my 3.slow rebuild

#1

Registered User

Thread Starter

my 3.slow rebuild

SO there are those of you who hate the 3.slow, and those of us that have a love hate relationship with it but gennerally like it.

so when my 3vze tired it self out in my 4runner i decided that i would go about rebuilding one for it.

so i aquired 2 motors from a fellow yotatechie and this thread will follow the progress.

we start by getting the stuff home (2 motors, a tranny and a cannoe)

then we get the hoist and stand from the neighbor ... and sqeeze everything into the shop

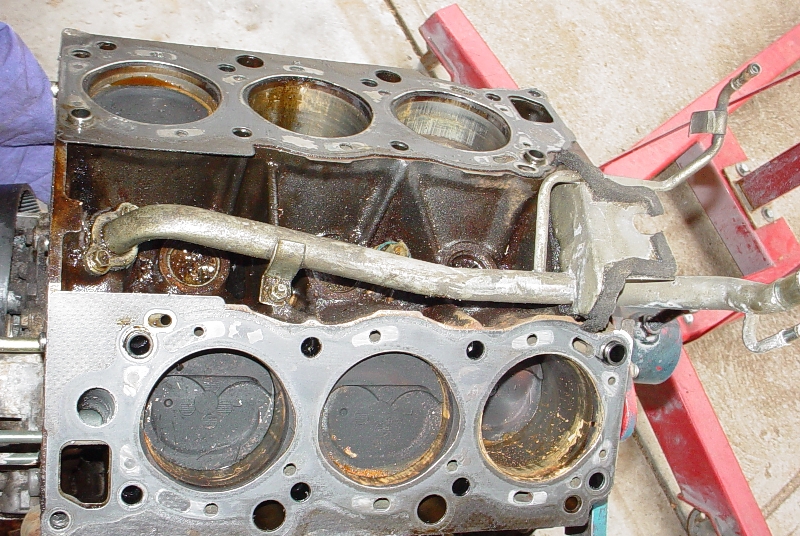

This motor was already fairly stripped down. Supposidly only like 108K miles on it so only planning on, hone, rings, bearings, gaskets... nothing major

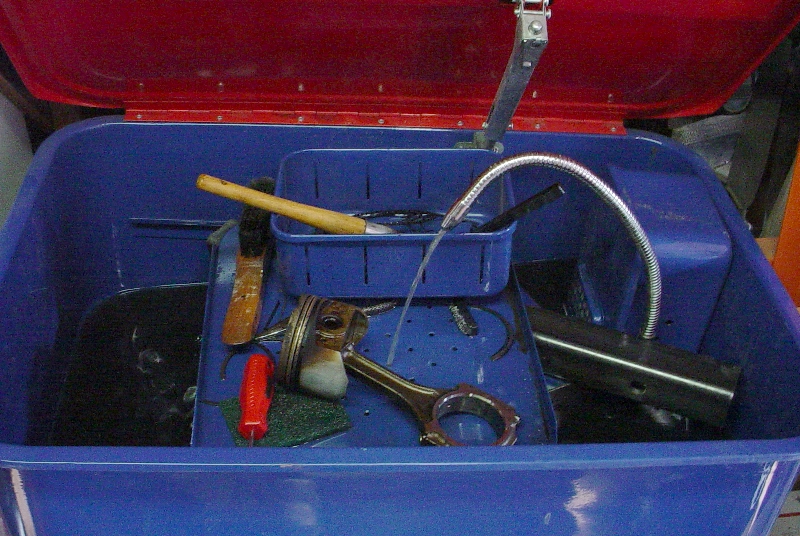

da oil pickup

It looks worse than it is. not much sludge (less than i thought there would be)

more pics to come as i tare it down and rebuild it.

not to exciteing i know, but something to look at for people that may not have seen one torn down before

so when my 3vze tired it self out in my 4runner i decided that i would go about rebuilding one for it.

so i aquired 2 motors from a fellow yotatechie and this thread will follow the progress.

we start by getting the stuff home (2 motors, a tranny and a cannoe)

then we get the hoist and stand from the neighbor ... and sqeeze everything into the shop

This motor was already fairly stripped down. Supposidly only like 108K miles on it so only planning on, hone, rings, bearings, gaskets... nothing major

da oil pickup

It looks worse than it is. not much sludge (less than i thought there would be)

more pics to come as i tare it down and rebuild it.

not to exciteing i know, but something to look at for people that may not have seen one torn down before

Last edited by snap-on; 11-15-2005 at 08:20 AM.

