T100 MT/AT ECU swap

#1

T100 MT/AT ECU swap (fixed/completed)

EDIT: Since I have everything figured out, I'll summarize the data here. Below the line is the original posts for reference.

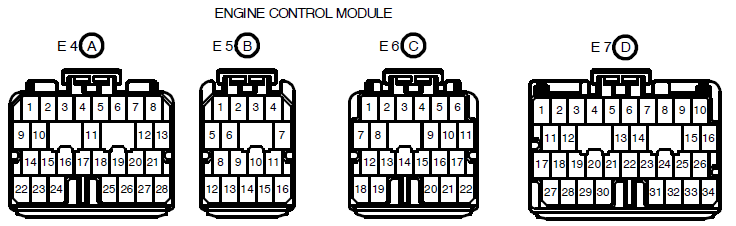

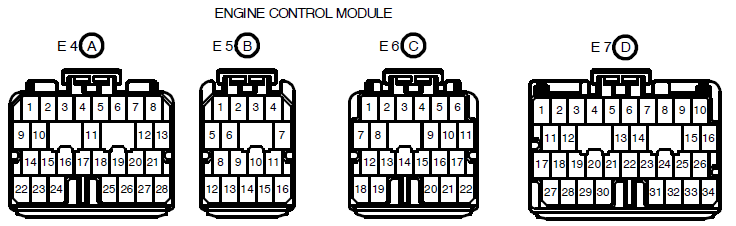

I bought a 1998 T100 SR5 4x4 3.4L (5VZ-FE) with Manual Transmission (R150) which had a bad ECU. I went the cheap route because I had plenty of time to deal with the wiring and ended up using a 1997 T100 DLX 4x4 3.4L Auto Transmission ECU. Here are the repinning I did on the truck's harness at the ECU plugs:

Format is: From pin -> To pin

I did end up with two error codes relating to the transmission, but the little I've drove it around the yard, it doesn't seem to effect the engine's performance at all.

Just a quick note, in my case I plugged in the computer not knowing the pinout differences and it burned up all 3 ignition coils, and the igniter. I had the start, run for a few seconds, then cut off/die like no signal from the MAS, but it ended up being the igniter's IGF signal wasn't working right so the ECU didn't think the engine was running.

__________________________________________________ __________________________________________________ __________

You can skip this block of text if you don't want the back story. Pretty much I bought a 1998 SR5 4x4 T100 for a pretty good price with a good frame, and a pretty rusty body to use as a winter beater and wood hauler. I bought it knowing it has a bad ECU and possible fuel pump issues. It came with nearly new winter tires that are about worth what I paid for the whole truck . The last owner's story on the truck was his son was driving it and it just suddenly died. I diag'ed it on the spot as bad ECU (no ecu light with key on) which matches what his mechanic said. The two parts T100's I have are both 97 and 3.4L autos with high miles, some parts stripped, broken crank sensor mounts on the engines, and high miles with a very hard life. Last owner was a bear hunter from nothern michigan, and claims he trail rides 70mph though the woods, one truck even has a broken torsion bar to show the proof. I have some tacoma's for parts, however all are automatic and probalby would complicate things further being from a different platform (also have a 4runner but it's still drive-able for a yard buggy).

. The last owner's story on the truck was his son was driving it and it just suddenly died. I diag'ed it on the spot as bad ECU (no ecu light with key on) which matches what his mechanic said. The two parts T100's I have are both 97 and 3.4L autos with high miles, some parts stripped, broken crank sensor mounts on the engines, and high miles with a very hard life. Last owner was a bear hunter from nothern michigan, and claims he trail rides 70mph though the woods, one truck even has a broken torsion bar to show the proof. I have some tacoma's for parts, however all are automatic and probalby would complicate things further being from a different platform (also have a 4runner but it's still drive-able for a yard buggy).

What I'm attempting to do is swap the ECU from the 97 auto t100 to the 98 manual t100 to replace the bad ecu. I've downloaded the EWD for both trucks (well all T100s) and made my pin by pin check and have everything swapped over. There were a few wires that are possible issues missing on the manual harness, here is the list of auto ecu pins with no wire running to them currently.

A17 - TFN - (looks to be transfer case neutral detection, grounded only when it's in neutral, not sure why the ecu would care)

C11 - G- (based on the EWD images, it shows it is internally connected to NE- which is what the auto harness does externally)

C12 - OIL - (based on a description I found online for the pin, it's the auto atf temp sensor, under 1.5v = overheat and causes the oil light to light up. Sounds like it isn't a big deal to leave unhooked, but might splice B+ to it so no oil light)

D14 - NSW - (This is where I'm a bit stuck, manual truck is the same wire diagram except the wire doesn't go to the ECM. It only cranks when clutch in or clutch cancel is pressed, so not sure if the ECU needs the connection, and I find conflicting info as to what the signal actually is. Some say it's grounded, others say it's +12v. This is the neutral/park saftey signal. Wire diagram from my understanding suggests it's +12v signal.)

