tiny pits around cyclinder

#1

Registered User

Thread Starter

iTrader: (4)

Join Date: May 2010

Location: People's Republic of California

Posts: 720

Likes: 0

Received 15 Likes

on

12 Posts

Tiny Pits Around Cyclinder - Another Question

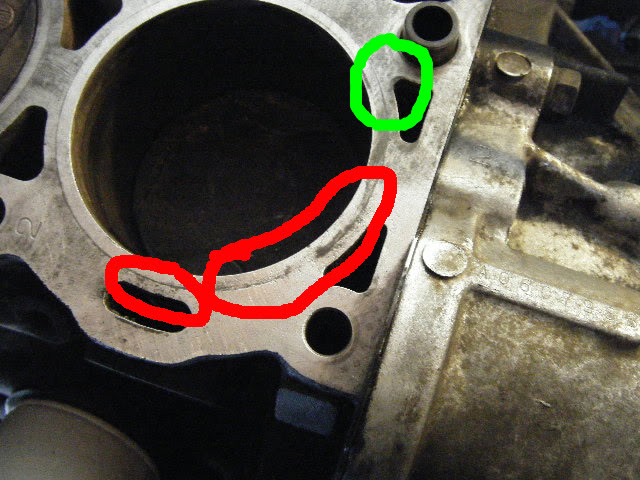

I'm replacing the head gaskets. I finally got around to cleaning off the engine side (heads were professionally done and are ready to go). This isn't my 92' 22re, but a 90' yota v6 camry, but regardless I'm sure the answer is the same no matter what.

If you look at the area where I circled in red, there are tiny pits after scraping and cleaning. Everywhere else on the block is smooth. Is that a no-go before putting the new gasket on? I've read you aren't suppose to put something down before the gasket unless the manufacturer says so, but if this is going to cause a leak is their anything I can do without removing the engine and having it fixed?

If you look at the area where I circled in red, there are tiny pits after scraping and cleaning. Everywhere else on the block is smooth. Is that a no-go before putting the new gasket on? I've read you aren't suppose to put something down before the gasket unless the manufacturer says so, but if this is going to cause a leak is their anything I can do without removing the engine and having it fixed?

Last edited by Grego92; 01-26-2011 at 06:48 PM.

#2

That is considered minor pitting due. That is natural, and was present on mine.

I spent about an hour using a scrubbing pad and higher grit sandpaper on the block deck, and it cleaned most of it up.

I remember I had the same concerns, and the *best* stuff you can use is a product called Permatex Hylomar (it gets 'painted' on the headgasket and block deck surface, and remains flexible even under combustion temperatures and pressures). Where I live, that was unavailable, so I simply used Permatex High-Tack sealant (this red tacky stuff).

Basically, this pitting is corrosion of the iron block which has occurred over time. If you can put something in there to prevent further corrosion, and can minimize the pitting on the block, really, this setup should last you another 10 or more years, considering the original setup lasted this far!

Cheers,

Yusuf

I spent about an hour using a scrubbing pad and higher grit sandpaper on the block deck, and it cleaned most of it up.

I remember I had the same concerns, and the *best* stuff you can use is a product called Permatex Hylomar (it gets 'painted' on the headgasket and block deck surface, and remains flexible even under combustion temperatures and pressures). Where I live, that was unavailable, so I simply used Permatex High-Tack sealant (this red tacky stuff).

Basically, this pitting is corrosion of the iron block which has occurred over time. If you can put something in there to prevent further corrosion, and can minimize the pitting on the block, really, this setup should last you another 10 or more years, considering the original setup lasted this far!

Cheers,

Yusuf

#3

Registered User

Thread Starter

iTrader: (4)

Join Date: May 2010

Location: People's Republic of California

Posts: 720

Likes: 0

Received 15 Likes

on

12 Posts

Thanks for the quick reply, I'll get the stuff you mentioned and keep on with the project.....unless someone has another opinion or recommendation to think about.

#5

Registered User

The pitting is due to corrosion - rust. Notice the corroded areas are near the coolant passages. At some point, the antifreeze was probably left in too long. As ethylene glycol breaks down, it forms acids. The main purpose of the corrosion inhibitors of antifreeze is to neutralize those acids. There is only a certain amount of acid neutralizing capacity (reserve alkalinity) in antifreeze. When the RA is all used up, the antifreeze turns acidic, and corrosion will form between the block and the steel fire rings of the head gasket (and elsewhere in the coolant loop). Conventional green Prestone has the least RA of any of the coolants that can be used in our engines. Two years/30k miles max - but if you combine it with tap water, that will neutralize some of the RA, or if you switch to Prestone from a different coolant type without thoroughly flushing the block, heater core, and plastic reservoir tank, then the remaining amount of the different coolant type will also neutralize some of the RA, giving less service life. Toyota Red has a different corrosion inhibiting chemistry, mainly sodium benzoate, which lasts longer and will inhibit corrosion better if left in too long (2 years or 30k miles is the recommended service life, but unlike the Prestone it will protect for a fair bit past that).

