A/C Compressor Replacement

#1

A/C Compressor Replacement

My 1994 22RE pickup had a/c installed by the dealer shortly after purchase. It has always used R134a. The compressor is bad now and I want to replace it myself so I ordered the Denso 471-1141, which is recommended for my model year, and which is identical to the one I'm replacing. My issue is that the compressor was designed for R12 and I'm not sure if the oil that ships inside it will be mineral oil (R12) or PAG (R134a). If it turns out to be mineral oil, can I just drain it and replace with PAG or do I have to do some kind of flush before I can replace the oil. Alternately, there is another Denso compressor (471-1428) that was designed for R134a for use on the 1994 22RE 4Runner, but I don't know if that will be an identical fit to the old compressor. Any words of wisdom from the experts would be appreciated.

#2

Registered User

all 1994 and up had to have r134a to be legal in the usa. A r12 compressor will have mineral oil. I would not use a r12 compressor with r143a. The pressures are different and may cause the compressor to fail prematurly. If you do use the r12 unit you will need to flush it to remove any mineral oil residue. poe and mineral oil are not compatible and will cause problems.

#3

Registered User

Double check the package when it comes in and there should also be a tag on the compressor that gives it's oil type. I looked that one up on Amazon and can clearly read the tag for R12. Depending on where you bought it from, they should take it back and cover the shipping if they told you that it was right for that vehicle. Superex87 is right about those trucks using 134A compressors. The 4Runners had it even earlier than that. You said the dealer installed it? They could have put an R12 compressor on it then. They would have still had those on the shelf. The type of connectors are on the system will tell you what it was originally filled with.

All that being said and since you are going to spend some money anyway, get the 134A compressor. When you replace it, absolutely, change the dryer and any o-rings that you can reasonably put your hands on. Use PAG46 or whatever the compressor calls for, and pull at least a three hour vac on it before checking for leaks. Also put you a little dye in there just in case you have a small leak somewhere or purchase your oil with dye in it already. That's not completely necessary but I always do. If they put mineral oil in there all those years ago, you're going to want to get as much of that out of there as possible and the dryer will be holding some. The dryer is something that needs to be done every time you open the system up anyway and they should be cheap. Also check your Schrader valves and make sure they aren't leaking. That's the main reason I put dye in systems that I know aren't leaking. It makes it easy to spot a stuck or failed valve as soon as you take the caps off.

Don't skip anything to save a little money or time. You don't want to be buying a second compressor in a couple months. You hardly ever get a warranty honored on one if it fails and a certified AC tech did not install it.

Good luck.

All that being said and since you are going to spend some money anyway, get the 134A compressor. When you replace it, absolutely, change the dryer and any o-rings that you can reasonably put your hands on. Use PAG46 or whatever the compressor calls for, and pull at least a three hour vac on it before checking for leaks. Also put you a little dye in there just in case you have a small leak somewhere or purchase your oil with dye in it already. That's not completely necessary but I always do. If they put mineral oil in there all those years ago, you're going to want to get as much of that out of there as possible and the dryer will be holding some. The dryer is something that needs to be done every time you open the system up anyway and they should be cheap. Also check your Schrader valves and make sure they aren't leaking. That's the main reason I put dye in systems that I know aren't leaking. It makes it easy to spot a stuck or failed valve as soon as you take the caps off.

Don't skip anything to save a little money or time. You don't want to be buying a second compressor in a couple months. You hardly ever get a warranty honored on one if it fails and a certified AC tech did not install it.

Good luck.

#4

I emailed Denso and they got back to me saying that the 471-1141 is indeed the unit installed by Toyota for my pickup and that it does ship with mineral oil for R12. They said it can be drained and refilled with ND8 oil (PAG), which is what the dealers did to comply with the then new R134a requirement. All of the connectors are R134a sized and they aren't adaptors either so the plumbing all seems to be R134a based, but the compressor seems to be a converted R12 unit unfortunately. Denso said the 471-1428 wasn't the best replacement choice, even though it was originally R134a oem for the 1994 4runner with the same 22re engine, because it is higher capacity unit than the 1141 and might not be compatible with the original condenser (I would have thought greater capacity would be a plus, but I guess not). They recommended a compressor used by the V6 pickups of the same era although the diameter of the pulley is a little larger so I might have to replace the belt with a slightly larger one, otherwise fit is supposed to be identical. I intend to replace the dryer and schraders along with the compressor. The dye idea sounds wise for future leak detection capability so I'll invest in some of that too. Thanks.

