95 T100 DX No-Start (Fuel?) Puzzler

#1

Registered User

Thread Starter

Hi all. I have a 1995 T100 DX 5sp 4WD extended cab with the 5VZ-FE with 345,000 miles on it. Truck sees infrequent service as a utility & tow vehicle (1500# boat), and runs pretty well though I've been chasing a misfire lately. New plugs appeared to resolve the misfire, and it gave good service for the next couple outings.

Just finished replacing the driver's side valve cover & plenum gasket to resolve an oil leak at the valve cover. Got her all buttoned up, and the truck started right up, but stalled about a minute into the test drive and wouldn't restart. Cranks fine, not firing up.

While it was running, it did the typical slightly higher initial idle, then settled in at ~1100 once it warmed up. There was an intermittent trace of the earlier misfire at idle, but no codes thrown and the misfire (if that's what it was) went away at higher throttle. There was no sign of significant vacuum leaks, and I'm comfortably sure that I tightened all bolts on the plenum and throttle body to FSM torque and reconnected intake, wiring connectors, vacuum lines & fuel return lines correctly. I had even replaced a couple of cracked vacuum lines during the repair.

We flat towed it back home (poor truck is used to being the rescuer, not the rescuee!) and I proceeded with diagnosis. Rechecked all wiring and vacuum connections. Checked the following:

When I disconnected the rear harness connector to check voltage on the blue line to the fuel pump, I saw the following:

The harness and connector appear original and unmolested - no wires spliced in, no sign of tampering over the truck's 25-year history. I haven't laid eyes on the fuel pump yet, because I guess it's on top of the tank and I'm not looking to drop the tank or remove the bed if I don't have to.

I'm awfully puzzled, but I have a couple theories and wanted to run them past you guys.

Does anyone have any insights or suggestions on this before I start throwing parts at guesses? I'm really just looking for a sanity check - am I correct that overpressure will flood the motor? Can a faulty regulator, or no vacuum to the regulator, create overpressure? Is there some other part I should be suspicious of, given these facts?

Thanks for taking the time to read all this, and for any help you can provide.

Just finished replacing the driver's side valve cover & plenum gasket to resolve an oil leak at the valve cover. Got her all buttoned up, and the truck started right up, but stalled about a minute into the test drive and wouldn't restart. Cranks fine, not firing up.

While it was running, it did the typical slightly higher initial idle, then settled in at ~1100 once it warmed up. There was an intermittent trace of the earlier misfire at idle, but no codes thrown and the misfire (if that's what it was) went away at higher throttle. There was no sign of significant vacuum leaks, and I'm comfortably sure that I tightened all bolts on the plenum and throttle body to FSM torque and reconnected intake, wiring connectors, vacuum lines & fuel return lines correctly. I had even replaced a couple of cracked vacuum lines during the repair.

We flat towed it back home (poor truck is used to being the rescuer, not the rescuee!) and I proceeded with diagnosis. Rechecked all wiring and vacuum connections. Checked the following:

- Will it start with starter fluid? NO

- Will it start with air mass meter disconnected? NO

- Pulled plug #4, is there spark? YES

- #4 electrode was wet with fuel, suggests flooding.

- Pulled fuel return line with truck off, fuel present? YES (Didn't test fuel flow with the truck cranking because I didn't have enough hands.)

- Will it start with 15A EFI fuse in engine bay fuse box removed? NO

When I disconnected the rear harness connector to check voltage on the blue line to the fuel pump, I saw the following:

- Ground (white w/black trace): good continuity

- Key OFF: 0V, as expected

- Key ON: 0V, as expected

- Key to start: cranks, ~13V reading, truck STARTED and ran, wtf?

- Key ON, engine running: ~13V still present.

- While running, OBD2 reports normal behavior for O2 sensor, MAF, throttle position, RPMs, coolant temp, load, intake air temp, etc., etc. No logged or pending codes present. Short-term fuel trim reads, where it earlier was not reading. (I use the Torque Light app for Android, and a Bluetooth OBD2 tool, in case that helps.)

The harness and connector appear original and unmolested - no wires spliced in, no sign of tampering over the truck's 25-year history. I haven't laid eyes on the fuel pump yet, because I guess it's on top of the tank and I'm not looking to drop the tank or remove the bed if I don't have to.

I'm awfully puzzled, but I have a couple theories and wanted to run them past you guys.

- Theory A) Maybe PO bypassed 12V supply to fuel pump, so it's still powered when the harness is disconnected? Some electrical load on the rear harness is bogging the truck down? But this truck pulls a 1500# boat up steep hills without complaining...

- Theory B) Bad fuel pressure regulator (or damaged vacuum line to it?) is creating overpressure at the fuel rail, which causes flooding. Disconnecting fuel pump relieves over-pressure; re-connecting it gradually builds pressure back up until truck floods and stalls. If this is correct, then the truck should eventually stall out with the pump disconnected, because eventually the existing fuel supply is exhausted and nothing new is being pumped in. (I haven't checked this, but will tonight.)

Does anyone have any insights or suggestions on this before I start throwing parts at guesses? I'm really just looking for a sanity check - am I correct that overpressure will flood the motor? Can a faulty regulator, or no vacuum to the regulator, create overpressure? Is there some other part I should be suspicious of, given these facts?

Thanks for taking the time to read all this, and for any help you can provide.

#2

Registered User

iTrader: (1)

On theory A, my dad pulls a 1200 pound trailer (sometimes overloaded) with his 95 T100, the load doesn't really effect how it runs much, it just gets up to speed a lot slower xD. Anyway, I'm thinking along the same lines, since no fuel pump = no fuel pressure, and with it disconnected it's running, that wouldn't make sense unless the pump got power some other way. If you went old school and slapped a carb on the engine, then theory B would make some sense, but giving it throttle while cracking would "clear flood" it. In an EFI system, you have to FLOOR it to enter clear flood while cranking (must be 100% and it won't inject fuel, anything less and it could be flooding the engine).

I don't think overpressure would really cause too much of an issue on an EFI system, it would inject more fuel and the computer would lean it out (shorter injection pulse). Having the pressure poorly regulated would make the engine not have consistent rpms and the computer would be always trying to correct it. If you have a fuel pressure gauge, you could try to see about hooking it up and seeing what psi you're actually at, if it's holding pressure with the fuel pump disconnected, then you know there's some wiring hacking going on.

A common area of hacked up wiring is at the tail lights, but the fuel pump wires don't make it that far back.

Anyway, since you fiddled with the fuel system and the problem changed, I'd focus on the wiring and figure out what's going on exactly. If it wasn't for that oddity, I'd say check ignition timing, spark means nothing if it's not timed correctly, timing belt could have jumped timing for example. Don't think it would have any spark if the belt broke though.

Did you check any other spark plugs besides #4? Are the plugs old? How about the wires? The boots under the coils? The actual coils themselves? My dad had a slight misfire at around 300k miles, it finally got bad enough it was causing problems and annoyed him enough to check into it. One plug wire was burnt in half, plugs were very old and worn excessively, 2 of the boots under the coils were burnt and dry rotted. Finally, if I remember right he had a code for a bad ignition coil. The price of the boots vs boots + ignition coil was so little, he just bought all new coils (aftermarket on rock auto). Right after replacing all of that, it misfired even worse! After a test drive it ran better, within a day or two driving it, it runs great. I suspect he didn't reset the ECU so it was using the settings when there were major problems.

