1986 4Runner 22RE rough idle, rich, no power

#21

Registered User

iTrader: (1)

I agree I believe there is more than one issue. Before I swapped the 89 ECU then removed it. Then swapped the MAF then removed it. Two different people have told me I need to switch both at same time. I did and it ran the best it ever has. It even pulled up a hill like it should. It ran for about 15 minutes then started running bad again. I'm going to start it in the AM with the same setup when it is cold and see what it does. I measured the 86 MAF The first test showed out of range by 40 ohms. I want to test the 89 with the same test and see what it comes up with. My vote is that unmetered air is entering intake some place, thus for the first 15 mins the engine is in open loop and the 5th (cold injector) is squirting extra fuel in. Kind of compensating for the unmetered air entering the engine. Try the ether (starting fluid) trick to see if idle kicks up, definately check around that hole that someone placed and routed a line for the throttle dampener. Thats not stock

If the EGR was leaking that is the same as a vac leak correct? It runs really well when I enduce a major vac leak like disconnecting the brake booster hose. It leans it out.

The egr is intended to recycle exhaust gasses into the intake to cool combustion temps at prolonged cruising speeds(as the fuel mix leans out), they depend on vacuum to open and close it (high vacuum and low vacuum). With time it becomes "crudded" and can't close thus exhaust gasses get recycled constantly equalling a crappy idle. The block off plate will remove EGR from the equation

That's a good trick for the EGR block off.

The TPS is new and the spring feels really good. The old one didn't return to idle.

Firing order correct. I've read at different places that after market O2 sensors aren't a good option. Is that true? Should I go with an OE? I'm getting the same readings with the old O2 and the new Bosch. Either their both good (which I doubt), or they are both bad. I'm confident with the test on the O2 except for those last few steps. if memory serve there was only one or two O2 sensor manufactors at the time and bosch sold o2 sensors to everybody, I haven't had a problem but don't use bosch spark plugs the same isn't true there.

If the EGR was leaking that is the same as a vac leak correct? It runs really well when I enduce a major vac leak like disconnecting the brake booster hose. It leans it out.

The egr is intended to recycle exhaust gasses into the intake to cool combustion temps at prolonged cruising speeds(as the fuel mix leans out), they depend on vacuum to open and close it (high vacuum and low vacuum). With time it becomes "crudded" and can't close thus exhaust gasses get recycled constantly equalling a crappy idle. The block off plate will remove EGR from the equation

That's a good trick for the EGR block off.

The TPS is new and the spring feels really good. The old one didn't return to idle.

Firing order correct. I've read at different places that after market O2 sensors aren't a good option. Is that true? Should I go with an OE? I'm getting the same readings with the old O2 and the new Bosch. Either their both good (which I doubt), or they are both bad. I'm confident with the test on the O2 except for those last few steps. if memory serve there was only one or two O2 sensor manufactors at the time and bosch sold o2 sensors to everybody, I haven't had a problem but don't use bosch spark plugs the same isn't true there.

#22

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

EDIT: There are some test that are the same between the 86 and 87, but not all. I was on all data looking at the 86 test info for the O2 and the procedures are different. I left the following pics in this message just in case they are the same, but not sure yet if the following info applies to both the 86 and 87. Assuming always gets me into trouble.

Thanks Muddpig I'll do the starter spray trick again. Has anybody use propane out of a hand held torch (of coarse no flame) to do the same thing. I saw it on youtube how to check for vac leaks. Never seen it before.

I started to start it this morning cold and it took along time to hit. And it ran terrible from the start. That's with the 89 AFM and ECU. I tried to erase the ECU memory and that didn't help.

