finally finished rebuild on head gaskets

#1

finally finished rebuild on head gaskets

fyi replaced with reman heads, water pump, timing belt and pulleys, rebuilt power steering pump that sqeualed and leaked before, alternator with hihg output one, optima gel battery, new calipers rotors, and some things ive forgotten, oh, the injectors with 4 holes and i already had the supra afm and an msd 6al and blaster 2 coil.. Okay so you all know this blew almost one year ago and Ive been collecting parts since (budget). Now this has been a bitch, I work at night and a few hours in the day and its hot as hell here in Ok right now. so I couldnt get it started, so I took anything off and checked my marks and cranked until i was back at tdc on all three marks and restabbed the distributor. no good. so i used my compression tester hose and found tdc by way of pressure in the #1, estabbed dstributor and voila it fires up. first issue is it sounds like a diesel. some washer or something. got in the intake. I carefuly used a magnet to get any accidental dropped items out but? Now ive run into several problems requiring me to tear the top apart three or four times. water leaking out of the waterneck with the pulley between the sprockets. pulled it and used rtv. then somehow had another leak forgetting to connect the outlet to the throttle blody. now everything in hooked up and though the connector to the distributor disentegrated. so the bare metaal plugins are connected to the tabs on the distributor. timing is perfect but driving his thing is unbelievable. it barely has power to carry me. theres no throttle response. driving slow under no load on flat ground hitting the throttle it doesnt surge at all. what is going on? Also my new calipers which i only installed the drives side is leaking fluid somewhere. whitout the e1 te1 connected the timing jumps occasionally by a lot. and the mark is retading not advancing time. when this happens I hear something happen in the engine. maybe a miss.,idk. but just running it sounds ine, not missing. I do notice usually it starts and idles up then settles down. now it does the opposite. Any ideas?

#2

Registered User

My eyes are killing me, that was hard to read.

You have a lot going on here. If I was in your shoes

I would start pulling codes. You need a starting point.

Also in my opinion I would use FIPG before using RTV.

Maybe your water neck is warped or corroded.

The o-ring should hold the pressure.

You have a lot going on here. If I was in your shoes

I would start pulling codes. You need a starting point.

Also in my opinion I would use FIPG before using RTV.

Maybe your water neck is warped or corroded.

The o-ring should hold the pressure.

#3

Registered User

That was difficult to read.

That was difficult to read.What are you working on? I assume you have the 3.0 L 3VZ-E since you changed the timing belt.

It is difficult to diagnose over the internet with aftermarket "performance" parts installed.

When you say timing is perfect, do you mean ignition timing, mechanical timing (camshafts to crankshafts), or both?

#4

Sorry for the long post

I agree on the brake issue. I found the "rebuilt" caliper had old pistons with new seals a good cleaning and bead blast, Turns out one piston had a bad nick o I replaced it with a perfect piston and replaced the seal. unfortunately it leaks still but now only under braking not constantly. I have spare calipers so I can deal with that.. First I ordeed a new rotor, got plugs not installed yet, and I cut the filer off. It was seized on both sides rounded on one so I will be repairing the line so I can use the correct filter. but today i just ran fuel injection hose with no filter, free flowing. I tried the original ignition, ran good but still had no pwer and now I notice misfiring under load. So I hooked up the MSD 6al and Blaster3 and still the same result. I get power pas 2500 to 3000 rpm but from low rpm like at a stop sign or light or uphill its totally gutless. I havent pulled codes yet. On a side note the noise up front has subsided every day or every time I drive I suppose. Cant't find any vacuum leaks, so thats all I learned today. I'm beat at the moment but I think theres an answer to fix this. it has headers btw so no exhaust restriction issue.