Anyway, it's generally best to test parts, or physically identify bad parts before replacing them. Sometimes new parts can be bad too, so knowing the old was bad is a solid step in diags, and testing the new parts isn't a bad idea too.

Injectors can go bad too, they can get stuck open for example, but it's uncommon for all to fail at once, maybe #4 cylinder failed open and the rest are fine. My 98 with 220k miles had a bad injector, but it failed with high resistance, so it wouldn't fire, but it was also heat related for when it wouldn't work (just a misfire, 2 cyls down).

Hopefully my ramblings are useful. If you need any wire diagrams, pinouts, etc, let me know. I have the EWD for the T100's which also gives some basic tech specs (ohm readings and such).

I don't think overpressure would really cause too much of an issue on an EFI system, it would inject more fuel and the computer would lean it out (shorter injection pulse). Having the pressure poorly regulated would make the engine not have consistent rpms and the computer would be always trying to correct it. If you have a fuel pressure gauge, you could try to see about hooking it up and seeing what psi you're actually at, if it's holding pressure with the fuel pump disconnected, then you know there's some wiring hacking going on.

A common area of hacked up wiring is at the tail lights, but the fuel pump wires don't make it that far back.

Anyway, since you fiddled with the fuel system and the problem changed, I'd focus on the wiring and figure out what's going on exactly. If it wasn't for that oddity, I'd say check ignition timing, spark means nothing if it's not timed correctly, timing belt could have jumped timing for example. Don't think it would have any spark if the belt broke though.

Did you check any other spark plugs besides #4? Are the plugs old? How about the wires? The boots under the coils? The actual coils themselves? My dad had a slight misfire at around 300k miles, it finally got bad enough it was causing problems and annoyed him enough to check into it. One plug wire was burnt in half, plugs were very old and worn excessively, 2 of the boots under the coils were burnt and dry rotted. Finally, if I remember right he had a code for a bad ignition coil. The price of the boots vs boots + ignition coil was so little, he just bought all new coils (aftermarket on rock auto). Right after replacing all of that, it misfired even worse! After a test drive it ran better, within a day or two driving it, it runs great. I suspect he didn't reset the ECU so it was using the settings when there were major problems.

Anyway, it's generally best to test parts, or physically identify bad parts before replacing them. Sometimes new parts can be bad too, so knowing the old was bad is a solid step in diags, and testing the new parts isn't a bad idea too.

Injectors can go bad too, they can get stuck open for example, but it's uncommon for all to fail at once, maybe #4 cylinder failed open and the rest are fine. My 98 with 220k miles had a bad injector, but it failed with high resistance, so it wouldn't fire, but it was also heat related for when it wouldn't work (just a misfire, 2 cyls down).

Hopefully my ramblings are useful. If you need any wire diagrams, pinouts, etc, let me know. I have the EWD for the T100's which also gives some basic tech specs (ohm readings and such).

The following users liked this post:

corich (08-24-2021)

#3

Registered User

Thread Starter

Thanks for the reply, atcfixer. I haven't yet pulled any plugs besides #4 (the "easy" plug) but they are brand new, less than 200 miles since I put them in.

We managed to get it to start with the rear harness connected last night. She started up immediately, idled high for a bit, and eventually settled in at 1100RPM. I let her run for a while to see if it would stall out, and it did gradually bog down and struggle, but in the end it just made an unburned fuel stink and struggled on at ~650 RPM with no sign of giving up. I shut her down and pulled #4 again, and it was absolutely black with carbon fouling. So she is running really rich, which effectively rules out the fuel pump and fuel filter.

That's all I had time for last night after work, but I'm planning to see tonight if she eventually stalls out with the rear harness disconnected, to verify whether I've got original wiring to the pump. I'll try to also pull some other plugs and see if they are fouled similarly to #4. When I replaced the plugs recently, the old plugs were fairly uniform, not too badly fouled, so I don't suspect any problems with coil packs or plug wires, but it's worth checking.

Since you offered, I'd love any info you have on component testing for the fuel pressure regulator and the vacuum switching unit that controls the regulator. They're my primary suspects. I think I have a fuel pressure gauge somewhere, but I need to find it and figure out how to hook it up.

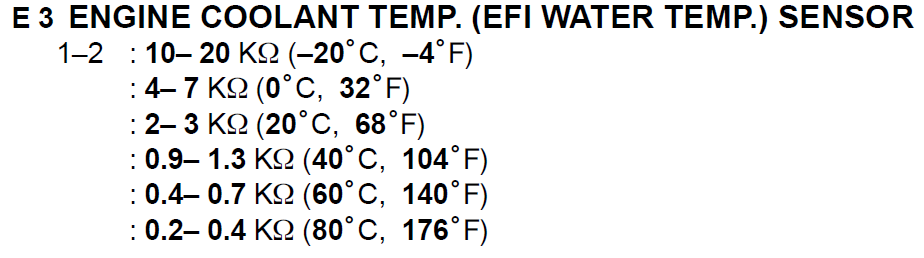

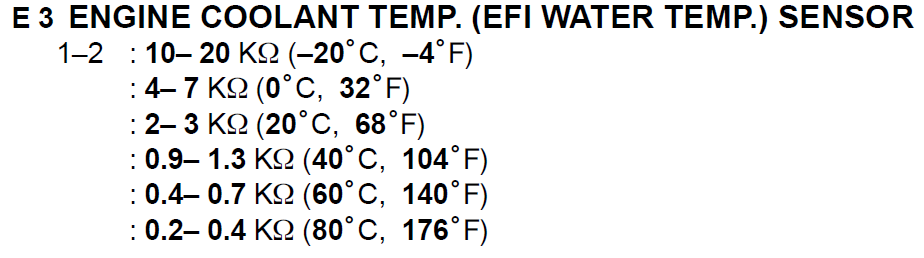

Also, I noticed last night that it was running in an open loop condition due to low temperature, according to the OBD2 reader. That would certainly make it run rich, though IME open loop is more like "runs fine, fails emissions test" than "hard to start, struggles to stay on." Not anything like what I'm seeing now. I've replaced the EFI coolant temp sensor once before due to that problem, and have another on hand, so I'll probably pop that in before all of this is over.

We managed to get it to start with the rear harness connected last night. She started up immediately, idled high for a bit, and eventually settled in at 1100RPM. I let her run for a while to see if it would stall out, and it did gradually bog down and struggle, but in the end it just made an unburned fuel stink and struggled on at ~650 RPM with no sign of giving up. I shut her down and pulled #4 again, and it was absolutely black with carbon fouling. So she is running really rich, which effectively rules out the fuel pump and fuel filter.

That's all I had time for last night after work, but I'm planning to see tonight if she eventually stalls out with the rear harness disconnected, to verify whether I've got original wiring to the pump. I'll try to also pull some other plugs and see if they are fouled similarly to #4. When I replaced the plugs recently, the old plugs were fairly uniform, not too badly fouled, so I don't suspect any problems with coil packs or plug wires, but it's worth checking.

Since you offered, I'd love any info you have on component testing for the fuel pressure regulator and the vacuum switching unit that controls the regulator. They're my primary suspects. I think I have a fuel pressure gauge somewhere, but I need to find it and figure out how to hook it up.

Also, I noticed last night that it was running in an open loop condition due to low temperature, according to the OBD2 reader. That would certainly make it run rich, though IME open loop is more like "runs fine, fails emissions test" than "hard to start, struggles to stay on." Not anything like what I'm seeing now. I've replaced the EFI coolant temp sensor once before due to that problem, and have another on hand, so I'll probably pop that in before all of this is over.

