1986 4Runner 22RE rough idle, rich, no power

#61

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

I still have not been able to reply to some of the previous post. I'll get there.  . I decided to test out my splicing and soldering skills. I'm a little rusty. Plus I had to see if my hand-me-down soldering gun worked. I did everything except the dialetric (sp) grease, could I use regular grease?

. I decided to test out my splicing and soldering skills. I'm a little rusty. Plus I had to see if my hand-me-down soldering gun worked. I did everything except the dialetric (sp) grease, could I use regular grease?

I couldn't get my macro to focus, but you get the idea. Heres the start. This is on a test piece.

The soldier

The shrink wrap.

I also called 2 people local that deal in used yota parts. One guy is checking and the other has not returned my call yet.

On to more checks oh yeah here is the block off on the EGR.

Forgot to mention that the charcoal canister makes a gurguling sound when the engine is shut off. I did swap it to the 89 and now it makes that sound on the 89. Here is a pic for the heck of it. The sound seems to have transferred to the 89.

. I decided to test out my splicing and soldering skills. I'm a little rusty. Plus I had to see if my hand-me-down soldering gun worked. I did everything except the dialetric (sp) grease, could I use regular grease?

. I decided to test out my splicing and soldering skills. I'm a little rusty. Plus I had to see if my hand-me-down soldering gun worked. I did everything except the dialetric (sp) grease, could I use regular grease?I couldn't get my macro to focus, but you get the idea. Heres the start. This is on a test piece.

The soldier

The shrink wrap.

I also called 2 people local that deal in used yota parts. One guy is checking and the other has not returned my call yet.

On to more checks oh yeah here is the block off on the EGR.

Forgot to mention that the charcoal canister makes a gurguling sound when the engine is shut off. I did swap it to the 89 and now it makes that sound on the 89. Here is a pic for the heck of it. The sound seems to have transferred to the 89.

#63

Registered User

How can you tell he didn't tin the wires? Because they're not tinned all the way to the wire jacket? Also, since you're going to comment on what Alan's done and offer criticism.......constructive as it may be intended, why not offer some words of advice on how it could be done? Just sayin'.......

#64

Registered User

Alan, it's funny you should mention the purge canister gurgling. I meant to ask you how functional that thing was when I'd posted on routing your vac lines at the TB.

Here's a good link about it...

http://www.autoshop101.com/forms/h62.pdf

I worked late and don't have time to add any more input. But, I'll be back.

Here's a good link about it...

http://www.autoshop101.com/forms/h62.pdf

I worked late and don't have time to add any more input. But, I'll be back.

#65

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

It's the Bosch sensors in particular that can cause trouble, at least on the later series of trucks with 4-wire sensors. See: https://www.yotatech.com/forums/f116.../#post51462256

Given the known problems with the Bosch sensors, and since the O2 sensor is the main feedback to the computer on mixture, I think it would be worth a try to swap in a Denso. Here's a promo code for 10% off on sparkplugs dot com that may work: "DEN1NOE" Or get the part number from there or densoproducts dot com and search for denso and the part # on Amazon.

I doubt that the pressure regulator is supposed to be connected directly to vacuum. I'll bet there is supposed to be a vsv in the loop - maybe the one that green-black wire used to connect to. Hopefully a couple of the guys with 85-88 22REs will be able to tell you if that's correct.

The effect of vacuum on the regulator is to reduce fuel pressure by 6 - 7 pounds. On the vehicles with a vsv the ecu only applies vacuum at idle, and I think not all the time at idle, I think only when hot. I have no idea if your series of truck has the same set-up, but it appears that the vacuum will cause your fuel pressure (if return line not clogged & regulator good) to be in the range of 27-31 psi. That seems very low, especially for higher rpm. Strange; if true I would think it would cause a lean condition, but maybe the ecu is doing something freaky.

Hopefully someone will check & post.

And good idea to check spark, and to clean and solder those splices.

Hang in there, you'll get it.

Given the known problems with the Bosch sensors, and since the O2 sensor is the main feedback to the computer on mixture, I think it would be worth a try to swap in a Denso. Here's a promo code for 10% off on sparkplugs dot com that may work: "DEN1NOE" Or get the part number from there or densoproducts dot com and search for denso and the part # on Amazon.

I doubt that the pressure regulator is supposed to be connected directly to vacuum. I'll bet there is supposed to be a vsv in the loop - maybe the one that green-black wire used to connect to. Hopefully a couple of the guys with 85-88 22REs will be able to tell you if that's correct.