#5

Registered User

I agree on the brake issue. I found the "rebuilt" caliper had old pistons with new seals a good cleaning and bead blast, Turns out one piston had a bad nick o I replaced it with a perfect piston and replaced the seal. unfortunately it leaks still but now only under braking not constantly. I have spare calipers so I can deal with that.. First I ordeed a new rotor, got plugs not installed yet, and I cut the filer off. It was seized on both sides rounded on one so I will be repairing the line so I can use the correct filter. but today i just ran fuel injection hose with no filter, free flowing. I tried the original ignition, ran good but still had no pwer and now I notice misfiring under load. So I hooked up the MSD 6al and Blaster3 and still the same result. I get power pas 2500 to 3000 rpm but from low rpm like at a stop sign or light or uphill its totally gutless. I havent pulled codes yet. On a side note the noise up front has subsided every day or every time I drive I suppose. Cant't find any vacuum leaks, so thats all I learned today. I'm beat at the moment but I think theres an answer to fix this. it has headers btw so no exhaust restriction issue.

Let me try and decipher, I understand you need brakes to work properly, but if it runs like crap I don't see how you can even drive it.

There is so much going on here, and you have not checked for any stored codes yet, which will give you a place to start.

I also wonder if your 3vze (which I'm assuming you have) doesn't like those new 4 hole fandangled fuel injectors.

Check for the stored codes.

Maybe break your post into separate paragraphs, It reads better.

#6

Registered User

iTrader: (1)

Paragraphs are your friends.

Lose the MSD box, you probably have way too small of a diode in the circuit. The coil is overkill, and sparking over your wires to ground and each other.

If you put in bigger injectors without moving to a DIY ECU you are flooding the engine. The stock ECU can work wonders but there is a limit.

No that is not a good way to time an engine. Actually its a good way to grenade a good engine. As I think about that, God would beat me with a tire iron if I timed an engine that way.

I hope you got the braking issues resolved, so the number of topics can go down by one.

Lose the MSD box, you probably have way too small of a diode in the circuit. The coil is overkill, and sparking over your wires to ground and each other.

If you put in bigger injectors without moving to a DIY ECU you are flooding the engine. The stock ECU can work wonders but there is a limit.

No that is not a good way to time an engine. Actually its a good way to grenade a good engine. As I think about that, God would beat me with a tire iron if I timed an engine that way.

I hope you got the braking issues resolved, so the number of topics can go down by one.

#7

Update

Okay so I have no intention of removing the MSD 6AL. It did make a big difference for the better and hasn't ever caused me a problem. Also I pulled it from my Trans Am with 350 Tuned Port so I had to cut a wire to make it v6 compatible. However I went to 8mm plug wires and added the Blaster 3 coil, and didn't notice much if anything. And I was spinning the rotor yesterday and noticed arcing from the two wires connected to the coil, to the center tower whic is hard plastic and the Blaster3 has an extra thick and tall tower to eliminate this arcing. So I'm certainly losing power there. Perhaps sing a different coil or even the stock one. And btw when I installed the MSD I did it in a way that would allow me to swap 2 wires and connect the factory coil to cap wire which is connected but just to the coil that's not firing, and voila I'm using the factory ignition. I tried this in fact yesterday and today with no change to the power problem in either setup.

So after changing plugs last night, and having done so many things since connecting the battery, I reset the ecm codes and drove to work, around town a bit and on the highway a bit. I noticed the engine light comes on under load at 2000 plus rpm. When I got home I checked for codes I came up with 41 and 52. So TPS and Knock sensor. now I don't think the knock sensor has a problem as I replaced it and when this thing gets moving under load it definitely knocks for whatever reason. Maybe right maybe not. I will look up the procedure for doing the TPS. Maybe it should be changed? I'm surprised I didn't get more codes.

When installing the timing belt, the marks for the cam sprockets could line up, however the crank marks couldn't. The mark on the crankshaft and the belt both fall on teeth, so I had to pick one side or another. ie left or right of the crankshaft mark. perhaps I chose the wrong side and am a tooth off? This problem does feel and or sound like a timing problem but who knows. So thats all I have to add so far.