#4

Registered User

iTrader: (1)

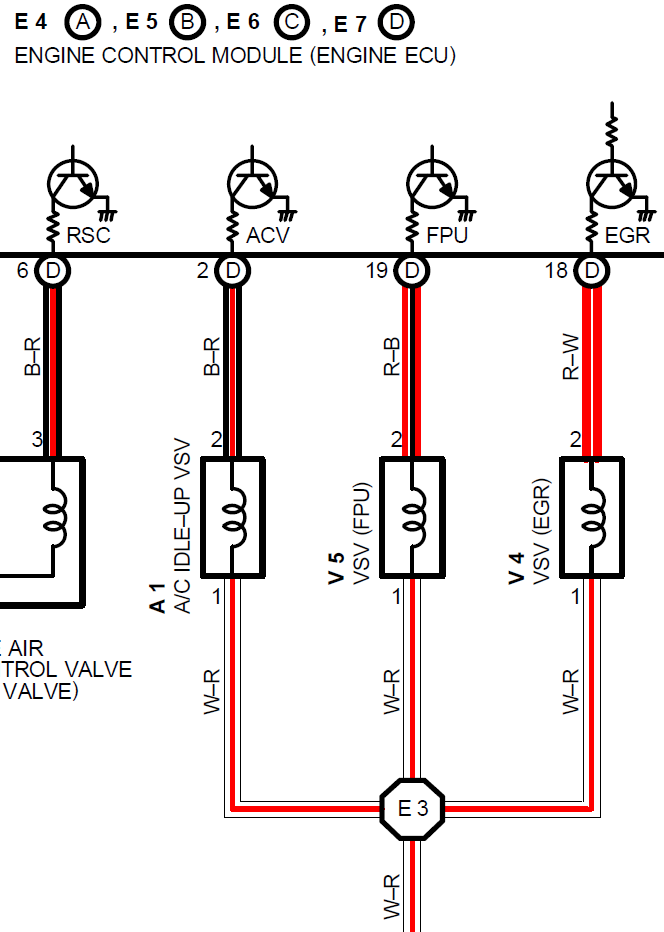

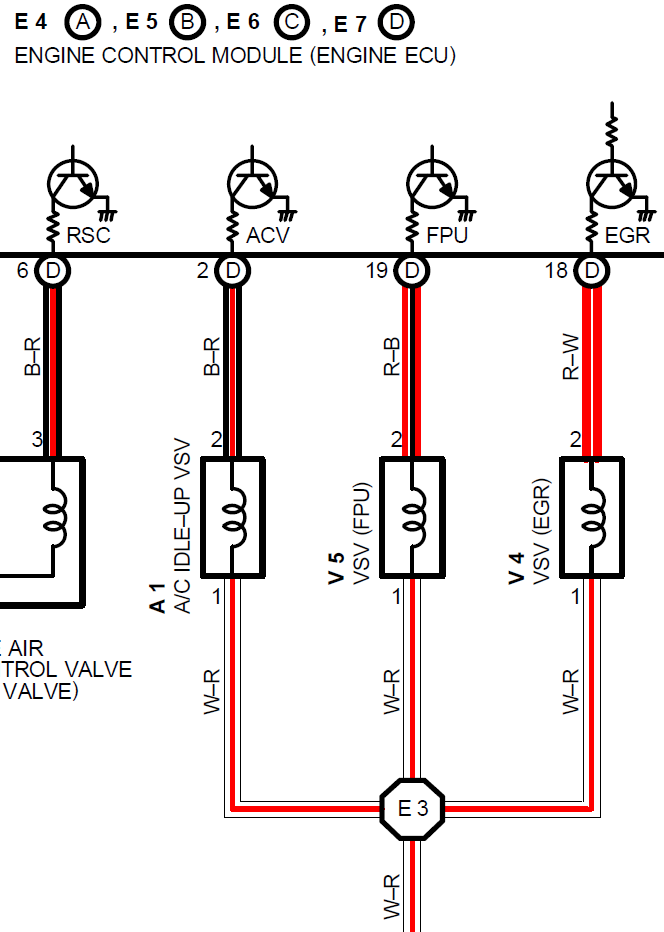

FPU VSV, white/red is power source (from EFI main relay, through 15a efi fuse). Oddly I don't have an ohms spec for the VSV. Can test it with a vacuum pump and a gauge, or do a "blow test". If you can blow through it with no power, with power you shouldn't be able to, or the opposite depending how it's designed. It's a vacuum switch, so electronically controls the vacuum on/off.

Before replacing the coolant sensor, test it! Maybe your old one wasn't bad, but it just happened to stop having issues when you messed with that area of the wiring.

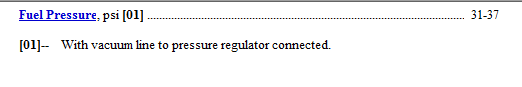

I recently got access to repair data, so let me see if I can dig up anything on the fuel pressure regulator. Looks like I just get a fuel pressure spec with vacuum applied.

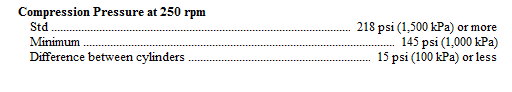

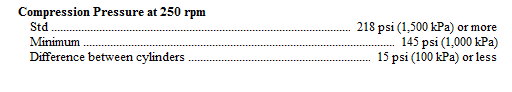

Since your engine is up there in miles, here's the cylinder compression specs. should be 145-218 psi.

