3vze Timing Belt Job

#1

3vze Timing Belt Job

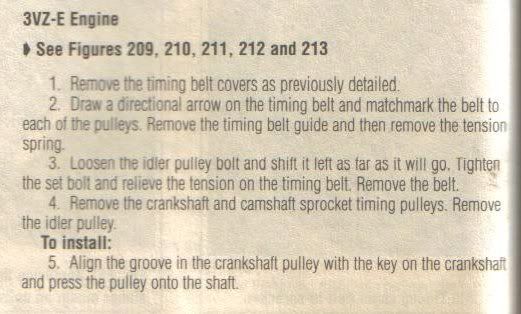

Working on my '92 4x4 3vze engine, have to replace the water pump so i have to do the whole timing belt change. Im at step 17 where you "remove timing belt tensioner" i dont see what it looks like in the picture in the FSM, so im confused about that

ALSO

at step 19 (a) Im using a tool i made from a 2x4 and some bolts as the tool, but when i turn the timing pulley, it just turns the whole crank and both cams. What am i doing wrong there?

ALSO

step 21, remove crankshaft pulley, am i really going to need those special tools? or is there another way?

Thanks for your help

Heres where im at in pictures:

ALSO

at step 19 (a) Im using a tool i made from a 2x4 and some bolts as the tool, but when i turn the timing pulley, it just turns the whole crank and both cams. What am i doing wrong there?

ALSO

step 21, remove crankshaft pulley, am i really going to need those special tools? or is there another way?

Thanks for your help

Heres where im at in pictures:

#3

Registered User

there is no need to remove the cam pulleys.make sure when you get the belt on & tensioned to turn the engine over by hand 2 full turns & make sure everything still lines up correctly.if not readjust & ck again,took me 4 tries to get mine right so dont get too tore up if its not right the first time.GOOD LUCK.you can do it!!!!!

#6

Contributing Member

Join Date: Oct 2002

Location: Charlotte, North Carolina

Posts: 1,661

Likes: 0

Received 0 Likes

on

0 Posts

You will need to remove the crank pulley to get the lower timing cover off and out of the timing belt's way.

Couple of thoughts on removing the crank pulley:

If your truck is a manual, you can park it in gear and this should keep the crank from turning.

The wooden tool you made sounds like a good idea. If you bolt it to the crank pulley where the power steering pulley usually goes, you can use it to keep the crank from turning. Use a socket to turn the nut in the middle of the pulley. It requires 181ftlb torque to put it on, so it's going to be a pain to get it off. This is kinda how I did mine, but I used a piece of metal instead of wood.

Some folks have had good results removing the crank bolt by placing a breaker bar on the nut and the other end against the frame rail. Bump the starter, and it should break loose. I've never done this and don't recommend it, but I'm just a lot more cautious than most folks. From what I hear, you can strip the flywheel teeth, so I would try the other ideas first.

Anyways, just my $.02.

Couple of thoughts on removing the crank pulley:

If your truck is a manual, you can park it in gear and this should keep the crank from turning.

The wooden tool you made sounds like a good idea. If you bolt it to the crank pulley where the power steering pulley usually goes, you can use it to keep the crank from turning. Use a socket to turn the nut in the middle of the pulley. It requires 181ftlb torque to put it on, so it's going to be a pain to get it off. This is kinda how I did mine, but I used a piece of metal instead of wood.

Some folks have had good results removing the crank bolt by placing a breaker bar on the nut and the other end against the frame rail. Bump the starter, and it should break loose. I've never done this and don't recommend it, but I'm just a lot more cautious than most folks. From what I hear, you can strip the flywheel teeth, so I would try the other ideas first.

Anyways, just my $.02.

Last edited by DH6twinotter; 08-14-2007 at 06:30 PM.

Trending Topics

#8

Contributing Member

I just used a LONG wrench with the truck in gear then a normal pulley puller to remove it.

I didn't need any special tool for the tensioner. As I recall, it's under the cam pulley on the passenger side. The bolt is long enough to take it off and put it on safely.

I didn't need any special tool for the tensioner. As I recall, it's under the cam pulley on the passenger side. The bolt is long enough to take it off and put it on safely.

