friggen clutch

#1

Registered User

Thread Starter

friggen clutch

Its late.. 1am.. spent all damn day on this thing and yesterday.

I got it all back together, I went over the clutch and pressure plate installation 5 times book to clutch, book to clutch over and over double checking all the torque specs, bolts, clutch alignment

get everything back together (even new master and slave cylinders)

turn the motor over.. sounds like the clutch is about to fly out of the bellhousing. CLUTTTACLUTTALCUTTTAACLUTTTAA.. like its shaking around between the flywheel and pressure plate.

everytime i turn it over probably doing horrible damage to all the new components but not sure how else to diagnose before i tear the mother effer out again.

when the clutch is depressed seems to make a quieter clackity noise then when tranny in neutral and engaged.

I got marlins heavy duty 1200lb clutch kit and a new flywheel. all the bolts were torqued to FSM spec and loctited (blue).

I made triple sure the clutch was aligned perfectly with the tool before torqueing down the pressure plate then checked it again and it was all dead center.

any ideas?!?!??! im out of days off and really really not looking forward to tearing the transmission out AGAIN.

also put on a new throwoutbearing and pilot bearing. everythings new!!!

=(

edit...

not sure if this helps but i did take a few pictures a long the way. im stumped.

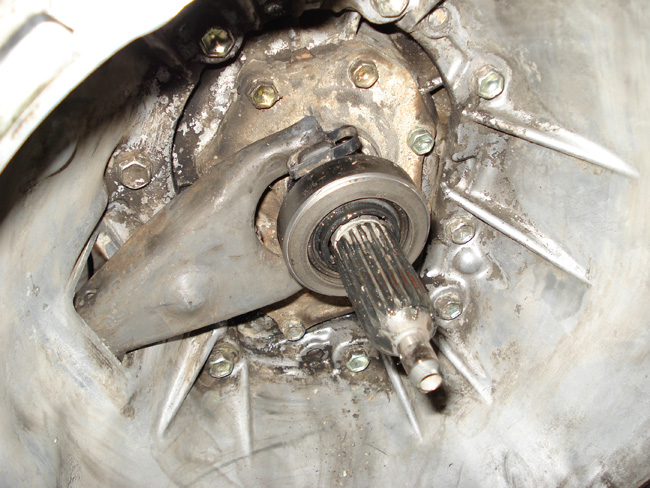

This is a shot of the release fork and new throwout bearing after everything was greased (before applying grease to the front of the bearing)

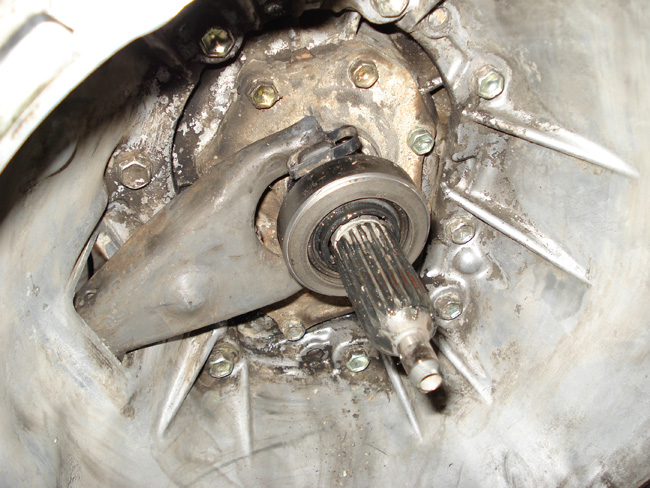

NEW flywheel put on. Loctite on the bolts to.

not a very good pic of the pressure plate bolted on. this was just before raising the transmission up.

I got it all back together, I went over the clutch and pressure plate installation 5 times book to clutch, book to clutch over and over double checking all the torque specs, bolts, clutch alignment

get everything back together (even new master and slave cylinders)

turn the motor over.. sounds like the clutch is about to fly out of the bellhousing. CLUTTTACLUTTALCUTTTAACLUTTTAA.. like its shaking around between the flywheel and pressure plate.

everytime i turn it over probably doing horrible damage to all the new components but not sure how else to diagnose before i tear the mother effer out again.

when the clutch is depressed seems to make a quieter clackity noise then when tranny in neutral and engaged.

I got marlins heavy duty 1200lb clutch kit and a new flywheel. all the bolts were torqued to FSM spec and loctited (blue).