#6

The deck of the block and fire rings on the head gaskets should never come into contact with any coolant. I'm not saying that they don't ever come into contact with the coolant. I'm just saying that once they do, the head gasket failure process has begun.

#7

Why did you pull the heads? The pitting can be a big deal if it is deep enough and completly bridges an area thats supposed to seal. If in doubt take it to a machine shop and have them check it , if its bad enough( which you cant tell from the photo) you might need to resurface the block.

Trending Topics

#9

Registered User

That is true. Like this camry, the veezy has a spot near the # 1 and 6 where there's way too little distance between the coolant passage and the ring, and it doesn't take much expansion contraction and time for the gasket to be degraded enough to allow contact. I know people talk about there being movement because of the aluminum head expanding more than the iron block, but I think the main problem is that when the aluminum head expands, it squashes the head gasket enough to flatten and damage it, and after enough times of that happening, the gasket doesn't bounce back, and gaps are formed.

#10

You cant tell from this photo. I am not even looking at the area circled. Im looking slightly above it. Its not a waste of money if it saves you from having to redo the job.

Last edited by sam333; 01-15-2011 at 03:18 PM.

#11

Registered User

Thread Starter

iTrader: (4)

Join Date: May 2010

Location: People's Republic of California

Posts: 720

Likes: 0

Received 15 Likes

on

12 Posts

Thanks for the discussion guys, the engine is a 2vz-fe if you're curious. There is no other pitting besides what is circled and all other areas are smooth (luckily the other side has no issues at all.) If you see something outside the circle it's nothing, maybe dirt and the angle of the camera. I removed the heads because it was burning coolant and overheating.

I think the best option is to remove and have it done right, however, I got the car for free and it's a project car, so I am going to clean it up as much as possible and look at using some of that sealant stuff that is mentioned. If it doesn't work out, I'll let the next guy know where I likely screwed up.

I think the best option is to remove and have it done right, however, I got the car for free and it's a project car, so I am going to clean it up as much as possible and look at using some of that sealant stuff that is mentioned. If it doesn't work out, I'll let the next guy know where I likely screwed up.

Last edited by Grego92; 01-15-2011 at 04:34 PM.

#12

Having it resurfaced will just cause more troubles/issues. Always to be avoided if possible. Toyota recommends replacing the block, and NEVER having it resurfaced if there's any warpage beyond specs or significant surface flaws. Check your FSM.

What we're talking about is the area surrounded by green at the corner of that coolant passage, which is likley the reason for the area surrounded by red just below it(or vice versa). The larger one.

Which if I was to hazard a guess, was where the head gasket failed, no? If it wasn't, it would have been in the future. It had to have atleast had a small coolant leak(into that CC) going on there. What I can't tell from the pic for sure is if that's just some discoloration or if it's corroded to the point that it's no longer at deck height near the topmost corner of that passage.

Last edited by MudHippy; 01-15-2011 at 08:45 PM.

#13

Alot of Toyota FSM manuals tell you not to do any machine work if parts are out of spec, but its done sucsessfully every day( including resurfacing blocks)He has allready had problems burning coolent. So the block surface is suspect. You should also check to make sure it is flat.

If the block is to pitted or pitted in the wrong places or warped beyond limits and there is a reason that the block cant be resurfaced( material is too thin)then it should be replaced.

If the block is to pitted or pitted in the wrong places or warped beyond limits and there is a reason that the block cant be resurfaced( material is too thin)then it should be replaced.

Last edited by sam333; 01-15-2011 at 09:43 PM.

#14

We assume he's had problems burning coolant. He hasn't stated such. And I still stand by what I've said. Whatever is the problem with that block's deck surface imperfection wise, NOT warpage wise as I have no clue, can be easily mended with an engine grade epoxy(such as JB weld) and/or your choice of the various gasket sealers on the market(recommended for use near gasoline and allowing for a high temp application, probably good to atleast 300°F or higher would do).

Toyota doesn't frivolously recommend not machining anything. They have a definite reason behind stating such. If it can and should be machined, they will tell you to do so. They don't recommend ANY engine block resurfacing because you're going to change much more than the deck surface of the block by having it machined. And you could potentially need to do ALOT more machining to ALOT more parts to make the engine a correctly functioning assembly afterwards. Things like shortening the connecting rods, and/or using non-specified pistons to correct deck height. And doing so will alter the engine permanently, as the block and said parts will no longer be within stock specifications(or any specifications for that matter). Thereby making any future servicing of the engine with stock parts, or OE spec aftermarket parts, an impossibility. Though you may not change the performance qualities of the engine too drastically by doing those things, that's also a concern as well. You will absolutely have a minimal impact atleast on compression ratio, stroke length, and as previously stated deck height requirement.

