Solid Axle Swap Has Begun!!!!!

#1

Registered User

Thread Starter

Join Date: Jan 2005

Location: High Point, NC/School at NC State

Posts: 398

Likes: 0

Received 1 Like

on

1 Post

Solid Axle Swap Has Begun!!!!!

So I got a phone call today at college from my dad saying there were some goodies in the driveway. Those goodies were none other than a solid axle swap kit from Marlin Crawler!!!!! Wow...delivered in less than a week too!!! Needless to say, I dropped my books and scooted on home. Didn't have any exams until Monday anyhow

The Goodies!!!!!

So tonight we started on the project.

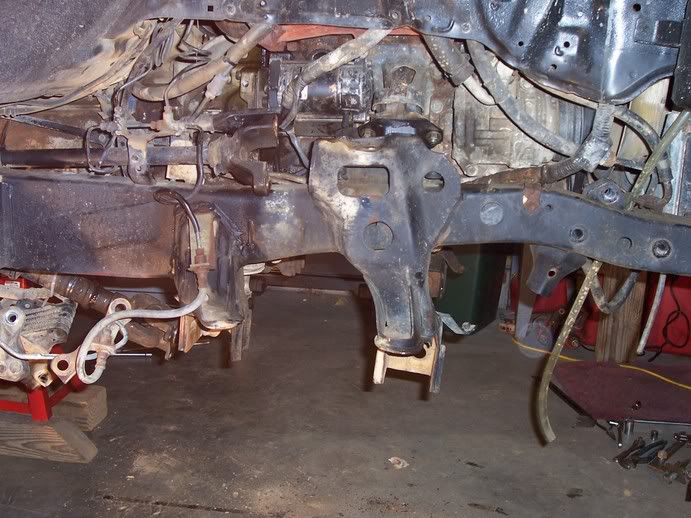

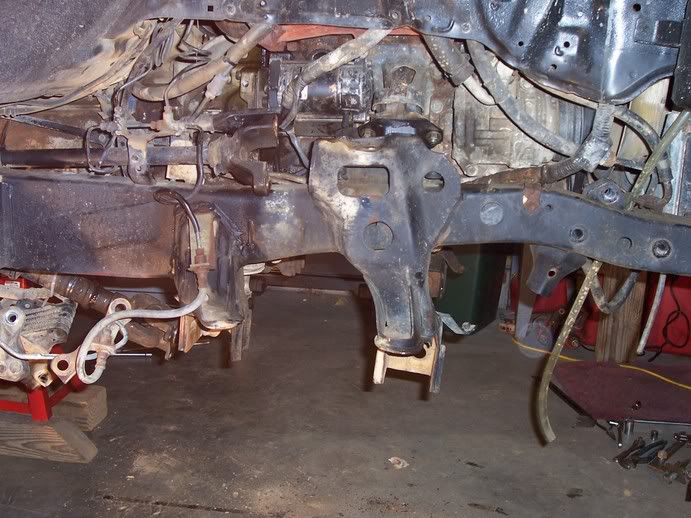

Last pic of it before the IFS is chopped off...

She looks ready, don't she??

Front spring hanger in place. (Clamps will be replaced with welds tomorrow )

)

Dad doing a little grinding. (Notice the super high-tech professional grinding goggles. AKA my racing goggles).

And we also got the holes cut in the frame for the rear spring hangers.

The tranny cooler has to be moved. Its in the way of the shackle.

And the heart of the project....

1985 Solid front axle, awaiting its new home.

So far everything is going great. Tomorrow we will get the welding done for the leaf springs, then she goes up on the jack stands and that IFS gets torched I'll keep you guys updated...

I'll keep you guys updated...

The Goodies!!!!!

So tonight we started on the project.

Last pic of it before the IFS is chopped off...

She looks ready, don't she??

Front spring hanger in place. (Clamps will be replaced with welds tomorrow

)

)

Dad doing a little grinding. (Notice the super high-tech professional grinding goggles. AKA my racing goggles).

And we also got the holes cut in the frame for the rear spring hangers.

The tranny cooler has to be moved. Its in the way of the shackle.

And the heart of the project....

1985 Solid front axle, awaiting its new home.

So far everything is going great. Tomorrow we will get the welding done for the leaf springs, then she goes up on the jack stands and that IFS gets torched

I'll keep you guys updated...

I'll keep you guys updated...

Last edited by 93ToyKid; 12-07-2005 at 08:31 PM.

#3

Registered User

Nice. Are you gonna use your IFS driveshaft for now or going to a square tube one?

