IFS in a 83

#42

Registered User

Thread Starter

iTrader: (1)

Join Date: Nov 2006

Location: Clarkston,WA

Posts: 363

Likes: 0

Received 0 Likes

on

0 Posts

Current plan is poly at the frame for the lower arms, a uni-balls for the upper and lower outers and not sure how I want to do the frame joints for the uppers. Maybe uni-balls maybe polys, maybe heims.

Heims are nice for adjustable but how much adjustable do I really need? It's not a DD, seldom sees the pavement if ever, never goes above 60mph even on the highway. I can build in the caster and camber I want. Hmmmm????

Heims are nice for adjustable but how much adjustable do I really need? It's not a DD, seldom sees the pavement if ever, never goes above 60mph even on the highway. I can build in the caster and camber I want. Hmmmm????

#43

Registered User

I've been thinking the same thing except can't decide between heims or uniballs for the UCA inner pivot. Threaded adjustment is nice, but it's incremental. Cammed bolts like the LCA on a stock IFS would work as well with uniballs with more fine adjustment, but also easier to knock them out of alignment.

Can also do a right/left hand threaded sleeve, but that has the potential to come loose and unthread itself while driving.

Can also do a right/left hand threaded sleeve, but that has the potential to come loose and unthread itself while driving.

#46

Registered User

#48

Registered User

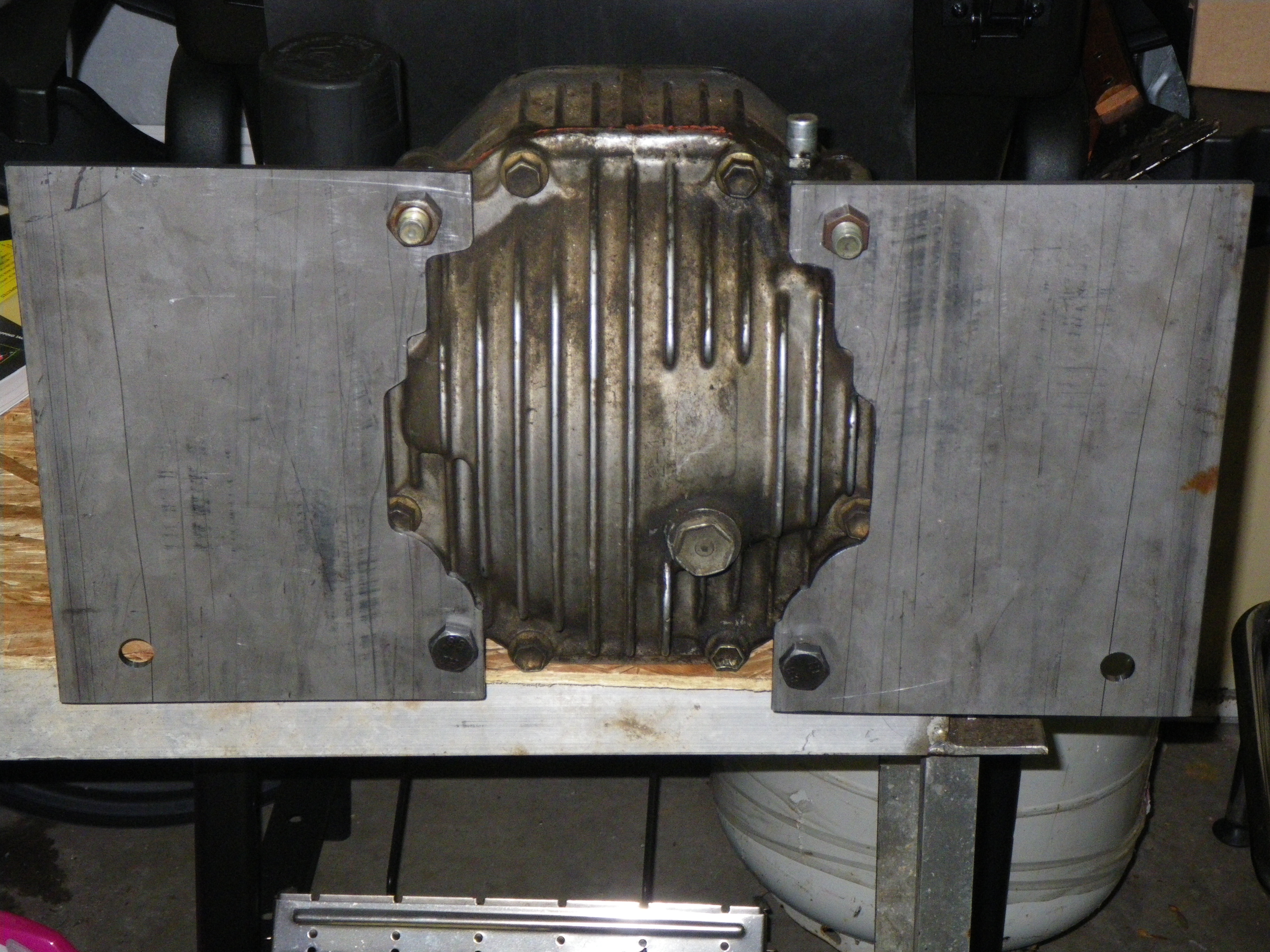

If you use a supra diff up front will it be running against the coast side or drive side of the gears. i always figured building a high pinion 8 inch would be the way to go up front. Obviously would require a custom housing.

#50

Registered User

Thread Starter

iTrader: (1)

Join Date: Nov 2006

Location: Clarkston,WA

Posts: 363

Likes: 0

Received 0 Likes

on

0 Posts

Probably not, again I think I can get more ground clearance with tucking the Supra diff up and a little fwd out of the way.

#53

Registered User

Very cool. Do you have the machine for work or hobby?

I just finished a manual machine class. Now we get to start learning some basic programming and set up on the cnc machines.

I just finished a manual machine class. Now we get to start learning some basic programming and set up on the cnc machines.

#54

Registered User

Thread Starter

iTrader: (1)