Engine block deck resurfacing it not something that manufacturers consider to be a given during the engine's lifetime, or during a reconditioning. Like they do with cylinder heads. Provisions are made during the manufacturing of cylinder heads to allow for it. And generally cylinder heads can be lightly resurfaced multiple times without hindering the functionality of the engine significantly. I should also point out that head gasket designs are a reflection of this principle too. They are constructed specifically to compensate for minor imperfections in the deck's surface. They would be designed quite differently if every engine block deck were supposed to be free of any surface imperfections entirely.

Toyota doesn't frivolously recommend not machining anything. They have a definite reason behind stating such. If it can and should be machined, they will tell you to do so. They don't recommend ANY engine block resurfacing because you're going to change much more than the deck surface of the block by having it machined. And you could potentially need to do ALOT more machining to ALOT more parts to make the engine a correctly functioning assembly afterwards. Things like shortening the connecting rods, and/or using non-specified pistons to correct deck height. And doing so will alter the engine permanently, as the block and said parts will no longer be within stock specifications(or any specifications for that matter). Thereby making any future servicing of the engine with stock parts, or OE spec aftermarket parts, an impossibility. Though you may not change the performance qualities of the engine too drastically by doing those things, that's also a concern as well. You will absolutely have a minimal impact atleast on compression ratio, stroke length, and as previously stated deck height requirement.

Engine block deck resurfacing it not something that manufacturers consider to be a given during the engine's lifetime, or during a reconditioning. Like they do with cylinder heads. Provisions are made during the manufacturing of cylinder heads to allow for it. And generally cylinder heads can be lightly resurfaced multiple times without hindering the functionality of the engine significantly. I should also point out that head gasket designs are a reflection of this principle too. They are constructed specifically to compensate for minor imperfections in the deck's surface. They would be designed quite differently if every engine block deck were supposed to be free of any surface imperfections entirely.

Last edited by MudHippy; 01-16-2011 at 12:00 AM.

#15

Registered User

iTrader: (1)

Looking at it that way I am sure there has to be a limit of how much can be removed before needing to machine all the other goodies. Without looking at a bunch of numbers it is hard to say what that number might be

At which point it is far cheaper just to replace the block or depending on the age the vehicle. If one is paying to have this done.

I say use some sealer you will be good to go.

It is one thing to be doing things to your own vehicle but if you are in business this is a customers vehicle. Something like this can be tricky if they are clueless as you try and explain the options only looking at the $$$ bottom line

At which point it is far cheaper just to replace the block or depending on the age the vehicle. If one is paying to have this done.

I say use some sealer you will be good to go.

It is one thing to be doing things to your own vehicle but if you are in business this is a customers vehicle. Something like this can be tricky if they are clueless as you try and explain the options only looking at the $$$ bottom line

#16

Registered User

Thread Starter

iTrader: (4)

Join Date: May 2010

Location: People's Republic of California

Posts: 720

Likes: 0

Received 15 Likes

on

12 Posts

What do you guys think? here are some more photos. The area previously circled in green is not damaged, it must have been the angle of the camera and light. I took out a magnifying glass and went over with a razor...smooth. I think the old gasket shows also that there wasn't a leak there.

This is my first head gasket change, so I know nothing about this...At the bottom is the new one, a Fel-Pro MLS has a red (raised) bead of some sort also.

This is my first head gasket change, so I know nothing about this...At the bottom is the new one, a Fel-Pro MLS has a red (raised) bead of some sort also.

Last edited by Grego92; 01-16-2011 at 10:00 AM.

#17

I think 5 things:

1. You/me/us are right. There was a leak there, coolant and combustion/compression.

2. That's a properly blown head gasket. Kudos for not trying to guess if you have a blown head gasket, as is questioned on a daily basis around here, and going ahead and waiting untill it went. At which point, by the looks of it, it was pretty easy to tell with all the white fog coming out the tailpaipe. And the engine making that "blap,blap,blap,blap,blap" sound that goes along with compression loss on one or more cylinders. I can't stand all the "is this a blown head gasket?" threads. When it blows, you'll know.

3. The area in green not being corroded doesn't suprise me. I just couldn't tell for sure. So to correct my previous statement, it looks like the majority of the problem was at the coolant passage just below it(in the pic).

4. You're going to catch some flak for the Fel-Pro gasket. Just not from me. It'll probably work just fine, if you do a proper installation of it.

