Welder/ing

#1

Registered User

Thread Starter

Welder/ing

So, i'm looking at picking up a 220V Stick welder

Most notably: http://www.lowes.com/lowes/lkn?actio...=cr&lpage=none

My 115V Mig won't do the spring perches that i want to do, or any other thick metals (above 1/4" penetration is meh).

How thick, exactly, will that 220V arc welder penetrate?

Most notably: http://www.lowes.com/lowes/lkn?actio...=cr&lpage=none

My 115V Mig won't do the spring perches that i want to do, or any other thick metals (above 1/4" penetration is meh).

How thick, exactly, will that 220V arc welder penetrate?

#2

Registered User

Join Date: Nov 2009

Location: Lonestar State

Posts: 102

Likes: 0

Received 0 Likes

on

0 Posts

So, i'm looking at picking up a 220V Stick welder

Most notably: http://www.lowes.com/lowes/lkn?actio...=cr&lpage=none

My 115V Mig won't do the spring perches that i want to do, or any other thick metals (above 1/4" penetration is meh).

How thick, exactly, will that 220V arc welder penetrate?

Most notably: http://www.lowes.com/lowes/lkn?actio...=cr&lpage=none

My 115V Mig won't do the spring perches that i want to do, or any other thick metals (above 1/4" penetration is meh).

How thick, exactly, will that 220V arc welder penetrate?

#4

Registered User

Join Date: Nov 2009

Location: Lonestar State

Posts: 102

Likes: 0

Received 0 Likes

on

0 Posts

it should i dont see why not, those are good little welders. just make sure you have the right kinda plug for it. not the trusty ole dryer plug, that could burn up the wiring in the wall.

eventually when i get the money and parts im going to sas my toyota and im gonna use a generator welder.

eventually when i get the money and parts im going to sas my toyota and im gonna use a generator welder.

#5

Registered User

Thread Starter

Cool.

Thank you very much.

I tried welding some perches onto a set of axles. I got it hot enough for decent penetration into the perch itself (it was about 1/4" steel), but after i tacked it i lifted the spring off it so i could roll the axle back out, and the darn thing just fell right off.

Looks like i'm hitting up a few stores tomorrow for this tombstone-lookin piece of machinery.

Thank you very much.

I tried welding some perches onto a set of axles. I got it hot enough for decent penetration into the perch itself (it was about 1/4" steel), but after i tacked it i lifted the spring off it so i could roll the axle back out, and the darn thing just fell right off.

Looks like i'm hitting up a few stores tomorrow for this tombstone-lookin piece of machinery.

#6

Registered User

Join Date: Nov 2009

Location: rochester wa

Posts: 123

Likes: 0

Received 0 Likes

on

0 Posts

i am a mech/welder for the army and we have a 220v lincoln yes it will weld up to half inch depending on the rod you use for the root pass you will want a 6010 rod has deep penetration it wont look good at all but then over that you can use either a 6013 or a 7018 either one will make a nice looking bead over the 6010

#7

Registered User

A friend of mine has one of those and he and I have both used it alot (before I picked up my old Forney)... It be plenty heavy enough for what you need.... With the proper prep you can weld thicker material (bevel the edges and clean the work surfaces etc.)

Good luck with your purchase and what you build with it!

Good luck with your purchase and what you build with it!

Trending Topics

#8

Registered User

Join Date: Nov 2009

Location: Lonestar State

Posts: 102

Likes: 0

Received 0 Likes

on

0 Posts

Cool.

Thank you very much.

I tried welding some perches onto a set of axles. I got it hot enough for decent penetration into the perch itself (it was about 1/4" steel), but after i tacked it i lifted the spring off it so i could roll the axle back out, and the darn thing just fell right off.

Looks like i'm hitting up a few stores tomorrow for this tombstone-lookin piece of machinery.

Thank you very much.

I tried welding some perches onto a set of axles. I got it hot enough for decent penetration into the perch itself (it was about 1/4" steel), but after i tacked it i lifted the spring off it so i could roll the axle back out, and the darn thing just fell right off.

Looks like i'm hitting up a few stores tomorrow for this tombstone-lookin piece of machinery.