#9

Registered User

Join Date: Oct 2005

Location: Berkeley, CA

Posts: 587

Likes: 0

Received 0 Likes

on

0 Posts

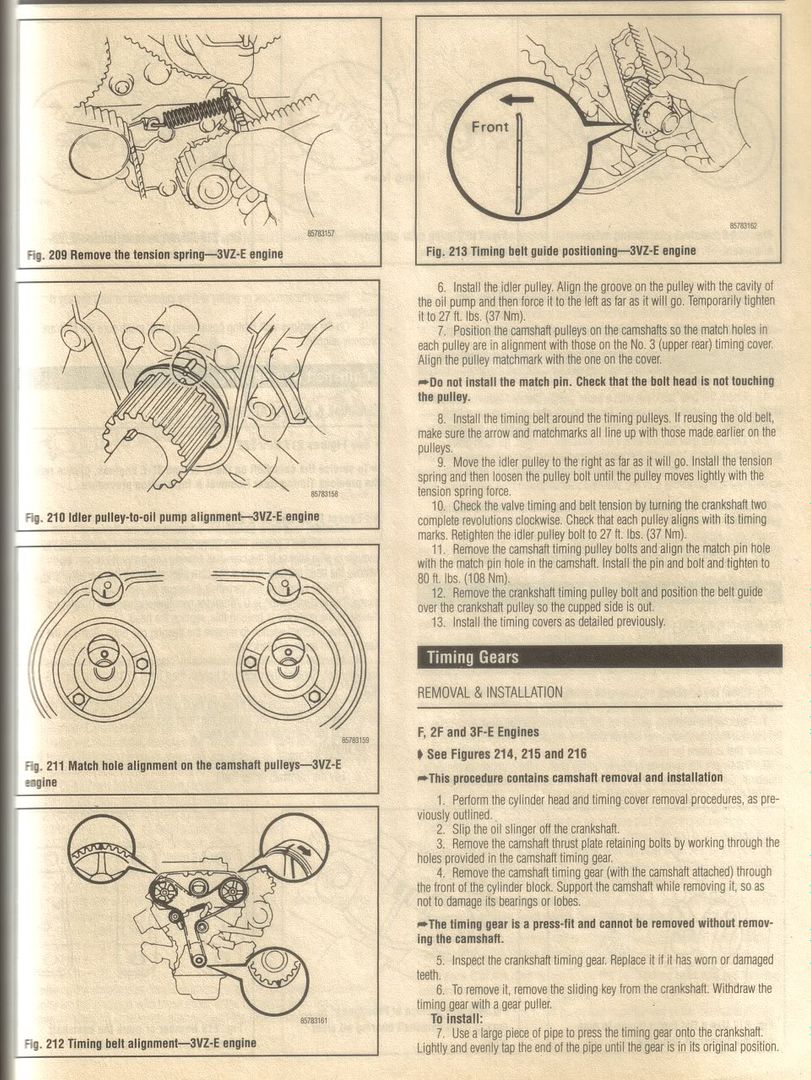

Here's a picture of the setup when I used it on the cam bolts.

Last edited by runethechamp; 08-15-2007 at 10:36 AM.

#10

Rune the champ, some people say removing the cam pulleys isn't necessary, is there an advantage? or did you do it because the manual said , or , im just trying to see if i need to remove mine.

#11

I believe that it's included in the timing belt removal instructions because it requires the same process. Then they don't have to reprint the same thing twice.

I took my right camshaft pulley off to replace the camshaft seal. Other than that or pulley damage, I would skip it. You need a tool to hold the pulley while you torque that bolt to 80 ft.lbs. too.

I took my right camshaft pulley off to replace the camshaft seal. Other than that or pulley damage, I would skip it. You need a tool to hold the pulley while you torque that bolt to 80 ft.lbs. too.

#12

Contributing Member

Join Date: Oct 2002

Location: Charlotte, North Carolina

Posts: 1,661

Likes: 0

Received 0 Likes

on

0 Posts

Yeah, there is no need to remove the cam sprockets. Just leave them on unless you plan on replacing the seals.

lol...yeah, no kidding. First time I took my crank bolt off and it made that snap, I thought I broke the bolt and left part of it still in the crank.

#15

Registered User

Join Date: Oct 2005

Location: Berkeley, CA

Posts: 587

Likes: 0

Received 0 Likes

on

0 Posts

I loosened mine with the engine in the car since I'm doing a complete rebuild. It makes it a lot easier to get them loose that way.

#16

with the truck in gear, the pulley still turns, i guess the clutch is slipping. The Toyota dealership around here doesn't rent tools... Youre supposed to keep the crank at '0' when you remove the pulley right? How am i going to get that off?!

#17

Registered User

Join Date: Oct 2005

Location: Berkeley, CA

Posts: 587

Likes: 0

Received 0 Likes

on

0 Posts

It seemed to turn at first for me too, but then I put it in 5th gear and it worked like a charm.

#18

Put the truck in third gear, works much better, harder to turn engine.

Put PB Blaster on every bolt you are going to loosen the day before and many more times before the loosening event.

I used a 3/4" breaker bar, impact socket and floor jack handle to break crank bolt loose. Yes, they snap when they loosen.

Keep trying, it will loosen. No need to remove cam sprockets unless you are planning on replacing cam seals. If they are not leaking, leave them alone.

My $0.02

Put PB Blaster on every bolt you are going to loosen the day before and many more times before the loosening event.

I used a 3/4" breaker bar, impact socket and floor jack handle to break crank bolt loose. Yes, they snap when they loosen.

Keep trying, it will loosen. No need to remove cam sprockets unless you are planning on replacing cam seals. If they are not leaking, leave them alone.

My $0.02

#19

I made a tool using the PS pulley as a template. I bolted it to the crank pulley using the bolts from the PS pulley. The way i drilled the holes, it the tool rests against the frame, so that the crank will stay at the 0 mark on the no 1 cover. Im not sure if that even matters since its keyed and you can just put it back there when you put the pulley back on. It worked great! pic:

#20

Nice!

Equally useful for getting that thing torqued back on there to 180 ft.lbs.

I bet you'll figure out how to make your own puller like I did too.

Equally useful for getting that thing torqued back on there to 180 ft.lbs.

I bet you'll figure out how to make your own puller like I did too.

Last edited by MudHippy; 08-16-2007 at 03:54 PM.

what about the crankshaft pulley?

what about the crankshaft pulley?