#3

Registered User

Join Date: Oct 2004

Location: NE GA (Between blizzads & hurricanes)

Posts: 481

Likes: 0

Received 0 Likes

on

0 Posts

Good luck! I have 2 "torn down" 3.0s in my yard now. I defineatly have a love hate relationship with them. The first was still running at 300k when it got pulled for one with 83k on it. I had to do the headgasket on the new one but found it to be a craked block or head. I finally have decided to just stick a 3.4 in and be done with it. So far so good. I'm supposed to pick one up this week for $600!!! Hard to beat that. The 3.0 isn't that bad if you have the right hookups on it.

#4

Contributing Member

Join Date: Mar 2005

Location: San Jose, CA

Posts: 1,009

Likes: 0

Received 0 Likes

on

0 Posts

I just rebuilt my 3.0 a couple months ago, er top end anyways... It was a pain for the fact that there is no room to work on it while it's still in the truck like the awsome 22-re. I didn;t really need the truck right away anyways as I just picked at it day by day. It is a chore, but now it runs like new and am very happy with it's performance...

#5

Registered User

Join Date: Aug 2005

Location: Indiana

Posts: 30

Likes: 0

Received 0 Likes

on

0 Posts

We have just finished a rebuild on our 3.0. We had 3 motors before we found a good one. 2 broken pistons in one and a trashed thrust bearing in the other taking out the crank and block. They really are quite simple to work on not too bad at all. We did the hone, valve job, rings and bearings too. Have just under $500 so far using Engnbldr stuff. The valve adjustment was a pain but finally got it, I recomend getting a micrometer before you start on this. Just one of those tools you cannot hardly do without for this job.

#6

Registered User

Thread Starter

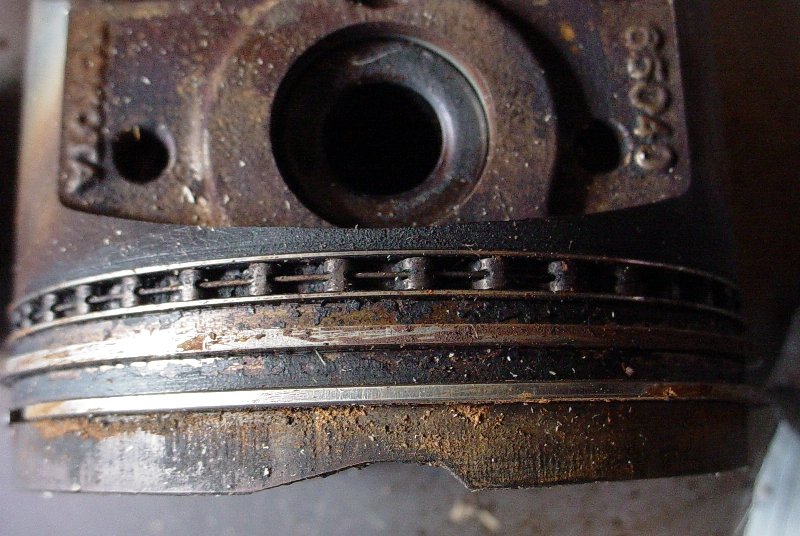

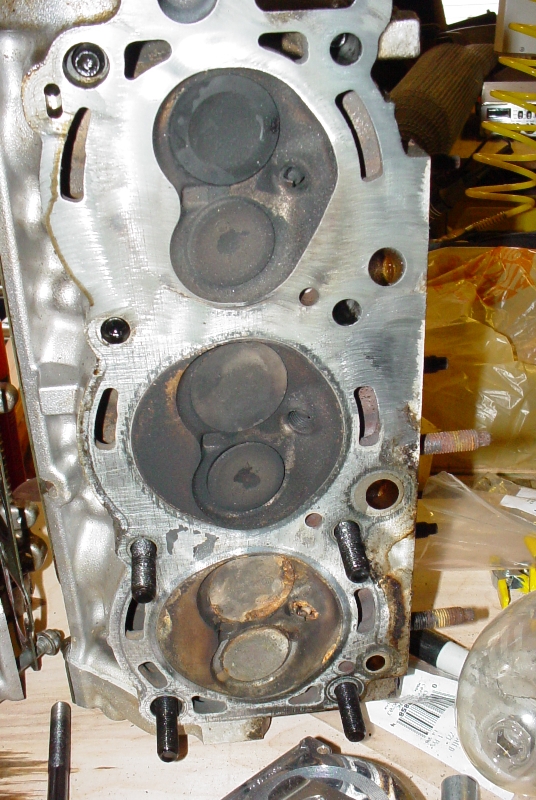

more pics. some progress but we went to the cabin last weekend, and week before that i got it honed.