So after changing plugs last night, and having done so many things since connecting the battery, I reset the ecm codes and drove to work, around town a bit and on the highway a bit. I noticed the engine light comes on under load at 2000 plus rpm. When I got home I checked for codes I came up with 41 and 52. So TPS and Knock sensor. now I don't think the knock sensor has a problem as I replaced it and when this thing gets moving under load it definitely knocks for whatever reason. Maybe right maybe not. I will look up the procedure for doing the TPS. Maybe it should be changed? I'm surprised I didn't get more codes.

When installing the timing belt, the marks for the cam sprockets could line up, however the crank marks couldn't. The mark on the crankshaft and the belt both fall on teeth, so I had to pick one side or another. ie left or right of the crankshaft mark. perhaps I chose the wrong side and am a tooth off? This problem does feel and or sound like a timing problem but who knows. So thats all I have to add so far.

Trending Topics

#8

Registered User

I sure hope you replaced the Knock Sensor Wire, that IMHO is more important than the Knock Sensor Itself.

Don't assume your TPS is bad either. Do the procedure and check for spec first. I bet it's out.

If it was me I would put a stock coil back in there.

The 3VZE is pretty much unfazed with some (I say most) of the mods that are done, but that's just my opinion.

The questionable concern, is the timing belt on correctly.

Don't assume your TPS is bad either. Do the procedure and check for spec first. I bet it's out.

If it was me I would put a stock coil back in there.

The 3VZE is pretty much unfazed with some (I say most) of the mods that are done, but that's just my opinion.

The questionable concern, is the timing belt on correctly.

#9

update

Well while I had it apart I rebuilt the power steering pump. Like I said that at least worked great, turned smoother and was silent. Then I got up yesterday and drove to my storage, then back home. Later I went to work, should mention from the first trip of the day it was whining a bit from the pump, I attributed it to rain that night so I get to work and after clocking in come out to see a lot of fluid on the ground under the pumps general area. I had a friend turn the wheel while I watched and it seemed to be coming slowly from the lid (frothing like crazy). Found a loose hose, the low pressure line, fixed that and went to my building. Soon as I kill the engine it starts pouring from what I know see is the front seal brand new. Now I hadnt bolted the bracket to the side of the block so the pump was angled a tiny bit, but could that have caused this failure?

Anyhow, I got a remanufactured pump and started tearing the front off before hitching to work. I work from 4:30 to 1:30 am. I plan to reset the timing belt, this time putting the mark for the crank to the other side which would tak slack from the driver side which seems to have more than it should based on the manual pictures and some videos i've watched. Hoping that it will still line up after the rotations and perhaps solve the problem. Any advice would be great. I will be trying to knock this out in time for work or sooner maybe.

Anyhow, I got a remanufactured pump and started tearing the front off before hitching to work. I work from 4:30 to 1:30 am. I plan to reset the timing belt, this time putting the mark for the crank to the other side which would tak slack from the driver side which seems to have more than it should based on the manual pictures and some videos i've watched. Hoping that it will still line up after the rotations and perhaps solve the problem. Any advice would be great. I will be trying to knock this out in time for work or sooner maybe.

#11

Knock sensor

Can't remember my password so I'm using a different account at work. I meant to answer your query, and to my knowledge yes I did. The new knock sensor came with a replacement pigtail that ran from the sensor to above the intake manifold.

. Now, I didn't do anything with the tps yet. I currently have the whole front pulled and am attempting to reset the timing belt. I'm not having much luck. It seems I can barely get enough slack to get where I was let alone move a tooth over on the crank. And as I said it's either the belts Mark is to one side or the other of the tooth with the dot.

. Also I put the hose for my.compression tester in the number one cylinder to try and get the compression stroke on that cylinder at tdc Mark. And it seems as though tdc by feeling compression would put the Mark counterclockwise of tdc by several teeth. I mean the first time I did this I put the belt on and it wouldn't start. Then I used the hose and turned until I felt number one start compressing, turned a little more then stabbed the distributor at number one for the rotor and that's what I've been driving on till now.

