85-95 22R 22RE Piston Ring sealing

#61

Thank you for posting, It was short right to the point and included a lot of pertinent information.

Also is your oil black? or normal "light honey---dark honey" color? Do you have black soot build up on the tip of your exhaust?

These seem to be signs of this problem as well.

Working together we all can help eachother out.

Also is your oil black? or normal "light honey---dark honey" color? Do you have black soot build up on the tip of your exhaust?

These seem to be signs of this problem as well.

Working together we all can help eachother out.

#62

I will need to check on the oil color, but the truck is a stinky one, I thought maybe because of the test pipe in place of the cat. There is a bit more dark soot on the tailpipe than I am used to seeing. The rear cylinder (4) seems it might be the one w/ the ring sealing problem, as that plug gets black and sooty quickly. The truck runs good, but the oil was definitely disappearing quicker than it should.

#64

I have always clocked my rings per the Toyota book. With no gap overlaping.

It is my guess that you are actually right about the oil ring tension. Because I achieve proper compression numbers leading me to believe the upper compression rings are seating.

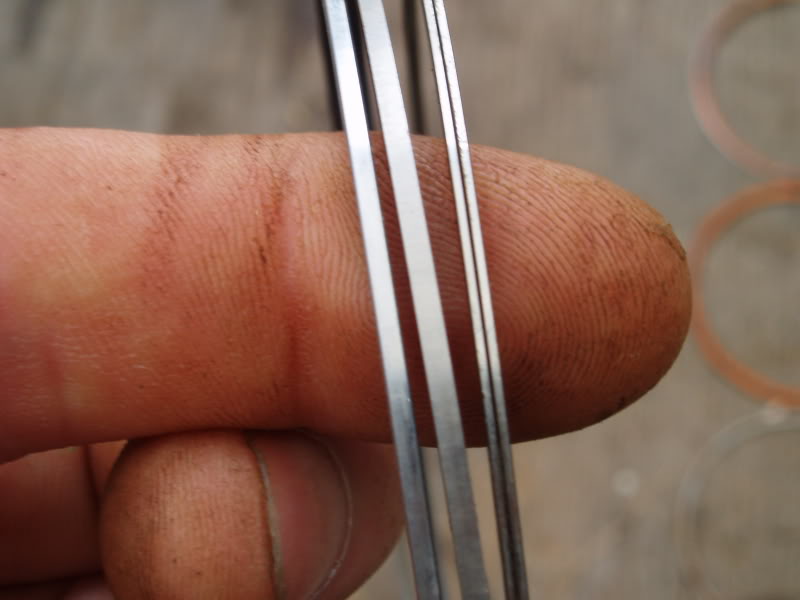

Rock rings slide right into the bore easily. Leading me to believe they have very low ring tension.

While Hastings and NPR take much more effort, Hastings taking the most effort to slide down the bore.

It is my understanding that there is no real way to adjust the tension of the oil ring expander. Am I wrong?

Ted has never mentioned needing to "Adjust" the oil expander ring. Maybe he could give his thoughts about this?

#65

I have always clocked my rings per the Toyota book. With no gap overlaping.

It is my guess that you are actually right about the oil ring tension. Because I achieve proper compression numbers leading me to believe the upper compression rings are seating.

Rock rings slide right into the bore easily. Leading me to believe they have very low ring tension.

While Hastings and NPR take much more effort, Hastings taking the most effort to slide down the bore.

It is my understanding that there is no real way to adjust the tension of the oil ring expander. Am I wrong?

Ted has never mentioned needing to "Adjust" the oil expander ring. Maybe he could give his thoughts about this?

It is my guess that you are actually right about the oil ring tension. Because I achieve proper compression numbers leading me to believe the upper compression rings are seating.

Rock rings slide right into the bore easily. Leading me to believe they have very low ring tension.

While Hastings and NPR take much more effort, Hastings taking the most effort to slide down the bore.

It is my understanding that there is no real way to adjust the tension of the oil ring expander. Am I wrong?

Ted has never mentioned needing to "Adjust" the oil expander ring. Maybe he could give his thoughts about this?

>>>*K..I will try again, I have some comments on several points..

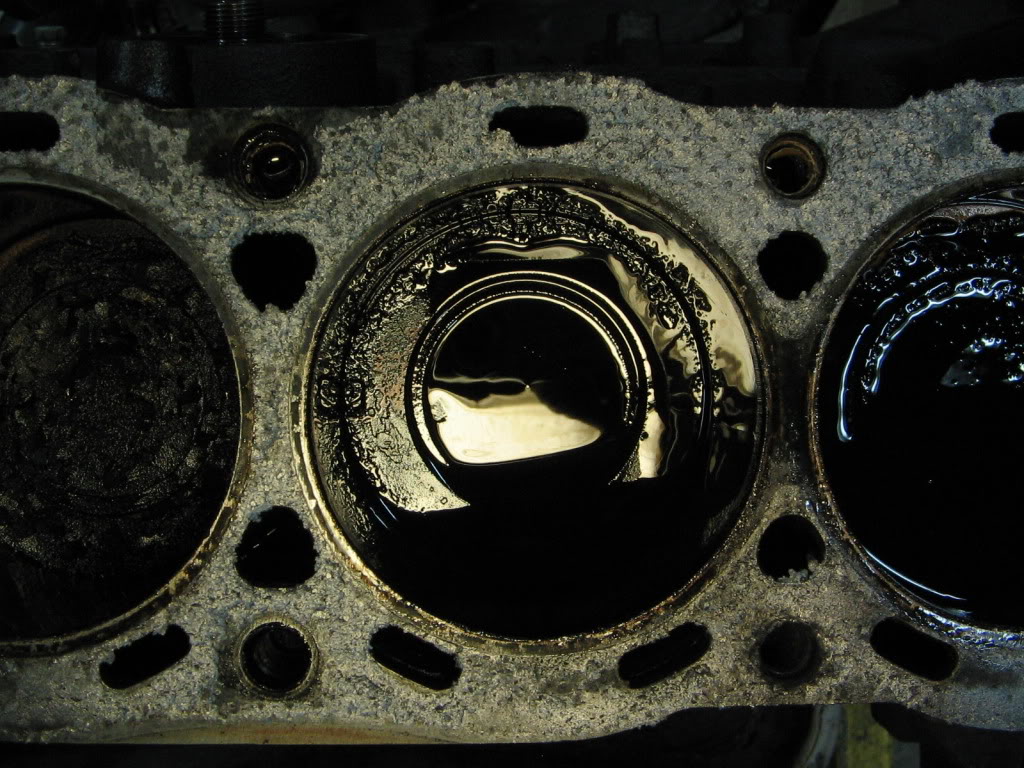

The photos posted above show enough oil passing above the piston tops that the engine would completely purge the crankcase of oil before it could make one turn around a city block. Anyone who understands engines at all can see that easily.