97 wire diagram: https://gyazo.com/dfbd9402a6cb6582463dbcdb50e4dc34

97 at ecu diagram: https://gyazo.com/4e69ddffa06a45682bb7128ebfef4538

D29 - L4 - (Used only when truck is in low range 4x4, likely only used to alter shift points, the other auto 3.4l trucks i've drove has a clear indication it's probably true.)

There is only one wire on the 98 MT harness with no home for the 97 AT ecu, pin location based on the 98 plug

D31 - PSW - (appears to be for an electronic based idle kick up for the power steering pump. Signal is just grounded when closed and is labeled as "Power Stering Oil Pressure SW". I assume it's safe to ignore unless I have stalling issues while turning the wheels at idle.)

Anyway to get to my actual problem, all pins are repinned for the 97 at ecu, and the truck acts like the mass air flow sensor is disconnected, starts and runs for a couple seconds then dies. I've ohm'ed the wires and validated TPS, cam sensor, and mass air flow sensor are correctly pinned. I think I've narrowed it down to the NSW signal wire since almost every mention of MT trans with auto ecu mentions tricking the ecu to think it's in neutral/park but no one ever mentions how. The other possible problem pin could be the G- if it isn't actually internally grounded to NE-, I have to ohm the pins on the ecu when I get to the truck again. I've tried to work with my dad to listen for the fuel pump running after it starts, but the fuel pump runs too smoothly to hear it well and just switching the key on it sounds nice and healthy so I don't think the fuel pump is bad as the last owner was thinking.

I have no inspection in my state, so no smog/emission issues from the ecu swap, and the logic behind it is because I'm self employed, I have time, but not money and several trucks around for parts. The only possible issue I didn't check on from the source truck is if it had an EGR or not, the 98 does not, and one of the motors from the 97 does not either but I'm not sure which truck the ecu is from, worst case I could just swap the ecu out if it's one with an egr, or just swap in the egr which might help get a little better MPG (my corolla has a plugged egr system currently, only ill effect is check engine light and slightly worse MPG).

Any help with this ecu swap would be great, or even just steering me in the right direction for the EWD files. Boggles my mind why it isn't contained in a single file for easy searching per year.

I bought a 1998 T100 SR5 4x4 3.4L (5VZ-FE) with Manual Transmission (R150) which had a bad ECU. I went the cheap route because I had plenty of time to deal with the wiring and ended up using a 1997 T100 DLX 4x4 3.4L Auto Transmission ECU. Here are the repinning I did on the truck's harness at the ECU plugs:

Format is: From pin -> To pin

Code:

A8 -> A18 (also moved OBD2 diag port pin 7 to pin 2, looking at the plug widest part on top, pin 1 is top left) A11 -> B1 A16 -> A20 A23 -> A22 A24 -> A25 B2 -> B15 B7 -> C18 B8 -> B13 B10 -> D15 B11 -> D16 B12 -> B8 (my truck didn't have B11 or B12, no EGR) B13 -> C15 B14 -> C21 C14 -> C16 C15 -> C17 C17 -> C10 C18 -> B4 C21 -> C14 D1 -> A26 D15 -> D26 D16 -> D25 D28 -> D1 C6 -> C6 and C11 (Need to splice together both pins to the NE- wire. Engine will run with out this done, but runs better with it). Remove Pin D31 as it isn't used.

Just a quick note, in my case I plugged in the computer not knowing the pinout differences and it burned up all 3 ignition coils, and the igniter. I had the start, run for a few seconds, then cut off/die like no signal from the MAS, but it ended up being the igniter's IGF signal wasn't working right so the ECU didn't think the engine was running.

__________________________________________________ __________________________________________________ __________

You can skip this block of text if you don't want the back story. Pretty much I bought a 1998 SR5 4x4 T100 for a pretty good price with a good frame, and a pretty rusty body to use as a winter beater and wood hauler. I bought it knowing it has a bad ECU and possible fuel pump issues. It came with nearly new winter tires that are about worth what I paid for the whole truck

. The last owner's story on the truck was his son was driving it and it just suddenly died. I diag'ed it on the spot as bad ECU (no ecu light with key on) which matches what his mechanic said. The two parts T100's I have are both 97 and 3.4L autos with high miles, some parts stripped, broken crank sensor mounts on the engines, and high miles with a very hard life. Last owner was a bear hunter from nothern michigan, and claims he trail rides 70mph though the woods, one truck even has a broken torsion bar to show the proof. I have some tacoma's for parts, however all are automatic and probalby would complicate things further being from a different platform (also have a 4runner but it's still drive-able for a yard buggy).

. The last owner's story on the truck was his son was driving it and it just suddenly died. I diag'ed it on the spot as bad ECU (no ecu light with key on) which matches what his mechanic said. The two parts T100's I have are both 97 and 3.4L autos with high miles, some parts stripped, broken crank sensor mounts on the engines, and high miles with a very hard life. Last owner was a bear hunter from nothern michigan, and claims he trail rides 70mph though the woods, one truck even has a broken torsion bar to show the proof. I have some tacoma's for parts, however all are automatic and probalby would complicate things further being from a different platform (also have a 4runner but it's still drive-able for a yard buggy).What I'm attempting to do is swap the ECU from the 97 auto t100 to the 98 manual t100 to replace the bad ecu. I've downloaded the EWD for both trucks (well all T100s) and made my pin by pin check and have everything swapped over. There were a few wires that are possible issues missing on the manual harness, here is the list of auto ecu pins with no wire running to them currently.

