Last edit by: IB Advertising

See related guides and technical advice from our community experts:

Browse all: Toyota Tundra Steering & Suspension Guides

- Toyota Tundra 2000-Present: Recalls and Technical Service Bulletins <br>Important information to help you understand your Tundra.

- Toyota Tundra How to Replace Ball Joints<br>Step by step instructions for do-it-yourself repairs.

- Toyota Tundra Suspension Diagnostic Guide<br>Guide to diagnose trouble and recommended solutions.

Browse all: Toyota Tundra Steering & Suspension Guides

Tundra Catastrophic Balljoint failure

#21

Registered User

Thread Starter

The mounting bolts don't fail on the second design because there's no lateral load being applied to them. As the are no longer being used to steer the wheels.

The wear shown on the ball joint stud above is not consistent with the older or newer steering knuckle designs. That type of wear would only be caused by the first steering knuckle designs used with coil spring suspensions. It's also shown next to the first design ball joint housing socket. Which suggests that I'm right in every aspect as far as my explanation for why that happened. In other words, that wouldn't happen with the second design steering knuckle.

So please quit while you're ahead here would ya? I get your point already. You obviously don't get mine. But that's just fine. You win. Let's just call it a game...

The wear shown on the ball joint stud above is not consistent with the older or newer steering knuckle designs. That type of wear would only be caused by the first steering knuckle designs used with coil spring suspensions. It's also shown next to the first design ball joint housing socket. Which suggests that I'm right in every aspect as far as my explanation for why that happened. In other words, that wouldn't happen with the second design steering knuckle.

So please quit while you're ahead here would ya? I get your point already. You obviously don't get mine. But that's just fine. You win. Let's just call it a game...

#22

Registered User

Were those OEM ball joints? Or were they ever replaced by someone at one point? You DO NOT wheel that hard on an IFS truck and NOT change out ball joints on a regular basis. Let alone on the original set. SO either :

1: The ORIGINAL Ball Joint failed. (Your fault for not replacing them after wheeling so much)

2: The replacements either 1 failed because of inferior design. (You get what you pay for)

3: The bolts fell out of the replacement because they weren't loctited in like the FSM states.

4: The bolts fell out because they were never torqued down with a torque wrench

5: The bolts broke because they were overtorued because a torque wrench wasn't used.

Yes the design without a torsion to hold the arms in place is a poor design, but that only compounds the effect, it's not the cause.

Like Wabbit said, Designs change not just because design flaws, they change to update and strengthen, lessen the after effects of a failure, or cheaper to produce.

1: The ORIGINAL Ball Joint failed. (Your fault for not replacing them after wheeling so much)

2: The replacements either 1 failed because of inferior design. (You get what you pay for)

3: The bolts fell out of the replacement because they weren't loctited in like the FSM states.

4: The bolts fell out because they were never torqued down with a torque wrench

5: The bolts broke because they were overtorued because a torque wrench wasn't used.

Yes the design without a torsion to hold the arms in place is a poor design, but that only compounds the effect, it's not the cause.

Like Wabbit said, Designs change not just because design flaws, they change to update and strengthen, lessen the after effects of a failure, or cheaper to produce.

Last edited by xxxtreme22r; 09-05-2012 at 08:33 AM.

#23

Shear strength is defined as the maximum load that can be supported prior to fracture, when applied at a right angle to the fastener’s axis. A load occurring in one transverse plane is known as single shear. Double shear is a load applied in two planes where the fastener could be cut into three pieces.

And I would argue that the newest design is probably just as strong as the oldest(though it's yet to be as thoroughly tested in the field to determine that it is, hence it could actually be stronger). With the one weaker design in between them.

I know the old/torsion bar IFS design is stong because I do wheel my 88 IFS hard, and I've never changed the ball joints. AFAIK, they're the original ball joints that came on the truck from the factory. And they're still holding up just fine.

Last edited by MudHippy; 09-10-2012 at 10:04 AM.

