Driveline dilema

#1

Registered User

Thread Starter

Join Date: Mar 2005

Location: Cleveland, Ohio

Posts: 308

Likes: 0

Received 0 Likes

on

0 Posts

Driveline dilema

I have a SAS '93 p/u with the V6. I have the sky 5" springs up front and Marlins 6" setup in the rear. I went to a driveshaft place today to get a front driveshaft made and it cannot be done. my angles are too severe. so I did some thinking and this is what I came up with:

My rise from center of flange to center of flange (diff and tcase respectively) is a little over 10" and the distance from cener of flange to center of flange is 28". So if you were to draw a little picture you would see that I am screwed right now. I am planning on getting a high pinion e-locker for the front, but after doing some measuring and some sketching. I still don't think the 3-4 inches vertical the high pinion will give me will be enough. The only other way that I can think of decreasing the angle is to do a dual t case setup which will give me another 6-7 inches of room to work with. I know that I could take out a leaf and probably get close enough but I dont want to do that. Does my reasoning with the high pinion and dbl tcase make sense as a good solution or is there something out ther that I am missing.

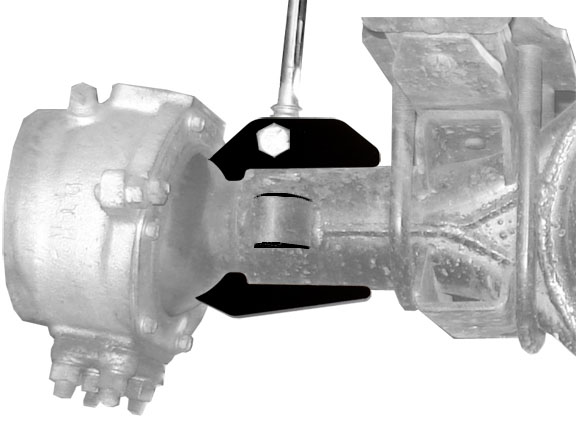

By the way here is my truck as it sits now on 35's and the second picture is of my front driveangle. Also why does the shackle set up for the front not look right to me? oh and while you are at it you can see how my truck has progressed over the two years i have owned it.

http://www.cardomain.com/ride/629249/7

Any help would be appreciated.

My rise from center of flange to center of flange (diff and tcase respectively) is a little over 10" and the distance from cener of flange to center of flange is 28". So if you were to draw a little picture you would see that I am screwed right now. I am planning on getting a high pinion e-locker for the front, but after doing some measuring and some sketching. I still don't think the 3-4 inches vertical the high pinion will give me will be enough. The only other way that I can think of decreasing the angle is to do a dual t case setup which will give me another 6-7 inches of room to work with. I know that I could take out a leaf and probably get close enough but I dont want to do that. Does my reasoning with the high pinion and dbl tcase make sense as a good solution or is there something out ther that I am missing.

By the way here is my truck as it sits now on 35's and the second picture is of my front driveangle. Also why does the shackle set up for the front not look right to me? oh and while you are at it you can see how my truck has progressed over the two years i have owned it.

http://www.cardomain.com/ride/629249/7

Any help would be appreciated.

#2

Registered User

This is a stab in the dark, but here goes: The only way I can think of to get around this problem is to use a double cardon joint on the tcase and tilt the differential to zero the driveline angle on its end. Of course, if you tilt the differential, the wheel caster is going to have to be reset. Yep, this is a real big job and considering how short the shaft is going to be, I'm not even sure it would work either.

#3

Contributing Member

I have never done a dual t-case so call me stupid if you want but it seems to me that by going with a dual t-case you will be shortening your driveshaft and in return increase the angle of the driveshaft. Am I correct on this assumption?

I have never done a dual t-case so call me stupid if you want but it seems to me that by going with a dual t-case you will be shortening your driveshaft and in return increase the angle of the driveshaft. Am I correct on this assumption?

#4

Contributing Member

Originally Posted by cootees

I have never done a dual t-case so call me stupid if you want but it seems to me that by going with a dual t-case you will be shortening your driveshaft and in return increase the angle of the driveshaft. Am I correct on this assumption?

I have never done a dual t-case so call me stupid if you want but it seems to me that by going with a dual t-case you will be shortening your driveshaft and in return increase the angle of the driveshaft. Am I correct on this assumption?