A17 - TFN - (looks to be transfer case neutral detection, grounded only when it's in neutral, not sure why the ecu would care)

C11 - G- (based on the EWD images, it shows it is internally connected to NE- which is what the auto harness does externally)

C12 - OIL - (based on a description I found online for the pin, it's the auto atf temp sensor, under 1.5v = overheat and causes the oil light to light up. Sounds like it isn't a big deal to leave unhooked, but might splice B+ to it so no oil light)

D14 - NSW - (This is where I'm a bit stuck, manual truck is the same wire diagram except the wire doesn't go to the ECM. It only cranks when clutch in or clutch cancel is pressed, so not sure if the ECU needs the connection, and I find conflicting info as to what the signal actually is. Some say it's grounded, others say it's +12v. This is the neutral/park saftey signal. Wire diagram from my understanding suggests it's +12v signal.)

97 wire diagram: https://gyazo.com/dfbd9402a6cb6582463dbcdb50e4dc34

97 at ecu diagram: https://gyazo.com/4e69ddffa06a45682bb7128ebfef4538

D29 - L4 - (Used only when truck is in low range 4x4, likely only used to alter shift points, the other auto 3.4l trucks i've drove has a clear indication it's probably true.)

There is only one wire on the 98 MT harness with no home for the 97 AT ecu, pin location based on the 98 plug

D31 - PSW - (appears to be for an electronic based idle kick up for the power steering pump. Signal is just grounded when closed and is labeled as "Power Stering Oil Pressure SW". I assume it's safe to ignore unless I have stalling issues while turning the wheels at idle.)

Anyway to get to my actual problem, all pins are repinned for the 97 at ecu, and the truck acts like the mass air flow sensor is disconnected, starts and runs for a couple seconds then dies. I've ohm'ed the wires and validated TPS, cam sensor, and mass air flow sensor are correctly pinned. I think I've narrowed it down to the NSW signal wire since almost every mention of MT trans with auto ecu mentions tricking the ecu to think it's in neutral/park but no one ever mentions how. The other possible problem pin could be the G- if it isn't actually internally grounded to NE-, I have to ohm the pins on the ecu when I get to the truck again. I've tried to work with my dad to listen for the fuel pump running after it starts, but the fuel pump runs too smoothly to hear it well and just switching the key on it sounds nice and healthy so I don't think the fuel pump is bad as the last owner was thinking.

I have no inspection in my state, so no smog/emission issues from the ecu swap, and the logic behind it is because I'm self employed, I have time, but not money and several trucks around for parts. The only possible issue I didn't check on from the source truck is if it had an EGR or not, the 98 does not, and one of the motors from the 97 does not either but I'm not sure which truck the ecu is from, worst case I could just swap the ecu out if it's one with an egr, or just swap in the egr which might help get a little better MPG (my corolla has a plugged egr system currently, only ill effect is check engine light and slightly worse MPG).

Any help with this ecu swap would be great, or even just steering me in the right direction for the EWD files. Boggles my mind why it isn't contained in a single file for easy searching per year.

Last edited by atcfixer; 02-12-2017 at 12:01 PM.

The following users liked this post:

Somethingisntright (06-07-2023)

#2

I got to mess around with the truck and found a couple of interesting things.

NE- and G- were internally connected in the ecu, however it had a fairly high resistance, somewhere around 3k ohms. I spliced NE- to also go to the G- pin which resulted in no change (the actual G- signal is combined to NE- before the plug per the wire diagram).

For the NSW signal, everything I can make out from the wire diagrams, it is a +12v signal, so I ran a test wire to the positive terminal on the battery, and same thing no change.

Next I targeted the fuel pump since I can't tell 100% if it's running after it starts or not. I found the location/pinout for the fuel pump relay ... aka circuit opening relay and jumped B+ to Fp to energize the fuel pump whenever the key is on. Things did change, but also the battery was getting low, but it stopped starting and acts flooded. Currently charging up the battery and give it a go again. Might have to pull the plugs and "burn" them to clear out the fuel from them and check if they are even NGK/Denso and the double ground strap. I'll likely replace them once I get it going anyway.

Hopefully it will fire up and continue to run with the jumper wire installed and work my way backwards from there to find the issue. Also the fuel pump is pumping very well, with the key on and the jumper installed you can hear the fuel flowing though the fuel rail very well.

Anymore ideas/suggestions very much welcomed. Would have to have to swap an engine + trans just because the low miles engine has something likely simple wrong with it. Oh I also ohm'ed the COR coils and they tested within spec.

NE- and G- were internally connected in the ecu, however it had a fairly high resistance, somewhere around 3k ohms. I spliced NE- to also go to the G- pin which resulted in no change (the actual G- signal is combined to NE- before the plug per the wire diagram).

For the NSW signal, everything I can make out from the wire diagrams, it is a +12v signal, so I ran a test wire to the positive terminal on the battery, and same thing no change.