. Now, I didn't do anything with the tps yet. I currently have the whole front pulled and am attempting to reset the timing belt. I'm not having much luck. It seems I can barely get enough slack to get where I was let alone move a tooth over on the crank. And as I said it's either the belts Mark is to one side or the other of the tooth with the dot.

. Also I put the hose for my.compression tester in the number one cylinder to try and get the compression stroke on that cylinder at tdc Mark. And it seems as though tdc by feeling compression would put the Mark counterclockwise of tdc by several teeth. I mean the first time I did this I put the belt on and it wouldn't start. Then I used the hose and turned until I felt number one start compressing, turned a little more then stabbed the distributor at number one for the rotor and that's what I've been driving on till now.

#12

Okay I'm banking or hoping the timing belt, though the lines matched up after the two revolutions, was on tdc but exhaust not compression. So all the manuals and information I can gather isn't that helpful.

. Turn the crank until the tdc and make sure the rotor is pointed at #1, for example. Since I have pulled the heads and of course distributor, and had both sprockets and the crank cog turn independent of one another, I'm starting from scratch. Again, this time hopefully with more knowledge and luck. So can anyone suggest my procedure the timing belt this time knowing everything is unknown.

. I.e. as long as the camera sprockets are lined up I'm good there, maybe ways to make sure the #1 is at tdc on compression, when to stab the distributor. Anything. I didn't have time to get to it today so I plan on having it done this weekend.

. Turn the crank until the tdc and make sure the rotor is pointed at #1, for example. Since I have pulled the heads and of course distributor, and had both sprockets and the crank cog turn independent of one another, I'm starting from scratch. Again, this time hopefully with more knowledge and luck. So can anyone suggest my procedure the timing belt this time knowing everything is unknown.

. I.e. as long as the camera sprockets are lined up I'm good there, maybe ways to make sure the #1 is at tdc on compression, when to stab the distributor. Anything. I didn't have time to get to it today so I plan on having it done this weekend.