Join Date: Nov 2006

Location: Clarkston,WA

Posts: 363

Likes: 0

Received 0 Likes

on

0 Posts

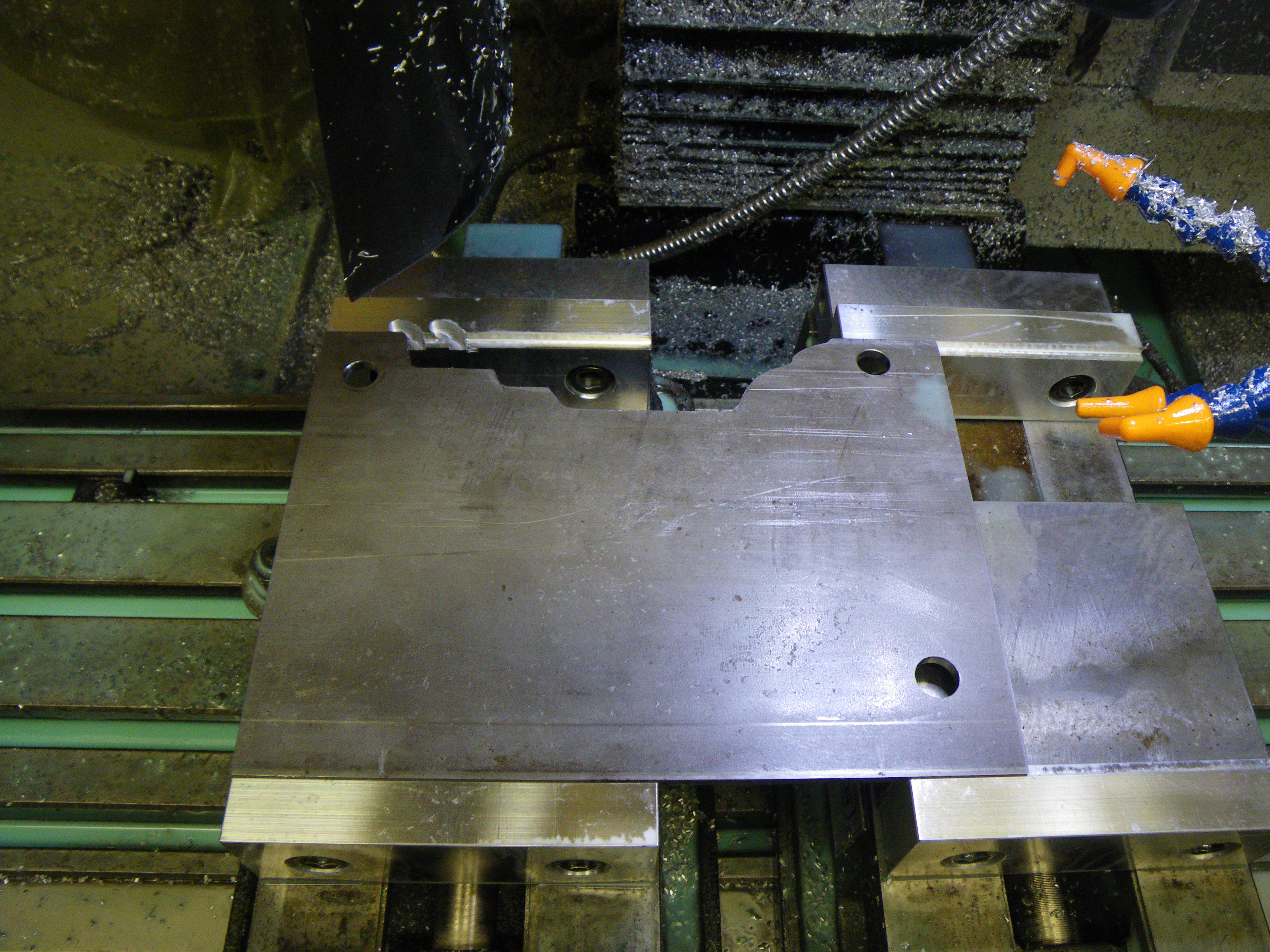

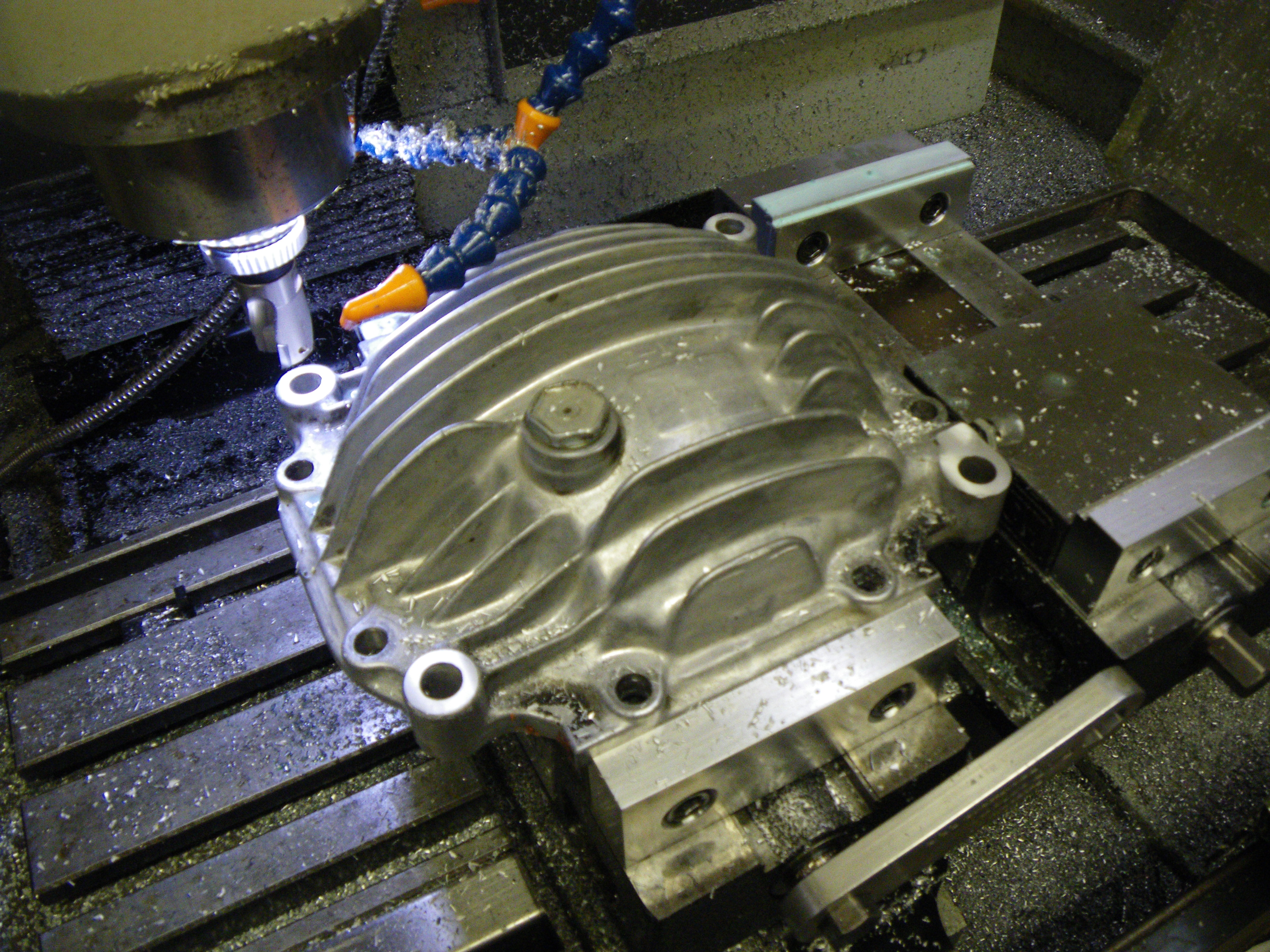

It's what I have at home to build all my parts on. I worked in a machine shop for 15yrs and did my Machinist apprenticeship before I started working as a R&D Engineer.

The CNC is a Tormach PCNC1100, I've added the power draw bar and tool changer, 4th axis. I've had it 5yrs now in Dec., it's great to be able to have CNC capabilities for all my crazy ideas. CNC plasma is next, I have a design idea for one that no one else is doing, so I'll use the plasma at work to make one on.

The CNC is a Tormach PCNC1100, I've added the power draw bar and tool changer, 4th axis. I've had it 5yrs now in Dec., it's great to be able to have CNC capabilities for all my crazy ideas. CNC plasma is next, I have a design idea for one that no one else is doing, so I'll use the plasma at work to make one on.

#55

Registered User

Yeah, I bet. I've used the manual machines at school to make some threaded adapters for some projects are home, but having the machines at home would be awesome.