I made triple sure the clutch was aligned perfectly with the tool before torqueing down the pressure plate then checked it again and it was all dead center.

any ideas?!?!??! im out of days off and really really not looking forward to tearing the transmission out AGAIN.

also put on a new throwoutbearing and pilot bearing. everythings new!!!

=(

edit...

not sure if this helps but i did take a few pictures a long the way. im stumped.

This is a shot of the release fork and new throwout bearing after everything was greased (before applying grease to the front of the bearing)

NEW flywheel put on. Loctite on the bolts to.

not a very good pic of the pressure plate bolted on. this was just before raising the transmission up.

Last edited by drew303; 03-29-2007 at 12:33 AM.

#2

Registered User

Thread Starter

I put the springs on the clutch towards the transmission and the flush side towards the flywheel.

The transmission wouldnt be able to mate back to the block unless the input shaft went THROUGH the clutch and into the pilot bearing RIGHT?

even if the clutch was a lil off (which i was dead on when i bolted down the pressure plate) the input shaft should center it anyways?

I even used the pressure plate bolt kit from marlin so even the bolts are new

..ugh...

this is the clutch

The transmission wouldnt be able to mate back to the block unless the input shaft went THROUGH the clutch and into the pilot bearing RIGHT?

even if the clutch was a lil off (which i was dead on when i bolted down the pressure plate) the input shaft should center it anyways?

I even used the pressure plate bolt kit from marlin so even the bolts are new

..ugh...

this is the clutch

Last edited by drew303; 03-29-2007 at 12:43 AM.

#4

Registered User

Thread Starter

I did some more diagnosing this morning. the sound is made by the throwout bearing when it touches the fingers on the pressure plate.

if i move the fork off the fingers manually it stops vibrating. If you disengage the clutch (apply pressure to the fingers) it starts the clattering.

the throwout bearing (release bearing) has a flush side and indented side, i put the indented side toward the pressure plate (as seen in the pic above). This is how it showed in the pictures in the FSM.

Could the pressure plate be messed up? .. I dont think i can do any serious harm to the components as its not the clutch chattering between the flywheel and pressure plate since it engages and doesnt chatter.. its only when the release bearing (throwout bearing, whatever u wanna call it) makes contact with the pressure plate fingers.

the input shaft also is aligned right since its not chattering.

.... =( im looking back at the picture of the bell housing and i cant figure out even if i did take it all apart how id do anything different..

if i move the fork off the fingers manually it stops vibrating. If you disengage the clutch (apply pressure to the fingers) it starts the clattering.

the throwout bearing (release bearing) has a flush side and indented side, i put the indented side toward the pressure plate (as seen in the pic above). This is how it showed in the pictures in the FSM.

Could the pressure plate be messed up? .. I dont think i can do any serious harm to the components as its not the clutch chattering between the flywheel and pressure plate since it engages and doesnt chatter.. its only when the release bearing (throwout bearing, whatever u wanna call it) makes contact with the pressure plate fingers.

the input shaft also is aligned right since its not chattering.

.... =( im looking back at the picture of the bell housing and i cant figure out even if i did take it all apart how id do anything different..