The effect of vacuum on the regulator is to reduce fuel pressure by 6 - 7 pounds. On the vehicles with a vsv the ecu only applies vacuum at idle, and I think not all the time at idle, I think only when hot. I have no idea if your series of truck has the same set-up, but it appears that the vacuum will cause your fuel pressure (if return line not clogged & regulator good) to be in the range of 27-31 psi. That seems very low, especially for higher rpm. Strange; if true I would think it would cause a lean condition, but maybe the ecu is doing something freaky.

Hopefully someone will check & post.

And good idea to check spark, and to clean and solder those splices.

Hang in there, you'll get it.

On my '86, all the VSV's.....FPR and A/C......have two wires. A hot and ground. Later models than atleast '86 were equipped with also a VSV for the EGR. I can't comment on how many wires would go to it, but I bet it's a safe guess two considering how they work. Nevertheless, no concern for you since you wouldn't have an EGR VSV. But, you should have a vac line between the FPR and VSV for it. If you don't have a fuel pressure up switching valve for the '86, you should. I could swear I saw one in one of the first pics you supplied on the first page of your thread here????

Anyway, link.....

See pages 8,9, and 10.....

http://www.autoshop101.com/forms/h22.pdf

Now, what's the concern with the throttle dampener? As long as the end of that filter looking thing is open to the atmosphere, the tube is connected to the dashpot, and only a minute amount of air.......if you blow through it....is able to pass, it's fine. IOW, it's only function is to slow down the throttle plate closing by providing some air resistance. The only concern I'd have is if that hole in the intake was/is sealed really well.

I'll go out and look on my '86 as to how the FPR lines are routed. I don't recall offhand. My photographic memory has too many nudie pics downloaded.....hehe. Hoggin' up RAM, as it were...... <<<<<<KIDDING!!!>>>

<<<<<<KIDDING!!!>>>

Anyway, link.....

See pages 8,9, and 10.....

http://www.autoshop101.com/forms/h22.pdf

Now, what's the concern with the throttle dampener? As long as the end of that filter looking thing is open to the atmosphere, the tube is connected to the dashpot, and only a minute amount of air.......if you blow through it....is able to pass, it's fine. IOW, it's only function is to slow down the throttle plate closing by providing some air resistance. The only concern I'd have is if that hole in the intake was/is sealed really well.

I'll go out and look on my '86 as to how the FPR lines are routed. I don't recall offhand. My photographic memory has too many nudie pics downloaded.....hehe. Hoggin' up RAM, as it were......

<<<<<<KIDDING!!!>>>

<<<<<<KIDDING!!!>>> So the VSV on the FPR is still an open item.

So the VSV on the FPR is still an open item.I'll check that link out.

The only concern on the dampner is the orientation of it. I'm 99% sure it's not an issue just something bugging me.LOL

Oh, and the deal with the Bosch O2 sensors on the early 22re's with the sensor mounted on the manifold is that circular lip on the underside of the mating flange is too large for the port in the manifold. Atleast, that's what I found when I tried to install one of them on mine a while back. The flange bowed over and didn't give a good seal allowing atmospheric O2 into the exhaust. There is speculation, and probably some good evidence, that the Bosch sensor probe is too short to accurately sample the exhaust mix, but I have a friend who claims it shouldn't be an issue and that there is enough turbulance in the exhaust to reach the probe sufficiently. I'm leaning towards the idea that Bosch is just not good, but until I do some further expiramenting on my own vehicles and prove it to myself (even after testimony from the local dealer and head tech) I'm not 100% convinced. What can I say? I'm stubborn....lol!

One more thing....

Do you have a vacuum tool? You know.....one of those little pumps that hook up to vac lines? Well, even if you don't, here's what I'd do with the EGR for now:

Either pump the EGR vac line until the valve closes or suck through it and clamp it off quickly and, then, see if the EGR bleeds off. This will tell you if the diaphragm leaks. If it doesn't, temporarily block the vac line with a BB so that it will remain shut. This will temporarily eliminate the EGR from your troubleshooting until you can work out all the other details. I think optimally you should have the EGR operational.....emissions testing aside, but it won't pose any problems while your getting other things working.

Do you have a vacuum tool? You know.....one of those little pumps that hook up to vac lines? Well, even if you don't, here's what I'd do with the EGR for now:

Either pump the EGR vac line until the valve closes or suck through it and clamp it off quickly and, then, see if the EGR bleeds off. This will tell you if the diaphragm leaks. If it doesn't, temporarily block the vac line with a BB so that it will remain shut. This will temporarily eliminate the EGR from your troubleshooting until you can work out all the other details. I think optimally you should have the EGR operational.....emissions testing aside, but it won't pose any problems while your getting other things working.