Next I targeted the fuel pump since I can't tell 100% if it's running after it starts or not. I found the location/pinout for the fuel pump relay ... aka circuit opening relay and jumped B+ to Fp to energize the fuel pump whenever the key is on. Things did change, but also the battery was getting low, but it stopped starting and acts flooded. Currently charging up the battery and give it a go again. Might have to pull the plugs and "burn" them to clear out the fuel from them and check if they are even NGK/Denso and the double ground strap. I'll likely replace them once I get it going anyway.

Hopefully it will fire up and continue to run with the jumper wire installed and work my way backwards from there to find the issue. Also the fuel pump is pumping very well, with the key on and the jumper installed you can hear the fuel flowing though the fuel rail very well.

Anymore ideas/suggestions very much welcomed. Would have to have to swap an engine + trans just because the low miles engine has something likely simple wrong with it. Oh I also ohm'ed the COR coils and they tested within spec.

#3

Update on this encase anyone else is following along. I got my OBD2 diag port working, signal wire in pin 7 needed to be moved to pin 2. Scanned for errors and only had one for the auto trans which was expected. I checked TPS, Mass airflow meter, engine coolant temp, air intake temp, etc and everything I could think of checked out as at least functioning enough to change numbers on my display.

The battery is low so I'm charging it up, so while it's doing that I'm making this update post.

Hoping to go though and check resistance values that I found in the EWD pages for the injectors etc.

The battery is low so I'm charging it up, so while it's doing that I'm making this update post.

Hoping to go though and check resistance values that I found in the EWD pages for the injectors etc.

#4

Update on this encase anyone else is following along. I got my OBD2 diag port working, signal wire in pin 7 needed to be moved to pin 2. Scanned for errors and only had one for the auto trans which was expected. I checked TPS, Mass airflow meter, engine coolant temp, air intake temp, etc and everything I could think of checked out as at least functioning enough to change numbers on my display.

The battery is low so I'm charging it up, so while it's doing that I'm making this update post.

Hoping to go though and check resistance values that I found in the EWD pages for the injectors etc.

The battery is low so I'm charging it up, so while it's doing that I'm making this update post.

Hoping to go though and check resistance values that I found in the EWD pages for the injectors etc.

#5

Truck runs yahoo. Long story short, the IGF signal from the igniter stayed at 4.6v all the time, and should go 6v or more when running. Swapped it out with one from a 97 which ironically the part number said it wouldn't work in the 98, but the pinouts matched up perfect so I plugged it in anyway. First try and she fired up well. It had a slight "off" sound to it not 100% right (I drive a 3.4L tacoma and my dad has a t100 too so I know their sound well), and my temp twisted G- and NE- came undone for G-. Hooked it up and it stalled, started it again and sounded just right, so to confirm, the 98 wire harness needs to splice NE- to also go to G- for best performance.

The igniter part number I used on the 98 is: 89621-35011

*note* I'm using the 97 computer, and that's where the igniter came from, so really the interchange could be off if the signals are slightly different for the ecu, but I suspect that isn't the case.

The NSW signal (neutral safety) isn't hooked up, so looks like the ECU doesn't really care about neutral/park when starting as long as the starting relays can get power to the starter.

Just to be clear, I plugged in the 97 AT ecu into the 98 before I found out they were not direct swappable, this mistake burned out all 3 ignition coils and the igniter. Basically the O2 heater circuits gave constant power to two of the igniter wires.

Drove the truck around some and she runs well, putting it in 4x4 didn't work so I'll have to look into that yet (add system), and the heater blower doesn't work on any setting. Fun stuff to play with, but at least it's drive able. Just in time too because my rear driver's leaf spring's front mount broke away from the frame hauling wood and the Michigan salt/rust.

The igniter part number I used on the 98 is: 89621-35011

*note* I'm using the 97 computer, and that's where the igniter came from, so really the interchange could be off if the signals are slightly different for the ecu, but I suspect that isn't the case.

The NSW signal (neutral safety) isn't hooked up, so looks like the ECU doesn't really care about neutral/park when starting as long as the starting relays can get power to the starter.

Just to be clear, I plugged in the 97 AT ecu into the 98 before I found out they were not direct swappable, this mistake burned out all 3 ignition coils and the igniter. Basically the O2 heater circuits gave constant power to two of the igniter wires.

Drove the truck around some and she runs well, putting it in 4x4 didn't work so I'll have to look into that yet (add system), and the heater blower doesn't work on any setting. Fun stuff to play with, but at least it's drive able. Just in time too because my rear driver's leaf spring's front mount broke away from the frame hauling wood and the Michigan salt/rust.

Last edited by atcfixer; 02-12-2017 at 11:43 AM.

#6

Checked out the ADD VSVs and the 2wd and 4wd ones worked correctly when in 2wd vs 4h so figured it was just the actuator being stiff from lack of use. Sat in the truck with it running for a few mins switching it from 2wd to 4h and back. Figured I'd have to mess around with the ADD under the truck or the 4wd switch was bad on the transfercase, so I tried to spin the tires in 4h and when I did it locked in 4wd, how ironic. 4x4 works fine now, locks in / out like normal.

I found the blower motor's 2 pin connector was a bad connection, I wiggled it and it came to life and has worked since. Going to keep an eye on it, might have to make a new pig tail for it down the road.