MASTERWACKER;

It looks like you have the shackles on backwards. Those shackles are made to clear the body mount when compressed. Reverse them and you will not have that problem.

my front drive shafthas a BAD angle to it also. I am running the 4" lift from Marlin with a high angle drive shaft. Call jessie at high angle and ask if he can help you out.

nice build BTW. Rig lookd good

#5

Contributing Member

Originally Posted by seaflea

It will lengthen the front drive shaft and make the angle better for him. At the same time (obviously) it will shorten the rear shaft.

#6

Contributing Member

Originally Posted by InternetRoadkill

double cardon joint on the tcase and tilt the differential to zero the driveline angle on its end. Of course, if you tilt the differential, the wheel caster is going to have to be reset.

I would think Sky has been around this block before - what did they say?

Trending Topics

#8

Contributing Member

Join Date: May 2002

Location: Wandering around Phoenix

Posts: 6,033

Likes: 0

Received 3 Likes

on

3 Posts

I think you'll get better information from the fab section...

What kind of driveshaft were they going to put on? Two U joints or a CV shaft? There are several people around who are running a CV shaft with HP diff, single cases and 4" springs. I'll be running the same, shortly.

What kind of driveshaft were they going to put on? Two U joints or a CV shaft? There are several people around who are running a CV shaft with HP diff, single cases and 4" springs. I'll be running the same, shortly.

Last edited by Robinhood150; 06-06-2006 at 09:36 PM.

#9

Contributing Member

Join Date: Jul 2004

Location: Ft. Collins, Co

Posts: 988

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by seaflea

Thats right, they did. Here is a write up from 4x4wire about doing it. I plan on doing this later this summer.

Be sure to add marlins new gussets. They look sweet.

Oh yea and some dude on pirate made his perches on the axle big enough to bolt the spring plate down to = u-bolt eliminator

*edit* found the thread*

That would probably be cool to do with this project too.

Last edited by getitdone; 06-08-2006 at 11:26 AM.

#10

Registered User

Be careful cutting and turning. You will have to reweld the balls and the perches and any time you put heat to the axle you risk warpage.

You ought to be able to get a shaft with two joints in at that angle. The problem I would assume was getting enough slip yoke.

Dual CV shafts are not a cure all. There is an angle range/orientation they were designed for and there is a orientation shafts with two joints are made for.

Both my pinions point at my t-case outputs. Both my shafts are CV shafts because of the angle I created.

You ought to be able to get a shaft with two joints in at that angle. The problem I would assume was getting enough slip yoke.

Dual CV shafts are not a cure all. There is an angle range/orientation they were designed for and there is a orientation shafts with two joints are made for.

Both my pinions point at my t-case outputs. Both my shafts are CV shafts because of the angle I created.

#11

Registered User

Seaflea is right, your shackles are installed backwards. As the spring compresses, the shackle will hit the body mount and stop uptravel. You might be getting some extra lift from this, and by only lifting the rear of the spring(by the shackle), caster of the front axle will be affected.

As far as solutions, unless you work for currie or dynatrac, DON'T cut the ends off and reweld them to restore caster. The chance of a mistake is too great. Instead, slowly cut off the spring perches, grind the housing clean and install new, boxed perches with an eye towards driveline angle. I wouldn't go less than 3deg positive, stock is close to 7-8deg. Make triple sure to center the housing under the truck, take your time and it'll be the better, easier way to go.

The marlin box will help the front driveline angle, as it will move the yoke rearward. If your into crawlin', you'll want the marlin anyway. This has been the best upgrade for my 82. Use a cv at the t-case side and u-joint at the axle, upgrading to larger(1310, 1330) joints at the same time.

Kinda along the same line, why are people lifting their trucks so high? They run into problems like this. My 82' runs 4" allpro springs and 36's. These springs move the axle 1.5" forward for firewall clearance. They helped, but I trimmed 5" out of the floor for addition clearence when I went to 36's from 33's. Keep the truck reasonably low, stuff some tire underneath and trim what's in the way.

As far as solutions, unless you work for currie or dynatrac, DON'T cut the ends off and reweld them to restore caster. The chance of a mistake is too great. Instead, slowly cut off the spring perches, grind the housing clean and install new, boxed perches with an eye towards driveline angle. I wouldn't go less than 3deg positive, stock is close to 7-8deg. Make triple sure to center the housing under the truck, take your time and it'll be the better, easier way to go.

The marlin box will help the front driveline angle, as it will move the yoke rearward. If your into crawlin', you'll want the marlin anyway. This has been the best upgrade for my 82. Use a cv at the t-case side and u-joint at the axle, upgrading to larger(1310, 1330) joints at the same time.

