86 Clutch Take 2!

#21

Registered User

Thread Starter

As for the t-case its coming out of a 2wd so no case!

As for the rear main seal I guess I will go ahead and replace it. The only problem I have is that the oil pain is what is holding the engine up so I'm not sure how I can brace the engine so I can remove the pan and get to the seal.

Any ideas?????

#23

Registered User

Thread Starter

As for the transmission if I'm not mistaken isn't it just an extension housing that mates the tranny to the transfercase? I have all those parts. I need to pull the tranny to see but looking at the repair manual I think it will work. And if it doesn't then it's back to the drawing board

As for the engine hoist no I do not have one and don't know anyone with one. I will try and figure a way out

As for the engine hoist no I do not have one and don't know anyone with one. I will try and figure a way out

#24

Registered User

As for the transmission if I'm not mistaken isn't it just an extension housing that mates the tranny to the transfercase? I have all those parts. I need to pull the tranny to see but looking at the repair manual I think it will work. And if it doesn't then it's back to the drawing board

As for the engine hoist no I do not have one and don't know anyone with one. I will try and figure a way out

As for the engine hoist no I do not have one and don't know anyone with one. I will try and figure a way out

BTW i was talking about your transfer case that your truck has in it now cause I am selling the tranny and transfer mated for the prevoius mentioned price. So I meant if your transfer that you have for your truck is a top shift I could go as low as 300, if the 2wd trans doesnt work out.

Good luck man

#25

Registered User

Join Date: Aug 2007

Location: El Monte, Ca.

Posts: 32

Likes: 0

Received 0 Likes

on

0 Posts

Its not hard, who says you need "friends" hahahahah I rebuilt my 22r and threw it in by myself. Mating engine and tranny is the hardest part but def feasable. Make sure to get the clutch aligbnment tool.

Good luck.

Where's your "friends" when you need em

Good luck.

Where's your "friends" when you need em

#26

Yes, mating the engine and transmission is the toughest part, but in every case the problem will yield to patience and small corrections/adjustments. Some sort of transmission jack is very helpful though, just as the OP experienced, some rental yards' idea of a functioning transmission jack is a joke, though no laughing matter. Also consider supporting the transmission from inside the cab. Someone here had pictures of a successful transmission stab with the transmission supported with an engine hoist inside the cab -- pretty slick.

Be patient, persevere, and you will prevail.

Be patient, persevere, and you will prevail.

#27

Registered User

Thread Starter

Pics...Finally

As promised here are the pics from getting the clutch out.

Here are the pics I took but I had done some work before I started taking pics, but for anyone that wants to use this a reference here are the steps that arenít shown in the pictures.

1) Remove the rear drive line bolts (this was a PITA because there were on there tight as HECK and I even broke a wrench trying to get them to break loose)

2) Remove the front driveline (to do this I placed a jack under the transmission and removed the cross member. This opened up a lot of room to get at the bolts on the transfer case.)

3) I bolted the cross member back up and removed the jack to allow for more room under the truck.

4) Disconnect the battery (probably should be step one)

5) Disconnect all the electrical connections to the transmission and the speedo cable

6) I may have done this in backwards order but I removed the started

7) Unbolt the clutch slave cylinder (with this out of the way it would have opened up a little more room to get at the starter.

8) Remove the transmission and transfer case shift levers from the cab

9) Loosen all the bolts that hold the tranny to the engine (Note there is an exhaust shield on the drivers side removing that opened up a lot of room to get in at the top bolt on that side)

10) Support the engine with a floor jack

11) Support the transmission with a jack (transmission jack is recommended I bought an attachment from Autozone that worked great and was only $50

12) Remove the cross member

13) Remove the rest of the bolts from the tranny (I had left all but the top 2 in) NOTE there is one bolt on the drivers side that is bolt through the engine block into the tranny opposite of all the others and I had loosened it but forgot to take it out on my first attempt to pull the tranny.

