What kind of welding class should I be taking?

#85

Registered User

Join Date: Dec 2008

Location: Southwestern ON

Posts: 173

Likes: 0

Received 0 Likes

on

0 Posts

#89

Registered User

In a jig, fixed at 45 degrees, purged, tacks at 12, 3 and 9 o'clock. Did about a 1/8th in root gap with a 1/16th root face.

I used 155 amps root and 160 amps fill. I used 1/16th rod for the root and 3/32nd for the they've fill and an 1/8th for the cover.

Theoriated tungsten.

Welded from 6 O'clock up to 12.

I used 155 amps root and 160 amps fill. I used 1/16th rod for the root and 3/32nd for the they've fill and an 1/8th for the cover.

Theoriated tungsten.

Welded from 6 O'clock up to 12.

#97

Registered User

Join Date: Dec 2011

Location: Warrenton, VA

Posts: 19

Likes: 0

Received 0 Likes

on

0 Posts

Dont bother with the classes. If you on this site u must have some smarts. By some books and a small miller or lincoln flux welder and some scrap steel. Ive been welding since the 70ies. Took a class once and it was a waste of time.

#98

Registered User

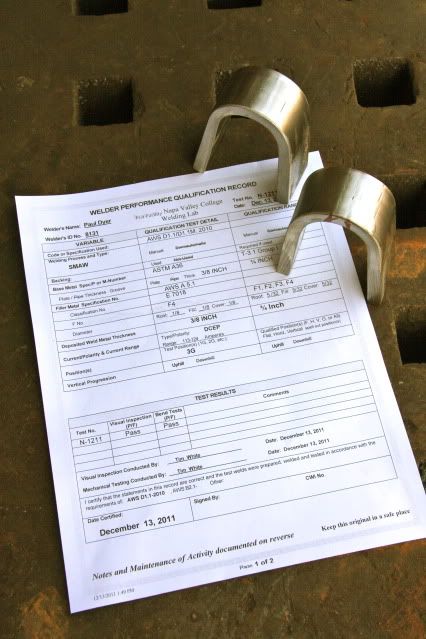

Take a class or two. Every little bit helps. A good part being safety and procedure. Practice, practice, practice. A year and a half ago I knew not much of welding. Now I have a cert and will begin working at Mare Island shipyard monday. Basic grunt work in a dry dock but its experience. My .02

Take a class or two. Every little bit helps. A good part being safety and procedure. Practice, practice, practice. A year and a half ago I knew not much of welding. Now I have a cert and will begin working at Mare Island shipyard monday. Basic grunt work in a dry dock but its experience. My .02

#99

Registered User

Classes definitely help, IF you make good use of them. Ask questions, bring your work up to the instructor and get feedback.

2 years ago I didn't have any idea the difference between the different types of welding. Now I am certified and get paid to weld trucks just like this one. I can promise you that would not have happened without going to school.

2 years ago I didn't have any idea the difference between the different types of welding. Now I am certified and get paid to weld trucks just like this one. I can promise you that would not have happened without going to school.

#100

Registered User

Join Date: Apr 2010

Location: Kingston, Ontario CANADA

Posts: 815

Likes: 0

Received 0 Likes

on

0 Posts

Right on guys. I finally got registered for my 'welding technology' class, starts next Monday night at a local college. We will be learning/doing Basic Oxy-acetylene Welding, Shielded Metal Arc Weld, Tungsten Inert Gas Weld, and Metal Inert Gas Weld. I can't wait!

think I'm going to work on aluminum now.

think I'm going to work on aluminum now.

and I agree Nice root.... caps a little rough

and I agree Nice root.... caps a little rough