Bypass the OE tranny cooler?

#241

Registered User

Join Date: Feb 2009

Location: Central Oregon

Posts: 122

Likes: 0

Received 0 Likes

on

0 Posts

#242

Contributing Member

Not trying to hijack this thread, but I wanted to add something regarding temps and this seems to be tied in with the tranny cooler.

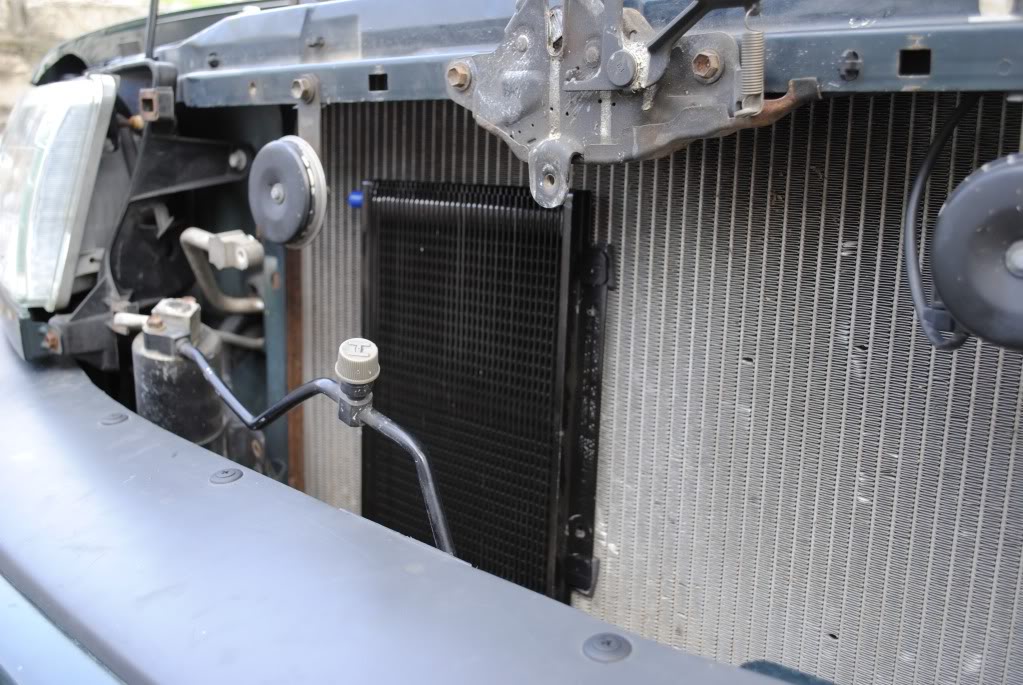

I was really bored today and wanted to test an idea. On the '99 + Runners with the fat lip bumper I was always wondering how much air made it to the radiators coming from the lower section of the bumper. To me it seems like the air pressure would build up once it went throught he grill and tried to travel through the radiators. What didn't go through would take the path of least resistance and be forced down and under the skidplate.

Now most of you couldn't care less, but because I have 4 170 LightForce lights blocking most of my grill I did notice my temps go up some. So I fabbed up this plate, bolted it up and went for a run. Sure enough my temps were lower then normal. Now I only went for one drive so it's not set in stone, but I think it might have potential... Even though my intake temps were about 20* higher (from this morning) My tranny temps were about the same. Compared to temps from last night where my intake temps were very close to current (50 degrees) my tranny temps were about 10* lower with this plate on.

