Could problem be anything but cracked head?

#1

Registered User

Thread Starter

Could problem be anything but cracked head?

Hi,

I've searched and troubleshot and can't find out what's wrong with my 1994 4X4 with a 22RE. I am writing this to save some time, money and energy. I thought I'd pick your brains before taking the head off again.

Symptoms: steam out of tailpipe and bog when I hit the throttle after replacing and servicing the following parts. There is no overheating and for the most part, it idles fine.

New Parts and services:

Story:

The truck ran fine until I blew a head gasket. When it went, I saw steam out of the tail pipe and had a loss of power. The temp gauge read normal when it went which is just a little below half way. There was no corrosion visible in the radiator. I made a plan to replace the head gasket, rebuild the head and replace the clutch all at once. I followed the best practices that I am aware of EXCEPT for not having the block decked. It didn't look great. Because I just started an electrical apprenticeship and I'm working 60 hours per week (time and money) I decided to skip the rebuilding of the bottom end. I don't think this has caused my problem. My assumption is that the block will be fine for a couple of years. By that time I'll be making more money and buy a long block or replace the vehicle.

Question:

-Ethan

Link to photos https://photos.app.goo.gl/cCdSi3bab5utTPqL7

I've searched and troubleshot and can't find out what's wrong with my 1994 4X4 with a 22RE. I am writing this to save some time, money and energy. I thought I'd pick your brains before taking the head off again.

Symptoms: steam out of tailpipe and bog when I hit the throttle after replacing and servicing the following parts. There is no overheating and for the most part, it idles fine.

New Parts and services:

- OEM head gasket

- head bolts

- block head bolt holes tapped and cleaned

- rebuilt head (was told it was checked for cracks, valves and seats were ground, seals replaced and decked)

- new RV cam

- new water pump

- new timing chain and guides

- new injectors

- new spark plugs

- new clutch kit

- new coolant temp sender (the one below the throttle body)

- cleaned throttle body

- cleaned upper and lower plenum

- timing set

- I did not touch the TPI

- Copper spray used on head gasket

Story:

The truck ran fine until I blew a head gasket. When it went, I saw steam out of the tail pipe and had a loss of power. The temp gauge read normal when it went which is just a little below half way. There was no corrosion visible in the radiator. I made a plan to replace the head gasket, rebuild the head and replace the clutch all at once. I followed the best practices that I am aware of EXCEPT for not having the block decked. It didn't look great. Because I just started an electrical apprenticeship and I'm working 60 hours per week (time and money) I decided to skip the rebuilding of the bottom end. I don't think this has caused my problem. My assumption is that the block will be fine for a couple of years. By that time I'll be making more money and buy a long block or replace the vehicle.

Question:

- What, other than a compromised head gasket, could be letting coolant into the combustion chamber?

- Could the head be cracked? The shop said they checked it but then again, they are only humans.

- Could coolant be leaking into the plenum through the throttle body? I bypassed the TB coolant lines and saw no different results.

- Could the block be cracked? Since I saw ≈170 psi from all cylinders after the work I don't see how this could be the problem.

- What should my next steps be?

-Ethan

Link to photos https://photos.app.goo.gl/cCdSi3bab5utTPqL7

The following users liked this post:

etharfurning_pdx (01-20-2019)

#4

Is the white smoke there after it warms up? It's not water in the tailpipe?

The bogging is what is weird to me. Recheck timing chain position and distributor position.

The bogging is what is weird to me. Recheck timing chain position and distributor position.

#5

Registered User

iTrader: (-1)

Perform a cylinder leakdown test. This gives you a better overall sense of each cylinders seal. You can have excellent compression and still have a leaking head gasket.

Are you loosing coolant, seeing as it's winter in North America some steam is to be expected.

suck squirt, squish bang, blow.. Repeat.

Double check your work, then do it again!

Are all the ground wires clean and connected?

Lines and wires routed correctly and tight/clean?

Is the initial timing set to the right ballpark?

Are you loosing coolant, seeing as it's winter in North America some steam is to be expected.

suck squirt, squish bang, blow.. Repeat.

