/4" flavor. I don't do tube, square is easy to work with.

The empty candidate (Bobbed and high clearanced)

Mounts using existing holes in the frame

Mock up

110V/135A Flux core

Current state. It looks bent down because the bedside directly under the light is pushed in. But I assure you that is just optical illusion

That's all for now.

Plans : 4X2 for the main body, 2X2 for fender wrap around, 1.5X1.5 for the bed side and tail light protection. All of it is in the 3/16th's-1/4" flavor. I don't do tube, square is easy to work with.

The empty candidate (Bobbed and high clearanced)

Mounts using existing holes in the frame

Mock up

110V/135A Flux core

Current state. It looks bent down because the bedside directly under the light is pushed in. But I assure you that is just optical illusion

That's all for now.

#4

Registered User

Thread Starter

#5

Hey scub, if I may, when welding with flux core, you always want to drag your weld (puddle), using "C" patterns. When using MIG w/gas, you want to push the weld (puddle), and prep your weld surface as best you can to minimize splatter and better penetration. Keep your gun at a 4-5 degree angle (use two hands if need be). Looks good so far though........

#7

Registered User

Thread Starter

Getting the side wrap arounds done right now (taking a dinner break)

Had to get a new chop saw because my HF one took a dump on my chest today

I have the wrap around sticking out so far so that the 1.5x1.5 will fit on the whole 2x2. It only sticks out about an inch more then my sliders and I don't think it will be a detriment on the trail.

Had to get a new chop saw because my HF one took a dump on my chest today

I have the wrap around sticking out so far so that the 1.5x1.5 will fit on the whole 2x2. It only sticks out about an inch more then my sliders and I don't think it will be a detriment on the trail.

Trending Topics

#8

Nice job on this thing. I am using my 115 volt $64 HF flux core welder. Figured for the price I got it (on sale plus a coupon) i can use it to learn to weld again...Flapper wheels cure a lot of splatter

Looking forward to seeing the finished product

edit: are you gonna run a brace behind the wheel well too?

Last edited by dropzone; 05-11-2010 at 07:11 PM.

#9

Contributing Member

Personally, I would cut the other crosspiece to keep the side wings just inside the outer edge of the tire.

#10

Registered User

Join Date: Feb 2007

Location: Sierra Nevada's or the Deserts of Las Vegas

Posts: 2,203

Likes: 0

Received 0 Likes

on

0 Posts

Do you know someone with a tube bender? I think the square bed protection is gunna look funky. Just my opinion though. Otherwise lookin good

#11

Registered User

Thread Starter

Nice job on this thing. I am using my 115 volt $64 HF flux core welder. Figured for the price I got it (on sale plus a coupon) i can use it to learn to weld again...Flapper wheels cure a lot of splatter

Looking forward to seeing the finished product

edit: are you gonna run a brace behind the wheel well too?

Looking forward to seeing the finished product

edit: are you gonna run a brace behind the wheel well too?

Brace from the side wing to the frame and the main mounts you mean ? Yes, they just aren't on the drawing.

I've already told my self : If I don't like the overall look with the square bed protection I'll cut it off and pay someone to do some tube work.

Update, both of the side wings are on, welded, ground down and welded again cause for some reason I was getting poopy welds. This mofo is getting heavy.

#14

Registered User

Looks great man. Good work so far can't wait to see the finished product.

Nothin like the feeling you get from fabbin up your own crap just how you like it

Nothin like the feeling you get from fabbin up your own crap just how you like it

#15

Registered User

Thread Starter

#16

Registered User

Oooo yeah i forgot to say this in the other post. I think you should bring in the side protectors a few inches..

It looks like if you were to go up against a tree or something that your bumper would get you hung up on the tree or rock or whatever.

Make it hug the body a bit, kinda like a set of sliders.

Plus there wont be as much leverage against the main body of the bumper.

It looks like if you were to go up against a tree or something that your bumper would get you hung up on the tree or rock or whatever.

Make it hug the body a bit, kinda like a set of sliders.

Plus there wont be as much leverage against the main body of the bumper.

#17

Registered User

Thread Starter

Thanks buddy

Yea I've spent around 25-30 hours on it so far. It's a lot of work, but I've only got 120 bucks into it. If I went to a fabber I'd be paying 4-600 bucks.. If I can do it myself why not.

A couple people have already asked me why not but one....

#20

Registered User

Thread Starter

Some fullish body pictures of how it sits right now. Didn't get any work done on it today and finals are next week. So I have no clue when I'll make more progress on it.