14) Slowly pull the transmission towards the back of the truck. (Mine was on there tight and took a lot of persuasion but finally started to give.

15) Once the input shaft is clear of the block you can lower it. (My truck is stock frame height with 31Ē tires I had a bit of trouble getting the transmission and transfer case to clear the frame so if your truck sits lower you will want to jack it up and support in on jack stands before you remove anything.

16) Next remove the clutch. To do this I used a breaker bar on the harmonic balancer to hold the engine from turning and then loosened the bolts holding the clutch housing on. Loosen them equally as there is spring tension on them.

17) Finally remove the flywheel. I had to use an impact wrench to get these to budge.

Thatís all I got for now as I havenít been able to get to work on getting it back together and I think I have a few other issues I need to address.

First the Flywheel looks too thin to be turned (replaced).

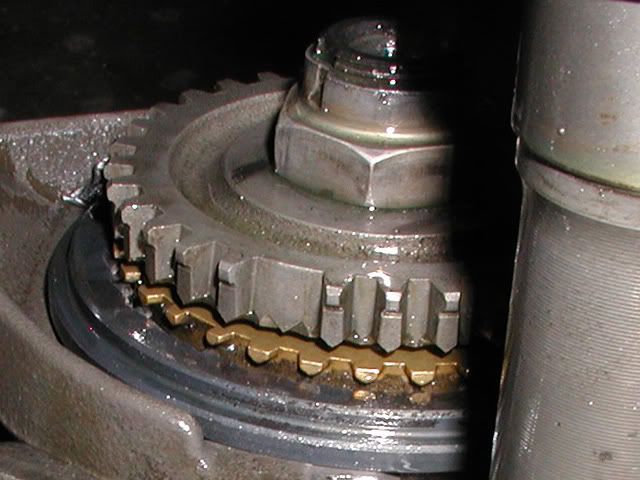

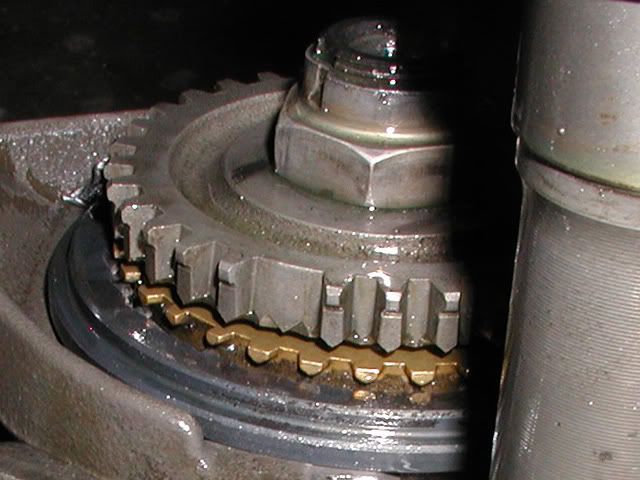

This picture shows a small amount of the metal that came out of the transmission so I am thinking that it needs to be replace (good news is I have another tranny from a parts truck with a lot less miles)

And third I think I found the reason that I thought the clutch was going out. The pilot bearing was broken.

So the plan for now is ordered a new flywheel, replace the pilot bearing and see about replacing the transmission with the other one. Iím hoping that I can get this all done by next Sunday but with work this week it is looking like it might be near impossible to get that done but I will try. The hard part will be the new transmission as it is about 17 miles from my tools and wind sheltered garage!!!!!

Here are the pics I took but I had done some work before I started taking pics, but for anyone that wants to use this a reference here are the steps that arenít shown in the pictures.

1) Remove the rear drive line bolts (this was a PITA because there were on there tight as HECK and I even broke a wrench trying to get them to break loose)

2) Remove the front driveline (to do this I placed a jack under the transmission and removed the cross member. This opened up a lot of room to get at the bolts on the transfer case.)

3) I bolted the cross member back up and removed the jack to allow for more room under the truck.