Here's how to modify a IFS front shaft to use on a SFA:

http://www.4x4wire.com/toyota/tech/cvmod/

Here's how to modify a IFS front shaft to use on a SFA:

http://www.4x4wire.com/toyota/tech/cvmod/

#5

Registered User

Thread Starter

Join Date: Jan 2005

Location: High Point, NC/School at NC State

Posts: 398

Likes: 0

Received 1 Like

on

1 Post

Right now we have 4.88s in the diffs. Works perfect for 33s, but with the 37s we have on there now its pretty sluggish. We ordered some 5.29s to go in the axles. It has a Detroit Locker in the back, and the new axle gets a TruTrac in the front. We already have a guy who's going to be making us a driveshaft, but I'll have to check out that link for using the IFS one instead. Taking it to the shop as soon as I finish this to get it welded up (don't trust my welding on something that if it fails, you're in big trouble.) More pics tonight!

#7

Registered User

Join Date: Feb 2005

Location: Westminster, CO

Posts: 1,153

Likes: 0

Received 0 Likes

on

0 Posts

Man, that's nice. Did you rebuild the front axel before starting this swap? Wouldn't want something in there to fail after you have everything buttoned up. Keep up the pics.

Trending Topics

#9

Very interested in where/how you move the tranny cooler, mine is just wired tied out of the way right now. Any details on hose/fittings would be greatly appreciated.

Just a note, the IFS driveshaft (with clearancing) may not work without a low lift and/or a high pinion front.

That is a very nice looking truck before the swap, should look even better soon.

Just a note, the IFS driveshaft (with clearancing) may not work without a low lift and/or a high pinion front.

That is a very nice looking truck before the swap, should look even better soon.

Last edited by RobG; 12-08-2005 at 01:27 PM.

#11

Just a heads up.

You may want to check the Fit of the High Steer Rod ends in the steering and pitman arm. The rod ends I got with my Marlin kit had the wrong taper and wouldn't go into the arms far enough to allow the cotter pins to engage. They had to send me new rod ends. The ones that didn't work had the zerk fittings like in your picture.

You may want to check the Fit of the High Steer Rod ends in the steering and pitman arm. The rod ends I got with my Marlin kit had the wrong taper and wouldn't go into the arms far enough to allow the cotter pins to engage. They had to send me new rod ends. The ones that didn't work had the zerk fittings like in your picture.

#14

Registered User

Thread Starter

Join Date: Jan 2005

Location: High Point, NC/School at NC State

Posts: 398

Likes: 0

Received 1 Like

on

1 Post

Thanks for the heads up RobG. I need to check that. Well...half the IFS is off. What a pain in the a$$. Now its back out to do the rest of it. Once we determine where the tranny cooler is going to go, I'll let you guys know. BTW...the holes in the frame for the shackle tubes were cut using a $10 hole saw that goes on the end of a drill. It did amazingly well. Drilled all the way through. Now...back to the shop to get the rest of this crap off....pics tonight!

#16

Registered User

Join Date: Aug 2004

Location: SLO, CA

Posts: 1,028

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by 93ToyKid

BTW...the holes in the frame for the shackle tubes were cut using a $10 hole saw that goes on the end of a drill. It did amazingly well. Drilled all the way through.

#17

Registered User

Thread Starter

Join Date: Jan 2005

Location: High Point, NC/School at NC State

Posts: 398

Likes: 0

Received 1 Like

on

1 Post

The gusseting was a bit of a challenge. We cut it until the saw bottomed out, then took a pry bar and bent the gusset up out of the way and left it in the frame. Once it was bent up, the saw could make it the rest of the way through.

#18

Registered User

Thread Starter

Join Date: Jan 2005

Location: High Point, NC/School at NC State

Posts: 398

Likes: 0

Received 1 Like

on

1 Post

By the way, the only reason we didn't just come from the other side of the frame to finish the cut was due to clearance issues. Impossible to get a drill in there.

#19

Registered User

Thread Starter

Join Date: Jan 2005

Location: High Point, NC/School at NC State

Posts: 398

Likes: 0

Received 1 Like

on

1 Post

Time for an update. We got all the IFS crap (minus the bracketry) off. That was a pain.

The last of the IFS comes off...

Ready for a straight axle!!!

UPS man delivered some more parts today as well...

Brand new third member. We got the spring hangers all welded up today. Tomorrow (depending on if its icy or not), we'll either rent a torch and finish up the IFS removal, or we'll be rebuilding that front axle. Should be rolling by Saturday or next week sometime.

The last of the IFS comes off...

Ready for a straight axle!!!

UPS man delivered some more parts today as well...

Brand new third member. We got the spring hangers all welded up today. Tomorrow (depending on if its icy or not), we'll either rent a torch and finish up the IFS removal, or we'll be rebuilding that front axle. Should be rolling by Saturday or next week sometime.