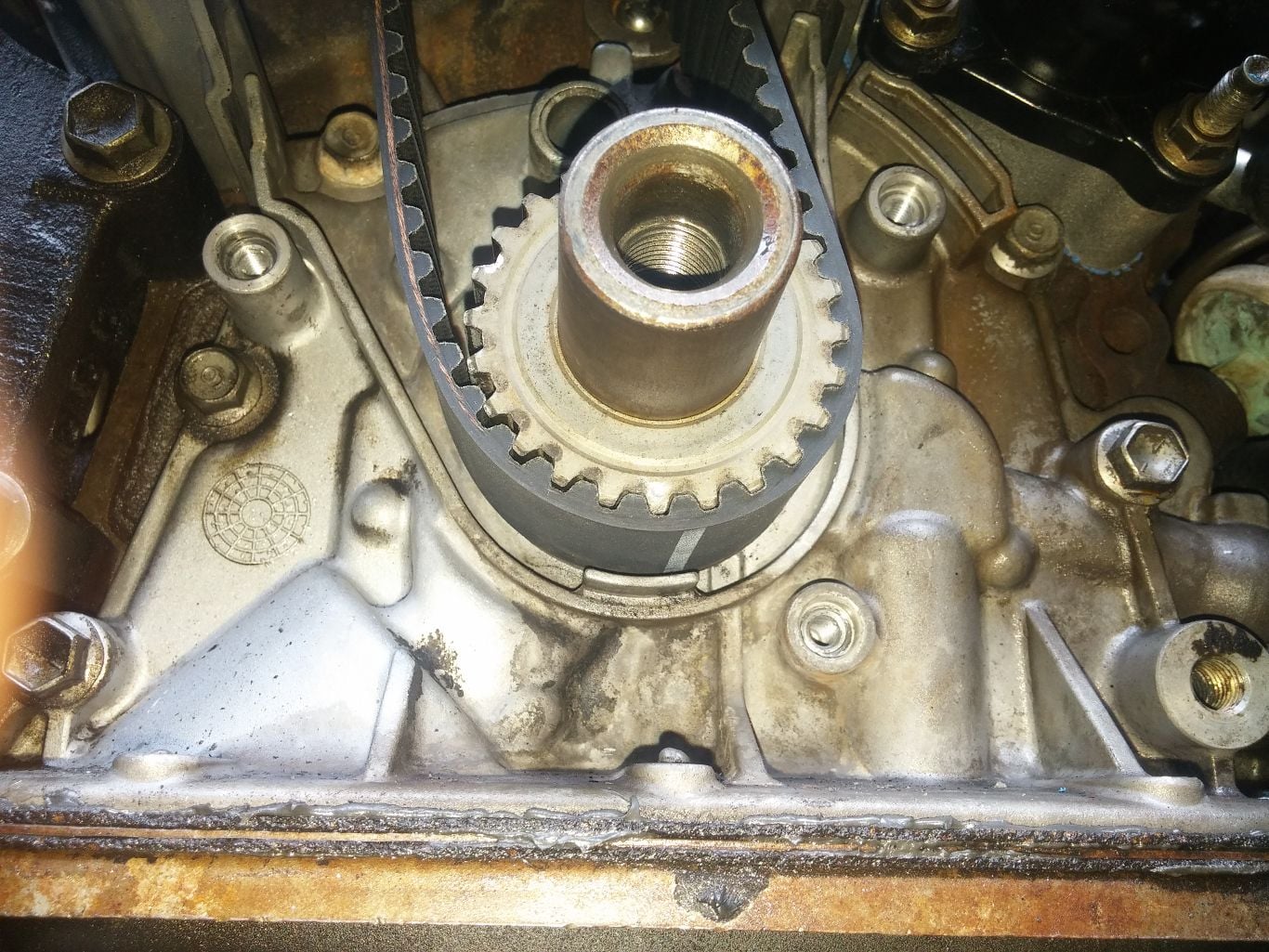

#13

I rotated the engine after installing pulley and tensioner housing, and pulling pin. I somehow missed the first time the marks came around on the timing belt but caught the second, Every mark was two teeth over from its starting position, and the balancer lined at zero with both sprockets still lined up with the backplate marks. I installed a new rotor and restabbed the distributor with the new rotor pointing right at the #1 mark on the distributor before turning the engine.

I don't see a problem myself. I am putting the new power steering pump together and also spent time yesterday welding a bracket I made to prevent the new 120 amp alternator from losing tension. And I will be installing the power steering bracket correctly this time now I'm not rushing so it shouldnt be leaning or angled.

#14

Okay, where to start....well after I took the weekend two weeks ago, it was actually from wednesday to sunday, and reset the timing belt as shown in the pictures which to me and everyone Ive shown and asked is dead on. I stabbed the distributor with a new rotor pointing directly at # 1 on the cap while everything was set at TDC and after the two rotations the marks had all moved two teeth and marks still lined up. So I reassembled the engine and big shock, it didn't start. I could tell it was close, and advancing the distributor made it almost run so I pulled the distributor and moved the rotor advancing the timing. Voila, it fired up, and next I got my inductive timing light out and couldn't even see the timing mark. It was so far advanced that the mark was actually at 12:00 and thus pretty damn far from the timing marks. Now I discussed this with my mechanic and his advice was just set the timing till it runs as good as I can get it and drive, at least for now.

Another problem is my bolt to tie the distributor in place is stripped, my fault but any how It was running better. But it is throwing the TPS and Knock sensor codes. So I tried to set the TPS but that was so complicated, feeler gauge kept falling out, the meter was untenable so I got as close as I could, and btw it was set the whole opposite of where it was and before I had never touched it at all. Now after that it idled lower and seemed to run a little better. However my first drive down the road I lost power steering and came home quick and pooped the hood to oil flying everywhere. Now I installed a sandwich inbetween the filter and the block that gave me two lines in and out that I ran to the tranny cooler hookups on the radiator. After hours of messing with it I found one of the lines had somehow rubbed against a pulley and so I got rid of that oil cooler.