I see no point in commenting further on that.

There are no "adjustments" to make to rings other than assuring proper gaps. If the gaps are correct, the ring size is correct for the bore size.

In nearly all cases a properly sized bore will result in end gaps within the normal ranges, if they do not any good tech would simply investigate. Filing is something we do in our shop when dealing with file to fit rings designed for performance type use. I have not filed a stock set of piston rings in 30 years.

I did have one of my workers set up to file the rings on a Chevrolet engine a few years ago. "Just one side." he told me. One glance and I asked him how he planned on getting the pistons in, it was bored .020" on one bank and .030" on the other.

The gentleman does not work for us any more.

By the same token, rings that "slide in too easily" would create pause in any good tech, and an investigation into the why of that. The way this happens is the tech installed one or more of the wrong size ring. Now having built engines for a shade over 45 years, this is something I can feel instantly, or as I rotate the assembly after installing each piston. Human beings pack ring pouches, and there are rare errors. But as a backup check, ring sets are weighed to fractions of a gram, just one off size ring for the set will result in the system rejecting. Still, human beings, things happen that should not.

I have stood in the factory packing them and watched that.

RockProducts went from a tiny little warehouse in California less than 15 years ago to 18 major regional facilities and hundreds of distributors, and now they are expanding to full line domestic engine parts nationwide. I have personally been involved from the beginning, even to the point of engineering design on items like timing chain kits and parts.

Huge cartons of piston rings come in to the sorting lines from manufactuers, just like pistons, bearings, gaskets, on and on. Yes, cases with the NPR logo, way back we saw Hastings but that company had production concerns due to a bankruptcy. Rarely a different manufacturer might be used when supplies tighten up, but every single supplier has that Q9002 process certification. So very often when someone purchases a favorite "brand", the ONLY difference in the product is the logo on the package. Sometimes there might be a different product in the "brand" name box.

As far as "bad" or "sub standard" products, there are almost none that are not perfectly serviceable.

+++

Ring tension is not what creates a seal in the top ring, it simply assists. Compression gasses are what force the top ring out against the bore. Since in use rings rotate, the ring facing will typically appear sealed unless the failure is catastrophic, the actual demonstration of leakage will show clearly to any good tech in the bore pattern itself. In a failure situation, we look for discoloration from excess heat, scarring from frictionals that will appear in seconds should a ring facing be exposed to combustion gasses. Leakage will show as a pattern in the bore itself typically a vertical elongated area. Those areas often show burnish, sometimes scarring, often from a simple cast top ring exposed to an upset tuning situation like a failed gasket similar to a photo you showed in another thread. Excess heat leaves very clear evidence.

These are obvious signs that any good tech can easily see.

The second combustion ring serves as a backup for the primary, and is always directional. It's other main job is to scrape oil downwards also. If installed inverted it can and will act as a pump. Once removed it is impossible to tell of course if that was the case. Note here the second ring runs much cooler than the primary as it is normally not exposed to the flame front. If the second ring ever becomes seriously exposed to the flame front, that seal is usually all done. That is why anyone setting the second ring end gap to the excess figure found in some FSM's will see consumption, the spec we use is .010" to .014", top of .012" to .016", around .012" oil.

Note here that the final bore size affects the ring gap, thus a bore just .001" larger than normal will add roughtly .003" to the end gap, typically not a concern.

Now I must admit to personally having a few oil control problems myself over the years. . Without fail, a personal error at installation, such as damage to an oil control ring, or breakage at install. I happen to be human too, and the phone can be one heck of a distraction when trying to meet a deadline. Plus one classic, a standard size oil screen ring in a .040" oversize pack, installed by one of my techs. That engine used a quart of oil every 300 miles through one cylinder, creating so much smoke it overwhelmed the catalytic convertor and was impossible to drive.

I got to find and fix that little problem myself.

That should be impossible but it happened, just one case in nearly 45 years. Nearly as impossible as the emails we get from time to time about ONE ring short in the package. Also impossible, we know they broke one. No problem, we just send them another.

Still that happened. Human beings pack the boxes. Any failure at all is an embarrassment, all one can do is try to correct and move on. My tech was young and lacked the experience to "feel" the problem at install, I like to think I would have felt it.

Maybe, maybe not. We are all human.

+++

The "oil control" ring or bottom ring is backed by grooving in the ring land, this is to allow oil to reach the screen. It's job is to distribute lubricant, the bottom thin wiper ring acts as a seal to hold oil in the screen, the top wiper does the same, to hold oil downward in the screen, this distributes lubricant to the bores on each stroke. Excess is then retained by the second ring which slides over the molecules thick layer of lubricant on the way up and scrapes on the way down.

Ring tensile is not enough to seal a bore, and there normally is no need for "adjustments."

I also see no need to knock one supplier's products to try and build up our own, the vast majority of brands available will work just fine. As I said, choose what you like best.

The email mentioning "10 engines in a row, then redoing 4 of them using the same products, ALL failing?" Just two in a row would have this old man digging into everything to find out what the HE** is going on!

*Which I just got done doing. Interestingly, thus far I have found nothing. I hope my suggestions on how rings actually work helps you.....

*EB

#66

>>>*K..I will try again, I have some comments on several points..

The photos posted above show enough oil passing above the piston tops that the engine would completely purge the crankcase of oil before it could make one turn around a city block. Anyone who understands engines at all can see that easily.

Exactly, customers state, and I have verified in my own vehicle usage of around 1 Quart per 300-400 miles

I see no point in commenting further on that.

There are no "adjustments" to make to rings other than assuring proper gaps. If the gaps are correct, the ring size is correct for the bore size.

I agree

In nearly all cases a properly sized bore will result in end gaps within the normal ranges, if they do not any good tech would simply investigate. Filing is something we do in our shop when dealing with file to fit rings designed for performance type use. I have not filed a stock set of piston rings in 30 years.

All the bores were bored EXACTLY to size. I measured all ring packs in the bores. All were well within spec. All I did then was to lightly touch with a file the edges of the ring ends.

I did have one of my workers set up to file the rings on a Chevrolet engine a few years ago. "Just one side." he told me. One glance and I asked him how he planned on getting the pistons in, it was bored .020" on one bank and .030" on the other.

I double check the bore before I start putting rings into the bore to check the end gaps.

The gentleman does not work for us any more.

By the same token, rings that "slide in too easily" would create pause in any good tech, and an investigation into the why of that. The way this happens is the tech installed one or more of the wrong size ring. Now having built engines for a shade over 45 years, this is something I can feel instantly, or as I rotate the assembly after installing each piston. Human beings pack ring pouches, and there are rare errors. But as a backup check, ring sets are weighed to fractions of a gram, just one off size ring for the set will result in the system rejecting. Still, human beings, things happen that should not.