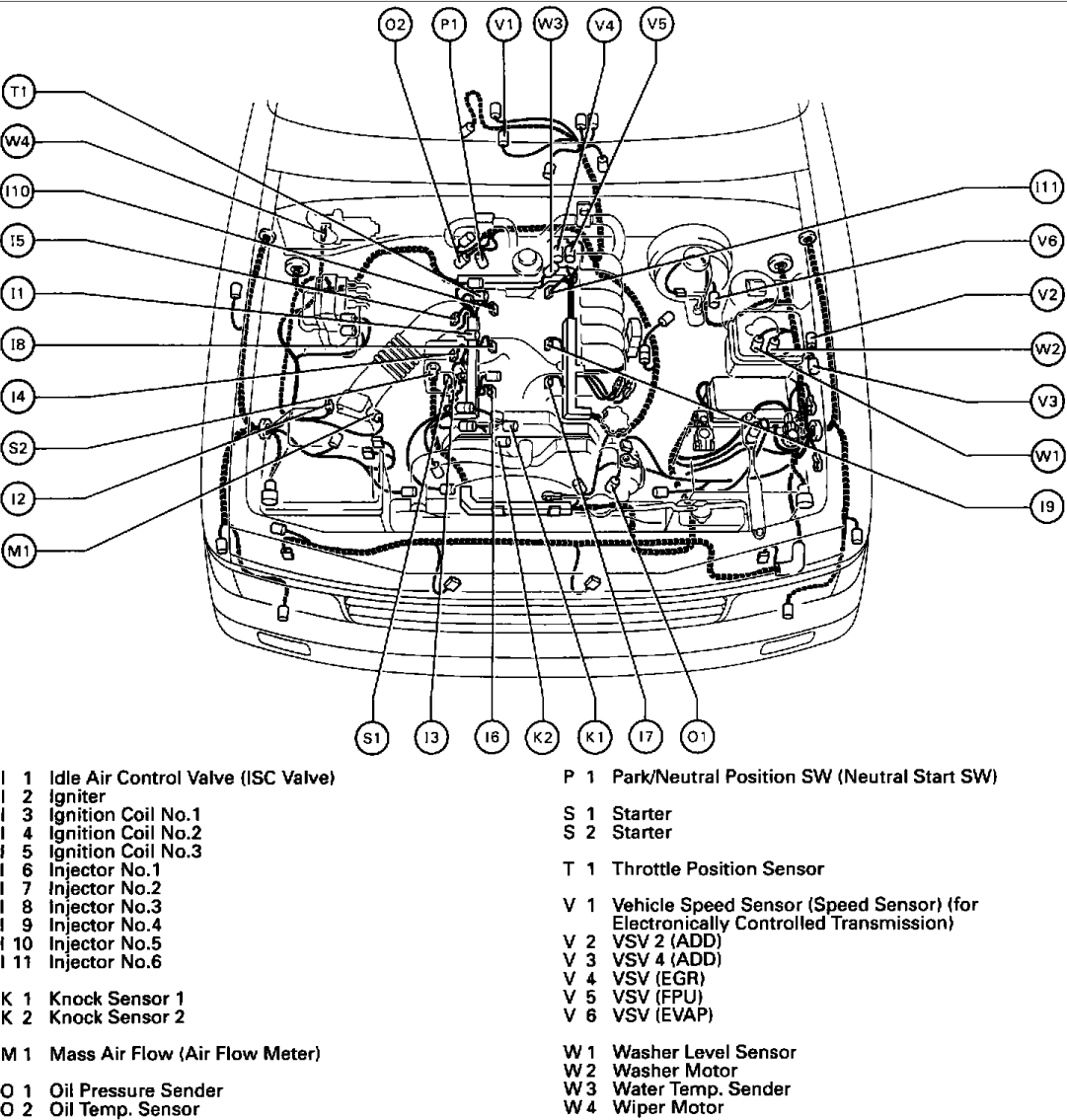

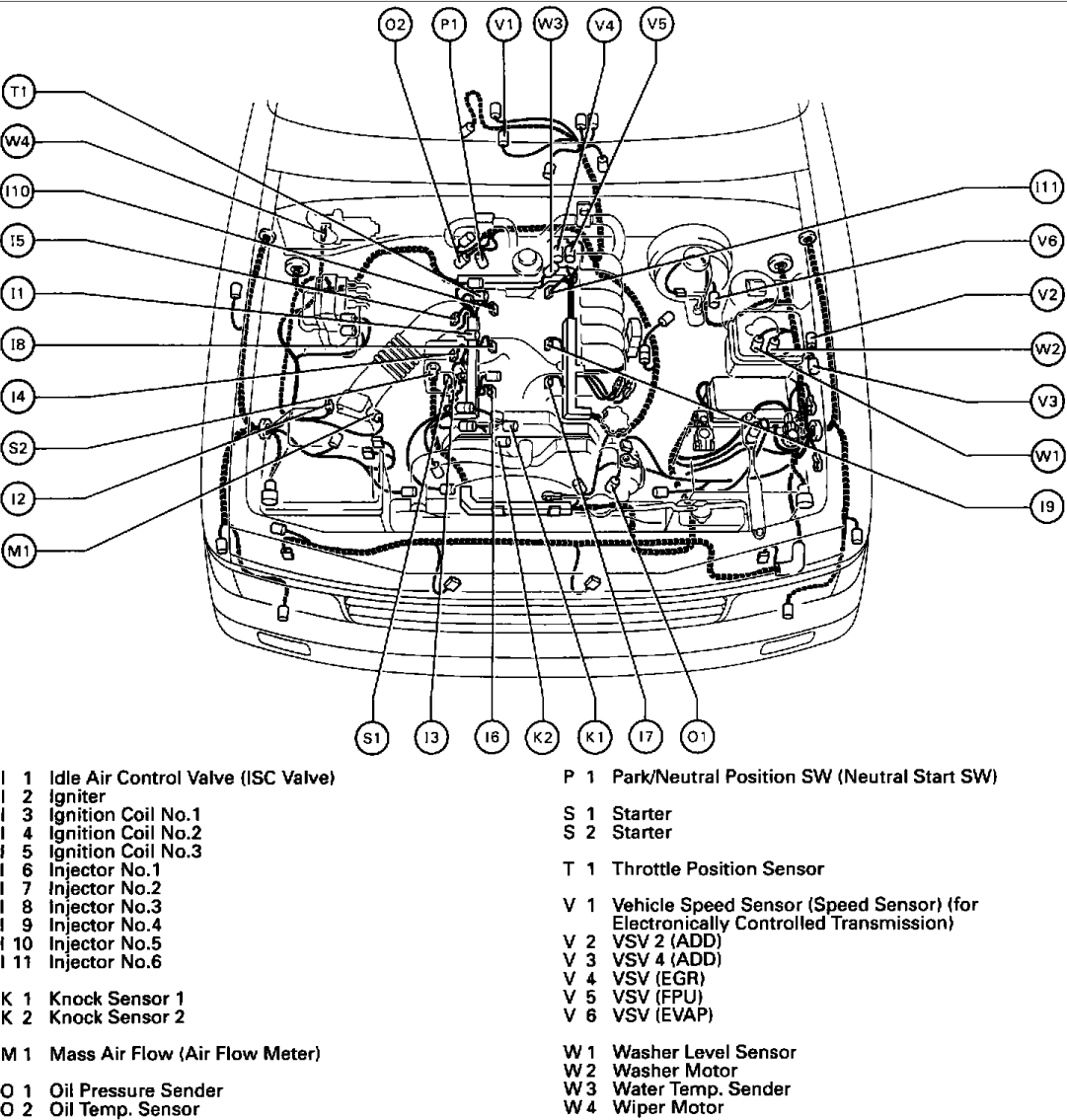

V5 is the VSV for FPU

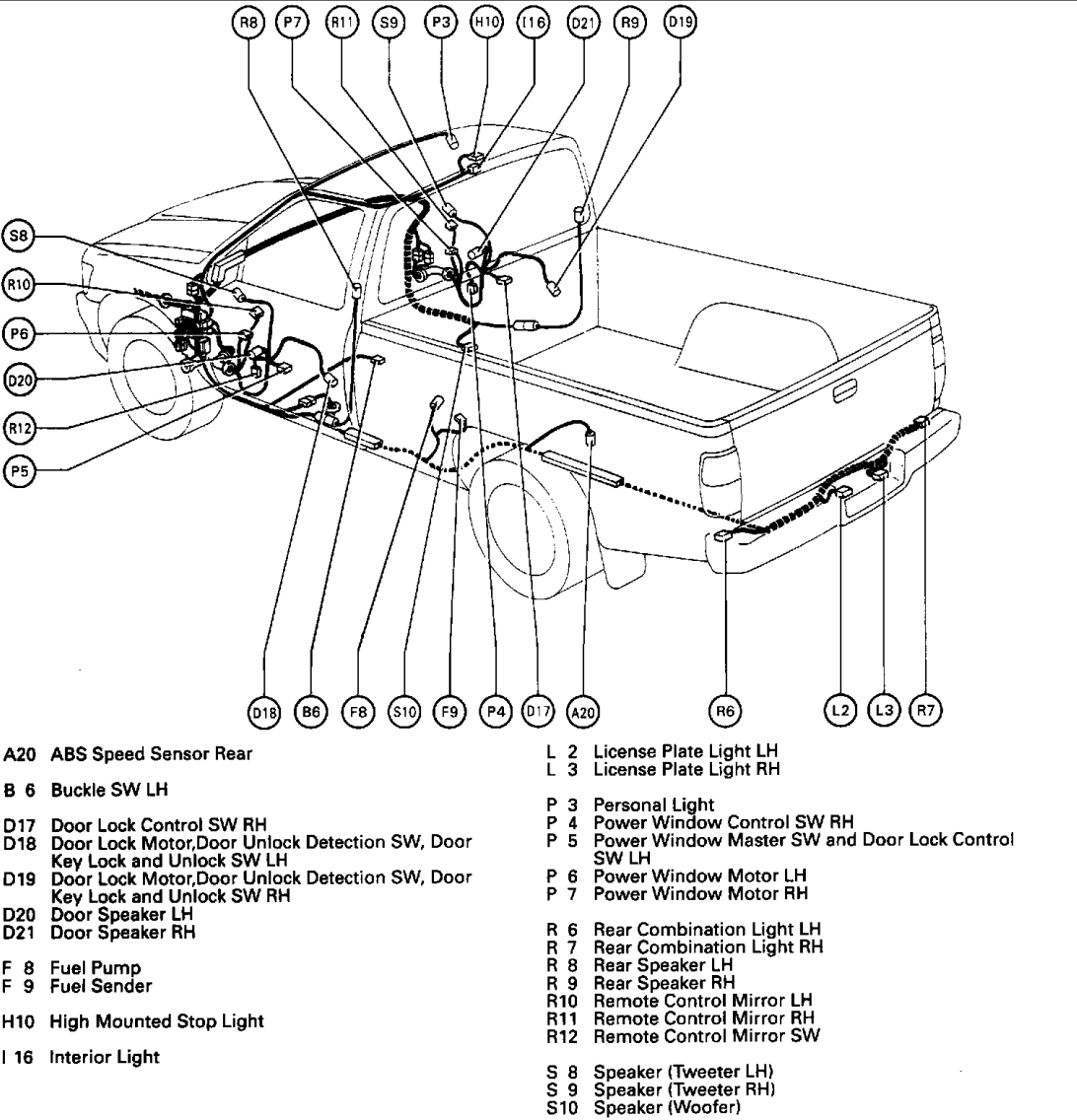

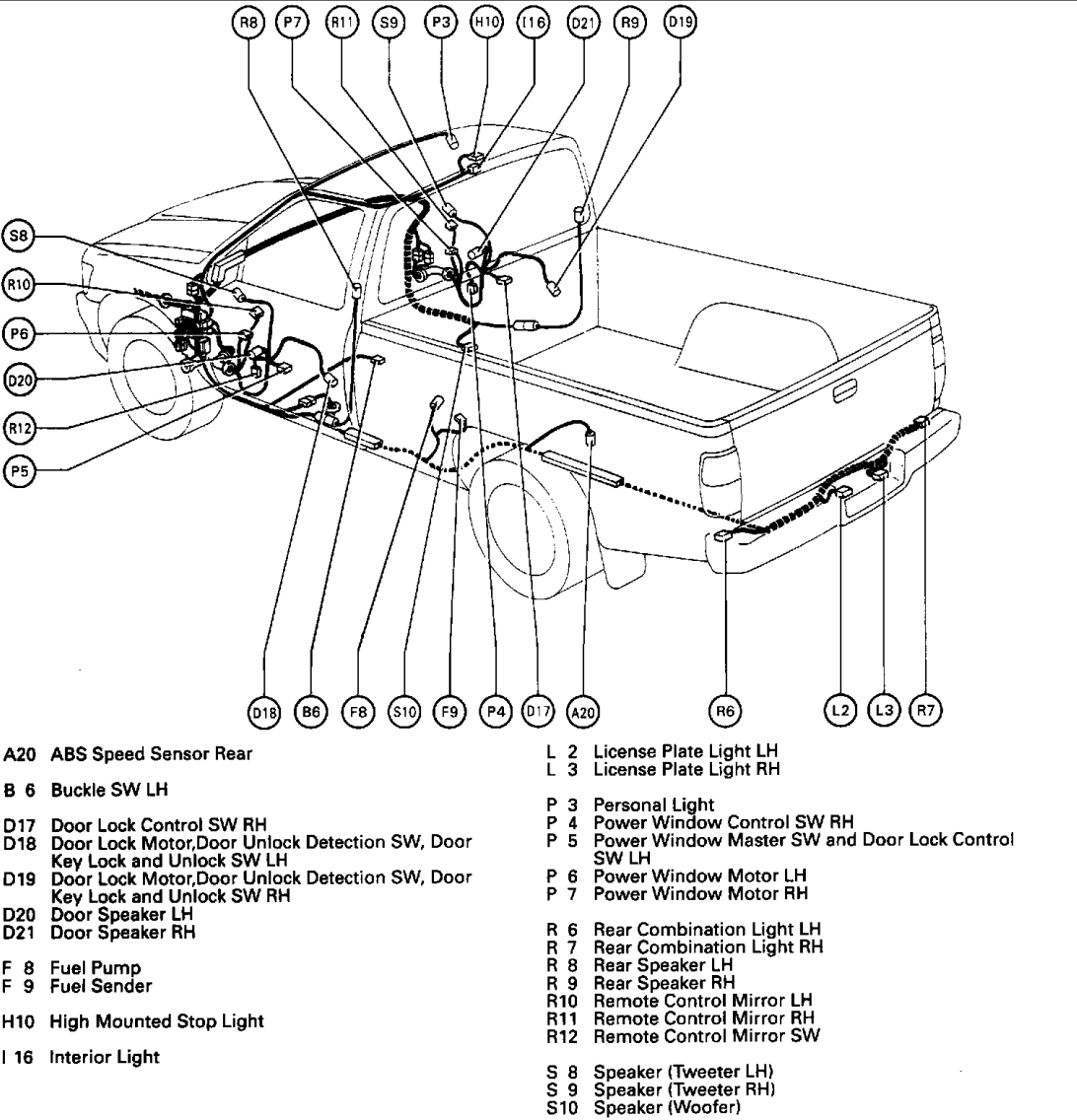

Here's an idea on the wire route for the fuel pump. I kind of think you could see (maybe feel) the connection points at the tank on my 98.

Anyway, this system is new to me, so finding stuff is like re-learning to walk, it makes no sense since everything is broken apart, but the orig books it's based on is ordered in a different style.

Before replacing the coolant sensor, test it! Maybe your old one wasn't bad, but it just happened to stop having issues when you messed with that area of the wiring.

I recently got access to repair data, so let me see if I can dig up anything on the fuel pressure regulator. Looks like I just get a fuel pressure spec with vacuum applied.

Since your engine is up there in miles, here's the cylinder compression specs. should be 145-218 psi.

V5 is the VSV for FPU

Here's an idea on the wire route for the fuel pump. I kind of think you could see (maybe feel) the connection points at the tank on my 98.

Anyway, this system is new to me, so finding stuff is like re-learning to walk, it makes no sense since everything is broken apart, but the orig books it's based on is ordered in a different style.

#5

Registered User

Thread Starter

Wow, thanks, atcfixer. Yes, V5 is the VSV in question.

The fuel pressure and EFI temp sensor figures are super helpful, thanks. Compression... I'm kinda scared to check, to be honest I'm sure the motor would benefit from a rebuild, though I'm not really willing to invest that heavily in it.

I'm sure the motor would benefit from a rebuild, though I'm not really willing to invest that heavily in it.