Okay, last thing until I get the FPR info for you......

Did you check the PCV valve? And, you really oughtta check the valve adjustments and square them away. If the valves are too tight, it's just going to make it harder to know how much better the motor's running when you have other things working right. And, AND.....you probably need to get a new ECU soon.

Did you check the PCV valve? And, you really oughtta check the valve adjustments and square them away. If the valves are too tight, it's just going to make it harder to know how much better the motor's running when you have other things working right. And, AND.....you probably need to get a new ECU soon.

I'M REALLY SORRY you're dealing with this, but you can do it, Alan! Man, .....I have to say, not sure if I'm right, but seeing that this guy did NOT take much care with keeping to specs or at least OE with things....It really bothers me that your compression is so high, unless this motor is 30 Miles old and has special KRYPTONITE RINGS and PISTONS and DIAMOND PLATED VALVES FROM CRAB NEBULA! My rebuild is pretty tight, and I'm pushing 168 Pretty much across the board, almost all Rock Parts, ....180?????? I know someone has mentioned that as being high, but it just seems REALLY high, especially the way it's running. Could it be, just maybe, that The bind in the holes is SO TIGHT that it's forcing oil or unburned fuel past the eshaust valves and back through the intake valves(Backfiring)? Also, could it be that it's not just rich, but also OIL that's carbonizing in that RED HOT EXHAUST, coming out of a RED HOT head due to things just being, well, TOO tight? VALVES WAY OFF? Just trippin on some of the issues you're having...I'll keep checking in, but you've got GOOD guys helping you. I'm just adding things as they come to me that I've seen with other vehicles-not necessarily Toys in all cases.

Sorry if I'm missing posts beyond this....If I've doubled up on something, oh well, right? YOU HAVE A LIST! hahaha.

hahaha.

Sorry if I'm missing posts beyond this....If I've doubled up on something, oh well, right? YOU HAVE A LIST!

hahaha.

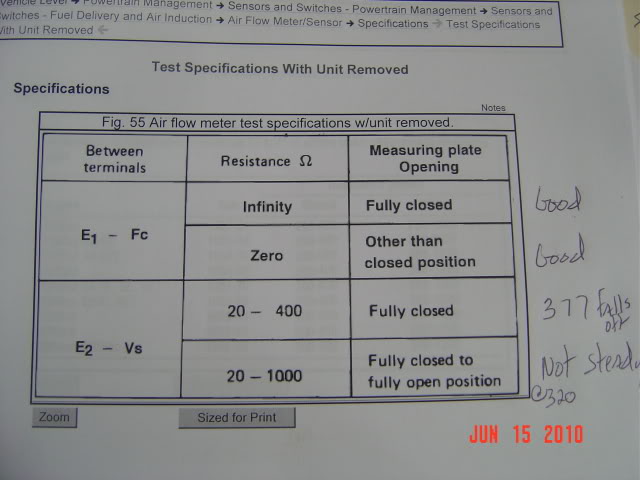

hahaha. THW resistance at the ECU is high range .2-.4 @176* reading .813 on a warm engine.

THW voltage at ECU range .25-2.5 @176* reading 1.42 on warm engine seems to be ok.

VS voltage at ECU are within range but the values fall off slowly the longer the meter stays hooked up.

I hope to get some time to look at your build some more, I browsed thru it pretty quick to see alll that you have done. You've done some very nice work.

The list will really help in a situation like this.

If you only knew how mad I am at myself for getting into this situation. I couldn't see it coming.

Okay, you'll learn if you read the autoshop link, but the fuel pressure up valve/VSV is for creating more fuel pressure under hot soak conditions. It's a good thing to have! But, the line........it runs from the FPR to the VSV and then to the three way on your plenum....where it's bolted off.

The only thing that single wire could be for is the temp switch that would otherwise be on the top of the thermo housing. You're truck should have one, but apparently someone.....for whatever reason......swapped out. No biggy. The temp switch would be there for a reason, but I forget why right now. It's not the source of your issues, though. I think the ECU's going to be a big one, though, if your finding out of spec areas.

