New Weber, Won't Start

#1

Registered User

Thread Starter

New Weber, Won't Start

I bought a new Weber 32/36 kit for the 20r in my '79 2wd. The truck ran ok before the swap, always started at least. Since installing the Weber, I haven't been able to keep it running longer than a few seconds. If I leave it for a few minutes it will start again but quickly die. It won't restart unless I leave it again for a few minutes. Tried a number of things but I'm out of ideas and need help.

I removed all the smog stuff, including the pump and I was careful to cap everything. I combed the entire compartment several times to make sure everything is covered. I put in a fuel pressure regulator and set it to 3psi according to the instructions. I set the idle and mixture screws in every conceivable way but nothing changes. Unfortunately, I can't even keep it running long enough to do this while it's running. Nor can I check the timing. If you have any ideas please let me know. Thanks!

I removed all the smog stuff, including the pump and I was careful to cap everything. I combed the entire compartment several times to make sure everything is covered. I put in a fuel pressure regulator and set it to 3psi according to the instructions. I set the idle and mixture screws in every conceivable way but nothing changes. Unfortunately, I can't even keep it running long enough to do this while it's running. Nor can I check the timing. If you have any ideas please let me know. Thanks!

Last edited by Sizzle Chest; 03-03-2018 at 07:18 PM.

#2

Registered User

iTrader: (-1)

I bought a new Weber 32/36 kit for the 20r in my '79 2wd. The truck ran ok before the swap, always started at least. Since installing the Weber, I haven't been able to keep it running longer than a few seconds. If I leave it for a few minutes it will start again but quickly die. It won't restart unless I leave it again for a few minutes. Tried a number of things but I'm out of ideas and need help.

I removed all the smog stuff, including the pump and I was careful to cap everything. I combed the entire compartment several times to make sure everything is covered. I put in a fuel pressure regulator and set it to 3psi according to the instructions. I set the idle and mixture screws in every conceivable way but nothing changes. Unfortunately, I can't even keep it running long enough to do this while it's running. Nor can I check the timing. If you have any ideas please let me know. Thanks!

I removed all the smog stuff, including the pump and I was careful to cap everything. I combed the entire compartment several times to make sure everything is covered. I put in a fuel pressure regulator and set it to 3psi according to the instructions. I set the idle and mixture screws in every conceivable way but nothing changes. Unfortunately, I can't even keep it running long enough to do this while it's running. Nor can I check the timing. If you have any ideas please let me know. Thanks!

Removed which pump?

What have you tried?

What size lines are you running?

Where did you buy this kit? (Ok to call out a source here even if it is user error its worth noting)

What was included?

As always the more detailed you give the better suited forum members are to hell.

...

You want to monitor the float bowl, pressure isn't every thing you also need flow volume. (Volume keeps it running, pressure keeps it from over powering the float valve)

To keep it running to verify timing and such feed it fuel manually, roadkill style out of a water bottle. Just make sure you have typical safety equipment handy like a large dry rag (to snuff out a carb fire) and fire extinguisher (in case something goes horrible wrong)

#3

Registered User

moor details!!

Removed which pump?

What have you tried?

What size lines are you running?

Where did you buy this kit? (Ok to call out a source here even if it is user error its worth noting)

What was included?

As always the more detailed you give the better suited forum members are to hell.

...

You want to monitor the float bowl, pressure isn't every thing you also need flow volume. (Volume keeps it running, pressure keeps it from over powering the float valve)

To keep it running to verify timing and such feed it fuel manually, roadkill style out of a water bottle. Just make sure you have typical safety equipment handy like a large dry rag (to snuff out a carb fire) and fire extinguisher (in case something goes horrible wrong)

Removed which pump?

What have you tried?

What size lines are you running?

Where did you buy this kit? (Ok to call out a source here even if it is user error its worth noting)

What was included?

As always the more detailed you give the better suited forum members are to hell.

...

You want to monitor the float bowl, pressure isn't every thing you also need flow volume. (Volume keeps it running, pressure keeps it from over powering the float valve)

To keep it running to verify timing and such feed it fuel manually, roadkill style out of a water bottle. Just make sure you have typical safety equipment handy like a large dry rag (to snuff out a carb fire) and fire extinguisher (in case something goes horrible wrong)

Removed which pump? This is a real good one cause you didn't mention what type of fuel pump. Was it the pump that fed the prior carb?

When did you remove the smog equipment in relation to doing the carb swap? before or during

#4

Registered User

Smog pump.