#5

Registered User

Thread Starter

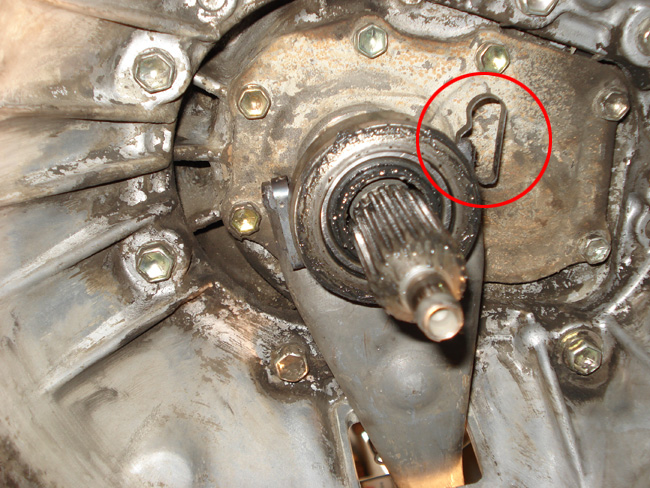

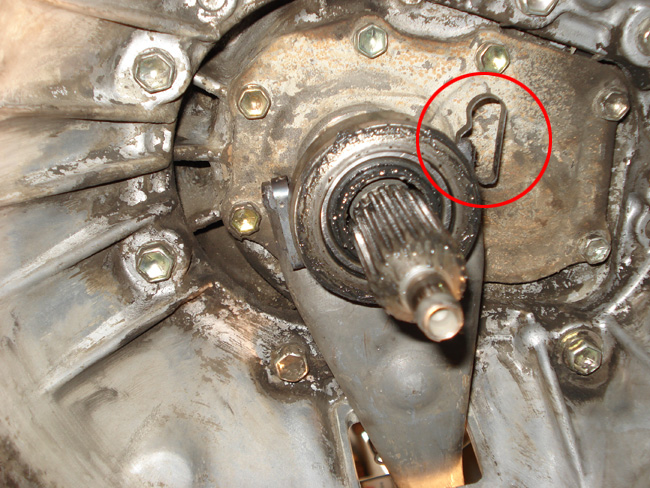

figured it out!

I was able to pull the transmission out in an hour this morning! Amazing how much faster stuff goes once you've already done it =)

Found the problem!

Not catastrophic but i suppose it could of been.

that was allowing the release bearing to clatter on the springs. more or less clatter on the fork as well.

to bad i gotta go to work, ugh.. not sure when ill have time to put the tranny back in. =(

THE END. =)

Found the problem!

Not catastrophic but i suppose it could of been.

that was allowing the release bearing to clatter on the springs. more or less clatter on the fork as well.

to bad i gotta go to work, ugh.. not sure when ill have time to put the tranny back in. =(

THE END. =)

Trending Topics

#8

Contributing Member

iTrader: (3)

Don't feel bad, when I dropped mine out to replace everything mine didn't even have those clips. I bought new clips, new throughout bearing hub and that little teflon puck on the bottom of the shifter (which made a HUGE difference). However, when I went to put it all back together, I wasn't satisfied with how well the clips were holding. I still put them in I just bent them up some so that they would hold more pressure against the fork.

#11

Registered User

Thread Starter

SOB...

ok i got the tranny back in tonight.. what a PITA that was. man doin this crap by yourself aint easy!!! I dont have a tranny jack but if i get the tie straps and the jack in the right place it holds it level and i can go straight up with it. Hard part is getting that jack in the right place and the straps in the right place! iuheiugiwbgiwaigsdasd

anyways, apparently the clip WASNT the problem because its STILL DOING IT!

im so beat. 3 days non stop. i pulled the tranny before work then worked my 8hrs then came home and been at it ever since, got er back in everything bolted in and started it up and clackity clackity when the throwout bearing hits the fingers!!!

HELP!!!!!

haha, yea no one was replying but i cant really wait for help haha.. this sucks, now the truck has to be out of the garage by Sunday ..that leaves me no sleep and no life. friggen a lol

man, im beat.

moral support is better than nothing haha =)

#12

Registered User

Thread Starter

more ranting .... when i got up in there to see how everything was the clutch was centered, the throwout bearing seated properly, spun like butter and solid like a rock. no damage to the pressure plate springs or anything for that matter. I didnt pull the pressure plate since it all looked fine.

COULD THE PRESSURE PLATE BE MISALIGNED? doesnt make sense how it could, it only goes on one way.

so now im thinking maybe the clutch IS kinda clackiting around in there when its disengaged (fingers pressed in...i dunno.. im stumped)

ugh...

COULD THE PRESSURE PLATE BE MISALIGNED? doesnt make sense how it could, it only goes on one way.

so now im thinking maybe the clutch IS kinda clackiting around in there when its disengaged (fingers pressed in...i dunno.. im stumped)

ugh...

#13

Registered User

Thread Starter

and just to bitch... the crossmember hardly lines up with any of the 8 holes that hold it to the frame (4 on each side) ... so it has 3 on one side 2 on the other.. since thats all that fits and im to pissed and tired to care or take the time to dremel out the holes ot make the bolts line up...

ok you can laugh now =P

ok you can laugh now =P

#14

Registered User

Thread Starter

well since this has turned into more of a lets talk to myself thread... hey.. when your doin all this crap yourself, workin long hours then workin even longer nights on your rig... sometimes you just gotta talk to yourself in other places besides the dirtball mess under your rig in the garage..

besides the only words that are said out there are words inappropriate for yotatech =)

IN OTHER NEWS... good news I brought this baby home Wednesday evening.