#24

Registered User

Join Date: Feb 2008

Location: the great Maine wilderness

Posts: 2,048

Likes: 0

Received 4 Likes

on

4 Posts

I didnt have to change the ball joints on my 93 till I hit 220k miles... And I can say that those were some pretty rough miles! That being said... I aslo ALWAYS checked my suspension before AND after every run off the pavement. And greased them every time I went thru mud/water/snow. I also always made sure to check the mounting bolts regularly as I have seen them looen up over time. After a few year of mud/water/snow, they do tend to rust, and can come apart. I think I repleced the mounting bolts around 160-170k to avoid issues down the road...

#25

Registered User

Join Date: Jul 2010

Location: vermont

Posts: 470

Likes: 0

Received 0 Likes

on

0 Posts

this happend to my 4runner but thats because i was using like ten dollor ball joints and they didnt have grease fitting and the ball got no grease and poped right out. but i havent had an issue since after i got the $40 napa ball joints with grease fittings.

#27

Registered User

Join Date: Jul 2010

Location: vermont

Posts: 470

Likes: 0

Received 0 Likes

on

0 Posts

#28

Registered User

#29

Registered User

#30

Registered User

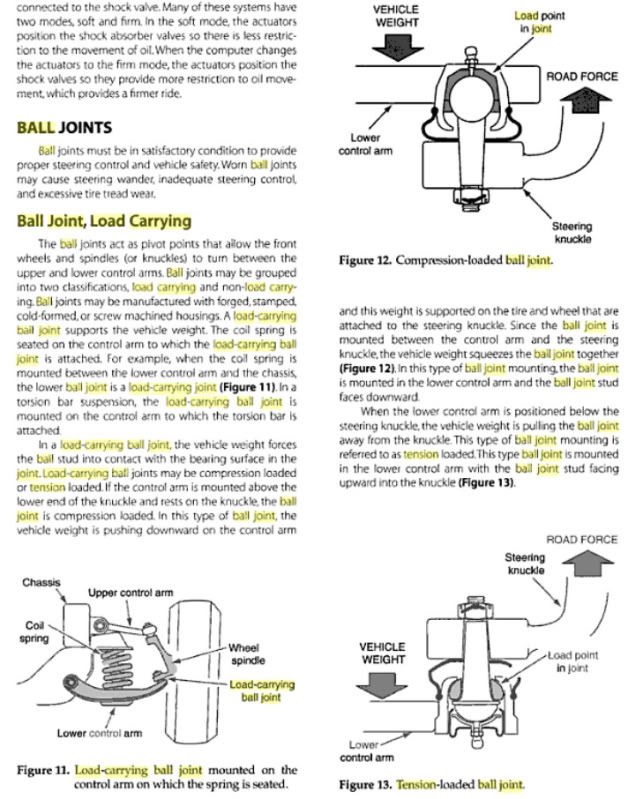

I have to agree as a design flaw. The weight of the truck is being used to pull the joint apart and not sit ontop.

My suggestion is to learn how to properly check for lower ball joint play and check every tire rotation.

My suggestion is to learn how to properly check for lower ball joint play and check every tire rotation.