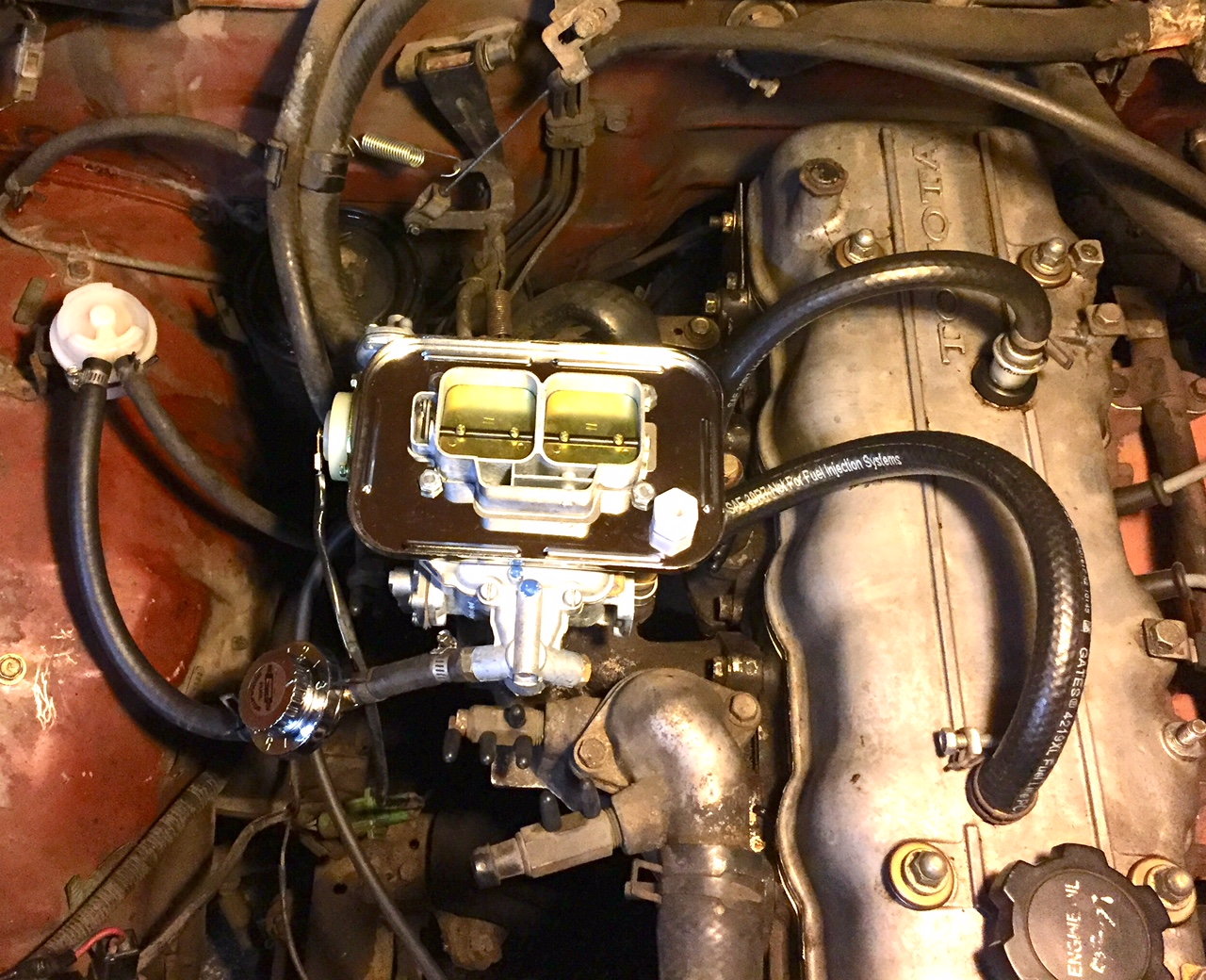

For whatever reason a lot of 20Rs had in-tank, electric fuel pumps, which his obviously has, seeing in the photo where the fuel line is coming from.

It's starting to have been too long since I thought much about carbs...but I'll think for a bit. Mine worked well enough to run & tune when I installed it, but I had also already done most of my de-smog before swapping for the Weber.

If it was me, I'd be looking at the de-smog stuff you did more than the actual carb, but it could definitely be either.

For whatever reason a lot of 20Rs had in-tank, electric fuel pumps, which his obviously has, seeing in the photo where the fuel line is coming from.

It's starting to have been too long since I thought much about carbs...but I'll think for a bit. Mine worked well enough to run & tune when I installed it, but I had also already done most of my de-smog before swapping for the Weber.

If it was me, I'd be looking at the de-smog stuff you did more than the actual carb, but it could definitely be either.

Last edited by 83; 03-04-2018 at 06:26 AM.