4) Disconnect the battery (probably should be step one)

5) Disconnect all the electrical connections to the transmission and the speedo cable

6) I may have done this in backwards order but I removed the started

7) Unbolt the clutch slave cylinder (with this out of the way it would have opened up a little more room to get at the starter.

8) Remove the transmission and transfer case shift levers from the cab

9) Loosen all the bolts that hold the tranny to the engine (Note there is an exhaust shield on the drivers side removing that opened up a lot of room to get in at the top bolt on that side)

10) Support the engine with a floor jack

11) Support the transmission with a jack (transmission jack is recommended I bought an attachment from Autozone that worked great and was only $50

12) Remove the cross member

13) Remove the rest of the bolts from the tranny (I had left all but the top 2 in) NOTE there is one bolt on the drivers side that is bolt through the engine block into the tranny opposite of all the others and I had loosened it but forgot to take it out on my first attempt to pull the tranny.

14) Slowly pull the transmission towards the back of the truck. (Mine was on there tight and took a lot of persuasion but finally started to give.

15) Once the input shaft is clear of the block you can lower it. (My truck is stock frame height with 31Ē tires I had a bit of trouble getting the transmission and transfer case to clear the frame so if your truck sits lower you will want to jack it up and support in on jack stands before you remove anything.

16) Next remove the clutch. To do this I used a breaker bar on the harmonic balancer to hold the engine from turning and then loosened the bolts holding the clutch housing on. Loosen them equally as there is spring tension on them.

17) Finally remove the flywheel. I had to use an impact wrench to get these to budge.

Thatís all I got for now as I havenít been able to get to work on getting it back together and I think I have a few other issues I need to address.

First the Flywheel looks too thin to be turned (replaced).

This picture shows a small amount of the metal that came out of the transmission so I am thinking that it needs to be replace (good news is I have another tranny from a parts truck with a lot less miles)

And third I think I found the reason that I thought the clutch was going out. The pilot bearing was broken.

So the plan for now is ordered a new flywheel, replace the pilot bearing and see about replacing the transmission with the other one. Iím hoping that I can get this all done by next Sunday but with work this week it is looking like it might be near impossible to get that done but I will try. The hard part will be the new transmission as it is about 17 miles from my tools and wind sheltered garage!!!!!

#28

Registered User

Join Date: Mar 2007

Location: Phoenix, Arizona

Posts: 680

Likes: 0

Received 0 Likes

on

0 Posts

2 of my friends and I spent about 16 hours combined, the past 2 days, changing the clutch on my 86 22r .

the first day we dropped the trans, and got down to replacing the rear main seal, but i couldnt get my oil pan off since the fipg was so fresh(3kmiles ago did HG) so we tried again the next morning.

my pilot bearing was unbelievably still in great condition, but didnt want to budge. the haynes manual says put hd grease behind it, and push a bolt through the center, thus pushing the bearing out. mine had to be dremeled out of the dang crankshaft >.>

only thing i have left to do is figure out why my transfer case shifter isnt going back in correctly.

good luck, its a pain to do, but well worth it. F*&* a 600 labor bill plus 300 in parts.

the first day we dropped the trans, and got down to replacing the rear main seal, but i couldnt get my oil pan off since the fipg was so fresh(3kmiles ago did HG) so we tried again the next morning.

my pilot bearing was unbelievably still in great condition, but didnt want to budge. the haynes manual says put hd grease behind it, and push a bolt through the center, thus pushing the bearing out. mine had to be dremeled out of the dang crankshaft >.>

only thing i have left to do is figure out why my transfer case shifter isnt going back in correctly.

good luck, its a pain to do, but well worth it. F*&* a 600 labor bill plus 300 in parts.

#29

Registered User

Thread Starter

When I tried it the first time I took the shifters off first and then bolted it all back togther to drive it to the repair shop. The transfer case was a pain but mostly because I had the thing flipped around think that it was backwards from what it should have been. Once I figured out that I was wrong it bolted right back up.