5. Pic a sealant and get to work!

1. You/me/us are right. There was a leak there, coolant and combustion/compression.

2. That's a properly blown head gasket. Kudos for not trying to guess if you have a blown head gasket, as is questioned on a daily basis around here, and going ahead and waiting untill it went. At which point, by the looks of it, it was pretty easy to tell with all the white fog coming out the tailpaipe. And the engine making that "blap,blap,blap,blap,blap" sound that goes along with compression loss on one or more cylinders. I can't stand all the "is this a blown head gasket?" threads. When it blows, you'll know.

3. The area in green not being corroded doesn't suprise me. I just couldn't tell for sure. So to correct my previous statement, it looks like the majority of the problem was at the coolant passage just below it(in the pic).

4. You're going to catch some flak for the Fel-Pro gasket. Just not from me. It'll probably work just fine, if you do a proper installation of it.

5. Pic a sealant and get to work!

Last edited by MudHippy; 07-12-2011 at 10:49 AM.

#18

We assume he's had problems burning coolant. He hasn't stated such. And I still stand by what I've said. Whatever is the problem with that block's deck surface imperfection wise, NOT warpage wise as I have no clue, can be easily mended with an engine grade epoxy(such as JB weld) and/or your choice of the various gasket sealers on the market(recommended for use near gasoline and allowing for a high temp application, probably good to atleast 300°F or higher would do).

Toyota doesn't frivolously recommend not machining anything. They have a definite reason behind stating such. If it can and should be machined, they will tell you to do so. They don't recommend ANY engine block resurfacing because you're going to change much more than the deck surface of the block by having it machined. And you could potentially need to do ALOT more machining to ALOT more parts to make the engine a correctly functioning assembly afterwards. Things like shortening the connecting rods, and/or using non-specified pistons to correct deck height. And doing so will alter the engine permanently, as the block and said parts will no longer be within stock specifications(or any specifications for that matter). Thereby making any future servicing of the engine with stock parts, or OE spec aftermarket parts, an impossibility. Though you may not change the performance qualities of the engine too drastically by doing those things, that's also a concern as well. You will absolutely have a minimal impact atleast on compression ratio, stroke length, and as previously stated deck height requirement.

Engine block deck resurfacing it not something that manufacturers consider to be a given during the engine's lifetime, or during a reconditioning. Like they do with cylinder heads. Provisions are made during the manufacturing of cylinder heads to allow for it. And generally cylinder heads can be lightly resurfaced multiple times without hindering the functionality of the engine significantly. I should also point out that head gasket designs are a reflection of this principle too. They are constructed specifically to compensate for minor imperfections in the deck's surface. They would be designed quite differently if every engine block deck were supposed to be free of any surface imperfections entirely.

Toyota doesn't frivolously recommend not machining anything. They have a definite reason behind stating such. If it can and should be machined, they will tell you to do so. They don't recommend ANY engine block resurfacing because you're going to change much more than the deck surface of the block by having it machined. And you could potentially need to do ALOT more machining to ALOT more parts to make the engine a correctly functioning assembly afterwards. Things like shortening the connecting rods, and/or using non-specified pistons to correct deck height. And doing so will alter the engine permanently, as the block and said parts will no longer be within stock specifications(or any specifications for that matter). Thereby making any future servicing of the engine with stock parts, or OE spec aftermarket parts, an impossibility. Though you may not change the performance qualities of the engine too drastically by doing those things, that's also a concern as well. You will absolutely have a minimal impact atleast on compression ratio, stroke length, and as previously stated deck height requirement.

Engine block deck resurfacing it not something that manufacturers consider to be a given during the engine's lifetime, or during a reconditioning. Like they do with cylinder heads. Provisions are made during the manufacturing of cylinder heads to allow for it. And generally cylinder heads can be lightly resurfaced multiple times without hindering the functionality of the engine significantly. I should also point out that head gasket designs are a reflection of this principle too. They are constructed specifically to compensate for minor imperfections in the deck's surface. They would be designed quite differently if every engine block deck were supposed to be free of any surface imperfections entirely.

#20

Registered User

Thread Starter

iTrader: (4)

Join Date: May 2010

Location: People's Republic of California

Posts: 720

Likes: 0

Received 15 Likes

on

12 Posts

Can someone tell me if these Toyota OEM gaskets are MLS ones? After doing some reading I see that everyone recommends the OEM ones, so I held off from installing my Fel-Pros. I got these today and they look just like the ones I pulled off and are real flimsy compared to the Fel-Pro's I have. The Fel Pros are pretty sturdy and beefy feeling, and the OEM's feel light and flimsy.

Are these not the latest and greatest ones?

comparison of old vs. Fel Pro

Are these not the latest and greatest ones?

comparison of old vs. Fel Pro