#5

Registered User

The capacity or efficiency of the compressor won't be an issue. The high and low side switches work off pressures to turn the compressor on and off when the pressures indicate that it needs to run. The pulley will be important though. You don't want to overstroke the compressor by having too small of a pulley on it. You said the one they recommended had a larger pulley which will turn the pump slower and you'd want to check on that belt. I have done mods to belt drive circuits before where I shortened or lengthened the belt a little. Most times you're ok but every once in a while you end up with something that requires a belt that you can't find anywhere. You won't have to worry with any of that if you use the OEM style compressor. I would take one of the caps off and roll it over to let the oil out and then do the other. I would say hook your vacuum pump up to the compressor by itself after that but I've never done it and can't swear to you what, if any, harm that will do to it. You draw the system down to the same negative pressure when you vac the system but, like I said, never done it before and don't want to steer you wrong. If a pro tells you that that would be ok, it would be a good way to vac the oil out of the compressor and actually measure the volume of oil that came out. If they say it's prefilled with 2oz and you get 1.8 oz out of it then I'd say it was ready for some PAG.

They may be right about the 4Runner compressor now that I think about it. Does your truck have a double stacked condenser up front? By that I mean two condensers stacked on top of one another and then plumbed together. My 89 4Runner 3VZE does and I'm not sure if the 22RE trucks did. That may be the issue they are referring to but who knows.

They may be right about the 4Runner compressor now that I think about it. Does your truck have a double stacked condenser up front? By that I mean two condensers stacked on top of one another and then plumbed together. My 89 4Runner 3VZE does and I'm not sure if the 22RE trucks did. That may be the issue they are referring to but who knows.

#6

Registered User

My AC was a "dealer install", not a "factory" install.

I've only seen the double stack condenser when looking up the part.

#7

The one I'm replacing is single stack and the replacement is also a single stack unit. I did a search on various auto part store catalogues and they all come back with the 471-1141 compressor as the correct part for my 1994 22re base pickup even though the compressor was designed for R12. The Denso tech recommended the 471-1167; designed for a V-6 p/u with HFC134a, 5mm diameter bigger, but according to him the belt should be OK within allowable adjustment. All I have to do is swap manifolds. The tech didn't elaborate about why the larger capacity of the 4Runner 471-1428 compressor would be problematic, but I assumed it was because it would create an over pressure situation that might shorten the life of the compressor (and other a/c components). The 1141 and 1167 units both say "15" on the body of the compressor whereas the 4Runner compressor 471-1428 says '17," which I'm told is a measure of capacity. Too bad, because I think the 1428 would have been a more seamless fit. I'm going to give the recommended v6 compressor a try this weekend.

Last edited by hybridspecies; 08-01-2016 at 11:03 AM.

Trending Topics

#8

Registered User

The V6 compressor will work fine. I'd go with the 4runner compressor were I in your shoes. Theoretically you wouldn't have pressure issues. Your high and low side pressure switches would kick out the clutch before that happened. They are what tells the compressor when to come on and when to stop. Think of it like an air compressor in your shop. I half horse single piston compressor will give your the same pressure at your air tool as a 10 horse dual stage 3 cylinder pump. The big pump will just run for 5 seconds to refill the tank while the little one will run for 45 seconds per cycle. More efficient if you ask me. I'm probably showing my ignorance here but it makes sense to me. I am no pro so don't go that route just because I said I would.

#9

Thanks. When I pull a vacuum with my pump, will that draw out the oil as well as the Freon and moisture? I've seen some say yes and others say no, but I've never done it before and was wondering if I can add oil to the compressor before install or if I have to add it with the Freon? In a way I'm hoping it will remove all of the oil from the entire system in case there's contamination, but on the other side it would be nice just to get the oil in there when I install the new compressor. Also, do I really need to pull vacuum for 3 hours or is that just the amount of time I need to watch for leaks? and finally, what is a "micron" in reference to the vacuum pump? I'll be borrowing a pump that says 50 microns, but I don't know what that refers to. Any other tips and recommendations are appreciated - thanks.