Oh....that crimped steel vac line, if it's not for the EGR, is probably for the fuel evap canister. Look on you throttle body for the "P" port. See if there's a hose there. If there is, see if it's running to the evap can. If not, you can bypass that hard line a run a solid right to the can. The other two ports on the TB would be for the EGR modulator.........I do believe. Like I said, mine's gone now, so not sure.

The only thing that single wire could be for is the temp switch that would otherwise be on the top of the thermo housing. You're truck should have one, but apparently someone.....for whatever reason......swapped out. No biggy. The temp switch would be there for a reason, but I forget why right now. It's not the source of your issues, though. I think the ECU's going to be a big one, though, if your finding out of spec areas.

Oh....that crimped steel vac line, if it's not for the EGR, is probably for the fuel evap canister. Look on you throttle body for the "P" port. See if there's a hose there. If there is, see if it's running to the evap can. If not, you can bypass that hard line a run a solid right to the can. The other two ports on the TB would be for the EGR modulator.........I do believe. Like I said, mine's gone now, so not sure.

It appears to be run directly to the plenum in the diagram, yes. All I can say is my '86 is bone stock and has one..........a FPU system, that is. In the link I posted, the autoshop article states the FPU is used "many" engines......which to me would mean it may have not been used on all engines. In which case, it could mean it may not be entirely necessary. But, then again, the design differences between engines may dictate whether it's necessary or not. If I were to make an educated guess, as long as you're getting consistent and adequate fuel pressure via the FPR, the VSV may not be needed at this point and/or not part of your problem.

Gotta go. Later......

Gotta go. Later......

Both the 85 and 88 FSMs seem to show the fuel pressure going DOWN when vacuum is attached, not up. Look in the Fuel Injection - Fuel Pump section for the pressure test specs. Fuel pressure should be 33-38 psi with no vacuum, and 27-31 psi with vac attached.

Compare to the 89 and later 22REs which should be 38-44 psi with no vac and 33-37 w/vac.

I still believe there should be a vsv in the vac line from FPR to plenum, otherwise, why use vac at all? You could just use a lower pressure regulator. I wouldn't stake too much by that diagram - it is very simplified in many areas.

Compare to the 89 and later 22REs which should be 38-44 psi with no vac and 33-37 w/vac.

I still believe there should be a vsv in the vac line from FPR to plenum, otherwise, why use vac at all? You could just use a lower pressure regulator. I wouldn't stake too much by that diagram - it is very simplified in many areas.

Here's what I came up with on alldata

Disconnect the vacuum sensing hose from the pressure regulator and plug it off.

Measure the fuel pressure at idling. Fuel pressure: 2.3 - 2.7 kg/cm2 (33 - 38 psi, 226 - 265 kPa)

Reconnect the vacuum sensing hose to the pressure regulator.

Measure the fuel pressure at idling. Fuel pressure: 1.9 - 2.2 kg/cm2 (27 - 31 psi, 186 - 216 kPa) If no pressure, check the vacuum sensing hose and pressure regulator.

Stop the engine. Check that the fuel pressure remains above 1.5 kg/cm2 (21 psi, 147 kpa) for 5 minutes after the engine is turned off. If not within specification, check the fuel pump, pressure regulator and/or injectors.

Optimally, yeah....there should be. But, I don't think it's going to be a problem until the engine sees regular operating conditions. IOW, it's barely running, yet. So, a last thing on the list sorta thing, I'd say. The FPU valve need only operate and does only operate under hot soak starting conditions allowing only a certain amount of atmospheric air (a controlled vacuum leak, as it were) into the regulator to prevent fuel vapor formation and for only up to two minutes after cranking. The ECU energizes it via input from the THW and STA signals. I'm not real sure it has any function when under heavy loads considering the '86 model ECU doesn't have the set up necessary to operate it at that point. Not that I could tell, anyway. I looked, but I've been wrong before. I'm inclined to believe it's not until later models that that function was available or maybe even just on different engines other than the 22re.

I'm just tossin in while you wait for the more experienced YotaTechies...

Are the readings on the unit's you're testing against the ECU coming out ok, but not really on the ECU tests? I see you're swapping things back, but I'm a lil confused now as to what you're putting back....are they metering out ok, just not performing due to what you think might be wiring or ECU issues?

Seems more of the Back East side Trucks more often have issues with the Harness, etc., ...at least from what I've read, ..due to humidity and cold and then hot as heck, etc., right? lol. Can you get it to a yard that has an ECU you could swap out with? Most of the yards near me, if they have one, say "come on in and try it if it's running enough to get here...if it works, great, if not, try something else and let me know and I'll see if I have it"....Not much available to you, I think you said, right?