Kinda along the same line, why are people lifting their trucks so high? They run into problems like this. My 82' runs 4" allpro springs and 36's. These springs move the axle 1.5" forward for firewall clearance. They helped, but I trimmed 5" out of the floor for addition clearence when I went to 36's from 33's. Keep the truck reasonably low, stuff some tire underneath and trim what's in the way.

#12

Registered User

Cutting and turning perches alone will kill caster. Pinion angle is not the only thing to change here.

There is no reason to use Spicer joints. Toyota stuff is plenty strong. Failure is usually maintenance if a problem at all.

There is no reason to use Spicer joints. Toyota stuff is plenty strong. Failure is usually maintenance if a problem at all.

#13

Registered User

Done properly, redoing the spring perches is an effective way to restore front caster. By doing it this way, you avoid heating the housing and the possibility of mis-aligning the housing ends. You have to measure properly and use a quality angle finder, and, most importantly, take your time and triple check everything before welding.

Spicer 1310 ujoints are a slight upgrade from the early mini truck joints. They are also easier to find and cheaper to buy. Proper care and maintence is essiental for any part of the truck, but upgrades while your spending money in an area are always a great idea.

Spicer 1310 ujoints are a slight upgrade from the early mini truck joints. They are also easier to find and cheaper to buy. Proper care and maintence is essiental for any part of the truck, but upgrades while your spending money in an area are always a great idea.

#14

Contributing Member

Join Date: May 2002

Location: Wandering around Phoenix

Posts: 6,033

Likes: 0

Received 3 Likes

on

3 Posts

No it doesn't. Rotating the spring perches also rotates the knuckles along with the housing. The only way to restore caster is by rotating the knuckles independently of the housing.

Put another way, rotating the perches does the same thing as using angled shims.

Put another way, rotating the perches does the same thing as using angled shims.

#15

Registered User

Join Date: Aug 2004

Location: SLO, CA

Posts: 1,028

Likes: 0

Received 0 Likes

on

0 Posts

i'm running a square tube d-shaft with two u-joints. my 4Runner is single case with 5" springs. i used High Angle's yota V6 flange on the t-case end. it has the right bolt pattern for V6 cases and has the clearance needed at those steep angles.

#16

Registered User

Caster and pinion are set on a stock housing at about 14 degrees of difference. If you choose to rotate the perches on the housing to optimize pinion angle, you will likely have beyond crappy caster. Just rotating the perches is not the way to skin this cat.

This thread points me to why I have Diamonds. You can get exactly what you want without putting all this heat, time, money into a stock housing that still needs spacers and won't steer.

This thread points me to why I have Diamonds. You can get exactly what you want without putting all this heat, time, money into a stock housing that still needs spacers and won't steer.

#18

Registered User

What I was talking about was removing the stock perches, and installing new, boxed perches at no less than 3deg positive caster. The housing ends remain unchanged. I agree that shims aren't a good thing, sometime acting like a lift block and trying to wiggle their way out. How is the diamond housing set up? Do they make it for your specific app, or for the majority of mods out there? It looks like a great upgrade.

#19

Contributing Member

Join Date: Jul 2004

Location: Ft. Collins, Co

Posts: 988

Likes: 0

Received 0 Likes

on

0 Posts

The only way to not change the degree of the housing ends while rotating the pinion angle is to cut the axle housing. No amount of mods to the perches will do this no matter what it is. The ends will always rotate with the pinion... cause they are directly connected via the axle housing.

#20

Contributing Member

Join Date: May 2002

Location: Wandering around Phoenix

Posts: 6,033

Likes: 0

Received 3 Likes

on

3 Posts

Mike, are we all talking about the same thing here?

We're assuming one is running a CV driveshaft and the pinion must be pointed at the tcase output. The caster will be way off. The only way to adjust the caster WITHOUT changing the angle of the pinion is by cutting and turning the knuckles.

Cutting the perches off and rotating the housing 3 degs will change the pinion angle AND ALSO the caster angle 3 deg.

We're assuming one is running a CV driveshaft and the pinion must be pointed at the tcase output. The caster will be way off. The only way to adjust the caster WITHOUT changing the angle of the pinion is by cutting and turning the knuckles.

Cutting the perches off and rotating the housing 3 degs will change the pinion angle AND ALSO the caster angle 3 deg.