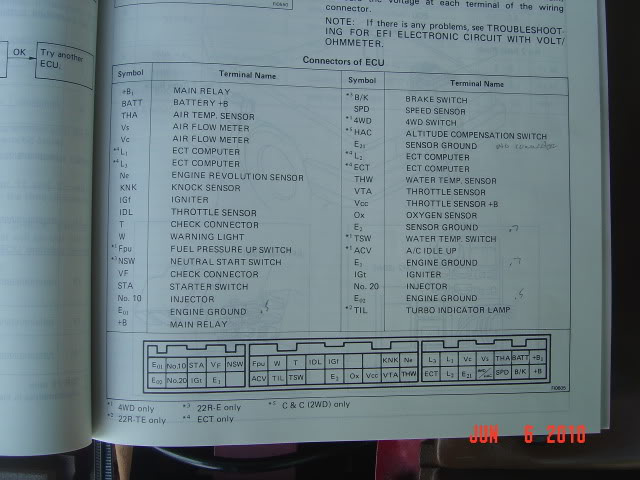

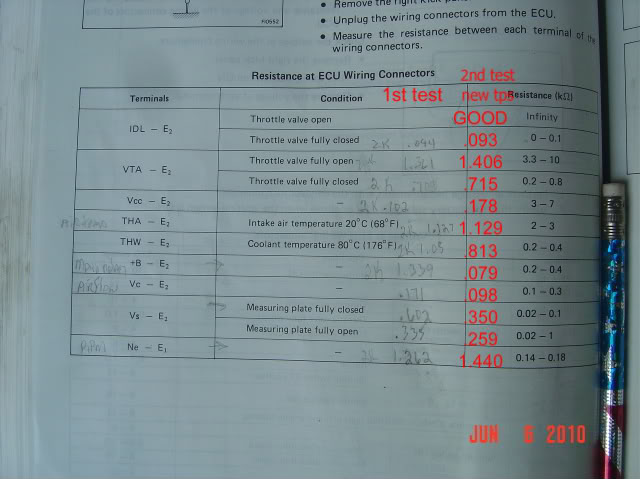

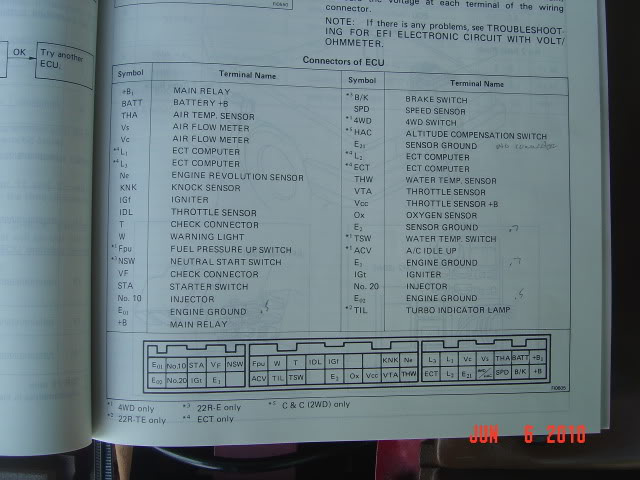

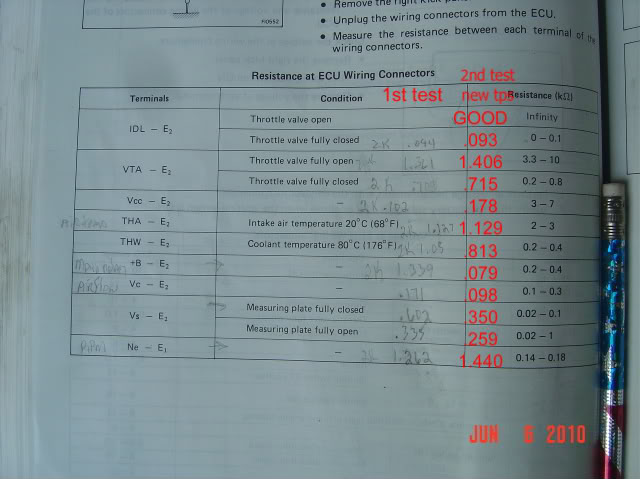

Here are some more test I did. I checked all the grounds on the ECU to chassis ground all seem to be fine. I wrote the results in pencil. There is not a connector in E21

ECU resistance check, there are several out of spec. Meter set on 2K.