Double check your work, then do it again!

Are all the ground wires clean and connected?

Lines and wires routed correctly and tight/clean?

Is the initial timing set to the right ballpark?

The following users liked this post:

Jimkola (03-13-2020)

#7

Registered User

It will take some driving to get the moisture out of the entire system... i just did a head gasket replacement myself and mine smoked for a while till after my second oil change... the first one looked like coffee with creamer in it... but it cleared up and the oil is clear...

did you set your valves?

did you set your valves?

Last edited by 87-4runner; 01-21-2019 at 05:39 AM.

Trending Topics

#8

Perform a cylinder leakdown test. This gives you a better overall sense of each cylinders seal. You can have excellent compression and still have a leaking head gasket.

Are you loosing coolant, seeing as it's winter in North America some steam is to be expected.

suck squirt, squish bang, blow.. Repeat.

Double check your work, then do it again!

Are all the ground wires clean and connected?

Lines and wires routed correctly and tight/clean?

Is the initial timing set to the right ballpark?

Are you loosing coolant, seeing as it's winter in North America some steam is to be expected.

suck squirt, squish bang, blow.. Repeat.

Double check your work, then do it again!

Are all the ground wires clean and connected?

Lines and wires routed correctly and tight/clean?

Is the initial timing set to the right ballpark?

^^Spot on.^^ I've had them show great static #'s but a leak down would show slow bypass. And i've had different readings on a cold engine VS. one that is close to operating temp. But as mentioned, double check everything before thinking the worst.

I did not have my block decked, but the head was surfaced. Also the intake mating surfaces all need to be cleaned well. I went over mine with a 8" sanding block and 80 grit followed by 120 grit paper until all low spots were taken.

I didn't use any copper or other sealing goo on the gasket or deck surface. Only cleaned several times with brake clean and blew out everything well.

Last edited by Blownchevelle68; 01-21-2019 at 05:44 AM.

#9

Registered User

Thread Starter

the white smoke is constant. It's steam I'm sure. There isn't a ton until I try to rev the engine. There was water in the tailpipe but the engine has run now for a total of ≈40 minutes. Any water in there has been cleared out imho.

The timing is spot on and the distributor is in the same location that it was before I removed it. I think that rules out chain/distributor position.

#10

Registered User

Thread Starter

Perform a cylinder leakdown test. This gives you a better overall sense of each cylinders seal. You can have excellent compression and still have a leaking head gasket.

Are you loosing coolant, seeing as it's winter in North America some steam is to be expected.

suck squirt, squish bang, blow.. Repeat.

Double check your work, then do it again!

Are all the ground wires clean and connected?

Lines and wires routed correctly and tight/clean?

Is the initial timing set to the right ballpark?

Are you loosing coolant, seeing as it's winter in North America some steam is to be expected.

suck squirt, squish bang, blow.. Repeat.

Double check your work, then do it again!

Are all the ground wires clean and connected?

Lines and wires routed correctly and tight/clean?

Is the initial timing set to the right ballpark?

I have not noticed the coolant level drop at all. There is just a little bit of steam at idle and that's what the engine has done most. I haven't driven it.

I love the suck squirt bang blow saying.

The engine compartment is clean and the ground locations looked the same.

To my knowledge all wires and lines are clean, correctly located and functioning.

The timing is set per factory service manual.

#11

Registered User

Thread Starter

#12

Registered User

Thread Starter

It will take some driving to get the moisture out of the entire system... i just did a head gasket replacement myself and mine smoked for a while till after my second oil change... the first one looked like coffee with creamer in it... but it cleared up and the oil is clear...

did you set your valves?

did you set your valves?

The valves have been set per factory service manual specifications.

#13

Registered User

Thread Starter

^^Spot on.^^ I've had them show great static #'s but a leak down would show slow bypass. And i've had different readings on a cold engine VS. one that is close to operating temp. But as mentioned, double check everything before thinking the worst.

I did not have my block decked, but the head was surfaced. Also the intake mating surfaces all need to be cleaned well. I went over mine with a 8" sanding block and 80 grit followed by 120 grit paper until all low spots were taken.