1987 Single Cab, Short bed. Same model as my truck same year. My truck was hit before i bought it and i didnt know that when i bought it and... frame is tweaked and IFS pass side is fuxored and... and...and...

so.. new frame in order. Want to SAS it. got the axle already.. but... if you actually sit down and do a spreadsheet on the costs of a SAS the cheapest you can realy come is about $3000 ... its less than that on the spread but you gotta figure in all the expenses you WONT expect.. all the things that wont go right, that costs lots of money.. like every endeavour ive done with this truck haha

...

ok... time i get a life =P

besides the only words that are said out there are words inappropriate for yotatech =)

IN OTHER NEWS... good news I brought this baby home Wednesday evening.

1987 Single Cab, Short bed. Same model as my truck same year. My truck was hit before i bought it and i didnt know that when i bought it and... frame is tweaked and IFS pass side is fuxored and... and...and...

so.. new frame in order. Want to SAS it. got the axle already.. but... if you actually sit down and do a spreadsheet on the costs of a SAS the cheapest you can realy come is about $3000 ... its less than that on the spread but you gotta figure in all the expenses you WONT expect.. all the things that wont go right, that costs lots of money.. like every endeavour ive done with this truck haha

...

ok... time i get a life =P

#15

Registered User

Join Date: Dec 2006

Location: Wenatchee WA

Posts: 972

Likes: 0

Received 0 Likes

on

0 Posts

not really sure what your problem is, but is it possible that you got a defective clutch that was damaged somehow? just something to think about because there are always some defective parts, even from good companies, thats why there are warranties

#16

Registered User

Join Date: Jan 2007

Location: Kentucky

Posts: 79

Likes: 0

Received 0 Likes

on

0 Posts

That sucks man. At least its narrowed down to the throwout or the pressure plate. This may be a stupid question, but does the throwout spin freely? Are the fingers on the pressure plate all level? I'm still pretty green when it comes to wrenching on trucks, but that's all I can think of.

Good luck.

Good luck.

#17

Registered User

Thread Starter

ill let you all know what i find once i tear it ALL apart tomorrow afternoon. Hopefully I find something.

and that something hopefully will be easily correctable.

and that something hopefully will be easily correctable.

#18

Contributing Member

Join Date: Mar 2005

Location: WA ,monroe

Posts: 1,871

Likes: 0

Received 0 Likes

on

0 Posts

dumb question but do you have the disc in backwards? i cant remember how similar both sides are. oh and those clips i never use them and have never had a problem.

#20

Registered User

Thread Starter

The clutch disk is put in per text book. The raised side (that contains the springs) faces the transmission or the clutch cover. The shallow or more flat side faces the flywheel.

Also, I'm not sure how you folks can run without the clips, What keeps the part that holds the release bearing from just spinning and losing contact with the fork fingers??

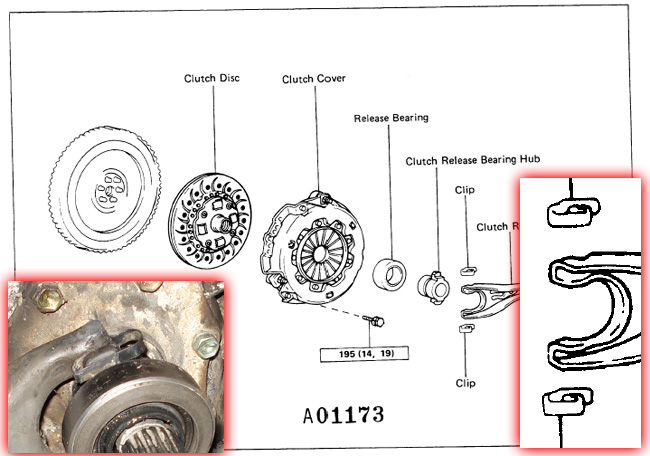

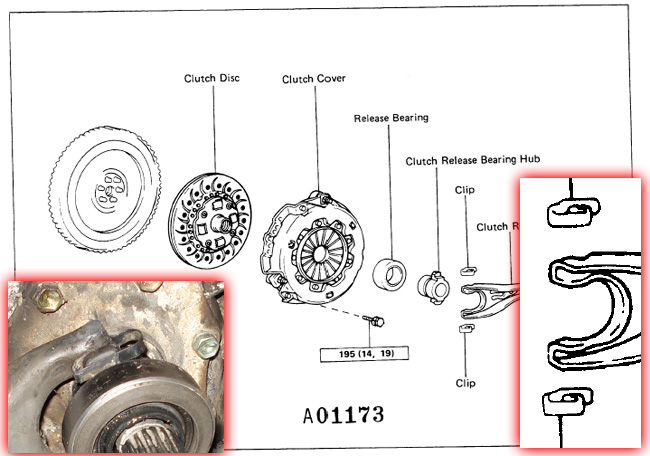

Heres a diagram from the FSM:

I have my clips on opposite what they have pictured there. I couldnt get them to stay the other way... but.. ill mess with it some more when i get the transmission out for a 3rd time this week, today.