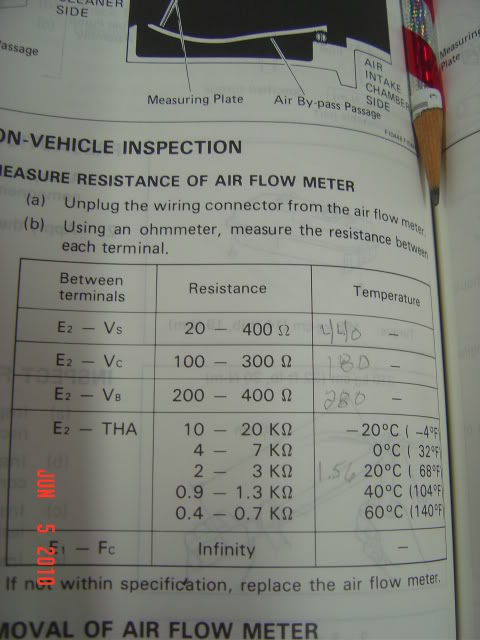

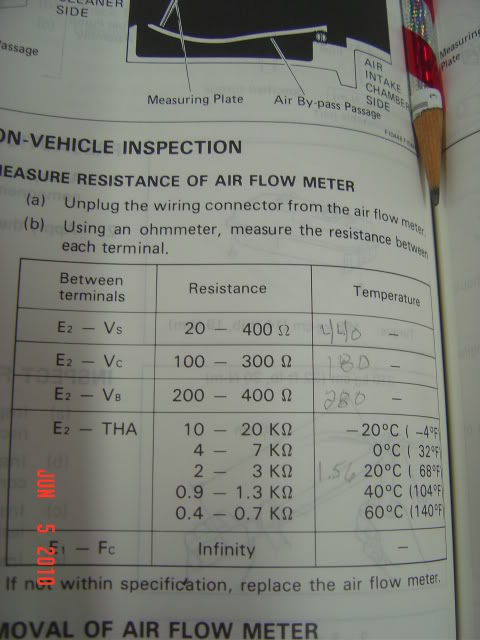

AFM check meter set at 20K

Thanks Muddpig I'll do the starter spray trick again. Has anybody use propane out of a hand held torch (of coarse no flame) to do the same thing. I saw it on youtube how to check for vac leaks. Never seen it before.

I started to start it this morning cold and it took along time to hit. And it ran terrible from the start. That's with the 89 AFM and ECU. I tried to erase the ECU memory and that didn't help.

Here are some more test I did. I checked all the grounds on the ECU to chassis ground all seem to be fine. I wrote the results in pencil. There is not a connector in E21

ECU resistance check, there are several out of spec. Meter set on 2K.

AFM check meter set at 20K

Last edited by Alan's Classic; 06-06-2010 at 01:23 PM.

#23

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

It's been 3 weeks and no improvement. The 86 has consumed me and all of my spare time. I think I will stick to bodywork. LOL It might be cheaper for me to get the 89 buttoned up. It needs exhaust gaskets, water pump and might as well do the chain and dampners etc. Not sure yet what I will do. I might check to see what it would cost me to have somebody (mechanic) come to the house.

#24

Registered User

#25

Registered User

Oh, and btw..........the AFM can be a bugger. It can pass the standard tests in the FSM and still be the problem. But, you said you've tried two different ones. The ECU being out of spec could be the problem. Maybe the vehicle just wants to be set on fire? Maybe it just wants to come to my house and be the donor chassis for my motor/tranny?

#26

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

Oh, and btw..........the AFM can be a bugger. It can pass the standard tests in the FSM and still be the problem. But, you said you've tried two different ones. The ECU being out of spec could be the problem. Maybe the vehicle just wants to be set on fire? Maybe it just wants to come to my house and be the donor chassis for my motor/tranny?

#27

Registered User

Yeah well, according to the last AFM testing you posted, it's bad. And, if the TPS is checking good, then the last test you performed at the ECU connector means, to me, there's a wiring or connector issue. Hmmmm.....

Do whatever feels downstream to you. But, if you still want to get the '86 going, definitely post up. I know EFI has it's complications, but it's also real sweet when you can get them running right. Of course, usually by the time we get these older Yotas they need a lot of TLC. Sometimes it's worth it, though. I've got mine running great.