#5

Registered User

Thread Starter

I'll try to provide more details: Zach is correct, I removed the smog pump, along with all the other smog equipment during the carb swap. It has an electric fuel pump.

The kit was from Redline. I made and installed a block plate for the rear EGR and used the included block plate with port to run a PCV from the manifold to the valve cover.

I'm not sure about the question of what size lines I used: I replaced the fuel line with the one provided in the kit. I noticed the inner diameter of the provided fuel line was larger than the stock hose. Does that matter?

Even if I could get it to run long enough to get next to the carb I'm hesitant to feed it fuel by hand. My coworker was badly, badly burned doing that.

Oh, I did leave the charcoal canister along with the line to the fuel tank. I capped both the vacuum port and second fuel line on top.

The kit was from Redline. I made and installed a block plate for the rear EGR and used the included block plate with port to run a PCV from the manifold to the valve cover.

I'm not sure about the question of what size lines I used: I replaced the fuel line with the one provided in the kit. I noticed the inner diameter of the provided fuel line was larger than the stock hose. Does that matter?

Even if I could get it to run long enough to get next to the carb I'm hesitant to feed it fuel by hand. My coworker was badly, badly burned doing that.

Oh, I did leave the charcoal canister along with the line to the fuel tank. I capped both the vacuum port and second fuel line on top.

Last edited by Sizzle Chest; 03-04-2018 at 07:05 AM.

#6

Registered User

I'll try to provide more details: Zach is correct, I removed the smog pump, along with all the other smog equipment during the carb swap. It has an electric fuel pump.

The kit was from Redline. I made and installed a block plate for the rear EGR and used the included block plate with port to run a PCV from the manifold to the valve cover.

I'm not sure about the question of what size lines I used: I replaced the fuel line with the one provided in the kit. I noticed the inner diameter of the provided fuel line was larger than the stock hose. Does that matter?

Even if I could get it to run long enough to get next to the carb I'm hesitant to feed it fuel by hand. My coworker was badly, badly burned doing that.

Oh, I did leave the charcoal canister along with the line to the fuel tank. I capped both the vacuum port and second fuel line on top.

The kit was from Redline. I made and installed a block plate for the rear EGR and used the included block plate with port to run a PCV from the manifold to the valve cover.

I'm not sure about the question of what size lines I used: I replaced the fuel line with the one provided in the kit. I noticed the inner diameter of the provided fuel line was larger than the stock hose. Does that matter?

Even if I could get it to run long enough to get next to the carb I'm hesitant to feed it fuel by hand. My coworker was badly, badly burned doing that.

Oh, I did leave the charcoal canister along with the line to the fuel tank. I capped both the vacuum port and second fuel line on top.

if you are not comfortable pouring gas in the carb try squirting starting fluid in just to see if it stays running with more fuel or if it is already too rich and it kills it altogether.

#7

Registered User

Which jets came in your carb? Specifically in the smaller primary idle, but knowing what you have in there to start with is important.

I'm assuming you've set the idle speed valve and throttle position screw based on Redline Weber's lean best idle requirements.

I see in the photo that you have an electric choke and the choke butterfly looks fully closed or nearly fully closed. Is the choke working properly? Admittedly I have more experience with manual choke Webers but the choke should open when you engage the throttle.

I typically only need the choke closed on cold mornings or when the temperature is near freezing. Otherwise a couple pumps of the pedal and turn the key.

You said you can get it to start. So what happens when you get it started and keep the pedal down a little? Will it stay running?

Even after getting it to start and sputter out, what do your spark plugs look like?

I'm assuming you've set the idle speed valve and throttle position screw based on Redline Weber's lean best idle requirements.

I see in the photo that you have an electric choke and the choke butterfly looks fully closed or nearly fully closed. Is the choke working properly? Admittedly I have more experience with manual choke Webers but the choke should open when you engage the throttle.

I typically only need the choke closed on cold mornings or when the temperature is near freezing. Otherwise a couple pumps of the pedal and turn the key.

You said you can get it to start. So what happens when you get it started and keep the pedal down a little? Will it stay running?

Even after getting it to start and sputter out, what do your spark plugs look like?

Last edited by Punjab; 03-04-2018 at 08:51 AM.

Trending Topics

#8

Registered User

Thread Starter

I actually don't know which jets came on it. I assumed they would be the correct ones when I ordered it but after reading so many threads it seems that's not necessarily the case. Is there an easy way to check or do I need to disassemble the carb?

I did set the initial setup according to the lean best idle. Tried messing around with it and resetting it a few times.