Don't get me wrong, I'm not saying "it's probably what I was dealing with", or even that it's bad wiring in the harness. Neither am I suggesting you just start swapping out things at the yards near you. Just a thought...maybe you could rule it out if you tried a couple known working ones and then have no/much change, ya know?

I'll be watching for the Thook, Flecker and so on responses....Hope you're almost there, bud!

Are the readings on the unit's you're testing against the ECU coming out ok, but not really on the ECU tests? I see you're swapping things back, but I'm a lil confused now as to what you're putting back....are they metering out ok, just not performing due to what you think might be wiring or ECU issues?

Seems more of the Back East side Trucks more often have issues with the Harness, etc., ...at least from what I've read, ..due to humidity and cold and then hot as heck, etc., right? lol. Can you get it to a yard that has an ECU you could swap out with? Most of the yards near me, if they have one, say "come on in and try it if it's running enough to get here...if it works, great, if not, try something else and let me know and I'll see if I have it"....Not much available to you, I think you said, right?

Don't get me wrong, I'm not saying "it's probably what I was dealing with", or even that it's bad wiring in the harness. Neither am I suggesting you just start swapping out things at the yards near you. Just a thought...maybe you could rule it out if you tried a couple known working ones and then have no/much change, ya know?

I'll be watching for the Thook, Flecker and so on responses....Hope you're almost there, bud!

The only other thing I have checked by itself was the pickup coil on the dizzy and shoed 172

I'm not able to drive it yet. So I can't drive it to a yard. Plus we don't have but one yard within 20 miles from me. I live in a town that time forgot. LOL

Alan, it's funny you should mention the purge canister gurgling. I meant to ask you how functional that thing was when I'd posted on routing your vac lines at the TB.

Here's a good link about it...

http://www.autoshop101.com/forms/h62.pdf

I worked late and don't have time to add any more input. But, I'll be back.

Here's a good link about it...

http://www.autoshop101.com/forms/h62.pdf

I worked late and don't have time to add any more input. But, I'll be back.

#66

Registered User

Join Date: May 2010

Location: Kingsland, GA

Posts: 90

Likes: 0

Received 0 Likes

on

0 Posts

How can you tell he didn't tin the wires? Because they're not tinned all the way to the wire jacket? Also, since you're going to comment on what Alan's done and offer criticism.......constructive as it may be intended, why not offer some words of advice on how it could be done? Just sayin'.......

If he has questions he will ask, or google them.

You know when you are doing something right, you don't know when you are screwing up. I'm much harsher to my students.

#67

Registered User

Join Date: May 2010

Location: Kingsland, GA

Posts: 90

Likes: 0

Received 0 Likes

on

0 Posts

Kind of. Tinning is where you coat the wires you are using with solder individually. To get that, people sometimes use flux. It helps concentrate the heat, bending wire helps too.

http://video.google.com/videoplay?do...1670041105097#

http://video.google.com/videoplay?do...1670041105097#

Last edited by barrel roll; 06-15-2010 at 08:07 PM.

#68

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

EDIT: I just saw you posted a clip I'll watch it. Thanks

#69

Registered User

iTrader: (5)

Barrel Roll ,......THANK YOU, ...that was very helpful and will be VERY useful to me in the next couple days. I'm going to be attempting to reconnect a shielded wire from harness to the connector of my 02 Sensor connector(harness side), ....The OEM Denso O2 is already shielded, so I WONT BE TOUCHING THAT ONE! LOL.

Sorry Alan....didn't mean to highjack, ...just wanting to give Props to Barrel for the Vid

I'm watching, Alan, ...just nothing helpful to add at the moment.....Especially being EX-FREAKIN-HAUSTED! lol. Trying to keep up, though, in case I see that 'somethin' that I might be able to add a nugget to.

Sorry Alan....didn't mean to highjack, ...just wanting to give Props to Barrel for the Vid

I'm watching, Alan, ...just nothing helpful to add at the moment.....Especially being EX-FREAKIN-HAUSTED! lol. Trying to keep up, though, in case I see that 'somethin' that I might be able to add a nugget to.

#70

Registered User

Good thing soldering is easy, Alan. You could use some easy 'bout now, I'd say...lol.