Every set of Rock rings, after I check the bore, check the gap, and assemble the rings onto the pistons (making sure that the correct markings are facing up) slide into the bores with relative ease. I would say about normal.

The Hastings brand takes quite a bit of force, and the NPR is inbetween the two in the amount of force.

This is simply a "mental note" not that I think there is a problem.

As far as "bad" or "sub standard" products, there are almost none that are not perfectly serviceable.

I agree with, and understand, everything you have said in this post and all your others except I respectfully dissagree with this one statement. From my experiences there are large differences in quality, weather it be car parts or anything else in life. Things may "work" but for how long and how much messing with it does it take to make it fit right.

+++

I also see no need to knock one supplier's products to try and build up our own, the vast majority of brands available will work just fine. As I said, choose what you like best.

I have not made one comment about knocking anyones supplier. A couple other people have. I don't like it either. However people discussing issues they have had with products, and giving suggestions on other products that seem to work "better" or "longer" shouldn't be a problem.

Me personally I would like to be able to purchase Toyota parts and install them into all my product. However "people" are not willing to pay the extra amount for an engine rebuilt with those parts. So "WE" as engine builders have to walk a tight line between getting the least expensive parts we can to be competative on pricing, while also attempting to get the best quality of product we can.

I have said over and over, Most of the rock products are servicable. I simply have discussed some of what I have seen that could be issues. Every company has issues. You yourself even stated you like everything TOPLINE makes except their Rocker arms.

The email mentioning "10 engines in a row, then redoing 4 of them using the same products, ALL failing?" Just two in a row would have this old man digging into everything to find out what the HE** is going on!

The moment !!! I knew I had a problem, I started asking questions, called my Rock representative. I then asked many machine shops about what the problem could be. Showed them the rings and other products from Rock. Took blocks to other machine shops to see what they thought of "other peoples" work. I then came online searching for information. I rebuilt 5 engines now specifically in an attemt to figure this out, changing and quadrouple checking every tiny little detail.

I hope my suggestions on how rings actually work helps you.....

Informaiton is always a big plus, I'm sure anyone reading this entire thread will learn a whole bunch.

*EB

The photos posted above show enough oil passing above the piston tops that the engine would completely purge the crankcase of oil before it could make one turn around a city block. Anyone who understands engines at all can see that easily.

Exactly, customers state, and I have verified in my own vehicle usage of around 1 Quart per 300-400 miles

I see no point in commenting further on that.

There are no "adjustments" to make to rings other than assuring proper gaps. If the gaps are correct, the ring size is correct for the bore size.

I agree

In nearly all cases a properly sized bore will result in end gaps within the normal ranges, if they do not any good tech would simply investigate. Filing is something we do in our shop when dealing with file to fit rings designed for performance type use. I have not filed a stock set of piston rings in 30 years.

All the bores were bored EXACTLY to size. I measured all ring packs in the bores. All were well within spec. All I did then was to lightly touch with a file the edges of the ring ends.

I did have one of my workers set up to file the rings on a Chevrolet engine a few years ago. "Just one side." he told me. One glance and I asked him how he planned on getting the pistons in, it was bored .020" on one bank and .030" on the other.

I double check the bore before I start putting rings into the bore to check the end gaps.

The gentleman does not work for us any more.

By the same token, rings that "slide in too easily" would create pause in any good tech, and an investigation into the why of that. The way this happens is the tech installed one or more of the wrong size ring. Now having built engines for a shade over 45 years, this is something I can feel instantly, or as I rotate the assembly after installing each piston. Human beings pack ring pouches, and there are rare errors. But as a backup check, ring sets are weighed to fractions of a gram, just one off size ring for the set will result in the system rejecting. Still, human beings, things happen that should not.

Every set of Rock rings, after I check the bore, check the gap, and assemble the rings onto the pistons (making sure that the correct markings are facing up) slide into the bores with relative ease. I would say about normal.

The Hastings brand takes quite a bit of force, and the NPR is inbetween the two in the amount of force.

This is simply a "mental note" not that I think there is a problem.

As far as "bad" or "sub standard" products, there are almost none that are not perfectly serviceable.

I agree with, and understand, everything you have said in this post and all your others except I respectfully dissagree with this one statement. From my experiences there are large differences in quality, weather it be car parts or anything else in life. Things may "work" but for how long and how much messing with it does it take to make it fit right.

+++

I also see no need to knock one supplier's products to try and build up our own, the vast majority of brands available will work just fine. As I said, choose what you like best.

I have not made one comment about knocking anyones supplier. A couple other people have. I don't like it either. However people discussing issues they have had with products, and giving suggestions on other products that seem to work "better" or "longer" shouldn't be a problem.

Me personally I would like to be able to purchase Toyota parts and install them into all my product. However "people" are not willing to pay the extra amount for an engine rebuilt with those parts. So "WE" as engine builders have to walk a tight line between getting the least expensive parts we can to be competative on pricing, while also attempting to get the best quality of product we can.

I have said over and over, Most of the rock products are servicable. I simply have discussed some of what I have seen that could be issues. Every company has issues. You yourself even stated you like everything TOPLINE makes except their Rocker arms.

The email mentioning "10 engines in a row, then redoing 4 of them using the same products, ALL failing?" Just two in a row would have this old man digging into everything to find out what the HE** is going on!

The moment !!! I knew I had a problem, I started asking questions, called my Rock representative. I then asked many machine shops about what the problem could be. Showed them the rings and other products from Rock. Took blocks to other machine shops to see what they thought of "other peoples" work. I then came online searching for information. I rebuilt 5 engines now specifically in an attemt to figure this out, changing and quadrouple checking every tiny little detail.

I hope my suggestions on how rings actually work helps you.....

Informaiton is always a big plus, I'm sure anyone reading this entire thread will learn a whole bunch.

*EB

I need an asprin

#67

1: I have used a few different hones, diamond and stone. What sucks is stone numbers are not really the same as diamond numbers. But I have used 320 grit stone Which is very common, 400 grit stone, and a diamond hone with the equivalent to the 320 grit stone. In reading and talking to many machine shops I have heard either you want smooth finish or rough finish nobody knows it seem. BTW there is NO information/instructions given by the ring manufacturers not even if you ask. I'm assuming they dont want the possibility of liability.

The only problems I have ever had with rings not sealing if all the fitment specs are correct is when the bores have been overhoned with too fine a stone/finish diamond.

Both Moly lap and Chrome require a proper finish. Some shops use one grit, and remove any fractured material from the boring process all the way.

My opinion is this is wrong, the bore should be machined to size (about the last .003" or so) with a rather aggressive grit, then that plateau honed in with lighter pressure and 30 degree pattern.

Both Moly lap and Chrome require a proper finish. Some shops use one grit, and remove any fractured material from the boring process all the way.