Got all my parts in (no pics yet) so im starting to put it back together this week. Trying to figure out if i want to send the heads out.

Got all my parts in (no pics yet) so im starting to put it back together this week. Trying to figure out if i want to send the heads out.

Trending Topics

#10

Registered User

Thread Starter

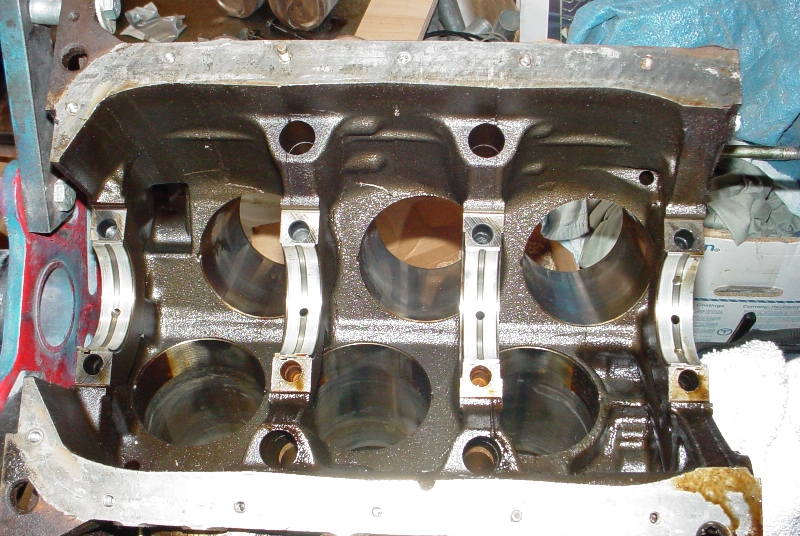

notice in one of the pics you can see some 2's stamped in the top of the block. anyone know what those mean?

(off topic, how do i edit the name of my thread)

Nothing really wrong with this motor. Everything seems fine, bearings look good, rings moved, cylinders were good and honed out nicely.

no cracks in anything yet.

any reason to plasti gauge it if im just took out stock bearings and am puting stock ones back in. (not haveing any work done to the crank etc)

I Really really dont want to put the stock manafolds back on but both downey and NWOR are out of headers at the moment. My goal was to have it running by t-day, but without the headers i dont think thats going to happen.

(off topic, how do i edit the name of my thread)

Nothing really wrong with this motor. Everything seems fine, bearings look good, rings moved, cylinders were good and honed out nicely.

no cracks in anything yet.

any reason to plasti gauge it if im just took out stock bearings and am puting stock ones back in. (not haveing any work done to the crank etc)

I Really really dont want to put the stock manafolds back on but both downey and NWOR are out of headers at the moment. My goal was to have it running by t-day, but without the headers i dont think thats going to happen.

Last edited by snap-on; 11-15-2005 at 08:36 AM.

#11

Registered User

Join Date: Aug 2005

Location: Tucson, Arizona

Posts: 35

Likes: 0

Received 0 Likes

on

0 Posts

I would definitley plastigage all the bearings. Also check the manual to be sure you understand there is no "standard size" bearing for the 3.0. Each engine is unique from the factory and you identify the bearing size by looking at the stamped numbers on the block to determine if they are a standard 1,2, or 3. Then it's always good idea to plastigage even when you think you have it right. Easier to verify now then be wrong and have to pull the engine again. :-)

#13

Registered User

Join Date: Aug 2005

Location: Tucson, Arizona

Posts: 35

Likes: 0

Received 0 Likes

on

0 Posts

You buy plastigage at any auto parts store. Its a pre-measured string of plastic that you set across the bearing surface and then torque the bearing caps down. Then you remove the bearing caps and measure how far the plastigage spread inside the assembled bearing. That tells you what the oil clearance is an if you have the proper bearing installed.

#14

Registered User

Thread Starter

Originally Posted by Tucson T4R

I would definitley plastigage all the bearings. Also check the manual to be sure you understand there is no "standard size" bearing for the 3.0.