Do whatever feels downstream to you. But, if you still want to get the '86 going, definitely post up. I know EFI has it's complications, but it's also real sweet when you can get them running right. Of course, usually by the time we get these older Yotas they need a lot of TLC. Sometimes it's worth it, though. I've got mine running great.

#28

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

Don't get me wrong  I'm not giving up. I will get someone that has more of a clue than I do to come by and look at it. I will post up what we find. Maybe it will be better info than what I have provided. I need this as my daily driver so I can rest my F350 and save on fuel.

I'm not giving up. I will get someone that has more of a clue than I do to come by and look at it. I will post up what we find. Maybe it will be better info than what I have provided. I need this as my daily driver so I can rest my F350 and save on fuel.

I'm not giving up. I will get someone that has more of a clue than I do to come by and look at it. I will post up what we find. Maybe it will be better info than what I have provided. I need this as my daily driver so I can rest my F350 and save on fuel.

I'm not giving up. I will get someone that has more of a clue than I do to come by and look at it. I will post up what we find. Maybe it will be better info than what I have provided. I need this as my daily driver so I can rest my F350 and save on fuel.

Last edited by Alan's Classic; 06-09-2010 at 08:39 PM.

#29

Registered User

Swapping efi parts between an 85 and 89 is a bad idea. There were major changes between 88 and 89. The 88 and earlier 22REs have very low resistance injectors, and the 89 and later much higher resistance. Apparently the older trucks use a resistor inline with the injector power supply, so it may not be an issue, but if you use the old low-resistance injectors in a newer truck for example, you will burn out the fuel injector circuits in the computer. Whether the resistor in the power supply used with your low-ohm injectors is sufficient to protect the 89 computer, IDK.

The coil and igniter also are different, and you will never get a motor running right by mismatching a new computer with older components, or vice-versa. You'll also get nothing worthwhile in terms of troubleshooting data. Swapping components is a good idea, but you have to use 88 or older components.

I see your THW (engine coolant temp sensor voltage) is good. If it were bad, the computer would run the motor in open loop with a lot more fuel, thinking it's a cold start situation. But seems like that is not an issue on your motor.

The 88 and earlier trucks as you mentioned use a one-wire O2 sensor. They rely on getting a good ground through the exhaust, which is crazy stupid. So one thing to test is the resistance between the metal body of the sensor and the neg batt post. There should be almost no resistance. If there is more than a few ohms, pinch a wire under one of the sensor mount nuts and run it to a good chassis ground.

Another thing that could mess with the O2 sensor readings is an exhaust leak, which could allow outside air to be drawn in, causing the O2 sensor to report more oxygen and so the computer would think it's running lean and would inject more fuel. But this would only affect the situation when the motor reached operating temp and began running in closed loop.

The 85 fsm wiring diagram shows the green wire with black stripe running from the ecu to a "Vacuum S/W" - a vsv. WHICH vsv, it doesn't say. Since you have a mixture issue, I would see if perhaps it should go to the fuel pressure vsv. Follow the vacuum tube from the top of the fuel pressure regulator back to the vsv to identify it. But it certainly could be the A/C Idle-Up vsv as thook mentioned. I doubt this is your problem, tho.

Unless I missed it, it sounds like you haven't yet tested fuel pressure. That would be good to eliminate. If the fuel return line were obstructed, you could have high fuel pressure. Also make sure that that the hose attached to the side of the regulator actually is the return line that goes to the tank. In older vehicles with multiple POs, you never know what was messed up by somebody in the past.