My opinion is this is wrong, the bore should be machined to size (about the last .003" or so) with a rather aggressive grit, then that plateau honed in with lighter pressure and 30 degree pattern.

Moly rings do require some added machinist skill to make seal properly. The material is very soft, so honing is done to size using a coarse grit, I personally use 280 grit under flood of honing oil, the reduce the flow to form a fine slurry, reduce the honing pressure and plateau with that same 280 grit. This creates a very fine final plateau, which offers good sealing combined with oil retention for lubrication.

Without proper lubrication, the bores burnish very quickly and the engine will consume oil.

Diamond tooling and others require different techniques, my method works for me and always has, even though some think I am crazy.

*Probably right, too, but my way works.

Too fine a finish pattern with little or no peaks and valleys in the underlying pattern will cause a bore to burnish. If it does, the engine will consume oil for as much as 30-40K before finally wearing in. Too coarse of a finish and the results are very quick.

Chrome rings require a rather coarse finish to seat properly

Many machinists prefer a pure iron ring, those will seat and seal up no matter how sloppy the bore finish is. That is an advantage, but iron rings have a much poorer service life than Moly, plus they will withstand far less heat.

One other thing to check is the final hone pattern angle. 30° is correct, and important.

Without proper lubrication, the bores burnish very quickly and the engine will consume oil.

Diamond tooling and others require different techniques, my method works for me and always has, even though some think I am crazy.

*Probably right, too, but my way works.

Too fine a finish pattern with little or no peaks and valleys in the underlying pattern will cause a bore to burnish. If it does, the engine will consume oil for as much as 30-40K before finally wearing in. Too coarse of a finish and the results are very quick.

Chrome rings require a rather coarse finish to seat properly

Many machinists prefer a pure iron ring, those will seat and seal up no matter how sloppy the bore finish is. That is an advantage, but iron rings have a much poorer service life than Moly, plus they will withstand far less heat.

One other thing to check is the final hone pattern angle. 30° is correct, and important.

Given that you've taken into consideration, atleast, that the problem may arise from the rings not seating properly(yes, I mean the oil rings too). I'd like to suggest what my conclusion is regarding the honing process and how it may effect the sealing properties of these rings. These are not purely speculation, but sound reasoning based on my personal experience with piston ring installation in general, and specifically my experience with installing NPR rings. And also my experience, minimal though it may be, in honing cylinders.

I, as you're aware, recently re-ringed my 3VZ-E using rings packaged as NPR. They were of the gas nitrided chrome faced steel top ring type(shiny blackish looking), cast iron type moly coated number 2 ring(black is the only descriptive I can give). I only bought those because they were in the CHEAPEST piston & ring kit I could find(e-bay). I used a hand drill mounted 3-stone flexible/adjustable cylinder hone, with brand new 240 grit stones installed on it, to hone the cylinders from start to finish. I got those replacement stones from Carquest.(Which was a lucky deal too, because those were the only replacement stones they had on the shelf and the only ones I could find anywhere except online) I used a variable-speed 3/8 drill with those to create a ~45° hone pattern with what I'd call med-heavy pressure applied to the stones. I chose to go with as close to a 45° pattern as I could. Why? First and foremost because the FSM doesn't say. I was going on info found in a 70-88 Toyota 4x4 Chilton manual. Which states that the honing pattern should be approx. 60°. BUT nearly all the places I found info on the web were stating 45° as being exactly what it should be. My only other backup info was from another very good book by Stockel/Stockel called "Auto Service and Repair" printed in 1991, which I HIGHLY recommend to anyone. BUT, it states that an approx. 50° pattern is optimal, and that anywhere between 20°-60° will suffice. It also says that a good finishing stone grit is anywhere from 180-220 grit. using light to medium pressure, but doesn't mention anything about moly rings in there. So I figured maybe that was why the stones I purchased were slightly finer grit(240)and that that was a necessary property. And the higher pressure I applied was simply to speed things up as I had some signifcant scoring to get through in the process. I'm aware that the pressure applied to the stones during honing will effect the final micro-inch of the finish too. I just guessed/hoped that I might be able to get away with a bit more pressure than I'd read was needed. I used honing oil during the entire honing process and installed the pistons and rings with a light coating of 15W-40 diesel oil on them and the cylinder walls. I also never even checked or adjusted the end-gaps, just lined them up how the FSM said to and put them in the holes. Now, as you're also aware, I was completely successful at applying this technique and believe it involved wise decisions being made on my part. Which were based on the best information available to me at the time. And I'd do it the same all over again without a second thought.

So, in conclusion, I'll offer these suggestions:

1. If you're dead-set on using the chrome rings try using a relatively coarse grit stone to hone the cylinders. Perhaps in the 180-220 grit range and see if that will help them to seat/seal better, for longer, or with less effort. Ted seems to agree with me on this atleast.

2. Have you tried adjusting the hone pattern angle? I know Ted suggests a STRICTLY 30° angle as being correct and important. But it's not the only angle that I've heard/read can be used. Nor is it the angle I found worked just fine and dandy for me.

3. Have you tried another method of honing? Like say the way I did mine. Sure, they may laugh you right out of the shop. But, maybe, just MAYBE I'm onto something? Worked great for me anyways. My engine don't burn oil any more than it should. And alot less than some engines that I've seen.

Are these suggestions going to be "a set of known good steps to follow that allows "magically" these rings to seat"? Wouldn't hurt to try 'em out and see. Up to you though.

Sidenote: I'd throw all the "Moly rings do require some added machinist skill to make seal properly","any ring other than Cast/Cast will take a more advanced knowlege/process to get the hone right" crap right out the window. I just did. And I'm living proof that those statements aren't necessarily, dare I say realistically, even half-way truthful. Unless I get to call myself a machinist with a high level of skill and a more advanced knowledge of advanced machining processes now too. Which is fine by me if that were the case. But, even I am not as full of myself as to believe that's so. I made it work in my driveway with a hand drill and a cheapo, 20 some year old, cylinder hone so...go figure I guess. I'd honed a cylinder or two before, BUT it was on the order of 20 years ago when I took an autoshop class in high school. And honestly, whatever knowledge I'd gained of the process at the time was now LONG GONE! I had to re-teach myself the entire process from start to finish.(pardon the pun)

PS: And...good GOD, PLEASE do NOT come back with some ignorant "yours is a 3VZ-E not a 22RE" bull. Not just you Trainwreckinseattle...but ANYBODY. Piston rings are piston rings. Any engine's going to require EXACTY the same installation procedures based on the constituency of the rings ONLY. BTW, the stock rings on my 88 appeared to me to be chrome faced steel top, cast iron(uncoated) 2nd compression. But that's the most speculative statement I've provided here. Based soley on examining the rusted up rings when I dug them out of the scrap metal heap yesterday to get a rough idea(and satisfy my own curiousity). Yeah...another exceedingly long post...I know...sorry about that.