Well i took the time to carfully remove each bearing and note the number of the bearing and which pistion it went to. but when i called engbldr he said that all he sells is a "standard" set and a few others if you have had the crank turned.

I asked him about the #'s He said in all the time he has been doing it he has never needed to replace a #2 with a #2. Said the diffrence was out in the 4 or 5 decimal and there just wasnt enough differance to matter.

He has quite a few posts round hear about rebuilding the 3vze and i trust him sooooo....

as for the plasti gauge i was just trying to avoid torqueing everthing down once then haveing to take it all apart then doing it again.

#15

Registered User

Join Date: Aug 2005

Location: Tucson, Arizona

Posts: 35

Likes: 0

Received 0 Likes

on

0 Posts

Yep, I understand the desire not to torque and them tear apart again....not fun but still good idea for total confidence.

I ran into the same problem when I tried ordering differnt sized main bearings for my 3.0 from one of the local dealers. The first parts dept said they only sold sets of standard or a set of smaller ones if the crank had been turned. They said they never heard of haveing different size main bearings from the factory.

When I called and asked a second dealer here in Tucson they new all about it and had no problem selling me the specific sized bearing I needed for each of the main bearings as identified on my block.

Since the factory manual covers the main bearing sizes and references the block stamped numbers to identify what size each of the main bearing are, I would go with that approach.

Your right on the rod bearings, just follow the number on the rod & cap and you should be fine. I still plastigaged all of my rod bearings just to be sure.

I ran into the same problem when I tried ordering differnt sized main bearings for my 3.0 from one of the local dealers. The first parts dept said they only sold sets of standard or a set of smaller ones if the crank had been turned. They said they never heard of haveing different size main bearings from the factory.

When I called and asked a second dealer here in Tucson they new all about it and had no problem selling me the specific sized bearing I needed for each of the main bearings as identified on my block.

Since the factory manual covers the main bearing sizes and references the block stamped numbers to identify what size each of the main bearing are, I would go with that approach.

Your right on the rod bearings, just follow the number on the rod & cap and you should be fine. I still plastigaged all of my rod bearings just to be sure.

#16

Registered User

Join Date: Aug 2005

Location: Tucson, Arizona

Posts: 35

Likes: 0

Received 0 Likes

on

0 Posts

FYI...the reason I was so anal about it was it was the second time around. :-) The first time my son had ordered a "standard" set of main bearings off the internet and just had the crank polished. After installing the new bearings and re-assembling the entire engine, the engine seized up while we were just manual turning it over. It got tighter and tighter until we couldn't move it all.

The second time around we followed the manual to a tee and used Toyota parts from the dealer and plastigaged everything. The engine has now been running for about 20K miles and runs like a clock. :-)

The second time around we followed the manual to a tee and used Toyota parts from the dealer and plastigaged everything. The engine has now been running for about 20K miles and runs like a clock. :-)

#17

Registered User

Join Date: Mar 2004

Location: Salem,Oregon

Posts: 511

Likes: 0

Received 0 Likes

on

0 Posts

I used all EB parts when I rebuilt my 3.0 a few months back. I looked at the number system and figured I would order the less expensive parts and plastigauge it all to be sure it was within spec. I have a little over 4500 miles and no problems since weeding out all of the DOA Racing junk.

#18

Registered User

Join Date: Sep 2003

Location: Wenatchee, WA

Posts: 252

Likes: 0

Received 0 Likes

on

0 Posts

Nobody orders the OEM denominations of STD sized bearings. The only time I've ever known those "special" bearings to be ordered was during a warranty repair. I've done no less than 5319 rebuilds/replacements of these motors. Everyone, buy the STD bearings if your crank is STD and put it together. The full range of possible bearing clearances still put it within spec with a STD set of bearings assuming your crank is like new. Just don't gouge your crank with the connecting rod studs when you're putting the pistons in and the cank won't slowly seize when you do the initial crank over. I've seen this happen a thousand times, there is always some abnormal/unobserved damage to blame. Let me guess, there was a big pile of gouged bearing material built up right down the middle of one of the bearings.

#19

Registered User

Thread Starter

I got the intakes torn down today (ready to go to a friend who is going to bake em and bead blast them)

Also need to snap a pic of the headers back from the machine shop.

Also need to snap a pic of the headers back from the machine shop.