#31

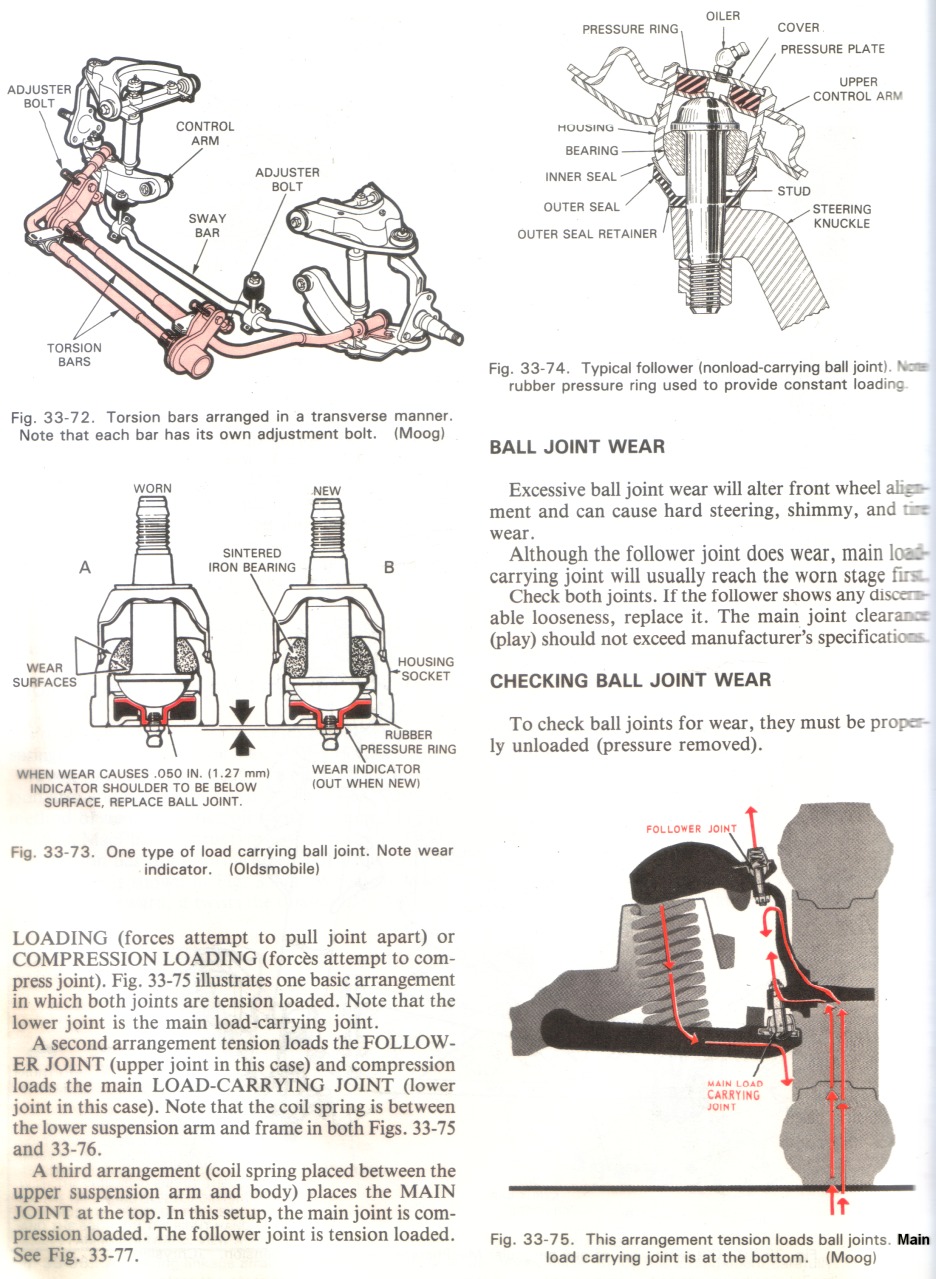

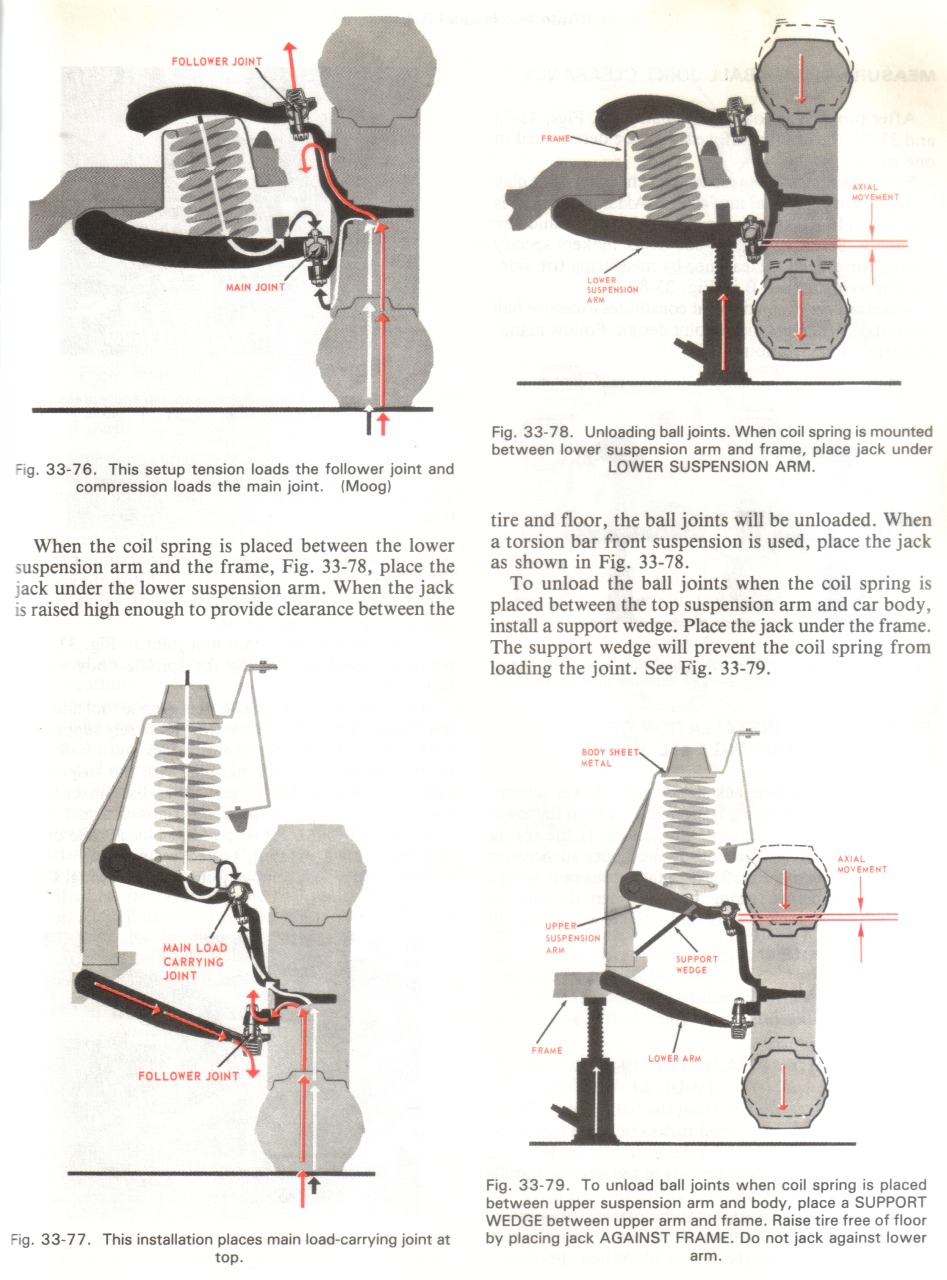

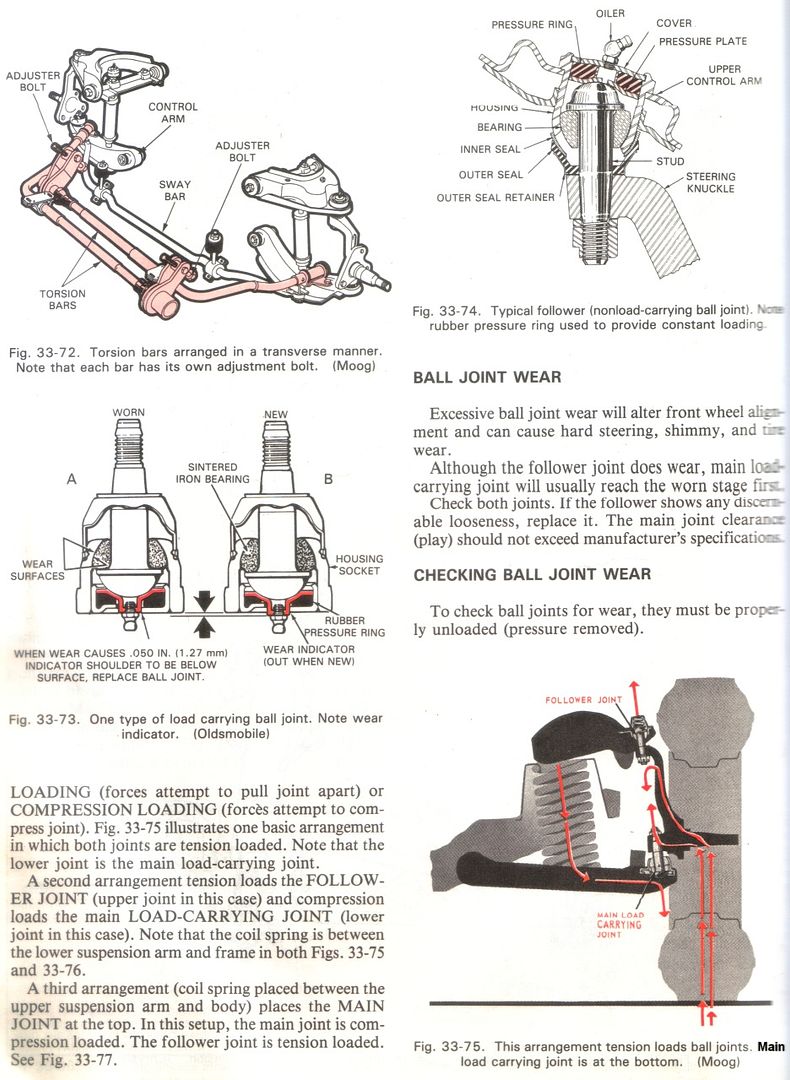

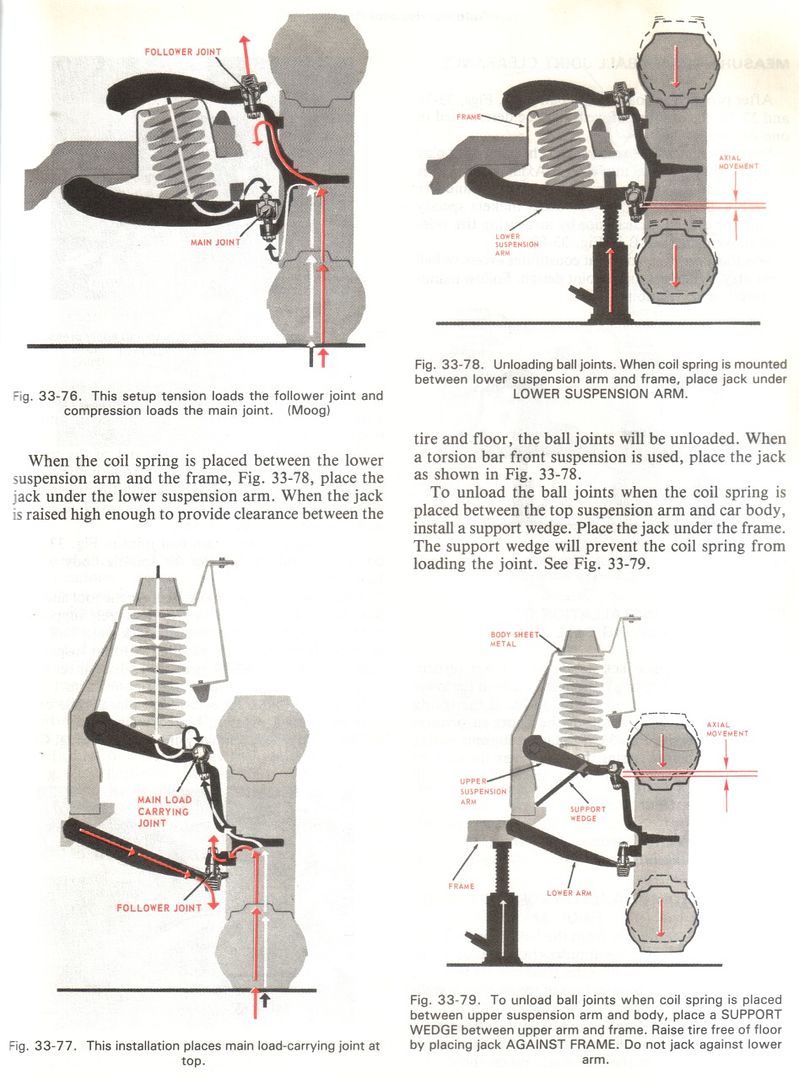

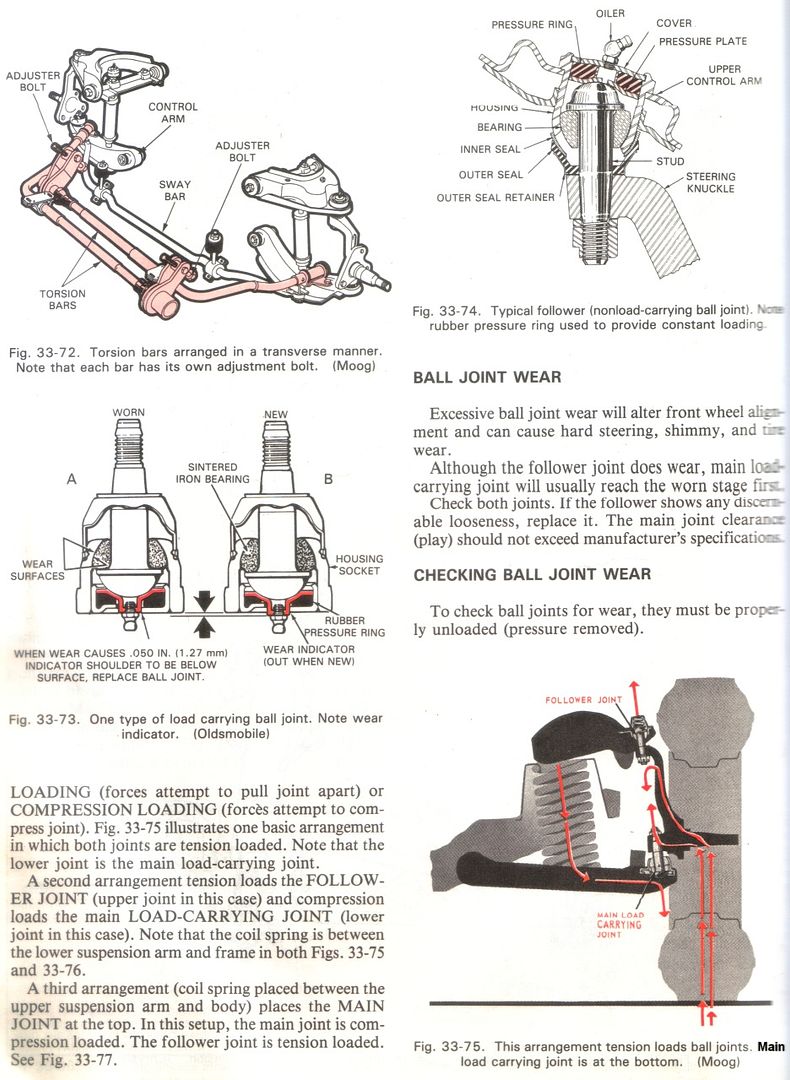

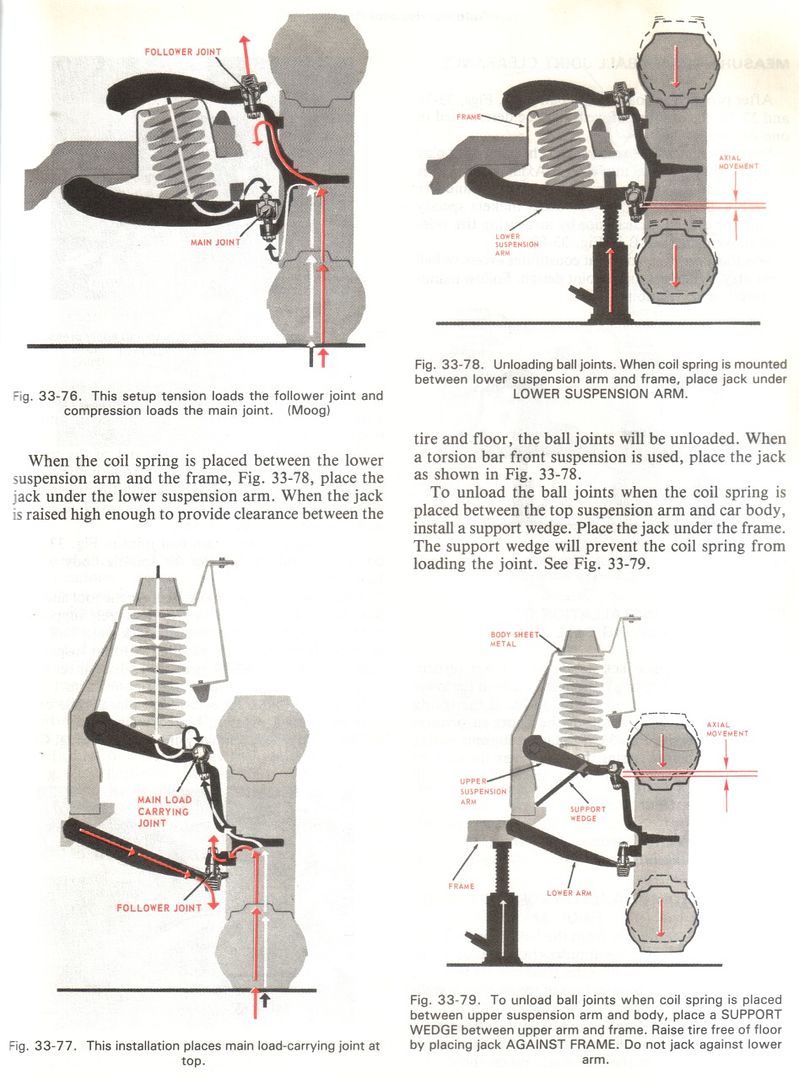

Fig. 33-76 shows how the newer/second version coil spring IFS design works. Fig. 33-77 shows how the old torsion bar IFS system works, except for showing a coil spring being used instead(but the operation theory remains the same).

Last edited by MudHippy; 09-10-2012 at 09:54 AM.

#32

Registered User

Thread Starter