Last edited by MudHippy; 09-24-2010 at 03:31 PM.

#68

>>>*Actually, Mudhippy, you are exactly correct! Honing a block is relatively easy. The primary step when using a blade type hone is to use enough pressure to cut metal, the goal is to assure the bores are round and straight.

That process it typically the 45 degrees you suggest (same as we use) because it cuts the metal the fastest. We are typically remove around .003" of metal following a rebore job, a simple rehone is much less. When working with cast rings, I always used a 280 grit, on a Rottler power hone machine.

Modern moly face or moly with underlying Chrome do require a finer finish, because too rough will strip the Moly lap right off, it is rather soft. I use the very same 280 grit and simply slow the stroke and use less pressure, shooting for the 30 degree plateau pattern most manufacturers suggest. This leaves the deeper high/low patterns underlying for oil retention, with the flatter plateau finish on top. 3 to 4 strokes at reduced pressure will create that pattern.

But then we have literally hundreds of do it yourself folks that grab a bottle brush hone, shine up a standard bore and put her together with no problems or even a concern about it. You are correct, it's actually quite easy.

You wrote a nice article here, hopefully it will help someone else have the confidence to just go for it. That 3VZE is a can of worms to build, it takes some time, care and a good ration of common sense so good job!

Installing and hooking everything up is the hard part...Thanks for the post!...*EB

That process it typically the 45 degrees you suggest (same as we use) because it cuts the metal the fastest. We are typically remove around .003" of metal following a rebore job, a simple rehone is much less. When working with cast rings, I always used a 280 grit, on a Rottler power hone machine.

Modern moly face or moly with underlying Chrome do require a finer finish, because too rough will strip the Moly lap right off, it is rather soft. I use the very same 280 grit and simply slow the stroke and use less pressure, shooting for the 30 degree plateau pattern most manufacturers suggest. This leaves the deeper high/low patterns underlying for oil retention, with the flatter plateau finish on top. 3 to 4 strokes at reduced pressure will create that pattern.

But then we have literally hundreds of do it yourself folks that grab a bottle brush hone, shine up a standard bore and put her together with no problems or even a concern about it. You are correct, it's actually quite easy.

You wrote a nice article here, hopefully it will help someone else have the confidence to just go for it. That 3VZE is a can of worms to build, it takes some time, care and a good ration of common sense so good job!

Installing and hooking everything up is the hard part...Thanks for the post!...*EB

#69

Thanks man!

Your the guy it means the most too me to hear that from here. If it makes sense to someone whose been doing it for 10 years longer than I've been alive, then that's more than I can ask for.

Oh...I did HIGHLY recommend this book to everyone, so to make it easier to grab a copy, here's the one you want.

Hint: Many copies for sale on the web too.

Your the guy it means the most too me to hear that from here. If it makes sense to someone whose been doing it for 10 years longer than I've been alive, then that's more than I can ask for.

Oh...I did HIGHLY recommend this book to everyone, so to make it easier to grab a copy, here's the one you want.

Hint: Many copies for sale on the web too.

Last edited by MudHippy; 09-17-2010 at 07:23 PM.

#70

But seriously. I mean...seriously? API rating? NOT IMPORTANT!

vvvImportantvvv

3 more words on break- in:

NO SYNTHETIC OIL !!

Use Valvoline, Halvoline, or similar 10 w 40 Petroleum Car Oil for at least 2 full days of hard racing or 1,500 miles of street riding / driving.

After that use your favorite brand of oil.

NO SYNTHETIC OIL !!

Use Valvoline, Halvoline, or similar 10 w 40 Petroleum Car Oil for at least 2 full days of hard racing or 1,500 miles of street riding / driving.

After that use your favorite brand of oil.

FYI, I used 15W-40 diesel oil in case you missed that. STP additive too. Would have used car oil, but why? That's what the engine's been using for awhile now. And didn't seem to matter....or make any difference that I didn't use it(car oil)for the break in. The author of the above quote was meaning to advise using car oil IN A MOTORCYCLE ENGINE instead of 4-stroke motorcycle oil.(He's a motorcycle engine builder) The weight and it's being NON-SYNTHETIC are what you need to pay attention to for car/truck engine break in. IMO.

Nor do I believe that it has any importantence or has much to do with the oil used to coate them and the cylinder walls while installing them. Hypothetically you may want to use one that's thicker, straight weight or bottom end number. Like 15W, 20W, or straight 20 sae or 30 sae. But I'd imagine 10W-whatever would probably be fine too.

Last edited by MudHippy; 09-21-2010 at 12:56 PM.

#71

These are all great posts and are doing exactly what is intended with this thread. To get as much information put together as possible.

I don't know why they all failed. I have tried all kinds of different processes.

Anyone can get lucky too. I had one motor using these Rock rings work. Not ONE drop of oil was consumed and I put 4,000 miles on it before I sold the truck. I did exactly what you did. The block was in good shape, so were the pistons. I honed it using a 320 equivalent ball hone with a air powered drill. Ten strokes per cylinder and hung the pistons. It worked great.

Ive said all along I don't think there is a defect with these rings. There is simply a hone process.

Just to verify that I wasnt doing it wrong I sent 4 different blocks to 4 different local machine shops along with ring packs. They all failed.

Frankly I'm finished trying. I've long sence moved onto NPR Pistons and Rings and don't have any problems with oil consumption. It still bugs the heck out of me that I couldn't get these rings to work consistantly, and that other people run into this frustrating problem. But at some point I just have to give up.

I don't know why they all failed. I have tried all kinds of different processes.

Anyone can get lucky too. I had one motor using these Rock rings work. Not ONE drop of oil was consumed and I put 4,000 miles on it before I sold the truck. I did exactly what you did. The block was in good shape, so were the pistons. I honed it using a 320 equivalent ball hone with a air powered drill. Ten strokes per cylinder and hung the pistons. It worked great.

Ive said all along I don't think there is a defect with these rings. There is simply a hone process.

Just to verify that I wasnt doing it wrong I sent 4 different blocks to 4 different local machine shops along with ring packs. They all failed.

Frankly I'm finished trying. I've long sence moved onto NPR Pistons and Rings and don't have any problems with oil consumption. It still bugs the heck out of me that I couldn't get these rings to work consistantly, and that other people run into this frustrating problem. But at some point I just have to give up.

#72

Registered User

Join Date: Jul 2010

Location: Morrison, CO

Posts: 36

Likes: 0

Received 0 Likes

on

0 Posts

Just wanted to add my 2 cents to this thread. I just rebuild my 22re motor with 188,000 miles on it. I bought the engnbuilder kit (pistons, rings, oil pump, water pump, etc...) Used everything except for the head gasket, went with a Toyota for that. I'm not a professional mechanic but I do have experience rebuilding motors. I took the block (with pistons and timing cover) and head to a local auto shop that had experience with 22r motors. I did not have to file the rings before installing them, all gaps were within spec after the block was bored/honed.