If I go out there, it will start up right now and sound normal for about 3-5 seconds. If I touch the pedal, it will die. If I let it run, it will still die. Then it will turn over but won't start again. If I leave it for 5-10 minutes, I can do the same thing: start up, run a few seconds and die.

I'm wondering about the choke. The source has keyed power, but I don't see the butterfly move at all. Thought I would but they don't.

I did set the initial setup according to the lean best idle. Tried messing around with it and resetting it a few times.

If I go out there, it will start up right now and sound normal for about 3-5 seconds. If I touch the pedal, it will die. If I let it run, it will still die. Then it will turn over but won't start again. If I leave it for 5-10 minutes, I can do the same thing: start up, run a few seconds and die.

I'm wondering about the choke. The source has keyed power, but I don't see the butterfly move at all. Thought I would but they don't.

#9

Registered User

Thread Starter

*update*

I tried pouring some fuel directly into the carb and it starts up. Once that fuel burns off it dies. I repeated this several times and it won't start unless I manually give it fuel. It still doesn't stay running long enough for me to get up there and deliver more fuel before it dies. So, it seems to be a fuel delivery problem, right?

I tried pouring some fuel directly into the carb and it starts up. Once that fuel burns off it dies. I repeated this several times and it won't start unless I manually give it fuel. It still doesn't stay running long enough for me to get up there and deliver more fuel before it dies. So, it seems to be a fuel delivery problem, right?

#10

Registered User

iTrader: (-1)

*update*

I tried pouring some fuel directly into the carb and it starts up. Once that fuel burns off it dies. I repeated this several times and it won't start unless I manually give it fuel. It still doesn't stay running long enough for me to get up there and deliver more fuel before it dies. So, it seems to be a fuel delivery problem, right?

I tried pouring some fuel directly into the carb and it starts up. Once that fuel burns off it dies. I repeated this several times and it won't start unless I manually give it fuel. It still doesn't stay running long enough for me to get up there and deliver more fuel before it dies. So, it seems to be a fuel delivery problem, right?

Does the Weber have a sight glass on the float bowl? Is this running dry?

Two things you can try that come to mind before calling it a pump issue, well three.

Turn up the regulator.

Rig up a gravity feed.

Measure the pump flow post regulator.

There should be some adjustment for the float but I have no specifics .

#11

Registered User

The idle jets are easy to check. They are located under a large brass screw on the outside of both sides of the carb. They have an o ring under the lip of the screw and then the jets are hand pressed into the bottom of the screw. Don't use pliers to remove the jets from the screws as the brass will get nicked. You should always be able to work them free with your fingers or maybe tweezers with a paper towel underneath.

The other jets will require disconnecting your choke linkage and unscrewing the top cover of the carburetor. You can disconnect your fuel line but I never do.

The main fuel jets are located in the bottom of the bowl and are going to be submerged in fuel. The air corrector jets sit above the mains, at the center point of the carb.

My 32/36 originally came with a 60 primary idle, 170 primary air corrector, and 140 primary main. 50 secondary idle, 160 secondary air corrector, and another 140 secondary main.

When the truck dies and won't restart, hold the gas pedal all the way to the floor while you turn the starter. Don't pump it. This will hold the carb full open and allow fuel to flow in freely. If it still won't fire to life then you could have an issue with your pump, timing could be waaaay off or the change in vacuum advance could be throwing the spark off.

You can unhook that little linkage on the side of your choke and just open the butterfly by hand to see if that helps.

The other jets will require disconnecting your choke linkage and unscrewing the top cover of the carburetor. You can disconnect your fuel line but I never do.

The main fuel jets are located in the bottom of the bowl and are going to be submerged in fuel. The air corrector jets sit above the mains, at the center point of the carb.

My 32/36 originally came with a 60 primary idle, 170 primary air corrector, and 140 primary main. 50 secondary idle, 160 secondary air corrector, and another 140 secondary main.

When the truck dies and won't restart, hold the gas pedal all the way to the floor while you turn the starter. Don't pump it. This will hold the carb full open and allow fuel to flow in freely. If it still won't fire to life then you could have an issue with your pump, timing could be waaaay off or the change in vacuum advance could be throwing the spark off.

You can unhook that little linkage on the side of your choke and just open the butterfly by hand to see if that helps.

#12

Registered User

Thread Starter

Thanks for the suggestions everyone. I'll give those things a try tomorrow.

I'm also starting to wonder if I was overly zealous removing things I thought were related to the smog equipment and accidentally removed something important. I went back through the box of stuff I removed and these three things have me wondering. I don't know what any of them do, but the left has a vacuum port so I figured it was some sort of shut off? The middle I have no idea and most suspect I shouldn't have removed. The right I believe was part of the fuel return line from the stock carb to the charcoal canister and I don't think it would effect anything but I don't really know.