I think that solves all the problems that I know of about the truck so planning to get it legal Monday and drive it around some. Hopefully no 5th gear vibrations like I've seen in the past on other T100's.

I found the blower motor's 2 pin connector was a bad connection, I wiggled it and it came to life and has worked since. Going to keep an eye on it, might have to make a new pig tail for it down the road.

I think that solves all the problems that I know of about the truck so planning to get it legal Monday and drive it around some. Hopefully no 5th gear vibrations like I've seen in the past on other T100's.

#7

I've put around 2k miles on the truck already =) working good. Blower motor I made a pig tail, and replace it with a 95 pickup blower motor since it's a metal housing with a length of wire before it's plug. ADD system sticks a little, but for the most part the truck has no issues and have been getting around 18-20mpg. It has a super slow fuel leak that I have to look into, but it's getting better MPG than my Tacoma did which is really odd, but it also seems to run so much better too for the bottom end power.

Talking of the Tacoma, got it sold for most of what I had into it, and another parts truck I had for a slight profit, overall I almost broke even on those two trucks. This T100 on the other hand was only $500 and a long trip to get it, so pretty hard to get burned on that deal =).

Talking of the Tacoma, got it sold for most of what I had into it, and another parts truck I had for a slight profit, overall I almost broke even on those two trucks. This T100 on the other hand was only $500 and a long trip to get it, so pretty hard to get burned on that deal =).

Trending Topics

#8

Registered User

Join Date: Mar 2008

Location: Kodiak, Alaska

Posts: 43

Likes: 0

Received 0 Likes

on

0 Posts

Nice

Thanks for the good post with info. I am looking at doing a manual swap on my 95 t100, since I don't have a manual ECU it would be more cost effective to rewire the at. Hope your enjoying the Michigan winter. I spent 5 winter's just outside of Traverse City, love that snow.

#9

You're welcome, figured it would be better to post more info on the ecu swap since it took me a lot of digging to figure it out.

Ironically the pickup I did this work on was from the Traverse City area. Body is very rusty, but frame, engine, trans, etc are sold. I've put around 8k miles on it so far and not one issue (220k on it now). I hauled about 30 face chord of fire wood (Ash mainly) with it last winter and going to be doing some more hauling this year. The only slightly annoying thing I've had so far is the AT ecu seems to make the engine idle quite a bit lower than MT so in some situations it can be fairly easy to stall, but the AT ecu seems to handle lower RPM better too, if my MT Tacoma would get below 600rpm it would basically stumble so bad it would stall, and my T100 idles around 600rpm lol (~1000rpm neutral coasting)

Ironically the pickup I did this work on was from the Traverse City area. Body is very rusty, but frame, engine, trans, etc are sold. I've put around 8k miles on it so far and not one issue (220k on it now). I hauled about 30 face chord of fire wood (Ash mainly) with it last winter and going to be doing some more hauling this year. The only slightly annoying thing I've had so far is the AT ecu seems to make the engine idle quite a bit lower than MT so in some situations it can be fairly easy to stall, but the AT ecu seems to handle lower RPM better too, if my MT Tacoma would get below 600rpm it would basically stumble so bad it would stall, and my T100 idles around 600rpm lol (~1000rpm neutral coasting)

#10

Registered User

Join Date: Mar 2008

Location: Kodiak, Alaska

Posts: 43

Likes: 0

Received 0 Likes

on

0 Posts

Interesting. I'm looking for a wrecked t100 so I can swap everything. But I got a shot at a 3.0 manual trans with transfer case for $100. Then again would still need to fix ECU and find pedals master cylinder and switches. Feel like a wrecked t100 gonna be the easy button.

#11

What's special about the T100? The 3.4L was used in Tacoma, T100, and 4runners. The T100s are the most uncommon vs the other two to have the 3.4L, atleast from my experience.

Also if you're doing a manual trans swap, the old style R150 trans (3.0L pickup/4runner) should work as well from what I've read, just the input shaft is a different length and you need the 3.0L clutch parts instead of 3.4L (match the trans). I have a few transmissions around and such so maybe we can work something out . I'll shoot you a pm to work out some details.

. I'll shoot you a pm to work out some details.

Also if you're doing a manual trans swap, the old style R150 trans (3.0L pickup/4runner) should work as well from what I've read, just the input shaft is a different length and you need the 3.0L clutch parts instead of 3.4L (match the trans). I have a few transmissions around and such so maybe we can work something out

. I'll shoot you a pm to work out some details.

. I'll shoot you a pm to work out some details.

#12

Registered User

i used a 95 T100 for my swap. the Charcoal canister is the same basic style as my 93 4 runner. so it made the swap practically plug and play. anything newer will require a next gen charcoal canister

#13

Please take a bow!!

Wish I would’ve found this post or year ago

Did you ever have a issue with a high idle

I am pretty sure I’ve tried almost everything to get rid of a hi idle..