Well, I wasn't using the correct terminology to describe the force applied to the bolts. It's called shear load(not lateral load, though they are similar concepts, exc. lateral load refers to a type of structural load), and it's what determines the shear strength of a fastener. The bolts in question(the 4 used on the first coil spring IFS design) would be experiencing a single shear load, because they are being used in a type of single shear joint.

And I would argue that the newest design is probably just as strong as the oldest(though it's yet to be as thoroughly tested in the field to determine that it is, hence it could actually be stronger). With the one weaker design in between them.

I know the old/torsion bar IFS design is stong because I do wheel my 88 IFS hard, and I've never changed the ball joints. AFAIK, they're the original ball joints that came on the truck from the factory. And they're still holding up just fine.

#33

Registered User

Thread Starter

That's the correct way to look at it. Just worded differently than I did. What I mean by the coil springs pushing the upper and lower control arms apart is, the weight of the vehicle pushing up on the upper control arms/ball joints(and pulling up on the lower ball joints) against the force of the coils springs pushing down on the lower control arms(and pulling down on the lower ball joints). See Fig. 33-75 below showing how the first version coil spring IFS design works.

Fig. 33-76 shows how the newer/second version coil spring IFS design works. Fig. 33-77 shows how the old torsion bar IFS system works, except for showing a coil spring being used instead(but the operation theory remains the same).

Fig. 33-76 shows how the newer/second version coil spring IFS design works. Fig. 33-77 shows how the old torsion bar IFS system works, except for showing a coil spring being used instead(but the operation theory remains the same).

Good job Mudhippy!!!

#34

Registered User

Thread Starter

Now how could a large motor car company make such a huge simple design flaw???

Design a suspension that can fail suddenly and catastrophically ...oh well!!

Design a suspension that can fail suddenly and catastrophically ...oh well!!

#35

Registered User

Thread Starter

Force arrows tell the story...compression balljoint on older an newer trucks...tension balljoint on first gen Tacomas, Tundras and 3rd gen 4Runners.

Last edited by milowilli; 09-12-2012 at 03:22 PM.

#39

Registered User

Thread Starter

I still would like to ask readers who disagree with me to show pics of first gen torsion bar IFS and Gen 3 Coilover balljoint failures!!!! Toyota dropped the ball on this first gen Coilover balljoint design..poor engineering.