#10

Registered User

You need to drain the mineral oil out of the R-12 compressor before pulling a vacuum on it. It also would be good to flush the compressor after draining the oil out. The vacuum pump will remove the air from the system along with any moisture in the air. Be sure to replace the dryer. Be sure to replace the dryer. I said that twice to make sure you understand how important that is. The dryer holds moisture and contaminants so it MUST be changed. Putting the system under vacuum lowers the boiling point of water to below room temperature so that the moisture can be removed with the air. Any time you open an A/C system to the atmosphere, you must pull a vacuum on it to remove the moisture. Three hours is a little extreme but , if you have the time, it wouldn't hurt anything to do it that long. I would do at least 45 minutes. If you use an A/C machine, you can add the oil before charging with R134A. Be sure to add the correct amount of oil as it is the oil circulating with the refrigerant that lubes the entire system

Last edited by mwisham; 08-02-2016 at 11:28 AM.

#11

Registered User

In reference to the three hour vac time, it's just like mwisham saying " Be sure to replace the dryer. Be sure to replace the dryer." It's really important to get a good vacuum. So important that I didn't want to tell you 45 minutes, which is what Toyota says to do, because I didn't want you to shorten it to 30 minutes. Anywhere from an hour to two hours is what I normally do. I would do it longer but my little vac gets real hot after about an hour.

Flush depends on what went wrong with your system in the first place. If your compressor locked up then you have to do it. If it had a bad bearing, do it and if the clutch just got weak from wear, you might want to do it. Better to do it and not need to than not do it and find out that you should have.

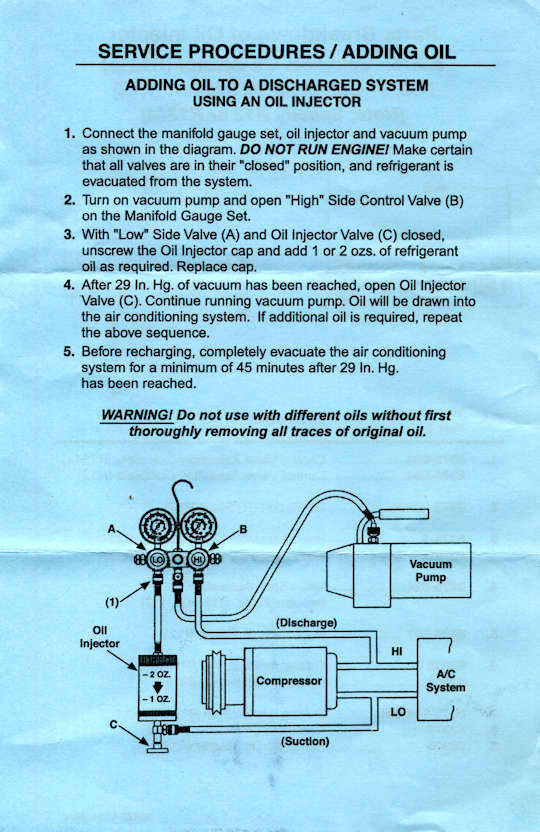

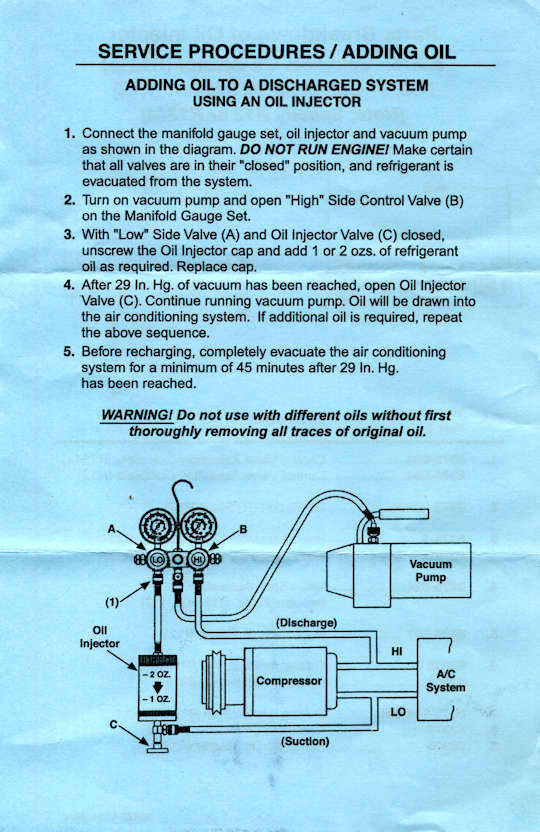

As far as getting your new oil in, attached is a picture of what I use and it works very well. Just carefully measure out the oil you need, add a little dye, screw on the cap and proceed with your freon fill. Bleed any air that you have in your line before you hook it up to your manifold set. Bought it from local ac shop for about $15.