I didn't use any copper or other sealing goo on the gasket or deck surface. Only cleaned several times with brake clean and blew out everything well.

I did not have my block decked, but the head was surfaced. Also the intake mating surfaces all need to be cleaned well. I went over mine with a 8" sanding block and 80 grit followed by 120 grit paper until all low spots were taken.

I didn't use any copper or other sealing goo on the gasket or deck surface. Only cleaned several times with brake clean and blew out everything well.

Things I have not double checked:

- head torque- I did this 3 or 4 times before putting the valve cover on though

- Valves- when I got the head back from the machine shop they were really loose. I assume they loosened them for disassemble or when installing the new cam. Before starting the engine for the first time I set the valves to spec per factory service manual instructions. I was going to set them again when I re-torque the head bolts.

- injectors with old injectors

- cold temp sender- I broke the old one and replaced it with a non-name brand off the internet. *no codes are present on the dash

#14

Registered User

iTrader: (-1)

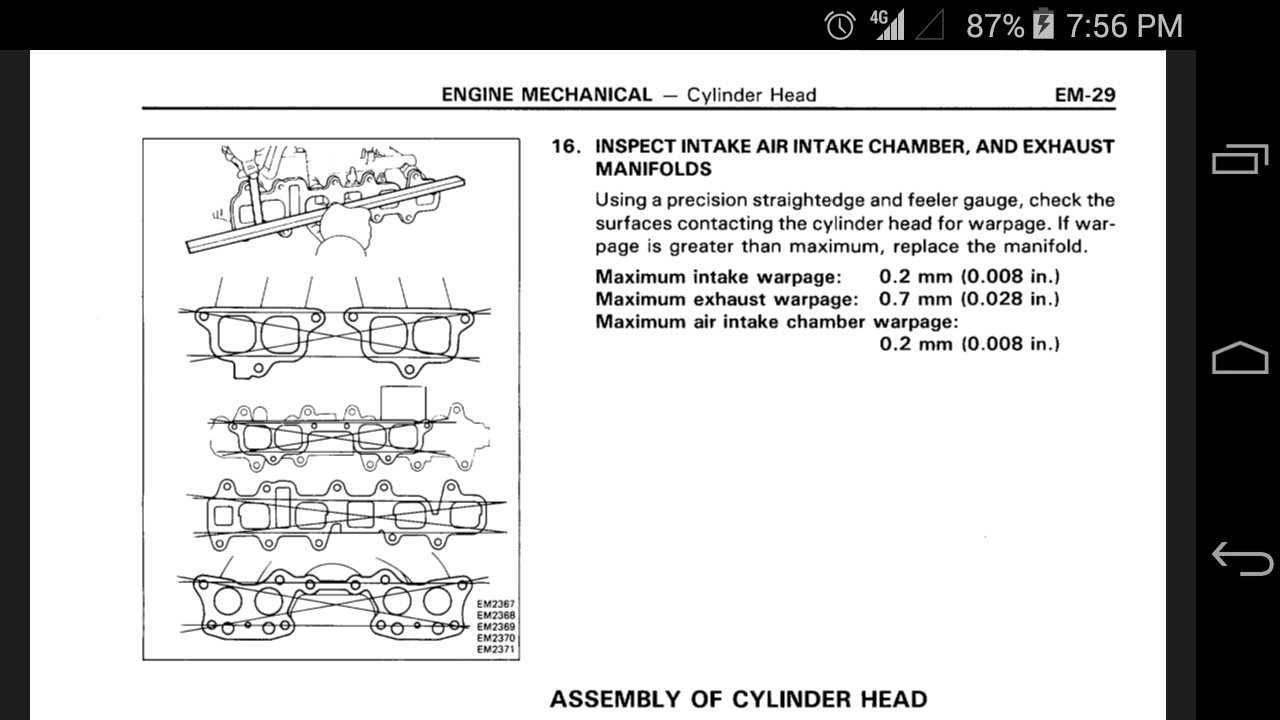

If the intake runner surface isn't to spec you can change that gasket as much as you want and it still very apt to leak... The spec is 0.2mm.. An "insignificant" scratch..