Next I drove for two days and the power steering pump went out, so I replaced that with a remanufactured one, and now that's working. Now I have new seats, lights, paint, side steps, winches, and plenty of stuff but I have to get this thing going right first.

So I have been noticing a leak everytime I stop, I thought it was brake fluid or fluid from the clutch, but I finally discovered a spot where oil was pouring down the side of the block and eventually saw oil next to the back half of the passenger side tappet cover. So I took the intake off and the tappet cover and cleaned the head and the tappet cover, then used black RTV in the cover then seated the gasket and I also put a really thin coat on the block side of the gasket, and then I bolted it on. Now unfortunately I had to get to work and immediately drove to work. It stopped leaking along the whole side but it's still leaking from the back quite a bit. The PCV valve was rattling fine and I still soaked it in rust remover and cleaned it very well so I know it is working and not causing a buildup of pressure.

I have a new TPS ordered and I replaced the phillips drive with allen drive machine screws so I can adjust it without taking the throttle body off. I'm planning on adjusting a little at a time till hopefully the code stops getting thrown up, and if not then change it. Probly change it anyway since one is on the way here. But on the valve cover I plan to do the same thing with the RTV but give it plenty of time to cure. So does anyone have advice or suggestions for me?

Another problem is my bolt to tie the distributor in place is stripped, my fault but any how It was running better. But it is throwing the TPS and Knock sensor codes. So I tried to set the TPS but that was so complicated, feeler gauge kept falling out, the meter was untenable so I got as close as I could, and btw it was set the whole opposite of where it was and before I had never touched it at all. Now after that it idled lower and seemed to run a little better. However my first drive down the road I lost power steering and came home quick and pooped the hood to oil flying everywhere. Now I installed a sandwich inbetween the filter and the block that gave me two lines in and out that I ran to the tranny cooler hookups on the radiator. After hours of messing with it I found one of the lines had somehow rubbed against a pulley and so I got rid of that oil cooler.

Next I drove for two days and the power steering pump went out, so I replaced that with a remanufactured one, and now that's working. Now I have new seats, lights, paint, side steps, winches, and plenty of stuff but I have to get this thing going right first.

So I have been noticing a leak everytime I stop, I thought it was brake fluid or fluid from the clutch, but I finally discovered a spot where oil was pouring down the side of the block and eventually saw oil next to the back half of the passenger side tappet cover. So I took the intake off and the tappet cover and cleaned the head and the tappet cover, then used black RTV in the cover then seated the gasket and I also put a really thin coat on the block side of the gasket, and then I bolted it on. Now unfortunately I had to get to work and immediately drove to work. It stopped leaking along the whole side but it's still leaking from the back quite a bit. The PCV valve was rattling fine and I still soaked it in rust remover and cleaned it very well so I know it is working and not causing a buildup of pressure.

I have a new TPS ordered and I replaced the phillips drive with allen drive machine screws so I can adjust it without taking the throttle body off. I'm planning on adjusting a little at a time till hopefully the code stops getting thrown up, and if not then change it. Probly change it anyway since one is on the way here. But on the valve cover I plan to do the same thing with the RTV but give it plenty of time to cure. So does anyone have advice or suggestions for me?

#15

Registered User

Join Date: Sep 2007

Location: San Francisco East Bay

Posts: 8,254

Likes: 0

Received 822 Likes

on

649 Posts

.... I stabbed the distributor with a new rotor pointing directly at # 1 on the cap while everything was set at TDC ... the timing mark. It was so far advanced that the mark was actually at 12:00 and thus pretty damn far from the timing marks. Now I discussed this with my mechanic and his advice was just set the timing till it runs as good as I can get it and drive, at least for now....

Oh, and you need a new mechanic.

... eventually saw oil next to the back half of the passenger side tappet cover. So I took the intake off and the tappet cover and cleaned the head and the tappet cover, then used black RTV in the cover then seated the gasket and I also put a really thin coat on the block side of the gasket, and then I bolted it on. ...