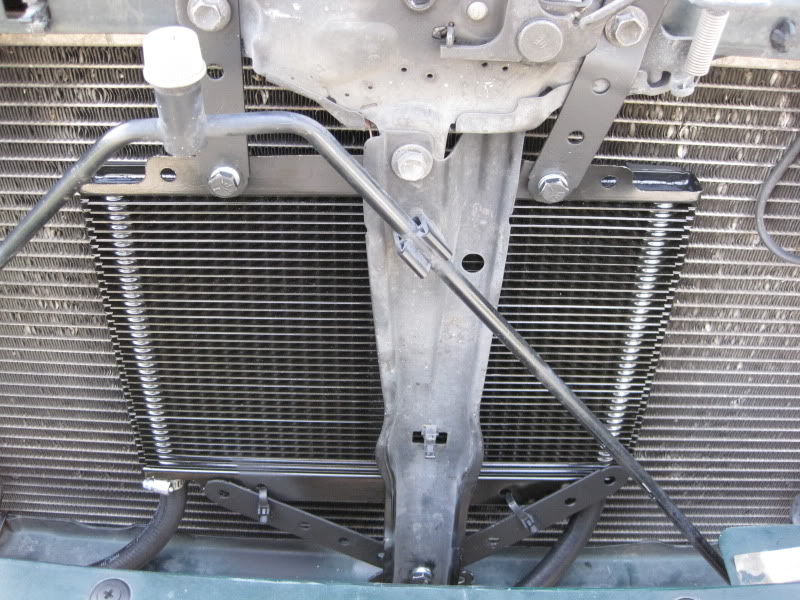

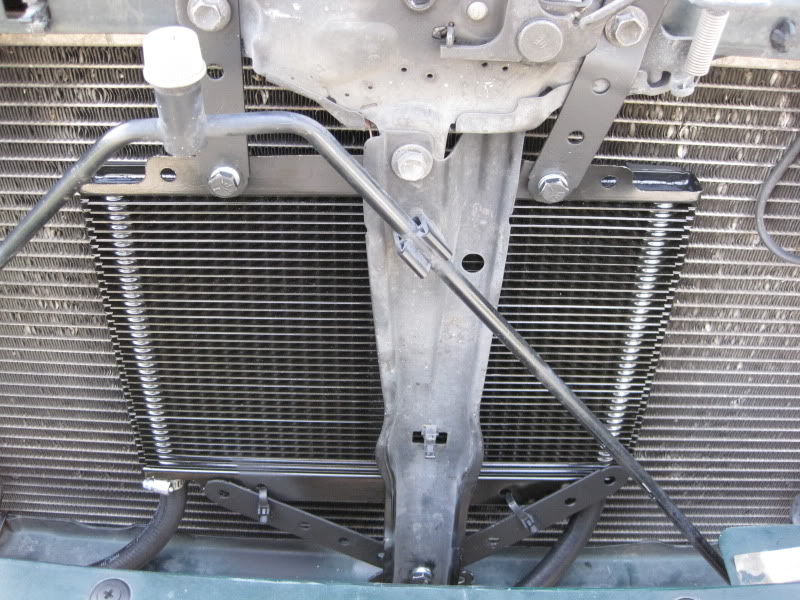

Pic of plate getting a fast coat of paint:

Bolted up:

Bolted up:

In this pic, you can see I can even expand the plate on it's edges to make it more "air tight". I can do it very easily by putting "wings" on it and secure them with rivets (I didn't yet because I want to test the theory first).

And from the front of the truck you can't even see it:

Opinions? Comments? Anyone have any science to back this up? Or blow it out of the water??? If nothing else it will keep road debre out of that area. But as of right now, I think it works. My opinion may change after a week or so.

I was really bored today and wanted to test an idea. On the '99 + Runners with the fat lip bumper I was always wondering how much air made it to the radiators coming from the lower section of the bumper. To me it seems like the air pressure would build up once it went throught he grill and tried to travel through the radiators. What didn't go through would take the path of least resistance and be forced down and under the skidplate.

Now most of you couldn't care less, but because I have 4 170 LightForce lights blocking most of my grill I did notice my temps go up some. So I fabbed up this plate, bolted it up and went for a run. Sure enough my temps were lower then normal. Now I only went for one drive so it's not set in stone, but I think it might have potential... Even though my intake temps were about 20* higher (from this morning) My tranny temps were about the same. Compared to temps from last night where my intake temps were very close to current (50 degrees) my tranny temps were about 10* lower with this plate on.

Pic of plate getting a fast coat of paint:

Bolted up:

Bolted up:

In this pic, you can see I can even expand the plate on it's edges to make it more "air tight". I can do it very easily by putting "wings" on it and secure them with rivets (I didn't yet because I want to test the theory first).

And from the front of the truck you can't even see it:

Opinions? Comments? Anyone have any science to back this up? Or blow it out of the water??? If nothing else it will keep road debre out of that area. But as of right now, I think it works. My opinion may change after a week or so.

#243

From further research on cooler orientation I came across this thread. It states: "The mounting orientation of the cooler is VERY important. I called B&M on this, because I was not sure. The least efficient way to cool is by having the hose outlets facing down. The MOST efficient is to have the cooler mounted with the outlets up or on the side. If you choose on the side, make sure the INLET (from the factory cooler) is on the bottom and the top hose goes to the tranny. This is VERY important." .