There is also the long bolt that goes into the water jacket which needs sealed.

There are also a few vacuum and water lines that could get mixed up, yes generally this means lots of water in the combustion but not always enough to hydrolock.

Find and fix the leak first, worry about the performance issue second.

There is also the long bolt that goes into the water jacket which needs sealed.

There are also a few vacuum and water lines that could get mixed up, yes generally this means lots of water in the combustion but not always enough to hydrolock.

Find and fix the leak first, worry about the performance issue second.

#15

Registered User

Thread Starter

If the intake runner surface isn't to spec you can change that gasket as much as you want and it still very apt to leak... The spec is 0.2mm.. An "insignificant" scratch..

There is also the long bolt that goes into the water jacket which needs to be sealed.

There are also a few vacuum and water lines that could get mixed up, yes generally this means lots of water in the combustion but not always enough to hydrolock.

Find and fix the leak first, worry about the performance issue second.

There is also the long bolt that goes into the water jacket which needs to be sealed.

There are also a few vacuum and water lines that could get mixed up, yes generally this means lots of water in the combustion but not always enough to hydrolock.

Find and fix the leak first, worry about the performance issue second.

Long bolt: Is the long bolt you are referring to the ≈60mm hex head that is one of ≈6 bolts and nuts that hold the lower manifold on? That would take fairly little time to seal if by seal you mean add rtv to the threads and hole in head. However, I don't see anything in the FSM about this.

Find and fix leak comment: My assumption is that the leak is causing the performance issue.

Thank you for your comments.

What can I learn or rule out from a leak down test?

#17

Get a Block Tester, and verify combustion yes or no in the coolant. You can rent one at O'Reilly or AutoZone. You will probably have to buy the test fluid. Either way just make sure you have the test fluid.

https://www.oreillyauto.com/detail/b.../67094/4700290

https://www.oreillyauto.com/detail/b.../75630/4414187

https://www.autozone.com/loan-a-tool...r-block-tester

https://www.oreillyauto.com/detail/b.../67094/4700290

https://www.oreillyauto.com/detail/b.../75630/4414187

https://www.autozone.com/loan-a-tool...r-block-tester

Last edited by snippits; 01-22-2019 at 05:12 AM.

#18

Registered User

For me the bottom line comes down to "are you loosing coolant"? If I suspect a head gasket leak I perform a cooling system pressure test and see if I am loosing pressure over time and how fast the pressure drops.

Then I start looking for where the coolant went. Pull the spark plugs and roll the engine over by hand and see if coolant comes out of one or more cylinders.

If it holds pressure and you don't seem to be loosing coolant keep in mind that antifreeze doesn't evaporate like water and after your first head gasket blew there would be coolant in the exhaust that will take quite a while to burn off.

Then I start looking for where the coolant went. Pull the spark plugs and roll the engine over by hand and see if coolant comes out of one or more cylinders.

If it holds pressure and you don't seem to be loosing coolant keep in mind that antifreeze doesn't evaporate like water and after your first head gasket blew there would be coolant in the exhaust that will take quite a while to burn off.

#19

Registered User

Thread Starter

Thank you. I'll cross reference that suggestion with the factory service manual. How do you suggest sealing that bolt? RTV in the threads?

#20

Registered User

Thread Starter

Get a Block Tester, and verify combustion yes or no in the coolant. You can rent one at O'Reilly or AutoZone. You will probably have to buy the test fluid. Either way just make sure you have the test fluid.

https://www.oreillyauto.com/detail/b.../67094/4700290

https://www.oreillyauto.com/detail/b.../75630/4414187

https://www.autozone.com/loan-a-tool...r-block-tester

https://www.oreillyauto.com/detail/b.../67094/4700290

https://www.oreillyauto.com/detail/b.../75630/4414187

https://www.autozone.com/loan-a-tool...r-block-tester

What does "combustion yes or no in the coolant" mean and what else can I learn from a block tester?