Another good thing to do is to measure the injector pulses. This requires a good automotive multimeter that can measure pulse width, and also you need to know what the pulse durations should be. I've read - but can't remember where - that during a cold start, injector pulses are at about 30 milliseconds. When motor is operating temp, I think they should be below 10 ms at idle. But the 22re fires all the injectors simultaneously, and does so once per revolution; in other words, twice per each ignition cycle. So should the pulse width be 15 ms instead of 30 during cold start?? IDK - maybe someone here can supply the specs. This is a pretty good thread on the question: https://www.yotatech.com/forums/f116...please-160477/ Which has this useful link: http://www.megamanual.com/index.html

Those splices in the igniter leads are really bad. Using barrel crimps will work ok at first, but soon the wires will corrode and resistance will go up. It looks from the pic you posted of the voltages at the ecu that you may have high resistance on the IGT lead - it has significantly low voltage at idle. How is the spark? Is it nice and bright blue? It should jump a half-inch gap or nearly so. If the low volt on IGT - which is the spark triggering signal from the ecu to the igniter - is causing the spark to misfire, those splices possibly could be causing your mixture trouble. Even if they aren't causing the rich running, they will prevent smooth running once you get your mixture issue sorted. Cleaning and soldering the wires, then coating with dielectric grease and then covering with heat shrink tubing is the way to go. Obviously, don't forget to get the heat shrink tubing over one of the wires before soldering (been there done that). This is a pretty good tutorial: http://www.mmxpress.com/technical/connections.htm

VS voltage (the air meter signal) at the ecu is a little high at idle, which is telling the computer that there is more air going in the motor than there actually is. Since the VS voltage is one of the main signals for mixture control, the computer will respond by making the mixture a little too rich at idle - probably not enough to cause your extreme rich problem, but it could be a contributing factor.

The high compression is probably coming from massive carbon deposits inside the combustion chamber. When you get the mixture issue taken care of, you'll need to feed about a gallon of water into the brake boost vacuum hose - VERY SLOWLY - like, take 20 minutes or so to prevent hydro-lock. See these:

http://www.toyotanation.com/forum/sh...70#post2946870

https://www.yotatech.com/forums/f116...l#post51124041

Yes, water really works: http://www.files.thinksitout.com/Alt...f%20engine.pdf

Always a good idea to check grounds. Make sure there is next to no resistance between motor & neg batt post, chassis & neg batt post, ecu terminal E1 & chassis ground, and E01/E02 & engine ground.

That's all that comes to mind, but I still have the niggling feeling that we're missing something. Good luck with it.

The coil and igniter also are different, and you will never get a motor running right by mismatching a new computer with older components, or vice-versa. You'll also get nothing worthwhile in terms of troubleshooting data. Swapping components is a good idea, but you have to use 88 or older components.

I see your THW (engine coolant temp sensor voltage) is good. If it were bad, the computer would run the motor in open loop with a lot more fuel, thinking it's a cold start situation. But seems like that is not an issue on your motor.

The 88 and earlier trucks as you mentioned use a one-wire O2 sensor. They rely on getting a good ground through the exhaust, which is crazy stupid. So one thing to test is the resistance between the metal body of the sensor and the neg batt post. There should be almost no resistance. If there is more than a few ohms, pinch a wire under one of the sensor mount nuts and run it to a good chassis ground.

Another thing that could mess with the O2 sensor readings is an exhaust leak, which could allow outside air to be drawn in, causing the O2 sensor to report more oxygen and so the computer would think it's running lean and would inject more fuel. But this would only affect the situation when the motor reached operating temp and began running in closed loop.

The 85 fsm wiring diagram shows the green wire with black stripe running from the ecu to a "Vacuum S/W" - a vsv. WHICH vsv, it doesn't say. Since you have a mixture issue, I would see if perhaps it should go to the fuel pressure vsv. Follow the vacuum tube from the top of the fuel pressure regulator back to the vsv to identify it. But it certainly could be the A/C Idle-Up vsv as thook mentioned. I doubt this is your problem, tho.

Unless I missed it, it sounds like you haven't yet tested fuel pressure. That would be good to eliminate. If the fuel return line were obstructed, you could have high fuel pressure. Also make sure that that the hose attached to the side of the regulator actually is the return line that goes to the tank. In older vehicles with multiple POs, you never know what was messed up by somebody in the past.