Yes, once again, the FSM tells you what you should have done. There are just four spots where the valve cover gasket makes a right angle turn (front and back, either side of the cam bearing). There you apply a dab of RTV. Before you do that, though, you need to make sure the surfaces are clean enough to eat off. RTV doesn't stick well to oily surfaces. Oil leaks on the back of the valve cover gasket are common, and failing to follow the FSM is the cause.

The TPS "code" (41, correct?) is usually caused by an "open or short in the VTA circuit." You test that by measuring resistance from VTA to E2; it should change SMOOTHLY as you rotate the sensor. If it has drop outs or dead spots, you'll get code 41. The setting procedure (which really isn't as complicated as many make out) sets the IDL switch. Which is necessary to be set correctly, but is less likely to throw the code.

Good luck!

#16

Registered User

You REALLY don't want to put RTV all over the place on the valve cover. There's no place on the plastic cover to get a really good grip, so the next time you need to remove the cover you may not be able to do it with out destroying it.

Yes, once again, the FSM tells you what you should have done.

!

Yes, once again, the FSM tells you what you should have done.

!

Also If your having to use RTV, it's possible your over tightening the valve cover. Myself, I go by the FSM tightening sequence and torque to 5.4 N-m (55 kgf-cm, 48 in.-lbf)

#17

Registered User

Join Date: Sep 2007

Location: San Francisco East Bay

Posts: 8,254

Likes: 0

Received 822 Likes

on

649 Posts

Good point. 48 in-lbf isn't very much, and you're putting a steel machine screw into an aluminum head. Overtightening can not only cause leaks, but it is very easy to strip the head.

I have a 1/4" torque wrench that is the tool you need. https://www.harborfreight.com/1-4-qu...ench-2696.html Walking the line between not-tight-enough to hold and strip-the-head is hard to do 'by hand'.

I have a 1/4" torque wrench that is the tool you need. https://www.harborfreight.com/1-4-qu...ench-2696.html Walking the line between not-tight-enough to hold and strip-the-head is hard to do 'by hand'.