So far I have 1500 miles on the motor and the level on the dipstick has gone down maybe about a 1/4 from the top. So it has consumed roughly about 200ml of oil in 1500 miles. This doesn't seem like too much to me and I'm thinking it will settle down after a while but I will report back after I have more miles on it.

So far I have 1500 miles on the motor and the level on the dipstick has gone down maybe about a 1/4 from the top. So it has consumed roughly about 200ml of oil in 1500 miles. This doesn't seem like too much to me and I'm thinking it will settle down after a while but I will report back after I have more miles on it.

#73

Registered User

iTrader: (1)

Wow! when I think of all the engines I fixed over the years and never had an issue. All were pre-Q9002 with no fancy machinery. Some were just a ridge cutter and bottle ball hone. All the oil consumption was through the valve guides from being sloppy. sometimes the valve guides just leaked despite everything we did.

#74

Registered User

I have about 6500 miles on the rebuild. And just did a compression check.

I will try to get more info regarding what they used for boring/finish honing from the machine shop I used.

I used the pistons/rings that came with the ENGNBLDR kit. Which I assume is the rock products rings? I am still not clear as to what these are made out of though.

I am 20 over bore, with the block (not head) milled 10 (Pretty darn close to 0 quench).

When I put this together I used 3-in-1 SAE 20 oil that is available in the little bottles from Lowes. And alot of it, not only on the cyl walls, but also coated the pistons and ring compressor with it.

After the initial cam break in (2500-3000RPM varying) I drove it hard with 3/4 throttle not going over 3,500 RPM and allowing the motor to back itself off by letting go of the throttle. I did this several times (maybe 8-10 times.) Then drove like normal for the rest of the time. I do however have a pretty good hill climb to work every day as well. Which I have heard helps seat pistons when the engine has a load with minimal throttle.

I changed the oil after the first initial 30 minute brake in, then again at 200,500,1500 and 3,000 miles, then 6,000 miles. Using Valvoline 10W30 the entire time except the last one when I went with the 15W40 Valvoline Diesel Oil.

here are the compression results using an Actron Compression gauge borrowed from 92 Toy:

#1 173 psi

#2 170 psi

#3 170 psi

#4 173 psi

Pretty darn good (almost perfect even) I would assume for a rebuild to 20 over and a milled block. Looks like I got my quench just right as I think the numbers would be higher or lower across the board. Maybe someone can chime in if I am thinking incorrectly.

Cannot tell if I am burning oil at all because of a pretty good oil pan leak. But with a brand new "stock" proline head from ENGNBLDR and compression like that I highly highly doubt it.

Hope this somewhat helps. I know you will look forward to the info from the machine shop.

I will try to get more info regarding what they used for boring/finish honing from the machine shop I used.

I used the pistons/rings that came with the ENGNBLDR kit. Which I assume is the rock products rings? I am still not clear as to what these are made out of though.

I am 20 over bore, with the block (not head) milled 10 (Pretty darn close to 0 quench).

When I put this together I used 3-in-1 SAE 20 oil that is available in the little bottles from Lowes. And alot of it, not only on the cyl walls, but also coated the pistons and ring compressor with it.

After the initial cam break in (2500-3000RPM varying) I drove it hard with 3/4 throttle not going over 3,500 RPM and allowing the motor to back itself off by letting go of the throttle. I did this several times (maybe 8-10 times.) Then drove like normal for the rest of the time. I do however have a pretty good hill climb to work every day as well. Which I have heard helps seat pistons when the engine has a load with minimal throttle.

I changed the oil after the first initial 30 minute brake in, then again at 200,500,1500 and 3,000 miles, then 6,000 miles. Using Valvoline 10W30 the entire time except the last one when I went with the 15W40 Valvoline Diesel Oil.

here are the compression results using an Actron Compression gauge borrowed from 92 Toy:

#1 173 psi

#2 170 psi

#3 170 psi

#4 173 psi

Pretty darn good (almost perfect even) I would assume for a rebuild to 20 over and a milled block. Looks like I got my quench just right as I think the numbers would be higher or lower across the board. Maybe someone can chime in if I am thinking incorrectly.

Cannot tell if I am burning oil at all because of a pretty good oil pan leak. But with a brand new "stock" proline head from ENGNBLDR and compression like that I highly highly doubt it.

Hope this somewhat helps. I know you will look forward to the info from the machine shop.

Last edited by xxxtreme22r; 09-20-2010 at 11:23 AM.

#75

I triple-checked the package and the stones I used were #240 grit. My NPR rings were SWT10144ZZ

http://www.perfectengine.com/Toyota_...r-swt10144.htm

On the cylinder honing for chrome rings subject...NPR rings for the 22RE and the 3VZE are W series mark/777 series#. They both have gas nitrided hardened steel chrome faced 1st compression, cast iron moly coated 2nd compression rings, Nifflex-S three piece chrome faced oil control rings. This NPR catalog describes the sets thoroughly.

1st ring: Steel + Cr

2nd ring: Cast iron

Oil ring: Nifflex-S (3 piece type)

NPR website

SO EVEN NPR RINGS MAY REQUIRE HONING PROCEDURES FOR CHROME RINGS.

Or #240 grit @ 45° honing pattern, like me.

http://www.enginebuildermag.com/Arti...er_honing.aspx

http://www.enginebuildermag.com/Arti..._finishes.aspx

http://www.enginebuildermag.com/Arti...finishing.aspx

http://www.enginebuildermag.com/Arti..._finishes.aspx

http://www.aa1car.com/library/honing98.htm

Description

NPR Piston Ring Set for Toyota 3.0L 3VZE engines

Includes Genuine NPR Pistons for Complete Engine

Applications:

Toyota 4Runner 1988-1995

Toyota Pickup Truck 1988-1995

Toyota T100 Truck 1993-1994

Reference Years: 1988, 1989, 1990, 1991, 1992, 1993, 1994, 1995

Bore Size: 87.5mm

Ring Pack: 1.5x1.5x4.0

Confirm Application and Bore Size Before Ordering

Piston Ring Reference #: 13011-62060, NPR Piston Ring #: SWT10144

Features

Genuine Nippon Piston Ring Company

Nitride Hardened Steel Piston Rings resist flaking and breaking under extreme heat.

Optimum design for increased power, efficiency and fuel economy.

NPR Piston Ring Set for Toyota 3.0L 3VZE engines

Includes Genuine NPR Pistons for Complete Engine

Applications:

Toyota 4Runner 1988-1995

Toyota Pickup Truck 1988-1995

Toyota T100 Truck 1993-1994

Reference Years: 1988, 1989, 1990, 1991, 1992, 1993, 1994, 1995

Bore Size: 87.5mm

Ring Pack: 1.5x1.5x4.0

Confirm Application and Bore Size Before Ordering

Piston Ring Reference #: 13011-62060, NPR Piston Ring #: SWT10144

Features

Genuine Nippon Piston Ring Company

Nitride Hardened Steel Piston Rings resist flaking and breaking under extreme heat.