I don't understand how (if mounted on it's side) it can matter that much whether the inlet is on top or bottom. Supposedly this is VERY important, but I don't understand how it can be that important. Fluid is going to flow through the whole cooler no matter what...it's under pressure....it's not like it's just dribbling through there.

Any one else have thoughts on this?

#244

Contributing Member

I don't understand how (if mounted on it's side) it can matter that much whether the inlet is on top or bottom. Supposedly this is VERY important, but I don't understand how it can be that important. Fluid is going to flow through the whole cooler no matter what...it's under pressure....it's not like it's just dribbling through there.

Any one else have thoughts on this?

Any one else have thoughts on this?

I'm actually wondering if the guy in that link got it backwards. I agree with this part:

I'm actually wondering if the guy in that link got it backwards. I agree with this part:

The least efficient way to cool is by having the hose outlets facing down. The MOST efficient is to have the cooler mounted with the outlets up or on the side.

Last edited by mt_goat; 04-19-2010 at 05:41 PM.

#245

I've always seen cooling systems in general go in at the top and out at the bottom. Radiators, factory ATF coolers they all seem to go this way. My thinking is because heat rises and gravity pulls down and that way you have the natural flow working for you. If you go in at the bottom the heat rises to the top and you are forcing the fluid against gravity through the small channels. But if they can explain why going in the bottom and out the top is better I'm all ears.  I'm actually wondering if the guy in that link got it backwards.

I'm actually wondering if the guy in that link got it backwards.

I'm actually wondering if the guy in that link got it backwards.

I'm actually wondering if the guy in that link got it backwards.

#246

Last edited by CLin9383; 04-20-2010 at 05:49 AM.

#247

Registered User

When you put those zip cord mounts in for the cooler, be sure to only put them through the condenser and not through both the condenser and radiator.

I've seen a good number of people slide them all the way through to the radiator and put the back clip on. In the process they bow the condenser and radiator towards each other and cause leaks. I know pulling the radiator just for that is a PITA but if ya don't it will cause leaks.

FOG

I've seen a good number of people slide them all the way through to the radiator and put the back clip on. In the process they bow the condenser and radiator towards each other and cause leaks. I know pulling the radiator just for that is a PITA but if ya don't it will cause leaks.

FOG

#248

so when you attach the cooler to the condenser, should it just be mildly snug? getting prepared to do it and wasn't sure what most people do. attach to the condenser or make brackets so it doesn't touch condenser. would it be wise to make brackets to where cooler is just off the condenser maybe a 1/4" so its not touching. i don't want to damage my condenser doing this and its safe to put those ties through the condenser?

#249

Registered User

Snug is good, just be sure that the little rubber spacers/pads are on the back of the trans cooler on the corners where the zip ties go through.

I've had mine in for two years on my current runner and have used those zip tie style mounts on other vehicles with no problems.

As far as mounting the cooler on metal straps away from the condenser, I wouldn't recommend it. The biggest times you need the cooler is stop and go or heavy 4 wheeling or other conditions where because of lack of speed there is no large amount of air being rammed through the cooler.

When mounted on the condenser its able to get the full benefit from the radiator fan pulling air through it especially at the low speeds when needed most.

FOG

I've had mine in for two years on my current runner and have used those zip tie style mounts on other vehicles with no problems.

As far as mounting the cooler on metal straps away from the condenser, I wouldn't recommend it. The biggest times you need the cooler is stop and go or heavy 4 wheeling or other conditions where because of lack of speed there is no large amount of air being rammed through the cooler.

When mounted on the condenser its able to get the full benefit from the radiator fan pulling air through it especially at the low speeds when needed most.

FOG

#250

thanks fogrunner.... you've been very helpful and i thank you with this project. you've given me lots of helpful info to make this job pretty easy even for me. ill take pics and let all know how it went

#251

Contributing Member

#253

Contributing Member

Join Date: May 2002

Location: Kirkland-ish, WA

Posts: 185

Likes: 0

Received 0 Likes

on

0 Posts

#254

So after reading through this entire thread I am reconsidering mounting mine on its side. Sounds like the inlets pointing down like I have is the least efficient way. But does anyone know for sure what temp differences or significance having it mounting my way may cause? Re-mounting and re-routing the lines isn't bad but it will be another $25 for the ATF hose

Would you guys re-route it if you were me? Thanks!