91 Toyota pickup

96 3.4 auto,

96 3.4 auto harness

97 3.4 Tacoma manual ecu

R150f

Repinned everything that was required

When first fired up in the morning it will rev 2200

After a lengthy warm up it will Eventually drop down to 1100 1200

well sometimes drop down to normal idle of 700

Did you ever have a issue with a high idle

I am pretty sure I’ve tried almost everything to get rid of a hi idle..

91 Toyota pickup

96 3.4 auto,

96 3.4 auto harness

97 3.4 Tacoma manual ecu

R150f

Repinned everything that was required

When first fired up in the morning it will rev 2200

After a lengthy warm up it will Eventually drop down to 1100 1200

well sometimes drop down to normal idle of 700

#14

That pretty much describes my old 1996 Tacoma 3.4L MT 4x4. By cold start it would be freezing or colder for the 2k+ rpm, warmer than that it would be more around 1500-1800 range. I don't think I've ever seen my Tacoma idle under 1k rpm, maybe 900 at the lowest. I had problems stalling that truck too, anything around 600rpm or lower it would stall, kind of like the ignition switch just switches off at that low. My T100 I can push down to 300-400rpm before it really bucks and snorts, but never just falls on it's face and dies.

I didn't do the research for Tacomas/4Runners, but the 95-96 T100 and 97-98 T100's have different TPS's, from memory, the newer one is 3 wire, and the older one is 4 wire. The extra wire is for the IDL signal and the cruiser control uses it, but the ECU also receives the signal. I'll look it up real quick in my EWD's, 97 Tacoma TPS is 3 wire and 96 Tacoma is 4 wire, so yea same thing. If I remember right, around 97 was also an injector change, but the ECU should be able to learn that difference on it's own, just closed loop will be a little off.

To test to see if IDL signal does anything different, wire it to E2 (dedicated sensor common "ground", it's isolated from frame/neg ground). In the diagram the IDL part of the TPS is just a switch which is closed when the throttle plate is at idle.

I'm not aware of any other differences between 96 and 97. When I replace my T100's MT ecu with an AT ecu (old one fried), it was just re-pin and everything worked great, but my truck is a 98 and the parts truck is a 97.

Anyway, if the IDL wire does effect things, you'd either need the older style throttle plate (i think it fits on either intake but not 100% sure), or you'd swap the ecu to the same gen the engine is from, 95-96 and probably have to re-pin again.

I didn't do the research for Tacomas/4Runners, but the 95-96 T100 and 97-98 T100's have different TPS's, from memory, the newer one is 3 wire, and the older one is 4 wire. The extra wire is for the IDL signal and the cruiser control uses it, but the ECU also receives the signal. I'll look it up real quick in my EWD's, 97 Tacoma TPS is 3 wire and 96 Tacoma is 4 wire, so yea same thing. If I remember right, around 97 was also an injector change, but the ECU should be able to learn that difference on it's own, just closed loop will be a little off.

To test to see if IDL signal does anything different, wire it to E2 (dedicated sensor common "ground", it's isolated from frame/neg ground). In the diagram the IDL part of the TPS is just a switch which is closed when the throttle plate is at idle.

I'm not aware of any other differences between 96 and 97. When I replace my T100's MT ecu with an AT ecu (old one fried), it was just re-pin and everything worked great, but my truck is a 98 and the parts truck is a 97.

Anyway, if the IDL wire does effect things, you'd either need the older style throttle plate (i think it fits on either intake but not 100% sure), or you'd swap the ecu to the same gen the engine is from, 95-96 and probably have to re-pin again.

#15

Truck runs yahoo. Long story short, the IGF signal from the igniter stayed at 4.6v all the time, and should go 6v or more when running. Swapped it out with one from a 97 which ironically the part number said it wouldn't work in the 98, but the pinouts matched up perfect so I plugged it in anyway. First try and she fired up well. It had a slight "off" sound to it not 100% right (I drive a 3.4L tacoma and my dad has a t100 too so I know their sound well), and my temp twisted G- and NE- came undone for G-. Hooked it up and it stalled, started it again and sounded just right, so to confirm, the 98 wire harness needs to splice NE- to also go to G- for best performance.

The igniter part number I used on the 98 is: 89621-35011

*note* I'm using the 97 computer, and that's where the igniter came from, so really the interchange could be off if the signals are slightly different for the ecu, but I suspect that isn't the case.

The NSW signal (neutral safety) isn't hooked up, so looks like the ECU doesn't really care about neutral/park when starting as long as the starting relays can get power to the starter.

Just to be clear, I plugged in the 97 AT ecu into the 98 before I found out they were not direct swappable, this mistake burned out all 3 ignition coils and the igniter. Basically the O2 heater circuits gave constant power to two of the igniter wires.

Drove the truck around some and she runs well, putting it in 4x4 didn't work so I'll have to look into that yet (add system), and the heater blower doesn't work on any setting. Fun stuff to play with, but at least it's drive able. Just in time too because my rear driver's leaf spring's front mount broke away from the frame hauling wood and the Michigan salt/rust.

The igniter part number I used on the 98 is: 89621-35011

*note* I'm using the 97 computer, and that's where the igniter came from, so really the interchange could be off if the signals are slightly different for the ecu, but I suspect that isn't the case.

The NSW signal (neutral safety) isn't hooked up, so looks like the ECU doesn't really care about neutral/park when starting as long as the starting relays can get power to the starter.