Optimum design for increased power, efficiency and fuel economy.

On the cylinder honing for chrome rings subject...NPR rings for the 22RE and the 3VZE are W series mark/777 series#. They both have gas nitrided hardened steel chrome faced 1st compression, cast iron moly coated 2nd compression rings, Nifflex-S three piece chrome faced oil control rings. This NPR catalog describes the sets thoroughly.

1st ring: Steel + Cr

2nd ring: Cast iron

Oil ring: Nifflex-S (3 piece type)

SO EVEN NPR RINGS MAY REQUIRE HONING PROCEDURES FOR CHROME RINGS.

So, in conclusion, I'll offer these suggestions:

1. If you're dead-set on using the chrome rings try using a relatively coarse grit stone to hone the cylinders. Perhaps in the 180-220 grit range and see if that will help them to seat/seal better, for longer, or with less effort. Ted seems to agree with me on this atleast.

1. If you're dead-set on using the chrome rings try using a relatively coarse grit stone to hone the cylinders. Perhaps in the 180-220 grit range and see if that will help them to seat/seal better, for longer, or with less effort. Ted seems to agree with me on this atleast.

RECOMMENDED CYLINDER BORE FINISH

Most ring manufacturers specify a #220 grit honing abrasive for finishing the bores when using cast iron or chrome rings... A #280 grit stone is generally recommended for moly rings...

Most ring manufacturers specify a #220 grit honing abrasive for finishing the bores when using cast iron or chrome rings... A #280 grit stone is generally recommended for moly rings...

Most OEMs and ring manufacturers specify a surface finish of 15 to 25 RA for moly faced rings, which can be achieved by finish honing with #280 grit stones. Cast iron and chrome rings can tolerate a somewhat rougher surface finish (20 to 35 RA), so coarser #220 grit stones can be used to produce this type of finish.

By comparison, traditional honing procedures require no finishing step. Typically most ring manufacturers recommend using #220 grit silicon carbide honing stones if the engine will be assembled with plain cast iron or chrome rings, #280 grit stones for moly-faced rings...

For plain cast iron or chrome rings in a stock, street performance or dirt track motor, hone with #220 grit silicon carbide stones (or #280 to #400 diamond stones)...For moly faced rings in a street performance, drag or circle track motor, hone with a conventional #280 grit silicon carbide vitrified abrasive...

If you’re switching from conventional stones to diamond, you’ll generally have to use a higher grit to achieve the same Ra (roughness average) when finishing a cylinder. For example, if you have been using #220 grit conventional stones to finish cylinders for chrome rings, the equivalent diamond stones might be a #325 grit. If you have been using #280 grit conventional stones to hone for moly rings, the diamond equivalent might be #550 grit stones. The actual numbers will vary somewhat depending on the brand and grade of the stones.

http://www.enginebuildermag.com/Arti..._finishes.aspx

http://www.enginebuildermag.com/Arti...finishing.aspx

http://www.enginebuildermag.com/Arti..._finishes.aspx

http://www.aa1car.com/library/honing98.htm

Last edited by MudHippy; 09-22-2010 at 06:38 PM.

#76

BTW, What do you mean by "good online source of OEM rings"? Cheap, or OEM manufacturer ONLY?

My Conclusion: They were probably nearly the same as the NPR rings I replaced them with. Steel chrome faced(? plated)#1 ring, Cast Iron(? plated)#2 ring, Nifflex-S 3 piece, chrome faced oil control rings. #1 ring and oil control rings sounded like steel when dropped, #2 makes a thud like cast iron. All shiny faced(indicative of chrome)when removed, and stayed so all except the cast iron #2 in the bottom pic. OEM rings then?...looks like a duck...quacks like a duck...They could be, or they could be OEM type. They weren't marked, other than "1R" and "2R" on the rings topsides. Which, IIRC, was the same for the NPR rings.

Uncorroded set.

Corroded set. The difference there is obvious. WAY less rust on the chrome faces vs. the cast iron.

Last edited by MudHippy; 09-23-2010 at 06:35 PM.

#77

NPR may make the Rock rings for Rock like Ted says.

However they are TOTALLY different than what comes in 22R/22RE's from the factory. The actual NPR boxed ring set direct from NPR "Looks" exactly like the factory ring set. NPR is supposed to be the original supplier.

However they are TOTALLY different than what comes in 22R/22RE's from the factory. The actual NPR boxed ring set direct from NPR "Looks" exactly like the factory ring set. NPR is supposed to be the original supplier.

#78

Registered User

Join Date: Sep 2007

Location: Bremerton, WA

Posts: 180

Likes: 0

Received 0 Likes

on

0 Posts

Looks like I'm a little late to the party, but I too have a ring issue. Roughly 25000 miles on a rebuild and have always had quite a bit of blowby, not much oil consumption though. Did a compression check and it was horrible, 95, 120, 120, 90. Pulled everything apart due to a blown head gasket and here's what I have.

The cylinder walls have no crosshatch left, smooth and shiny, so looks like they glazed over.

Was a rebuild kit from EB with Rock parts. Don't know if I didn't break it in properly or what, this was the first rebuild I had ever done. The block was taken to a machine shop where all the machining was done and they installed the pistons. Had a nice crosshatch pattern when I got it back from them. So getting ready to pull the pistons, use a bottlebrush hone on the cylinders and re-ring.

The cylinder walls have no crosshatch left, smooth and shiny, so looks like they glazed over.

Was a rebuild kit from EB with Rock parts. Don't know if I didn't break it in properly or what, this was the first rebuild I had ever done. The block was taken to a machine shop where all the machining was done and they installed the pistons. Had a nice crosshatch pattern when I got it back from them. So getting ready to pull the pistons, use a bottlebrush hone on the cylinders and re-ring.

#79

Registered User

Hey guys I thought I would finally chime in and share my experience with ROCK (ENGNBLDR) rings.

I currently have about 600 miles on the rebuilt engine, using Engnbldr's rings, pistons, wrist pins, rod bearings, main bearings, the whole deal.

So far I have only burned about 1/4 of a qt of oil, and this was for the "start up" oil, which I kept in the truck for about 50 miles. Im running the cheapest 5.30 on the market (NOT synthetic) and I used a comp cam engine oil break-in additive in the first batch of oil.

I changed the oil at 50 miles, and have about 550 miles on the current batch of oil. I have yet to see ANY oil being burned yet (yes I check it daily, or even before driving it), but I have a feeling it will eat up a little bit because these rigs shouldn't seat for roughly 1,000 miles since they are chrome.