Here is something interesting that I just learned thanks to some info from ewong. This is a quote from the Toyota service bulletin for converting to 134 from R12. I don't care what it says, I'm going to try and get the mineral oil out and PAG in. I might just not try and suck it all out of the workings of the compressor after reading this. You don't want to start it up with it dry inside.

"D. Flushing Requirements There is no need to remove or flush R–12 mineral oil from the system. Simply charge the system with the specified type and amount* of PAG oil to provide proper lubrication."

Anybody have any thoughts on that?

Flush depends on what went wrong with your system in the first place. If your compressor locked up then you have to do it. If it had a bad bearing, do it and if the clutch just got weak from wear, you might want to do it. Better to do it and not need to than not do it and find out that you should have.

As far as getting your new oil in, attached is a picture of what I use and it works very well. Just carefully measure out the oil you need, add a little dye, screw on the cap and proceed with your freon fill. Bleed any air that you have in your line before you hook it up to your manifold set. Bought it from local ac shop for about $15.

Here is something interesting that I just learned thanks to some info from ewong. This is a quote from the Toyota service bulletin for converting to 134 from R12. I don't care what it says, I'm going to try and get the mineral oil out and PAG in. I might just not try and suck it all out of the workings of the compressor after reading this. You don't want to start it up with it dry inside.

"D. Flushing Requirements There is no need to remove or flush R–12 mineral oil from the system. Simply charge the system with the specified type and amount* of PAG oil to provide proper lubrication."

Anybody have any thoughts on that?

#12

Registered User

FYI

The Document is an (ancient) Toyota TSB AC002-98

The doc is referenced in a few old posts, but no one really mentioned what a WEALTH of info is in there.

http://www.toyotaparts.metro-toyota....T-AC98-002.pdf

For example - from the chart on page 2 you can clearly determine that NOT ALL 22RE motors use the same AC compressor!!!

Also, in another thread on this forum, there is a notation that the MOUNTING bracket is DIFFERENT.

https://www.yotatech.com/forums/f115...racket-237826/

The Document is an (ancient) Toyota TSB AC002-98

The doc is referenced in a few old posts, but no one really mentioned what a WEALTH of info is in there.

http://www.toyotaparts.metro-toyota....T-AC98-002.pdf

For example - from the chart on page 2 you can clearly determine that NOT ALL 22RE motors use the same AC compressor!!!

Also, in another thread on this forum, there is a notation that the MOUNTING bracket is DIFFERENT.

https://www.yotatech.com/forums/f115...racket-237826/

#13

Registered User

From that amazing TSB

years - model - engine - compressor type

86-88 - 4Runner - L4 - 10P15

88 - 4Runner - v6 - 10PA17

89-94 - 4Runner - all - 10PA17

86-88 - Truck - L4 - 10P13

88 - Truck - v6 - 10PA15

89-94 - Truck - all - 10PA15

Im not sure what the difference is between the PA modes and the P models

years - model - engine - compressor type

86-88 - 4Runner - L4 - 10P15

88 - 4Runner - v6 - 10PA17

89-94 - 4Runner - all - 10PA17

86-88 - Truck - L4 - 10P13

88 - Truck - v6 - 10PA15

89-94 - Truck - all - 10PA15

Im not sure what the difference is between the PA modes and the P models

#14

Mineral oil mixed with PAG? Wow, that sounds like a recipe for premature failure. I think I'll try adding oil directly to the compressor and the dryer when I install them and am crossing my fingers that the oil doesn't get sucked out when I apply a vacuum to the whole system afterwards. The TSB is greatly appreciated, especially the part numbers and fill requirements. The compressor listings in the TSB confirm what the Denso tech told me about the 4Runner using a different compressor than my pickup. I would have bet the farm that they used the same compressor because whenever I enter my pickup's VIN in the search engine of an online parts catalogue it almost always comes back as the 1994 4Runner with the 22RE engine. I am surprised that the V6 compressor is the same as the one my I4 pickup uses. Thanks for all the tips.