#30

Registered User

Join Date: Mar 2007

Location: Phoenix, Arizona

Posts: 680

Likes: 0

Received 0 Likes

on

0 Posts

right after i posted last i went outside to look at it, and noticed i had it backwards as well xD

glad i left the shift knobs on them.

the marlin 1200 clutch is so smooth,

glad i left the shift knobs on them.

the marlin 1200 clutch is so smooth,

#31

Registered User

Thread Starter

Glad you got it right and I so can not wait to get my parts from Marlin and get my Yota back on the streets!

#32

Registered User

Thread Starter

Update

I haven't had a lot of time to work on the truck these last few days so not much new, however I did get the transfer case off and split the extension housing on the tranny (haven't managed to get it off because I need a giant allen wrench) but what I found wasn't good. Large chuncks and I mean LARGE chunks of metal and lots of chipped teeth so the tranny is toast for sure. Hopefully at some point this weekend I can get the other tranny out of the parts truck and get them all to mate back up, and into the truck.

Well only if my order to MC will ever ship!!!!!

More pics coming soon!

Well only if my order to MC will ever ship!!!!!

More pics coming soon!

#33

Registered User

I'm doing this next week on my 89 (22re) and am going to use this thread as a guide. The last time I did a clutch it was on a 3/4 Ton Ford diesel and we just pulled the motor to make it easier.

Nice write up and thanks!

Nice write up and thanks!

#34

Registered User

Thread Starter

Update

Well yeah the 2wd tranny is not going to work. I had looked a long time ago and saw that it was a "_52" and the tranny in my truck was a G52 well turns out is was a W52 so completely different and in prepping the old tranny I removed the extension housing to find several chipped teeth and missing ball bearings so that one would be in need of a complete rebuild!

I am currently looking for a low mile replacement PM sent to Plumbrbob. Finally my order from MC shipped today so hopefully I will have everything by the weekend and if I get a new tranny I may even have it up and running soon!

I will get pictures of the old tranny and also the rear main seal. In the reapir guide it says that it can be replaced without removing the oil pan so I am going to give that a try. And I will take lots of pics!

I am currently looking for a low mile replacement PM sent to Plumbrbob. Finally my order from MC shipped today so hopefully I will have everything by the weekend and if I get a new tranny I may even have it up and running soon!

I will get pictures of the old tranny and also the rear main seal. In the reapir guide it says that it can be replaced without removing the oil pan so I am going to give that a try. And I will take lots of pics!

#35

Registered User

Thread Starter

Finished!!

Here are the final steps. Sorry I didn't take as many photos putting it back together as I did taking it apart, I was getting excited to drive her again :-)

This first picture shows what was left of the pilot bearing. Also if you have an autozone their tool rental program rocks. I rented the puller after trying the socket and grease method but because the bearing was broken I didn't have enough surface area to get the grease to push the bearing out, using the bearing puller 3 seconds later I had the bearing out and it all was free!!!!

These pictures show some of the damage in the transmission. Needless to say it was due for a replacement!