Just to be clear, I plugged in the 97 AT ecu into the 98 before I found out they were not direct swappable, this mistake burned out all 3 ignition coils and the igniter. Basically the O2 heater circuits gave constant power to two of the igniter wires.

Drove the truck around some and she runs well, putting it in 4x4 didn't work so I'll have to look into that yet (add system), and the heater blower doesn't work on any setting. Fun stuff to play with, but at least it's drive able. Just in time too because my rear driver's leaf spring's front mount broke away from the frame hauling wood and the Michigan salt/rust.

I am doing the same thing but opposite! I have a 1998 A/T 5vz 4runner and have swapped a r150f and was able to source a M/T ECU. Your posts have been very very crucial to diagnosing what is going on. I think I have nailed it down to the igniter (hopefully).

Note that all I did was take my newly acquired 98 M/T 4runner ECU and swap it into the 98 A/T 4runner harness and bodge a clutch wire in so it will fire up.

Super happy as the truck runs, but it bogs and stalls randomly. After stalling it will be a long time before firing up. Sometimes hours.

The OBD2 code that is given is a crankshaft position sensor. I hardwired a new sensor into the ECU along with the camshaft position sensor as per the wiring diagram (similar tow hat you did I think?) but I wanted to narrow it down to your comment "the 98 wire harness needs to splice NE- to also go to G- for best performance" - I don't see a "G-" wire, but I suspect you mean the other side of the crankshaft position sensor. I have bought some 2-wire shielded wire to solder in directly, but I want to confirm that you did the same?

Even if you don't respond, Thanks again for your amazing detail and follow-thru to your posts!

#16

It's been a while since I did the wiring, but for my T100 I had to splice some wires to match up signals. I don't remember exactly which way it forked, but effectively one ECU had a common ground for the sensors (crank and cam if I remember right), and the other ECU had them seperate/dedicated per sensor. Either I had to split them or combine, but in either case the ECU has to be able to make a complete circuit, a signal wire is useless with out a ground or negative signal.

Anyway, I'll take a peek at the 98 4runner wire diagrams

98 4Runner 5VZ:

B5 - NE+ (aka crank sensor)

B6 - NE- (also the ground wire for the G+ signal, aka cam sensor)

B17 - G+

Are you 100% positive the Manual ECU is from a 98? The wire diagrams doesn't indicate a difference for crank/cam sensors for manual vs auto engines for that year unless I'm overlooking things. Here's the diagram I'm using which is directly for the 98 4Runner.

https://i.gyazo.com/eb6d396506d99c27...8ecec36c12.png

I've made a small atv website for tech info, https://atvmanual.com I've been tempted to make something similar for vehicles, or even just Toyota's. Making a tool to say from vehicle to vehicle for engine swaps, transmission swaps, and ECU swaps would probably help a lot of people. Of course my process isn't 100% fool proof, but should be pretty close to getting things wired right. Even just a pinout diagram would be handy since that info is hard to find even with the wire diagrams (have to compile a lot of data from several diagrams).

Also update on my T100 this post started from, it still runs great, I did have an injector fail, it ohm tested bad. Besides that no engine issues to report. The truck does currently have a fuel line leak near the tank, and recently replace it with a larger (diesel) truck for the larger loads I tend to haul (wood, vehicles, etc).

Here's a quick brake down for the pin out changes purely focused on crank (NE) and cam sensor (G) for the 4Runners with the 5vz engine. I suspect they match for T100 and Tacoma, but I'd have to validate per year. The connectors might change per manual, so the ABCDEF connectors might not correlate as the same connector across years.

1996-1997 MT

C12 - NE+

C6 - NE-

C11 - G

C5 - G-

1996-1997 AT

F5 - NE+

F6 - NE-

F10 - G

F11 - G-

1998

B5 - NE+

B6 - NE-/G-

B17 - G+

1999-2000

B16 - NE+

B24 - NE-/G2-

A10 - G2 (should be the same as G+)

2001-2002

B12 - NE+

B21 - NE-/G2-

B13 - G2

There should be a part number on the ECU, generally you can look up that number on a Toyota dealership website to validate fitment (what machines it was intended for). If everything checks out, maybe you have a bad connection/wire or the crank sensor is in fact failing on you. For my truck, it ran off just the crank or cam sensor since the source ECU uses 2 pins for the two ground signals and my truck only had one wire (shared ground) and it did run but it didn't run well. I effectively took that 1 wire and made it into 2 wires to hit both ground signals and the engine was happy. The 97 ECU used 2 grounds and 2 signals for the two sensors, while the 98 uses 1 ground and 2 signals.

I hope that all makes sense. Since the vehicle and ECU are the same year, I'm pretty sure the crank/cam sensors do not need modifying to function. The wire diagram seems to suggest the AT and MT both share the same or very similar pin outs for 98+. 97 and older it was a bit more tricky. To do this right, I'd have to make a table for all the pins on the ECU and track down what each pin is for and compare manual vs auto.