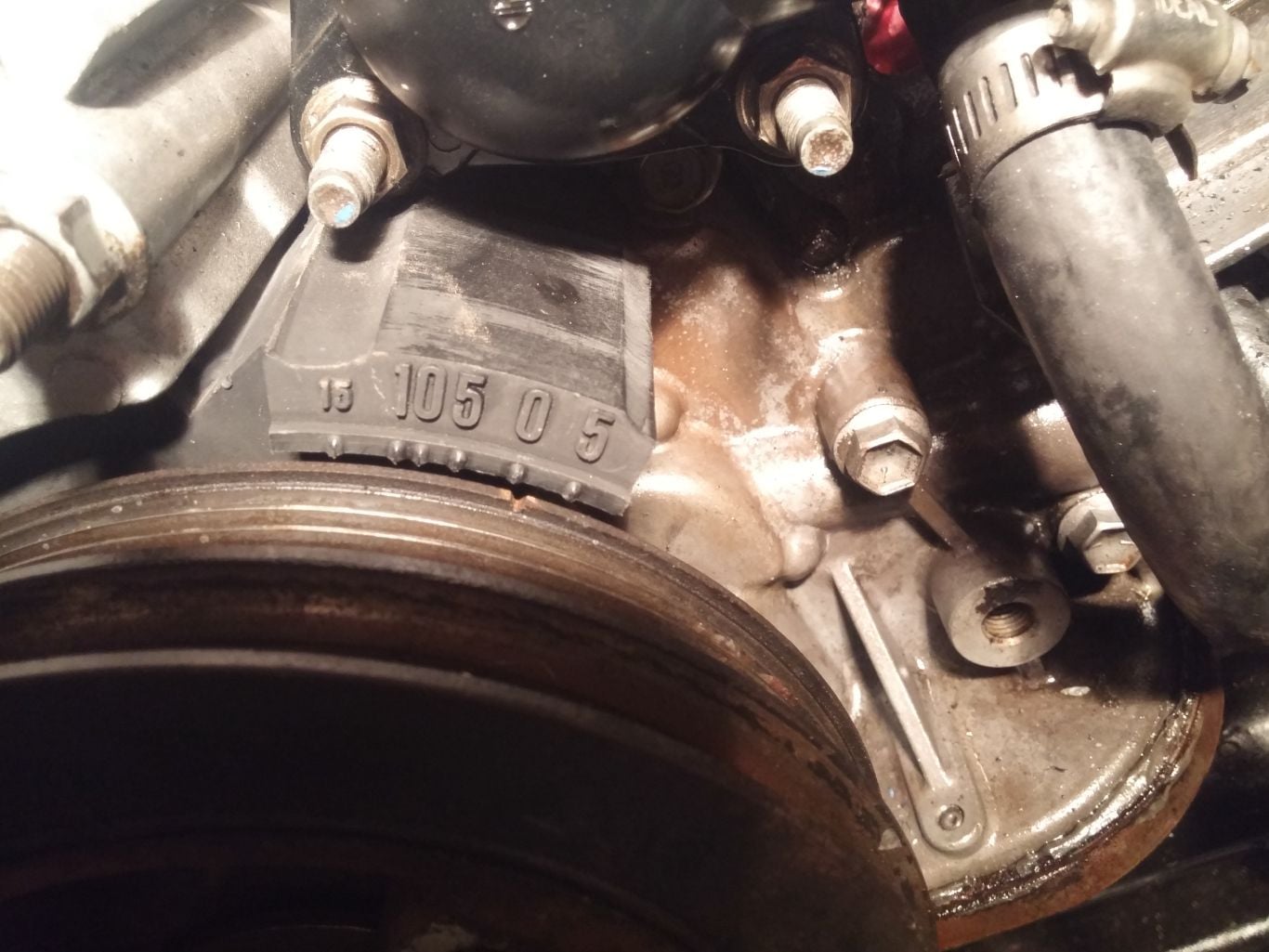

#19

I actually have multiple torque wrenches in half inch and /8's drive. I have learned the hard way on those bolts and broken one as well. At any rate I decided to pull the covers and check the belt and as you see in the pictures thats where it was set and after two rotations the marks still lined up. Upon pulling the covers and lining up the cam sprockets the balancer had moved or one way or another as about a tooth left of zero degrees putting it at about fifteen advanced. So I have purchased a new belt and am going to try again. I see a lot of people doing this rebuild and having the same issue so it's something common in my mind, but I cant figure out what the problem is. I also dont know where I should be moving a tooth and which direction, not to mention why would the marks line up repeatedly but after driving they don't. I'm just ready to drive this thing and stop working on it. Or at least the same part.

#20

Registered User

Join Date: Sep 2007

Location: San Francisco East Bay

Posts: 8,254

Likes: 0

Received 822 Likes

on

649 Posts

.... Upon pulling the covers and lining up the cam sprockets the balancer had moved or one way or another as about a tooth left of zero degrees putting it at about fifteen advanced. So I have purchased a new belt and am going to try again. I see a lot of people doing this rebuild and having the same issue so it's something common in my mind, ....

The belt, obviously, is not going to "slip," at least as long as the tensioner is in place. A bit of sloppiness can get the belt on wrong in the first place, but you check that just the way you did; two turns of the crank once the tensioner is snugged up.

But it is possible you have a bad harmonic balancer. There is an annular rubber ring between the part that slides onto the crankshaft, and the part around that with the pulley grooves and timing mark. At the vintage of our trucks, that rubber can tear allowing the outer ring to turn, so the timing mark no longer matches TDC.

But the mark on the crank sprocket isn't going anywhere, so the most positive test is to set the harmonic balancer to point at TDC, remove it (and the cover) without turning the crank, and check the mark on the crank sprocket. If that mark doesn't line up, replace the Harmonic Balancer.

Let me try again, did you replace the knock sensor wire?, the wire usually goes bad before the knock sensor.

Let me try again, did you replace the knock sensor wire?, the wire usually goes bad before the knock sensor.