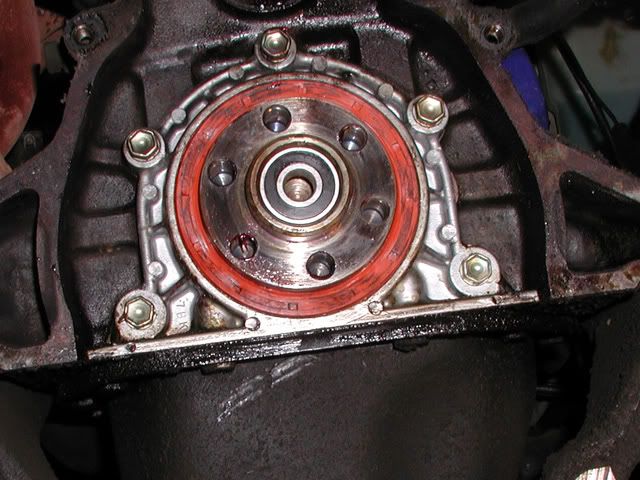

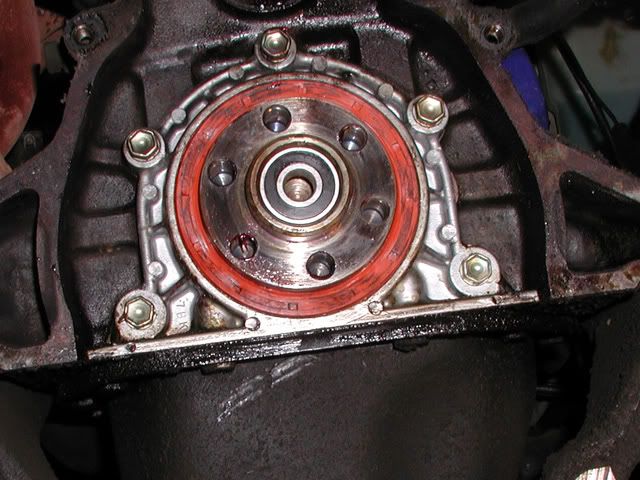

With everything out i changed the rear main seal, just pry out the old one and work the new on in, pretty simple and thanks for all the advice telling me I should do it. The old one looked...well old and needed to be replaced!

Seal out

New seal in

Re install the backing plate

Flywheel (Shinny new one from MC)

Reinstall the Clutch (New 1200lbs from MC)

Install the new throwout bearing (the picture is for reference because I didn't exactly remember how it went on so once I got it right I figured a pic was a good idea

And then the tranny. Here is the new tranny and t-case from Plumerbob. Its in great shape and I really should have cleaned it up a bit but I just wanted to get it in there and get back on the road!!!!!

This is about where I stopped talking pictures but the advice about using bolts as guides was a life saver. I went an extra step and actually bought two new bolts that were about an inch longer then the stock ones and then ground the heads off of those. It worked like a dream. Once I got the tranny on the jack where it would lift it as level as possible (took a couple of try's but not to bad) I was able to get it to mate to the two studs and then it was just a matter of sliding it home and in all honesty it was actually easier to get it on then it was taking it off. That thing was STUCK on there and it took a lot to get it off.

With the tranny bolted up it was just a matter of bolting everything back up as it came off. I did have one scare as I was bolting the starter back up I managed to drop the stud into the bell housing. I wanted to puke but I was lucky enough to get it out with a magnet or else I would have started crying like a little baby

Finally the last two and the best two pictures of the whole project that I took

Pulling the truck out of the garage was awsome!!!! First of all the new clutch feels great but that new transmission is what is really nice. Its funny what you put up with while it is running but as the pictures show it was clearly in need of being replaced but so what that it stuck going into 4th. This new tranny showed me the light, its shifts so nice and no noise! When I took it out for the first test drive I was really nervous because it was sooooo quiet I was sure something was wrong! But it drives so great, and I am really glad that I went with the heavier clutch, the stock one can't even compare!

I want to thank everyone here for the words of encouragement and the advice. Without it I probably wouldn't have done the rear main seal, I never would have thought about using the studs to get it to mate back up and I wouldn't have found a great transmission!

All in all it was actually a pretty simple project and if I didn't have to wait on parts and didn't have to work as much as I have these past few weeks I think it easily is a weekend project even for the most novice like I was. And if I can do it most anyone can. Thanks YotaTech!!!

This first picture shows what was left of the pilot bearing. Also if you have an autozone their tool rental program rocks. I rented the puller after trying the socket and grease method but because the bearing was broken I didn't have enough surface area to get the grease to push the bearing out, using the bearing puller 3 seconds later I had the bearing out and it all was free!!!!