#57

Registered User

IFS steering box all the way. rack and pinion is way less customizable unless you go full custom. You want front steer, rear steer like the tacomas is no good. With rear steer the slack in the joints will cause my steering angle instead of less.

With the IFS box, you can make your own center section and tie rod ends. custom placement and lengths for every part. Stronger, more serviceable and cheaper.

Obviously no bump steer is ideal, but you'll usually end up with some anyways, so...

You always want lean towards toe out for bump steer so that when you go around a corner the body roll will cause the outside wheel with more grip to toe out. Body roll causing increased steering angle is much harder to control and much more unpredictable.

I tend lean towards just the stock IFS box, I have it with my 81 and with 35s it already is very easy to steer and I like feeling the bump steer in the wheel. If you went full hydro or even hydro assist, I'd be afraid of losing that feedback on what the wheels are really doing.

With the IFS box, you can make your own center section and tie rod ends. custom placement and lengths for every part. Stronger, more serviceable and cheaper.

Obviously no bump steer is ideal, but you'll usually end up with some anyways, so...

You always want lean towards toe out for bump steer so that when you go around a corner the body roll will cause the outside wheel with more grip to toe out. Body roll causing increased steering angle is much harder to control and much more unpredictable.

I tend lean towards just the stock IFS box, I have it with my 81 and with 35s it already is very easy to steer and I like feeling the bump steer in the wheel. If you went full hydro or even hydro assist, I'd be afraid of losing that feedback on what the wheels are really doing.

Last edited by SCToy; 11-13-2013 at 03:20 PM.

#60

Registered User

R & P has a lot less adjustability in the future. Easier to make a longer center link if you decide to play with pivot lengths. The con is that it is difficult to move the idler and steering box once its placed.