Anyway, good luck with your project, based on what you describe, I'd be putting money on a bad crank sensor or an intermittent connection (corroded pin, damaged wiring, etc). You could visually inspect the pins on the 2 connectors (ECU and crank sensor). You could also validate the wire is good by using a multi meter in the beep setting then move the wire around w\o loosing connection on the terminal. If the beep is solid, then the wire should be good. If a wire is damaged, it's generally right at the connector on Toyota's.

Anyway, I'll take a peek at the 98 4runner wire diagrams

98 4Runner 5VZ:

B5 - NE+ (aka crank sensor)

B6 - NE- (also the ground wire for the G+ signal, aka cam sensor)

B17 - G+

Are you 100% positive the Manual ECU is from a 98? The wire diagrams doesn't indicate a difference for crank/cam sensors for manual vs auto engines for that year unless I'm overlooking things. Here's the diagram I'm using which is directly for the 98 4Runner.

https://i.gyazo.com/eb6d396506d99c27...8ecec36c12.png

I've made a small atv website for tech info, https://atvmanual.com I've been tempted to make something similar for vehicles, or even just Toyota's. Making a tool to say from vehicle to vehicle for engine swaps, transmission swaps, and ECU swaps would probably help a lot of people. Of course my process isn't 100% fool proof, but should be pretty close to getting things wired right. Even just a pinout diagram would be handy since that info is hard to find even with the wire diagrams (have to compile a lot of data from several diagrams).

Also update on my T100 this post started from, it still runs great, I did have an injector fail, it ohm tested bad. Besides that no engine issues to report. The truck does currently have a fuel line leak near the tank, and recently replace it with a larger (diesel) truck for the larger loads I tend to haul (wood, vehicles, etc).

Here's a quick brake down for the pin out changes purely focused on crank (NE) and cam sensor (G) for the 4Runners with the 5vz engine. I suspect they match for T100 and Tacoma, but I'd have to validate per year. The connectors might change per manual, so the ABCDEF connectors might not correlate as the same connector across years.

1996-1997 MT

C12 - NE+

C6 - NE-

C11 - G

C5 - G-

1996-1997 AT

F5 - NE+

F6 - NE-

F10 - G

F11 - G-

1998

B5 - NE+

B6 - NE-/G-

B17 - G+

1999-2000

B16 - NE+

B24 - NE-/G2-

A10 - G2 (should be the same as G+)

2001-2002

B12 - NE+

B21 - NE-/G2-

B13 - G2

There should be a part number on the ECU, generally you can look up that number on a Toyota dealership website to validate fitment (what machines it was intended for). If everything checks out, maybe you have a bad connection/wire or the crank sensor is in fact failing on you. For my truck, it ran off just the crank or cam sensor since the source ECU uses 2 pins for the two ground signals and my truck only had one wire (shared ground) and it did run but it didn't run well. I effectively took that 1 wire and made it into 2 wires to hit both ground signals and the engine was happy. The 97 ECU used 2 grounds and 2 signals for the two sensors, while the 98 uses 1 ground and 2 signals.

I hope that all makes sense. Since the vehicle and ECU are the same year, I'm pretty sure the crank/cam sensors do not need modifying to function. The wire diagram seems to suggest the AT and MT both share the same or very similar pin outs for 98+. 97 and older it was a bit more tricky. To do this right, I'd have to make a table for all the pins on the ECU and track down what each pin is for and compare manual vs auto.

Anyway, good luck with your project, based on what you describe, I'd be putting money on a bad crank sensor or an intermittent connection (corroded pin, damaged wiring, etc). You could visually inspect the pins on the 2 connectors (ECU and crank sensor). You could also validate the wire is good by using a multi meter in the beep setting then move the wire around w\o loosing connection on the terminal. If the beep is solid, then the wire should be good. If a wire is damaged, it's generally right at the connector on Toyota's.

Last edited by atcfixer; 03-10-2021 at 09:09 PM.

#17

Hmm.. 98 T100 SR5, white, 5vz fe, R150f, A10A, AT ECU, manual locking hubs, BCM (forced) delete, straight piped with cat delete, almost no front shocks, cherry bomb resting on proportioning valve, no fuel filter, stuck ac compressor, no speedometer, wires with alligator clips acting as window switch, half a sway bar, I'm sure there's more. Next time you see it I'll have the intake plenum/manifold and the throttle body sanded/polished, an odd take on a ram air intake, and I'm gonna clean the injectors. This truck makes enthusiasts cry. -D.S.

#18

Registered User

Join Date: Jan 2011

Location: exo-reality -wave if you see me; Front Range, CO

Posts: 652

Received 93 Likes

on

73 Posts

build thread

Hmm.. 98 T100 SR5, white, 5vz fe, R150f, A10A, AT ECU, manual locking hubs, BCM (forced) delete, straight piped with cat delete, almost no front shocks, cherry bomb resting on proportioning valve, no fuel filter, stuck ac compressor, no speedometer, wires with alligator clips acting as window switch, half a sway bar, I'm sure there's more. Next time you see it I'll have the intake plenum/manifold and the throttle body sanded/polished, an odd take on a ram air intake, and I'm gonna clean the injectors. This truck makes enthusiasts cry. -D.S.

Thread

Thread Starter

Forum

Replies

Last Post