I fired the truck up again yesterday evening. It starts eagerly when it's been sitting a while, and still gradually bogs down as it runs. Unplugging the rear harness depowers the fuel pump as it should and shuts it down very quickly - the previous behavior where it didn't shut down immediately must have been due to a very flooded condition. I pulled plugs #2, 4, and 5 while I was working on it, and they all were uniformly very sooty and fouled, which confirms the "running rich" diagnosis. Seeing no significant variation, I stopped pulling plugs.

No other new info at this time - I don't generally have a lot of time to work on it during the week, which is ok as it's not my primary transportation.

The fuel pressure and EFI temp sensor figures are super helpful, thanks. Compression... I'm kinda scared to check, to be honest

I'm sure the motor would benefit from a rebuild, though I'm not really willing to invest that heavily in it.

I'm sure the motor would benefit from a rebuild, though I'm not really willing to invest that heavily in it.I fired the truck up again yesterday evening. It starts eagerly when it's been sitting a while, and still gradually bogs down as it runs. Unplugging the rear harness depowers the fuel pump as it should and shuts it down very quickly - the previous behavior where it didn't shut down immediately must have been due to a very flooded condition. I pulled plugs #2, 4, and 5 while I was working on it, and they all were uniformly very sooty and fouled, which confirms the "running rich" diagnosis. Seeing no significant variation, I stopped pulling plugs.

No other new info at this time - I don't generally have a lot of time to work on it during the week, which is ok as it's not my primary transportation.

#6

Registered User

iTrader: (1)

That's interesting, not sure if it has a cold start injector, but maybe it failed and is dumping fuel like crazy. Once you figure out the issue, you'll want to throw some new NGK or Denso plugs in it, the double ground strap style. I like to stick with what OEM had in them, it generally makes the engines run the best. Don't run autolite, run into issues all the time from people installing them in Toyota engines.

My dad just bought a 200 RX300 with a 1MZ v6 3.0L, long story short, it wouldn't rev over 4k rpm, didn't have much power, and knock sensor was flagging in the computer as bad and was flagging atleast one cylinder as lean. First thing he did was check for air leaks and do a tune up (plugs and coil boots). He found some loose bolts on the intake too from when the valve cover gaskets were replaced by the last owner. He drove it a few miles and got on it and it reved up over 5k no problem with less throttle and it went pretty good. It had autolite platinums, but it calls for NGK Iridium, it even says right on the hood to not run any other plug type than Iridium.

Either case, that's about the only thing I can think of right now that would cause that kind of condition. Might be possible for the air metering system to be showing it's floored, don't recall which system these trucks run off the top of my head, pretty sure it was a MAF though (senes air flow) which shouldn't do that kind of failure. MAP are the ones that can make an engine really flood out when they go bad or aren't hooked up right (senses the vacuum on the intake side of the throttle plate).

My dad just bought a 200 RX300 with a 1MZ v6 3.0L, long story short, it wouldn't rev over 4k rpm, didn't have much power, and knock sensor was flagging in the computer as bad and was flagging atleast one cylinder as lean. First thing he did was check for air leaks and do a tune up (plugs and coil boots). He found some loose bolts on the intake too from when the valve cover gaskets were replaced by the last owner. He drove it a few miles and got on it and it reved up over 5k no problem with less throttle and it went pretty good. It had autolite platinums, but it calls for NGK Iridium, it even says right on the hood to not run any other plug type than Iridium.

Either case, that's about the only thing I can think of right now that would cause that kind of condition. Might be possible for the air metering system to be showing it's floored, don't recall which system these trucks run off the top of my head, pretty sure it was a MAF though (senes air flow) which shouldn't do that kind of failure. MAP are the ones that can make an engine really flood out when they go bad or aren't hooked up right (senses the vacuum on the intake side of the throttle plate).

#7

Registered User

Thread Starter

Just a quick update, the fuel pressure gauge I have is the type intended for carbureted engines, only reads up to 10psi. So I ordered a proper EFI-oriented pressure tester, and will probably get some numbers over the weekend. Didn't want you to think I disappeared on you ;-)

Trending Topics

#9

Registered User

Thread Starter

Okay, finally got a fuel pressure take-off installed on the truck, tapping in on the banjo fitting for the crossover line between the two rails with a GlowShift banjo bolt and a couple brass 1/8" NPT fittings terminating in a Schraeder valve that my pressure gauge can talk to. I'm seeing a very dependable 38psi. Vacuum is present at the hose leading to the fuel pressure regulator (12 inHg) and the fuel rail pressure rises to 46psi with the line disconnected, then recovers to 38psi when it's connected again. Pressure increases slightly with throttle, too, and recovers quickly on return to idle. The rail remains pressurized after the car is turned off, as it should. These numbers are all very slightly high, but within calibration margins for the gauge, I'd guess.

So all of that suggests that the fuel pump, fuel filter, pressure regulator and the regulator VSV are functioning as designed, right?

Dumping the fuel pressure to zero while the car is running has almost no effect - it seemed happy to keep running indefinitely with the pressure gauge dumping its trickle of fuel, which I think just means that my fuel pump was pumping faster than the gauge relief valve was draining. The system regains pressure quickly when you release the button.. Disconnecting wiring to the air mass meter caused the car to just about die (and throw code P0110, intake air temp sensor) but the engine recovered when I quickly plugged it back in.

I got my stethoscope out, and listened to the injectors for 1, 2, 3, and 5 (couldn't reach 4 & 6 easily, as they're under the plenum). They're happily clicking away as injectors should.

Overall, the truck idled fast, around 1800rpm, and took a while to settle down. It eventually bogged down and started idling at ever-decreasing RPM, as we've seen before. OBD reported "open loop due to insufficient temperature" and the O2 sensor read a steadily increasing value until it leveled off near the high end of the range. After a restart, OBD reported "Closed loop, using O2 sensor for fuel ratio" or something like that, and the truck seemed happier, though I didn't run it long enough to know for sure.

Vacuum pressure on one of the fat lines on the front of the engine read 14-15 inHg, which sounds maybe a little low but not like there's a serious vacuum leak - and vacuum leaks prior to combustion would result in lean, not rich, running conditions, anyway.

As for other stuff we've talked about, I checked my coolant temp sensor (using the specs you provided, atcfixer) and it was within spec and appeared to vary with temp as it should. I checked again through the wiring and it was the same, so the connector and harness for that part isn't problematic.

At this point, it's starting to sound like an O2 sensor, or a dirty/faulty/damaged MAF sensor, or...? Since this all started during the test drive after a gasket repair that didn't go anywhere near the O2 sensor, but *did* involve removing the MAF and intake pipe, I'm going to check the MAF for correct readings and cleanliness. I might also check the voltage on the O2 sensor. But I'm all about other ideas, as my original theory that it was overpressure in the fuel rail is completely shot at this point.

So all of that suggests that the fuel pump, fuel filter, pressure regulator and the regulator VSV are functioning as designed, right?

Dumping the fuel pressure to zero while the car is running has almost no effect - it seemed happy to keep running indefinitely with the pressure gauge dumping its trickle of fuel, which I think just means that my fuel pump was pumping faster than the gauge relief valve was draining. The system regains pressure quickly when you release the button.. Disconnecting wiring to the air mass meter caused the car to just about die (and throw code P0110, intake air temp sensor) but the engine recovered when I quickly plugged it back in.

I got my stethoscope out, and listened to the injectors for 1, 2, 3, and 5 (couldn't reach 4 & 6 easily, as they're under the plenum). They're happily clicking away as injectors should.