These pictures show some of the damage in the transmission. Needless to say it was due for a replacement!

With everything out i changed the rear main seal, just pry out the old one and work the new on in, pretty simple and thanks for all the advice telling me I should do it. The old one looked...well old and needed to be replaced!

Seal out

New seal in

Re install the backing plate

Flywheel (Shinny new one from MC)

Reinstall the Clutch (New 1200lbs from MC)

Install the new throwout bearing (the picture is for reference because I didn't exactly remember how it went on so once I got it right I figured a pic was a good idea

And then the tranny. Here is the new tranny and t-case from Plumerbob. Its in great shape and I really should have cleaned it up a bit but I just wanted to get it in there and get back on the road!!!!!

This is about where I stopped talking pictures but the advice about using bolts as guides was a life saver. I went an extra step and actually bought two new bolts that were about an inch longer then the stock ones and then ground the heads off of those. It worked like a dream. Once I got the tranny on the jack where it would lift it as level as possible (took a couple of try's but not to bad) I was able to get it to mate to the two studs and then it was just a matter of sliding it home and in all honesty it was actually easier to get it on then it was taking it off. That thing was STUCK on there and it took a lot to get it off.

With the tranny bolted up it was just a matter of bolting everything back up as it came off. I did have one scare as I was bolting the starter back up I managed to drop the stud into the bell housing. I wanted to puke but I was lucky enough to get it out with a magnet or else I would have started crying like a little baby

Finally the last two and the best two pictures of the whole project that I took

Pulling the truck out of the garage was awsome!!!! First of all the new clutch feels great but that new transmission is what is really nice. Its funny what you put up with while it is running but as the pictures show it was clearly in need of being replaced but so what that it stuck going into 4th. This new tranny showed me the light, its shifts so nice and no noise! When I took it out for the first test drive I was really nervous because it was sooooo quiet I was sure something was wrong! But it drives so great, and I am really glad that I went with the heavier clutch, the stock one can't even compare!

I want to thank everyone here for the words of encouragement and the advice. Without it I probably wouldn't have done the rear main seal, I never would have thought about using the studs to get it to mate back up and I wouldn't have found a great transmission!

All in all it was actually a pretty simple project and if I didn't have to wait on parts and didn't have to work as much as I have these past few weeks I think it easily is a weekend project even for the most novice like I was. And if I can do it most anyone can. Thanks YotaTech!!!

#36

#38

Registered User

Well I am still kicking my self sort of for selling you that tranny but I knew you would be happy with it. Now I will spend your money I have been holding it waiting for your approval. I went wheeling yesterday and created about $350 in damage LOL funny how these things work.

Good job on the doing the job the right way I have and my buddys have half butt these jobs just to tear it apart again. because of a noisy TO bearing, leaky rear seal, broken pilot bearing.

Good job on the doing the job the right way I have and my buddys have half butt these jobs just to tear it apart again. because of a noisy TO bearing, leaky rear seal, broken pilot bearing.

#39

Registered User

Thread Starter

Well I am still kicking my self sort of for selling you that tranny but I knew you would be happy with it. Now I will spend your money I have been holding it waiting for your approval. I went wheeling yesterday and created about $350 in damage LOL funny how these things work.

Good job on the doing the job the right way I have and my buddys have half butt these jobs just to tear it apart again. because of a noisy TO bearing, leaky rear seal, broken pilot bearing.

Good job on the doing the job the right way I have and my buddys have half butt these jobs just to tear it apart again. because of a noisy TO bearing, leaky rear seal, broken pilot bearing.

I am still worried about the main seal that is the one thing that is hard to tell if it was in there right or not, but I have been looking under the truck and all seems fine so I think I'm good. The one thing I need to do is bleed the clutch because the pedal is soft but I didn't finish until 10:30 last night and I just wanted to drive it.

#40

Registered User

Thread Starter

Yeah its a VERY nice clutch and well worth the extra money and the extra week and a half it took to get here!