Would you guys re-route it if you were me? Thanks!

#255

Contributing Member

So after reading through this entire thread I am reconsidering mounting mine on its side. Sounds like the inlets pointing down like I have is the least efficient way. But does anyone know for sure what temp differences or significance having it mounting my way may cause? Re-mounting and re-routing the lines isn't bad but it will be another $25 for the ATF hose

Would you guys re-route it if you were me? Thanks!

Would you guys re-route it if you were me? Thanks!

#256

Thanks for the reply goat. Despite looking at numerous threads I haven't found a definitive answer to what are normal or ok tranny temps. If I had to ball park I would say people see anywhere between 130-160 for normal conditions & 170-220 while towing/wheeling/stop & go...does this sound about right? What do you perceive to be ok? This may only be my 2nd post here but I know your well respected around these parts for your excellent knowledge so I appreciate your input

PS: I don't have a way to check the temps at the moment but I plan to install a scanguageII in the future

PS: I don't have a way to check the temps at the moment but I plan to install a scanguageII in the future

#257

Contributing Member

Thanks for the reply goat. Despite looking at numerous threads I haven't found a definitive answer to what are normal or ok tranny temps. If I had to ball park I would say people see anywhere between 130-160 for normal conditions & 170-220 while towing/wheeling/stop & go...does this sound about right? What do you perceive to be ok? This may only be my 2nd post here but I know your well respected around these parts for your excellent knowledge so I appreciate your input

PS: I don't have a way to check the temps at the moment but I plan to install a scanguageII in the future

PS: I don't have a way to check the temps at the moment but I plan to install a scanguageII in the future

#259

I'll take some when I get my new condenser installed. There's just barely enough room to squeeze them between the side of the condenser and the radiator bracket. There is some pressure on them, but nothing that will hurt anything I dont think. I'm going to try to bias the condenser to the opposite side when I re-install it, giving me just that much more space for the lines. Mounting wise, I could probably move the condenser a whole inch...but I don't think the hard lines would move that much. So I'll probably only get an extra 1/8th or so.

#260

Registered User

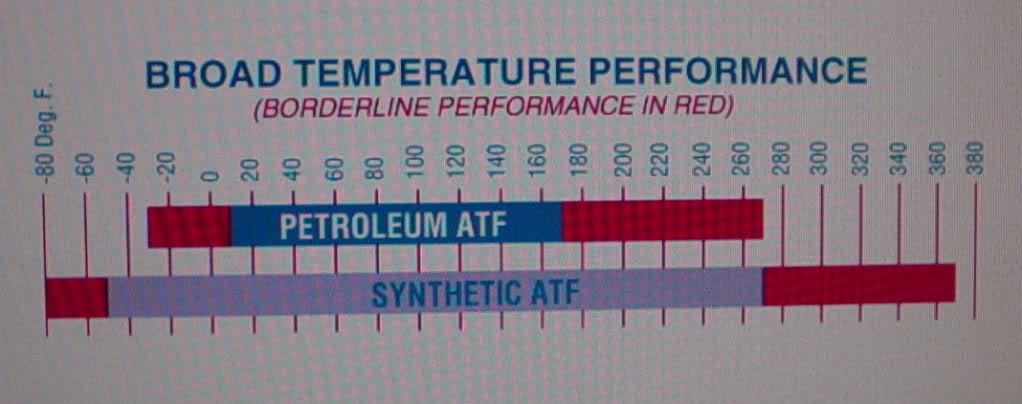

Running in the 170-220 window should only be done INTERMITTENTLY. Examples are steeping on it hard to get on the freeway with a trailer.

Going above 220F should never happen. If it does then you have seriously insufficient cooling and/or are overloading the transmission.

As far as mudding gos, its going to heat up the transmission. If the type of mudding/off roading you do causes the transmission to exceed 170-180 continuously then you should look at adding more transmission cooling.

Another issue that will cause excessive transmission temps when driving off road or mudding is if you have put larger tires on without properly re-gearing your axles.

But as stated above you shouldn't run your transmission continuously over 170-180 degrees. Yes the synthetic fluid can tolerate it but the rubber seals and the chemical compounds they use to laminate the clutch plates can't.

FOG