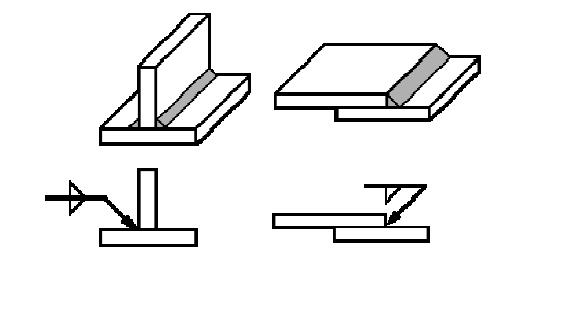

something like the pick below

#9

Registered User

Thread Starter

yeah i know, i did do that, lol.

edges were bevelled too.

it had great penetration on the perch, little to none on the axle.

Also: Thanks slime for the rod tips.

I'm not worried about looks, as long as the darn thing stays on there.

Hehe, bought the thing today.

Total came to around 294

edges were bevelled too.

it had great penetration on the perch, little to none on the axle.

Also: Thanks slime for the rod tips.

I'm not worried about looks, as long as the darn thing stays on there.

Hehe, bought the thing today.

Total came to around 294

Last edited by peow130; 12-26-2009 at 05:01 PM.

#12

Registered User

Join Date: Apr 2009

Location: Mocksville NC

Posts: 283

Likes: 0

Received 0 Likes

on

0 Posts

you can do it with the mig it just takes a little longer and a little more skill. you can triple pass it, wen i was in school for welding we had to do a multi pass t joint, first the root, then a stringer on the bottom, then one on the top to tie it all together. and there shouldn't be a butt crack in the center of your weld it should flow together even.

#13

Registered User

Thread Starter

.035 wire.

When i tacked it there was no stick at all, and i held it there a good 5-10 seconds at full power. I barely touched it and the thing just slid right off. Not to mention i also aimed it more at the axle (thicker metal), than the actual perch.

Also: Can't use E6010, that's DC only. The AC-225 is only AC, so i'm gonna use E-6011. I guess it has the same characteristics, just a ton of splatter.

When i tacked it there was no stick at all, and i held it there a good 5-10 seconds at full power. I barely touched it and the thing just slid right off. Not to mention i also aimed it more at the axle (thicker metal), than the actual perch.

Also: Can't use E6010, that's DC only. The AC-225 is only AC, so i'm gonna use E-6011. I guess it has the same characteristics, just a ton of splatter.

Last edited by peow130; 12-26-2009 at 10:45 PM.

#14

yes you are right 6010 and 6011 are basically the same rod. I think you have your settings off or something with your mig, because you should be able to lay down a good bead with just that little welder, i'd suggest cranking the voltage and doing a nice slow weave using a drag travel angle so you get more penetration for your root pass then follow it up with two more!

#15

Registered User

Join Date: Nov 2009

Location: rochester wa

Posts: 123

Likes: 0

Received 0 Likes

on

0 Posts

with your mig does it take argon gas or not because if not and you didnt get it to stick that means that you didnt use flux core wire and i should have said that 6010 was dc only the welder we have has both ac and dc sorry about that

#17

Registered User

Thread Starter

Flux core.

Look guys, it's not that big of a deal.

I can lay down a good bead, but that welder won't heat up the axle tube hot enough to actually get any good penetration.

If the tack weld that got held there for about 5 seconds wouldnt penetrate, i'm not going to try and lay down a bead with it.

Look guys, it's not that big of a deal.

I can lay down a good bead, but that welder won't heat up the axle tube hot enough to actually get any good penetration.

If the tack weld that got held there for about 5 seconds wouldnt penetrate, i'm not going to try and lay down a bead with it.

#20

I know this thread is a little old, but when I linked mine I tacked the brackets in, then heated the axle with an oxy torch. The axle isn't actually that thick, its is just high tensile. Give it a little heat first and it is much easier to get a good weld on.

I am using a lincon 180 MIG for all my work...I don't think I would touch chassis/axel work with anything less. 115V is really only good for panel work IMO.

I am using a lincon 180 MIG for all my work...I don't think I would touch chassis/axel work with anything less. 115V is really only good for panel work IMO.