(Okay.....I have a few minutes, then need to finish feeding birds)

As for the FPR and the VSV, they are two different items. But, like I said, don't worry about the switching valve until you can get the thing running. The FPR simply needs vacuum from the manifold to operate the internal spring loaded diaphragm to keep the pressure at a constant above manifold pressure. Hooking it directly to the plenum will suffice for that. One way to look at it is that it essentially is anyway were the switching valve in line between the FPR and plenum. It's just under certain conditions the switching valve opens to allow more air into the regulator to increase fuel rail pressure to maximum. Hope that makes sense.

A long story in short that will give you an idea that things could be worse and it's not that bad......

A friend gave my wife her '92 4rnr/3vze. The motor had been rebuilt. Once in our possession and at around 21k, the motor blew. Crank wobbled all over the place and dumped all the oil out the front seal. Spun a bearing, threw a rod....something like that. Bought a newly rebuilt motor. It ran poorly. After chasing down one thing after the other.....very long process.....discovered the motor burned a valve. Okay....had to rebuild the top end. Fortunately, the heads from the original 21k POS were still good and the bottom end of the newly rebuilt was all good. So, slapped it all together........a painful learning process, that was........and now it runs great. This was two motors than died because the previous persons did not do it right. (Someone else's mess!!) First, was the bottom end. Second, the fellow didn't follow the cam installation process correctly and cracked cam lobes sending metal into the rest of the head assemblies......hence the valve stuck and burned. So, I guess what I'm trying to say is atleast you're not rebuilding.........yet...lol!!! I don't see you having to that, though. I'm just kidding.

Last edited by thook; 06-15-2010 at 08:53 PM.

#71

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

Barrel Roll ,......THANK YOU, ...that was very helpful and will be VERY useful to me in the next couple days. I'm going to be attempting to reconnect a shielded wire from harness to the connector of my 02 Sensor connector(harness side), ....The OEM Denso O2 is already shielded, so I WONT BE TOUCHING THAT ONE! LOL.

Sorry Alan....didn't mean to highjack, ...just wanting to give Props to Barrel for the Vid

I'm watching, Alan, ...just nothing helpful to add at the moment.....Especially being EX-FREAKIN-HAUSTED! lol. Trying to keep up, though, in case I see that 'somethin' that I might be able to add a nugget to.

Sorry Alan....didn't mean to highjack, ...just wanting to give Props to Barrel for the Vid

I'm watching, Alan, ...just nothing helpful to add at the moment.....Especially being EX-FREAKIN-HAUSTED! lol. Trying to keep up, though, in case I see that 'somethin' that I might be able to add a nugget to.

#72

Registered User

If this helps, the wire on the sensor is shielded. Coaxial, I believe it's called. Unless your sensor is spliced in with bunk wire, yours would/should be too even if it's a Bosch. They come like that.

#73

Registered User

iTrader: (5)

Hahahaha, even if it's a Bosch, lol.

Alan, Thook, I only mentioned that in relation to my issue, ...sorry. See, I have the LCE Header, ....it takes the 02 location back quite a bit on the pipe, so they provide a wire to splice in and extend the O2 wire from harness to connector(harness side). The wire they provide is NOT shielded, so, while it could provide power to my 02, and while it's ground by the bolts to the pipe....it's now got a large section of wire, about 3-4', where there is no shielding, ......thus, NOISE! This noise created by not having the shielding(which I believe is also a backup ground, Thook?) may or may not be contributing to my 02 code with a brand new 02 Sensor...but I'm really just wanting to do it right to bring it back to specs. My code doesn't seem to go off until I throttle up during warm up, even right away when starting it up cold. The Noise created by not having shielding could be setting off my ECU...but it may not, we'll see.

I, like you, just want to do it right, is my point. Sorry for the confusion and rambling, lol.

Alan, Thook, I only mentioned that in relation to my issue, ...sorry. See, I have the LCE Header, ....it takes the 02 location back quite a bit on the pipe, so they provide a wire to splice in and extend the O2 wire from harness to connector(harness side). The wire they provide is NOT shielded, so, while it could provide power to my 02, and while it's ground by the bolts to the pipe....it's now got a large section of wire, about 3-4', where there is no shielding, ......thus, NOISE! This noise created by not having the shielding(which I believe is also a backup ground, Thook?) may or may not be contributing to my 02 code with a brand new 02 Sensor...but I'm really just wanting to do it right to bring it back to specs. My code doesn't seem to go off until I throttle up during warm up, even right away when starting it up cold. The Noise created by not having shielding could be setting off my ECU...but it may not, we'll see.

I, like you, just want to do it right, is my point. Sorry for the confusion and rambling, lol.