I have had no blue smoke, and no other oil consumption issues. As a matter of fact, the thing runs like a champ and doesn't even have 1k miles on it yet.

I assume (knock on wood) that this will continue, but if not I will post up my results. So far I would recommend rock rings to anyone, they are definitely doing there job

I currently have about 600 miles on the rebuilt engine, using Engnbldr's rings, pistons, wrist pins, rod bearings, main bearings, the whole deal.

So far I have only burned about 1/4 of a qt of oil, and this was for the "start up" oil, which I kept in the truck for about 50 miles. Im running the cheapest 5.30 on the market (NOT synthetic) and I used a comp cam engine oil break-in additive in the first batch of oil.

I changed the oil at 50 miles, and have about 550 miles on the current batch of oil. I have yet to see ANY oil being burned yet (yes I check it daily, or even before driving it), but I have a feeling it will eat up a little bit because these rigs shouldn't seat for roughly 1,000 miles since they are chrome.

I have had no blue smoke, and no other oil consumption issues. As a matter of fact, the thing runs like a champ and doesn't even have 1k miles on it yet.

I assume (knock on wood) that this will continue, but if not I will post up my results. So far I would recommend rock rings to anyone, they are definitely doing there job

#80

It's been quite a while since I've been online and thought I'd do some catching up.

I'd really like to know if there is any update information from Pismojoe reguarding his engine. Hopefully all is well. Either way I'd love to hear about it.

Also I recently had a customer who a year ago purchased a "lifetime warranty" engine from Oregon Engine Rebuilders (O.E.R.) and had it installed by a shop in Wisconsin. He then moved to Seattle. Approx. a year after the install he had severe problems with the engine. Long story short O.E.R. said they wouldn't cover the engine failure. I ended up doing another install of a fresh motor. Here is where it gets interesting. O.E.R. advertises in the local Craigslist and has pictures of an engine which clearly shows a Rock timing chain cover box in the background so I have always known/figured they use rock products. This is one of the reasons My problem with the rings frustraded me so much. Thinking or knowing others were using the product and making it work, while I couldn't seem to.

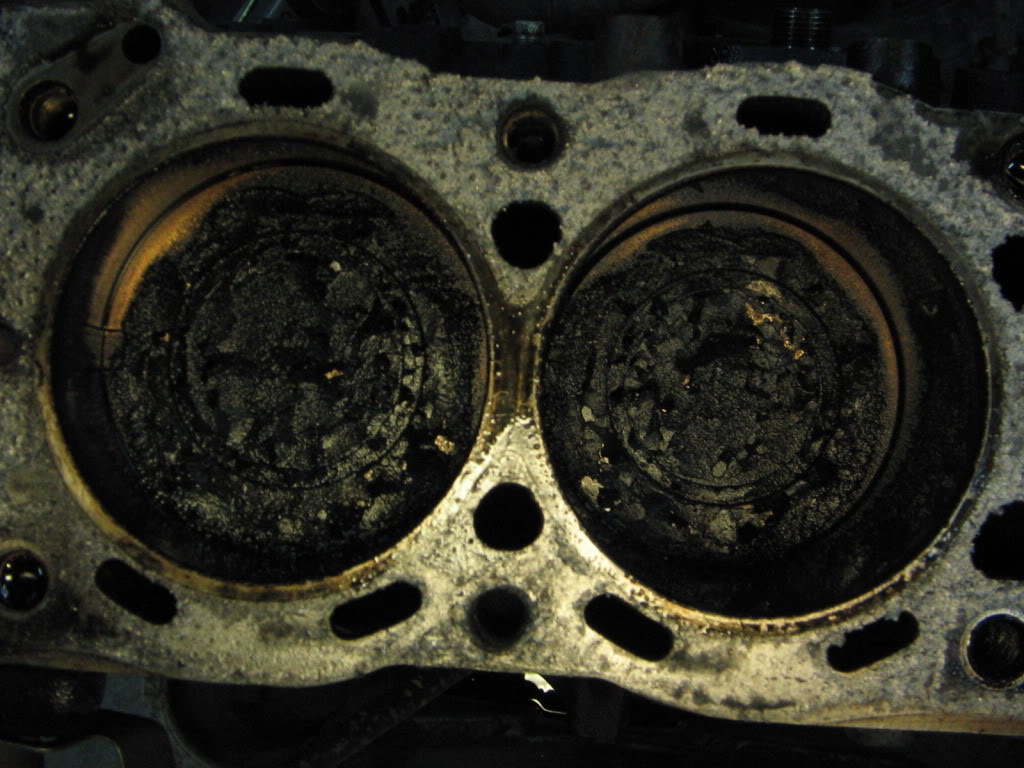

Well, as soon as I pulled the head off the customers damaged motor I knew EXACTLY what I was looking at. Around the edge of the piston it was clean/washed with heavy build up of carbon/soot in the centers. Also heavy soot build up in the tip of the tailpipe. Immediatly I sent a text to my customer asking IF he noticed oil consuption and IF he did how much. The response was as I expected. Yes indeed he had oil consumption !!! A few days later I ended up calling and speaking with the owner of Oregon Engine Rebuilders and he said and I quote "I have NEVER had any issues with our engines consuming oil"

Interesting.

I've encouraged that customer to describe in detail his experiences, hopefully soon as his his busy work schedule permits.

I'd really like to know if there is any update information from Pismojoe reguarding his engine. Hopefully all is well. Either way I'd love to hear about it.

Also I recently had a customer who a year ago purchased a "lifetime warranty" engine from Oregon Engine Rebuilders (O.E.R.) and had it installed by a shop in Wisconsin. He then moved to Seattle. Approx. a year after the install he had severe problems with the engine. Long story short O.E.R. said they wouldn't cover the engine failure. I ended up doing another install of a fresh motor. Here is where it gets interesting. O.E.R. advertises in the local Craigslist and has pictures of an engine which clearly shows a Rock timing chain cover box in the background so I have always known/figured they use rock products. This is one of the reasons My problem with the rings frustraded me so much. Thinking or knowing others were using the product and making it work, while I couldn't seem to.

Well, as soon as I pulled the head off the customers damaged motor I knew EXACTLY what I was looking at. Around the edge of the piston it was clean/washed with heavy build up of carbon/soot in the centers. Also heavy soot build up in the tip of the tailpipe. Immediatly I sent a text to my customer asking IF he noticed oil consuption and IF he did how much. The response was as I expected. Yes indeed he had oil consumption !!! A few days later I ended up calling and speaking with the owner of Oregon Engine Rebuilders and he said and I quote "I have NEVER had any issues with our engines consuming oil"

Interesting.

I've encouraged that customer to describe in detail his experiences, hopefully soon as his his busy work schedule permits.

Last edited by Trainwreckinseattle; 01-20-2011 at 12:46 PM.