One newbie question on refilling the refrigerant - do I start with the engine running or off? Is the pressure of a 12oz R134a can sufficient to fill the low side of the system that's under vacuum or do I need the compressor running to circulate it throughout the system? When I've used the manifold set to top off the Freon level previously I always did so with the engine running, but I'd prefer not to do that without any refrigerant in the system to begin with unless that's how it's supposed to be done. Any and all advice is appreciated so I get this thing done right the first time.

One newbie question on refilling the refrigerant - do I start with the engine running or off? Is the pressure of a 12oz R134a can sufficient to fill the low side of the system that's under vacuum or do I need the compressor running to circulate it throughout the system? When I've used the manifold set to top off the Freon level previously I always did so with the engine running, but I'd prefer not to do that without any refrigerant in the system to begin with unless that's how it's supposed to be done. Any and all advice is appreciated so I get this thing done right the first time.

#15

Registered User

You're going to lose some of that oil during the vac. I'd sure rather use an oil charge can which you can get in different volumes or an injector like I showed you. Lot's of folks do it the way you are talking about though. My thoughts on that are that when the only oil you have in the system is at and just past the compressor, when the compressor kicks on for the first time it's going to slowly send all of the oil down the circuit and not have any more oil in it until the oil makes it all the way back around to it. Injecting it into the supply line slowly will allow it some oil during the first lap around the block.

On your question about engine on or off. If everything is working right electrically when you start the engine with a vacuum on the ac system, the low side switch should sense no freon in the system and will not allow the compressor to kick on. When you start filling, the pressure from the can will wen sensed by the switch and allow the compressor to start. I don't know what it would hurt to go ahead and start the fill with the engine off or ac not on but either way, the compressor will not run until there is pressure in the line. I have seen lots of folks run a hot wire to the compressor to make it run when something wasn't working in the electrical side of the system. It will cool just great but if you ever get a leak in the system and the freon all leaks out along with the oil, you get to buy a new compressor at minimum.

On your question about engine on or off. If everything is working right electrically when you start the engine with a vacuum on the ac system, the low side switch should sense no freon in the system and will not allow the compressor to kick on. When you start filling, the pressure from the can will wen sensed by the switch and allow the compressor to start. I don't know what it would hurt to go ahead and start the fill with the engine off or ac not on but either way, the compressor will not run until there is pressure in the line. I have seen lots of folks run a hot wire to the compressor to make it run when something wasn't working in the electrical side of the system. It will cool just great but if you ever get a leak in the system and the freon all leaks out along with the oil, you get to buy a new compressor at minimum.

#16

Charchee, I bought an oiler that looked like yours, but the hookup instructions (see below) appear to be somewhat counterintuitive to me. In your setup, you are connecting the valve end of the oiler to the low pressure side of the engine and the hose end of the oiler goes directly top the refrigerant, correct? That makes more sense to me, but I just wanted to double check that I have it correct. Thanks.

Last edited by hybridspecies; 08-05-2016 at 07:49 PM.

#17

Registered User

Brilliant! Thank you very much for that. I knew there had to be a way to do that without spaying oil and dye in my face when I was bleeding that oil insertion line to the manifold but that's how I was taught to use it. That will be a big help when I get to that point on the project I'm working on right now.

Update:

Put a little dye in my system and ran it for a while. No leaks in the front or at the firewall but found a few bubbles in the pressure line from the compressor and a little haze of the dye on that line. Also saw a pretty little neon green line around the front housing seam of the compressor. Don't really know what I'm going to do about it other than see how long it will last on a charge. I'm not scared to take care of the issues but I've got three trucks and I hardly ever drive this one unless i've got the cap off or it's deer season and I don't need the AC. I may just replace that line and try some of that stop leak stuff or may not do anything to it. Been thinking about a complete rebuild of the truck. I will take care of it then if I decide to go for it.

Update:

Put a little dye in my system and ran it for a while. No leaks in the front or at the firewall but found a few bubbles in the pressure line from the compressor and a little haze of the dye on that line. Also saw a pretty little neon green line around the front housing seam of the compressor. Don't really know what I'm going to do about it other than see how long it will last on a charge. I'm not scared to take care of the issues but I've got three trucks and I hardly ever drive this one unless i've got the cap off or it's deer season and I don't need the AC. I may just replace that line and try some of that stop leak stuff or may not do anything to it. Been thinking about a complete rebuild of the truck. I will take care of it then if I decide to go for it.