#74

Registered User

Join Date: May 2010

Location: Kingsland, GA

Posts: 90

Likes: 0

Received 0 Likes

on

0 Posts

#75

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

Hahahaha, even if it's a Bosch, lol.

Alan, Thook, I only mentioned that in relation to my issue, ...sorry. See, I have the LCE Header, ....it takes the 02 location back quite a bit on the pipe, so they provide a wire to splice in and extend the O2 wire from harness to connector(harness side). The wire they provide is NOT shielded, so, while it could provide power to my 02, and while it's ground by the bolts to the pipe....it's now got a large section of wire, about 3-4', where there is no shielding, ......thus, NOISE! This noise created by not having the shielding(which I believe is also a backup ground, Thook?) may or may not be contributing to my 02 code with a brand new 02 Sensor...but I'm really just wanting to do it right to bring it back to specs. My code doesn't seem to go off until I throttle up during warm up, even right away when starting it up cold. The Noise created by not having shielding could be setting off my ECU...but it may not, we'll see.

I, like you, just want to do it right, is my point. Sorry for the confusion and rambling, lol.

Alan, Thook, I only mentioned that in relation to my issue, ...sorry. See, I have the LCE Header, ....it takes the 02 location back quite a bit on the pipe, so they provide a wire to splice in and extend the O2 wire from harness to connector(harness side). The wire they provide is NOT shielded, so, while it could provide power to my 02, and while it's ground by the bolts to the pipe....it's now got a large section of wire, about 3-4', where there is no shielding, ......thus, NOISE! This noise created by not having the shielding(which I believe is also a backup ground, Thook?) may or may not be contributing to my 02 code with a brand new 02 Sensor...but I'm really just wanting to do it right to bring it back to specs. My code doesn't seem to go off until I throttle up during warm up, even right away when starting it up cold. The Noise created by not having shielding could be setting off my ECU...but it may not, we'll see.

I, like you, just want to do it right, is my point. Sorry for the confusion and rambling, lol.

I took last night off in the shop but looked on car-part.com and found several ECU's for sale. I called on 2 today that were fairly close. One yard said you don't want this one...........Why even list it

The other yard didn't have one. HAs anybody used a ECU rebuilder service?

The other yard didn't have one. HAs anybody used a ECU rebuilder service?Here is the AFM pic I failed to post the other night.

Got the Denso O2 today and installed it with no change. I forgot to unhook the battey to reset the computer. I'll do that tonight and wil let it get up to temperature.

I also pulled a plug wire and put a plug in it to check spark. It was jumping about an inch.

Here is some comparision shots of the O2's

From left to right: old one, Bosch, Denson. Notice the exhaust maks on the Bosch. It was tight, but still leaked.

The next pic shows the Bosch on the bottom notice the ring under the flange. I believe Thook had mentioned this before. My spark plugs look like the bosch O2 LOL

#76

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

I unhooked the battery to clear memory. Then ran it up to temp. It's better at times, but for the most part it's still the same. Also started throwing code 5 after warm up. I believe that is the O2, but can't remember for sure. I'll have to check.

I decided to open up the computer to see what I can find. Looks like some one has already tried to get it open. Two screws heads were striped. And the cover had been folded back at one time. I had to fold it back as well to look inside.

There wasn't any signs on contamination from water other than some of the screws had a white powder corrosion. I really don't know much about circuit boards except to look for burnt spots. The only thing I found of interest is the same looking white powder coming from this black rectangle looking things. You can see the white stuff in the pic. I can see the white stuff goes up under it and wraps around several of the post.

I decided to open up the computer to see what I can find. Looks like some one has already tried to get it open. Two screws heads were striped. And the cover had been folded back at one time. I had to fold it back as well to look inside.

There wasn't any signs on contamination from water other than some of the screws had a white powder corrosion. I really don't know much about circuit boards except to look for burnt spots. The only thing I found of interest is the same looking white powder coming from this black rectangle looking things. You can see the white stuff in the pic. I can see the white stuff goes up under it and wraps around several of the post.

Last edited by Alan's Classic; 06-18-2010 at 03:35 AM.

#77

Registered User

Code 5 is O2.

That white powder is corrosion. I suppose you could try cleaning it with some electronic cleaner, but I wouldn't get my hopes up. I'd be surprised if it helped.

You're doing great work, Alan. Keep it up.

That white powder is corrosion. I suppose you could try cleaning it with some electronic cleaner, but I wouldn't get my hopes up. I'd be surprised if it helped.

You're doing great work, Alan. Keep it up.