I'm also starting to wonder if I was overly zealous removing things I thought were related to the smog equipment and accidentally removed something important. I went back through the box of stuff I removed and these three things have me wondering. I don't know what any of them do, but the left has a vacuum port so I figured it was some sort of shut off? The middle I have no idea and most suspect I shouldn't have removed. The right I believe was part of the fuel return line from the stock carb to the charcoal canister and I don't think it would effect anything but I don't really know.

#13

Registered User

Thread Starter

My suspicions were correct: I reconnected the thing in the middle and suddenly it runs! Disconnect it and it sputters out. Let that be a lesson to anyone as dumb as me to avoid cutting random things with reckless abandon. And now that it's running, I can start tuning it. Thanks again for everyone's helpful suggestions!

edit: just took it for a spin and the power increase is tremendous, feels like a different truck!

edit: just took it for a spin and the power increase is tremendous, feels like a different truck!

Last edited by Sizzle Chest; 03-05-2018 at 11:21 AM.

#14

Registered User

iTrader: (1)

My suspicions were correct: I reconnected the thing in the middle and suddenly it runs! Disconnect it and it sputters out. Let that be a lesson to anyone as dumb as me to avoid cutting random things with reckless abandon. And now that it's running, I can start tuning it. Thanks again for everyone's helpful suggestions!

edit: just took it for a spin and the power increase is tremendous, feels like a different truck!

edit: just took it for a spin and the power increase is tremendous, feels like a different truck!

I'll be doing a Weber install on my 84, (when it warms up) although I don't have what you have it's always a good idea to read all this information to see what others have run into. I have also started to remove all the smog stuff, but what I did was I removed 1 part and it's wiring and then started the truck to make sure it still started and ran, I did that with all the parts and wiring 1 at a time, For me I ended up with everything disconnected and the truck ran fine, I really think it ran better!

Glad you got it running and seems you're happy with the Weber, I can't wait till I can start on mine. I also bought a new intake manifold so no spacers under the carb, carb bolts right to the manifold.

#15

Registered User

Thread Starter

I tried to look it up on some wiring diagrams but I'm not good with that stuff. I bet someone here has an idea what it is and what it does.

I'm happy with the Weber now, but in the process I wondered many times if I should have just kept the stock carb. The problem for me was that the instructions weren't clear at all, and there is so much variation even within a model year that I couldn't find good information what to do. The location and design of many parts were different than what I found on my truck. I had to piece together advice from various threads and videos. I'm sure the whole install is fairly basic for most guys on this forum but this is the first carb I've ever worked and there is a lot of specific terminology I wasn't familiar with. I even thought about writing it up to help anyone in the future but I figured I would probably end up giving bad advice. "Cut all that stuff off, you don't need any of it . . . so it turns out you do need that stuff. Put it all back on." haha!

I'm happy with the Weber now, but in the process I wondered many times if I should have just kept the stock carb. The problem for me was that the instructions weren't clear at all, and there is so much variation even within a model year that I couldn't find good information what to do. The location and design of many parts were different than what I found on my truck. I had to piece together advice from various threads and videos. I'm sure the whole install is fairly basic for most guys on this forum but this is the first carb I've ever worked and there is a lot of specific terminology I wasn't familiar with. I even thought about writing it up to help anyone in the future but I figured I would probably end up giving bad advice. "Cut all that stuff off, you don't need any of it . . . so it turns out you do need that stuff. Put it all back on." haha!

#16

Registered User

I'd be interested to know. My carb didn't have any parts with electrical connections like the ones you've got pictured. That middle one almost looks like a resistor...something to drop the voltage down a bit. I don't know...

Did you follow the desmog thread, or just start unplugging stuff?

For all the reasons you list, Weber is the way to go. I never found a carb diagram that matched my 83's carb.

Did you follow the desmog thread, or just start unplugging stuff?

For all the reasons you list, Weber is the way to go. I never found a carb diagram that matched my 83's carb.

#17

Registered User

The Weber 32/36 DG series is available with 3 choke configurations. Manual (DGV), water (DGAV), and electric (DGEV).

#18

Registered User

Yeah...I'm trying to remember what my 83 had...I think the Aisin carb had a water choke, then I plugged that off for the manual choke. But is that one of the parts he removed? An electric choke? There's an electrical connection in one of his original photos of the Weber install. That middle part in the last photo doesn't look like a choke control (though I'll admit I've never seen one before...).

#20

Registered User

Yes the round white object on the left of my pic below is the e choke. It connects to the choke in the rectangular space on the right like the water and manual chokes do.