Last edited by Charchee; 08-05-2016 at 10:01 PM. Reason: More info after testing.

#18

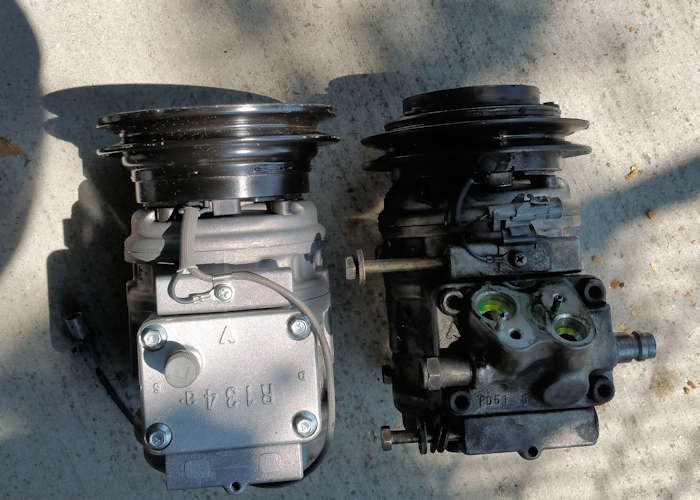

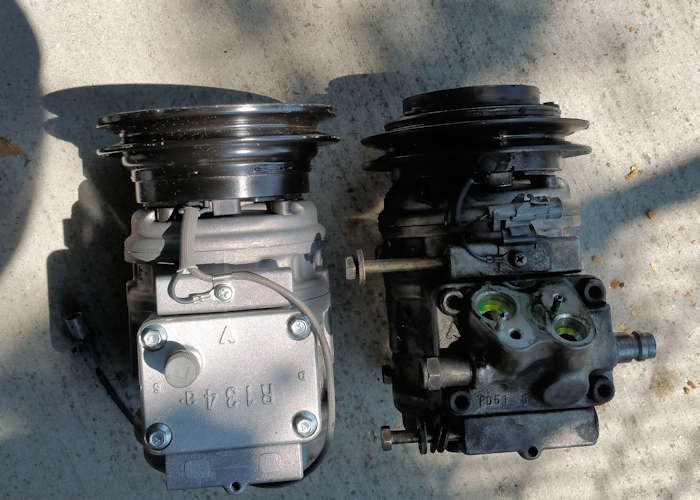

Woe is me. I pulled the compressor this morning and it turns out the pulley is in the wrong place on the new one. I specifically asked the Denso tech who recommended the new compressor if the pulley alignment was the same and he gave me an unequivocal yes. You can see from the photo that it is an unequivocal no. I should have gone with the 4Runner compressor like you said.

Any recommendations on how to seal the plumbing until next weekend? I currently have rags in the lines that went to the compressor and I don't want to have to put the old one back in just to take it out again when the correct compressor arrives. I though about taping some plastic wrap over the open fittings, but I'm worried the plastic might melt from the engine heat. Let me know what you do - thanks.

On a tangent, what's your weapon of choice for hunting deer?

Any recommendations on how to seal the plumbing until next weekend? I currently have rags in the lines that went to the compressor and I don't want to have to put the old one back in just to take it out again when the correct compressor arrives. I though about taping some plastic wrap over the open fittings, but I'm worried the plastic might melt from the engine heat. Let me know what you do - thanks.

On a tangent, what's your weapon of choice for hunting deer?

#19

Registered User

I guess you could remove your two compressor lines from their other points of attachment and cap those fittings.

Weapon of choice is going to be a bow for me unless my freezer is completely empty. Then it's my 300 Blackout or my 308 if I really mean business.

Weapon of choice is going to be a bow for me unless my freezer is completely empty. Then it's my 300 Blackout or my 308 if I really mean business.

#20

Registered User

I tried searching for plastic hose end caps.

I know they make em for AN fittings....

I found these

http://www.centurytool.net/Quick_Sea...ls_s/39027.htm

I know they make em for AN fittings....

I found these

http://www.centurytool.net/Quick_Sea...ls_s/39027.htm

Last edited by ewong; 08-06-2016 at 04:25 PM.