#78

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

I got what In thought was a fuel pressure gauge it turns out to be an auto trans and engine oil pressure tester. That fact doesn't concern me, it's still a pressure gauge right? What concerns me is the range is 0-400. It's hard to read in the low range and just how acurate is it in the low range? Should I trust these readings??

I tested it anyway and with the FPR vac hose disconnected it reads 40psi the best I can tell. The range is 33-38.

Then I hooked up the vac line and it was 34psi. The range is 27-31.

This pic was taken after I shut the engine off.

I removed the hard line to the cold start and connected the gauge to the fuel rail.

#79

Registered User

iTrader: (5)

DANG ALAN! YOU'RE ATTACKING THIS THING! LOL.....Hmmm, seems familiar to me, for some reason. GREAT right up and even better following of instructions and suggestions! Hmmmm, .......

A long time Toy Mechanic said that the Damper is more common to go out than the FPR, but it's a toss up with these things and we have to ELIMINATE things, rather than guess, ..I know, lol. He also said the VSV can have an effect as it switches vacuum at times to the FPR, and if it's not operating properly, I guess his greek that followed meant that it can not close the FPR like it's supposed to. Just throwing it out there. Good luck on the ECU, ...wouldn't that be nice, eh?

Best Wishes, Alan,

Mark

A long time Toy Mechanic said that the Damper is more common to go out than the FPR, but it's a toss up with these things and we have to ELIMINATE things, rather than guess, ..I know, lol. He also said the VSV can have an effect as it switches vacuum at times to the FPR, and if it's not operating properly, I guess his greek that followed meant that it can not close the FPR like it's supposed to. Just throwing it out there. Good luck on the ECU, ...wouldn't that be nice, eh?

Best Wishes, Alan,

Mark

#80

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

DANG ALAN! YOU'RE ATTACKING THIS THING! LOL.....Hmmm, seems familiar to me, for some reason. GREAT right up and even better following of instructions and suggestions! Hmmmm, .......

A long time Toy Mechanic said that the Damper is more common to go out than the FPR, but it's a toss up with these things and we have to ELIMINATE things, rather than guess, ..I know, lol. He also said the VSV can have an effect as it switches vacuum at times to the FPR, and if it's not operating properly, I guess his greek that followed meant that it can not close the FPR like it's supposed to. Just throwing it out there. Good luck on the ECU, ...wouldn't that be nice, eh?

Best Wishes, Alan,

Mark

A long time Toy Mechanic said that the Damper is more common to go out than the FPR, but it's a toss up with these things and we have to ELIMINATE things, rather than guess, ..I know, lol. He also said the VSV can have an effect as it switches vacuum at times to the FPR, and if it's not operating properly, I guess his greek that followed meant that it can not close the FPR like it's supposed to. Just throwing it out there. Good luck on the ECU, ...wouldn't that be nice, eh?

Best Wishes, Alan,

Mark

I don't know if I should be mad or not. I posted an add needing an ECU for 86 4Runner PN 89661-35070. I get a call saying he has one. I drive 2.5 hours round trip to find out he had PN 89661-3D070. He said that was the number (nicely). I said no and pulled my phone out and showed him the ad. I'm starting to steam bout now. He apologized and gave me $20 for gas and then gave me a vac manifold rail next to the valve cover. It's the wrong year, but I can make it work. He was very nice and tried to offer help with my trucks issues. Needless to say I'm not any closer to the remedy. I found reman ones for $229 @ solopcms.com with a 1 year warranty. I'm pretty confident it needs a ECU, but that is a lot of coins. I hate to gamble with a used one. The one I went after today was only $40. I feel better now since I vented. LOL

I don't know if I should be mad or not. I posted an add needing an ECU for 86 4Runner PN 89661-35070. I get a call saying he has one. I drive 2.5 hours round trip to find out he had PN 89661-3D070. He said that was the number (nicely). I said no and pulled my phone out and showed him the ad. I'm starting to steam bout now. He apologized and gave me $20 for gas and then gave me a vac manifold rail next to the valve cover. It's the wrong year, but I can make it work. He was very nice and tried to offer help with my trucks issues. Needless to say I'm not any closer to the remedy. I found reman ones for $229 @ solopcms.com with a 1 year warranty. I'm pretty confident it needs a ECU, but that is a lot of coins. I hate to gamble with a used one. The one I went after today was only $40. I feel better now since I vented. LOL

You didn't tin your wires. It also looks like cold joint.

You didn't tin your wires. It also looks like cold joint.