Overall, the truck idled fast, around 1800rpm, and took a while to settle down. It eventually bogged down and started idling at ever-decreasing RPM, as we've seen before. OBD reported "open loop due to insufficient temperature" and the O2 sensor read a steadily increasing value until it leveled off near the high end of the range. After a restart, OBD reported "Closed loop, using O2 sensor for fuel ratio" or something like that, and the truck seemed happier, though I didn't run it long enough to know for sure.

Vacuum pressure on one of the fat lines on the front of the engine read 14-15 inHg, which sounds maybe a little low but not like there's a serious vacuum leak - and vacuum leaks prior to combustion would result in lean, not rich, running conditions, anyway.

As for other stuff we've talked about, I checked my coolant temp sensor (using the specs you provided, atcfixer) and it was within spec and appeared to vary with temp as it should. I checked again through the wiring and it was the same, so the connector and harness for that part isn't problematic.

At this point, it's starting to sound like an O2 sensor, or a dirty/faulty/damaged MAF sensor, or...? Since this all started during the test drive after a gasket repair that didn't go anywhere near the O2 sensor, but *did* involve removing the MAF and intake pipe, I'm going to check the MAF for correct readings and cleanliness. I might also check the voltage on the O2 sensor. But I'm all about other ideas, as my original theory that it was overpressure in the fuel rail is completely shot at this point.

#10

Registered User

iTrader: (1)

Your scanner must be some consumer thing or app. I've never seen one that had to be rebooted and it said something different, but it also rarely gives like full descriptions either, atleast for the older stuff I use. The O2 sensor should bounce up and down if working right, steady state means it might be bad, has build up on it, etc. If the O2 is saying the engine is too rich to the ECU, then the ECU will adjust the fuel trim to be more lean. There's two readings over OBD2 that you can add to the reader to check them, one is the long fuel trim, and the other is short fuel trim. If I remember right, a negative number means it's going more and more lean.

Even though you didn't find the problem, knowing 100% your fuel system, atleast as far as pressures goes, is within spec. It does rule something out as being a problem, and now you have a test port for the future.

The MAF can be cleaned, there's special spray at the parts store you can buy. Electrical contact cleaner can work too, but there's a chance it could cause damage, I just used electrical contact cleaner today on a MAF for a 98 4runner and it helped. I'm chasing a bad IGF signal for #1 and #3 on a new "parts" vehicle I bought that runs/drives. It was rolled, so oil got in a lot of places it shouldn't be.

I've read that O2 sensors generally only stay accurate for 60-80k miles, but people run them for much longer. If you want your engine to run the best possible, changing it before it actually fails isn't a bad idea, kind of like a timing belt (assuming a non-interference engine where it doesn't matter if the belt breaks).

Anyway, it's been a while since I read through the thread, but if I remember things right, my mind was going for an injector stuck open. I've never experienced that personally, but know it's a possible failure mode. I suspect you couldn't ohm it to test that either since it's a physical thing. Don't really want to actually blame them though since having them cleaned or replacing them isn't exactly cheap and such. If you can get to the point that a single cylinder is mis firing, or has a lean/rich code, it could be that one injector, but if it's all of them, then it might not be the cause. There might be a cold start injector too in the intake where all the cylinders would be effected by it.

Sometimes tracking down issues isn't easy, but figuring them out can make you lean something useful for the future. Good luck on the hunt.

Even though you didn't find the problem, knowing 100% your fuel system, atleast as far as pressures goes, is within spec. It does rule something out as being a problem, and now you have a test port for the future.

The MAF can be cleaned, there's special spray at the parts store you can buy. Electrical contact cleaner can work too, but there's a chance it could cause damage, I just used electrical contact cleaner today on a MAF for a 98 4runner and it helped. I'm chasing a bad IGF signal for #1 and #3 on a new "parts" vehicle I bought that runs/drives. It was rolled, so oil got in a lot of places it shouldn't be.

I've read that O2 sensors generally only stay accurate for 60-80k miles, but people run them for much longer. If you want your engine to run the best possible, changing it before it actually fails isn't a bad idea, kind of like a timing belt (assuming a non-interference engine where it doesn't matter if the belt breaks).

Anyway, it's been a while since I read through the thread, but if I remember things right, my mind was going for an injector stuck open. I've never experienced that personally, but know it's a possible failure mode. I suspect you couldn't ohm it to test that either since it's a physical thing. Don't really want to actually blame them though since having them cleaned or replacing them isn't exactly cheap and such. If you can get to the point that a single cylinder is mis firing, or has a lean/rich code, it could be that one injector, but if it's all of them, then it might not be the cause. There might be a cold start injector too in the intake where all the cylinders would be effected by it.

Sometimes tracking down issues isn't easy, but figuring them out can make you lean something useful for the future. Good luck on the hunt.

#11

Registered User

Thread Starter

Re: the scanner, it was the truck we turned off and on again, not the scanner :-)

I did clean the MAF and the throttle body with electronic parts cleaner, not the special MAF stuff. I tried running some of the resistance and voltage tests on the MAF but got some weird results, and wanted to redo that process to make sure I was hitting the right pins...

In any case, we're definitely seeing uniformly fouled plugs, and there is no cold start injector on the 5VZ-FE, so this is a faulty EFI component somewhere (now that we've ruled out the fuel rail/injector system). I agree with you that the O2 sensor isn't a bad idea anyway, so maybe I'll start there.

I did clean the MAF and the throttle body with electronic parts cleaner, not the special MAF stuff. I tried running some of the resistance and voltage tests on the MAF but got some weird results, and wanted to redo that process to make sure I was hitting the right pins...

In any case, we're definitely seeing uniformly fouled plugs, and there is no cold start injector on the 5VZ-FE, so this is a faulty EFI component somewhere (now that we've ruled out the fuel rail/injector system). I agree with you that the O2 sensor isn't a bad idea anyway, so maybe I'll start there.

#12

Registered User

iTrader: (1)

That reminds me, maybe test your engine coolant temp sender (the one that the computer reads). If it's reporting the engine is -40F, it's going to dump a lot of fuel. Air intake temp might effect it some too.

If the temp is extreme cold like that, the engine should start up and run real rich, but as the engine comes up to temp, it needs less fuel, which might explain why the rpm drops and eventually stalls.

If the temp is extreme cold like that, the engine should start up and run real rich, but as the engine comes up to temp, it needs less fuel, which might explain why the rpm drops and eventually stalls.

Last edited by atcfixer; 09-06-2021 at 11:30 AM.

#13

Registered User

Thread Starter

Welp, time for a wrap-up. I got the problem resolved yesterday. TL;DR it was the upstream O2 sensor (AKA the A/F Ratio sensor).

But before we got there, I replaced the MAF. The MAF on this truck has a built-in Intake Air Temp sensor, and mine failed the multimeter test for the IAT, with no continuity showing between the IAT terminals. (Supposed to measure a certain amount of resistance, but I never picked up continuity at all.) There was also a complicated test for the MAF itself, which involved connecting battery voltage across two terminals and measuring resistance from one of them to a third while blowing air through the MAF body. I'm not certain I was doing that one right, but I never got a good reading there, either. In any case, the MAF was bad if the IAT component had failed.

Replacing the MAF didn't resolve the problem, however. The truck still started fine, idled high, and gradually bogged down while smelling strongly of excess unburned hydrocarbons. Symptoms pointed toward the upstream O2 sensor, but there was no clear indication because I'm pretty sure my OBD app had never really shown a reading for the upstream sensor on this truck. I figured it was probably because it was a 1995 model, before the OBD2 standard was fully enforced, or something.