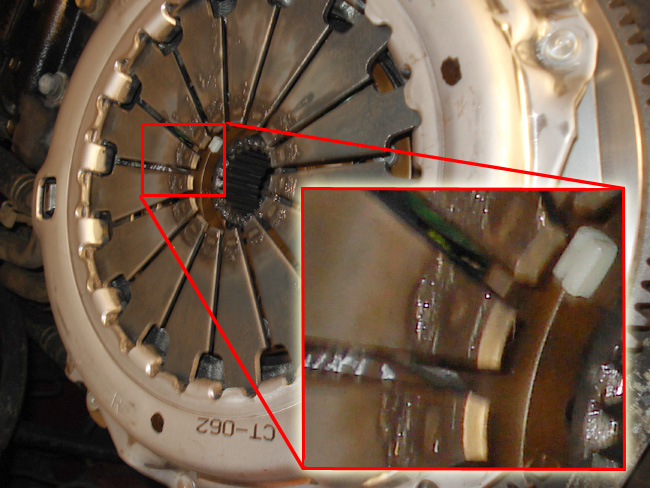

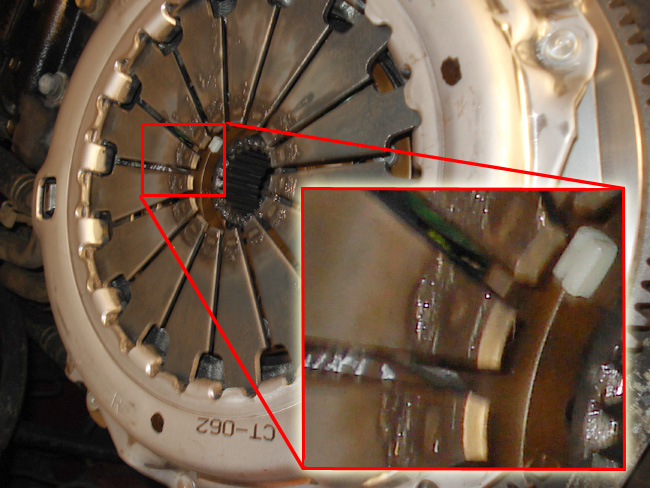

ok, so i took some pics before i put it back together Thursday night.

After re-examining a picture I noticed somethin fishy.. well a few things.

You can clearly see where the release bearing is making contact with the teeth. After playing around with the old release bearing and pressure diaphram I could recreate the chattering noise by kinda of draggin the old bearing in a non true circle (as if it was spinning not centered on the fingers).

I also noticed one finger was not making total contact with the bearing:

When I recreated a similar noise with the old parts it was more of a noise of the bearing chattering with ALL the teeth. But the noise I get from my truck now sounds like one click per revolution. like the radiator fan hitting the shroud. Similiar almost identical noise. I think if it was hitting and clattering with all the fingers it'd be a different vibration and noise.

Also its hard as hell to tell but it kind of appears that the old bearing made contact closer to the tips of the fingers compared to the new bearing and pressure plate (clutch cover).

Also, I'm not sure how you folks can run without the clips, What keeps the part that holds the release bearing from just spinning and losing contact with the fork fingers??

Heres a diagram from the FSM:

I have my clips on opposite what they have pictured there. I couldnt get them to stay the other way... but.. ill mess with it some more when i get the transmission out for a 3rd time this week, today.

ok, so i took some pics before i put it back together Thursday night.

After re-examining a picture I noticed somethin fishy.. well a few things.

You can clearly see where the release bearing is making contact with the teeth. After playing around with the old release bearing and pressure diaphram I could recreate the chattering noise by kinda of draggin the old bearing in a non true circle (as if it was spinning not centered on the fingers).

I also noticed one finger was not making total contact with the bearing:

When I recreated a similar noise with the old parts it was more of a noise of the bearing chattering with ALL the teeth. But the noise I get from my truck now sounds like one click per revolution. like the radiator fan hitting the shroud. Similiar almost identical noise. I think if it was hitting and clattering with all the fingers it'd be a different vibration and noise.

Also its hard as hell to tell but it kind of appears that the old bearing made contact closer to the tips of the fingers compared to the new bearing and pressure plate (clutch cover).