Shopping for upstream sensors was confusing, it wasn't clear which part I needed. I called my local dealership and they indicated there had been a running change to the part, and I needed to supply a VIN to get a definitive answer. My VIN indicated a part Toyota no longer supplies, but I was able to get it cross-referenced at the local NAPA and got an NTK part for $90 (I wanted Denso, but I'll take what I can get after all that runaround on this part....).

I had been spraying down the sensor and flange bolts with PB Blaster for a couple days. When the part came in, installation was a piece of cake - but I did have to remove the shift boot plate from the interior to reach the O2 sensor wiring and disconnect it. The new sensor went in, and the truck's behavior settled right down. We took it on an extended test drive in the local foothills and it performed like a champ.

Oh, and the OBD readings for O2 Bank 1/Sensor 1? It reads fine. The answer was staring me in the face the whole time, and I was assuming it was bad data. Oh well, at least I picked up the tools and knowledge to test fuel rail pressure in the future, so I leveled up as a mechanic a bit on this project.

Oh well, at least I picked up the tools and knowledge to test fuel rail pressure in the future, so I leveled up as a mechanic a bit on this project.

There's still a handful of little issues to chase around, but nothing that keeps the truck from doing what she's for. I'll be throwing some new split-ground-strap NGK plugs in soon, and she'll be back in duty. ATCFixer, thanks for keeping me company through all this ;-)

But before we got there, I replaced the MAF. The MAF on this truck has a built-in Intake Air Temp sensor, and mine failed the multimeter test for the IAT, with no continuity showing between the IAT terminals. (Supposed to measure a certain amount of resistance, but I never picked up continuity at all.) There was also a complicated test for the MAF itself, which involved connecting battery voltage across two terminals and measuring resistance from one of them to a third while blowing air through the MAF body. I'm not certain I was doing that one right, but I never got a good reading there, either. In any case, the MAF was bad if the IAT component had failed.

Replacing the MAF didn't resolve the problem, however. The truck still started fine, idled high, and gradually bogged down while smelling strongly of excess unburned hydrocarbons. Symptoms pointed toward the upstream O2 sensor, but there was no clear indication because I'm pretty sure my OBD app had never really shown a reading for the upstream sensor on this truck. I figured it was probably because it was a 1995 model, before the OBD2 standard was fully enforced, or something.

Shopping for upstream sensors was confusing, it wasn't clear which part I needed. I called my local dealership and they indicated there had been a running change to the part, and I needed to supply a VIN to get a definitive answer. My VIN indicated a part Toyota no longer supplies, but I was able to get it cross-referenced at the local NAPA and got an NTK part for $90 (I wanted Denso, but I'll take what I can get after all that runaround on this part....).

I had been spraying down the sensor and flange bolts with PB Blaster for a couple days. When the part came in, installation was a piece of cake - but I did have to remove the shift boot plate from the interior to reach the O2 sensor wiring and disconnect it. The new sensor went in, and the truck's behavior settled right down. We took it on an extended test drive in the local foothills and it performed like a champ.

Oh, and the OBD readings for O2 Bank 1/Sensor 1? It reads fine. The answer was staring me in the face the whole time, and I was assuming it was bad data.

Oh well, at least I picked up the tools and knowledge to test fuel rail pressure in the future, so I leveled up as a mechanic a bit on this project.

Oh well, at least I picked up the tools and knowledge to test fuel rail pressure in the future, so I leveled up as a mechanic a bit on this project.There's still a handful of little issues to chase around, but nothing that keeps the truck from doing what she's for. I'll be throwing some new split-ground-strap NGK plugs in soon, and she'll be back in duty. ATCFixer, thanks for keeping me company through all this ;-)

The following users liked this post:

tstockma (10-17-2021)

#14

Registered User

iTrader: (1)

Sounds like you ordered the right parts, NGK = NTK and it's very good quality stuff, Denso is good to, I'd run either brand with no hesitation. So glad you didn't grab a bosch o2 sensor, I've seen so many people try to run them on Toyota's and have problems. Bank 1 sensor 1 is in fact the upstream o2 sensor. It's a little weird toyota sometimes calls them air fuel ratio sensors, but that's kind of what they are, just a wide band o2 sensor.

I haven't tried to read a 95's sensors before over OBD, but if intake air temp is readable, you could just look at the readings to see if they make sense w\o the manual multi meter test. The MAF part is a little harder to know what "normal" is, but similar logic, if the numbers make sense, then it's atleast half working xD.

Make sure you do get the right plugs, the 3.4L takes the "Double ground strap" plugs. No V, grooved, 4 way, etc ones, stick with what's known to work well in these engines, same thing they came with factory. NGK and Denso are both factory brands for the plugs, some trucks even had one half the engine with one brand, and the other half with the other brand.

Anyway, with the truck running right, it should be pretty easy to break the tires loose on pavement, like trying to take off fast out of a drive way. I did it all the time by accident with my 98, and my dad did it once in a while with his 95 lol. Mine was 4.10 gearing, his was the 3.93, both R150 manual trans 5 speeds.

Nice job tracking down the issues though, my dad's o2 sensor was bad when he got it too, but it had like 270k miles. It's now around 325k and getting some blow by, but it's had a hard life pulling a 12k lb dump trailer full daily for the last several months for my dad's work. He's thinking about the 1UZ swap, or moving up to his F250 7.3L powerstroke. I kind of want to throw a 1UZ or 2UZ in a F250 4x4 frame and throw the tundra cab (or T100, the T100 is much better build quality) on it to get the heavy duty Toyota 3/4 ton truck that they never made, atleast for the 90's era. Should get reasonable mpg while having a nice heavy duty truck that can haul/work with super reliable engine/trans/electronics.

I haven't tried to read a 95's sensors before over OBD, but if intake air temp is readable, you could just look at the readings to see if they make sense w\o the manual multi meter test. The MAF part is a little harder to know what "normal" is, but similar logic, if the numbers make sense, then it's atleast half working xD.

Make sure you do get the right plugs, the 3.4L takes the "Double ground strap" plugs. No V, grooved, 4 way, etc ones, stick with what's known to work well in these engines, same thing they came with factory. NGK and Denso are both factory brands for the plugs, some trucks even had one half the engine with one brand, and the other half with the other brand.

Anyway, with the truck running right, it should be pretty easy to break the tires loose on pavement, like trying to take off fast out of a drive way. I did it all the time by accident with my 98, and my dad did it once in a while with his 95 lol. Mine was 4.10 gearing, his was the 3.93, both R150 manual trans 5 speeds.

Nice job tracking down the issues though, my dad's o2 sensor was bad when he got it too, but it had like 270k miles. It's now around 325k and getting some blow by, but it's had a hard life pulling a 12k lb dump trailer full daily for the last several months for my dad's work. He's thinking about the 1UZ swap, or moving up to his F250 7.3L powerstroke. I kind of want to throw a 1UZ or 2UZ in a F250 4x4 frame and throw the tundra cab (or T100, the T100 is much better build quality) on it to get the heavy duty Toyota 3/4 ton truck that they never made, atleast for the 90's era. Should get reasonable mpg while having a nice heavy duty truck that can haul/work with super reliable engine/trans/electronics.

Thread

Thread Starter

Forum

Replies

Last Post

Canadian POS Toyota

86-95 Trucks & 4Runners

8

05-27-2021 09:54 AM

Double D

86-95 Trucks & 4Runners

72

01-27-2011 07:04 AM