Another good thing to do is to measure the injector pulses. This requires a good automotive multimeter that can measure pulse width, and also you need to know what the pulse durations should be. I've read - but can't remember where - that during a cold start, injector pulses are at about 30 milliseconds. When motor is operating temp, I think they should be below 10 ms at idle. But the 22re fires all the injectors simultaneously, and does so once per revolution; in other words, twice per each ignition cycle. So should the pulse width be 15 ms instead of 30 during cold start?? IDK - maybe someone here can supply the specs. This is a pretty good thread on the question: https://www.yotatech.com/forums/f116...please-160477/ Which has this useful link: http://www.megamanual.com/index.html

Those splices in the igniter leads are really bad. Using barrel crimps will work ok at first, but soon the wires will corrode and resistance will go up. It looks from the pic you posted of the voltages at the ecu that you may have high resistance on the IGT lead - it has significantly low voltage at idle. How is the spark? Is it nice and bright blue? It should jump a half-inch gap or nearly so. If the low volt on IGT - which is the spark triggering signal from the ecu to the igniter - is causing the spark to misfire, those splices possibly could be causing your mixture trouble. Even if they aren't causing the rich running, they will prevent smooth running once you get your mixture issue sorted. Cleaning and soldering the wires, then coating with dielectric grease and then covering with heat shrink tubing is the way to go. Obviously, don't forget to get the heat shrink tubing over one of the wires before soldering (been there done that). This is a pretty good tutorial: http://www.mmxpress.com/technical/connections.htm

VS voltage (the air meter signal) at the ecu is a little high at idle, which is telling the computer that there is more air going in the motor than there actually is. Since the VS voltage is one of the main signals for mixture control, the computer will respond by making the mixture a little too rich at idle - probably not enough to cause your extreme rich problem, but it could be a contributing factor.

The high compression is probably coming from massive carbon deposits inside the combustion chamber. When you get the mixture issue taken care of, you'll need to feed about a gallon of water into the brake boost vacuum hose - VERY SLOWLY - like, take 20 minutes or so to prevent hydro-lock. See these:

http://www.toyotanation.com/forum/sh...70#post2946870

https://www.yotatech.com/forums/f116...l#post51124041

Yes, water really works: http://www.files.thinksitout.com/Alt...f%20engine.pdf

Always a good idea to check grounds. Make sure there is next to no resistance between motor & neg batt post, chassis & neg batt post, ecu terminal E1 & chassis ground, and E01/E02 & engine ground.

That's all that comes to mind, but I still have the niggling feeling that we're missing something. Good luck with it.

#31

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

Swapping efi parts between an 85 and 89 is a bad idea. There were major changes between 88 and 89. The 88 and earlier 22REs have very low resistance injectors, and the 89 and later much higher resistance. Apparently the older trucks use a resistor inline with the injector power supply, so it may not be an issue, but if you use the old low-resistance injectors in a newer truck for example, you will burn out the fuel injector circuits in the computer. Whether the resistor in the power supply used with your low-ohm injectors is sufficient to protect the 89 computer, IDK.

The coil and igniter also are different, and you will never get a motor running right by mismatching a new computer with older components, or vice-versa. You'll also get nothing worthwhile in terms of troubleshooting data. Swapping components is a good idea, but you have to use 88 or older components.

I see your THW (engine coolant temp sensor voltage) is good. If it were bad, the computer would run the motor in open loop with a lot more fuel, thinking it's a cold start situation. But seems like that is not an issue on your motor.

The 88 and earlier trucks as you mentioned use a one-wire O2 sensor. They rely on getting a good ground through the exhaust, which is crazy stupid. So one thing to test is the resistance between the metal body of the sensor and the neg batt post. There should be almost no resistance. If there is more than a few ohms, pinch a wire under one of the sensor mount nuts and run it to a good chassis ground.

Another thing that could mess with the O2 sensor readings is an exhaust leak, which could allow outside air to be drawn in, causing the O2 sensor to report more oxygen and so the computer would think it's running lean and would inject more fuel. But this would only affect the situation when the motor reached operating temp and began running in closed loop.

The 85 fsm wiring diagram shows the green wire with black stripe running from the ecu to a "Vacuum S/W" - a vsv. WHICH vsv, it doesn't say. Since you have a mixture issue, I would see if perhaps it should go to the fuel pressure vsv. Follow the vacuum tube from the top of the fuel pressure regulator back to the vsv to identify it. But it certainly could be the A/C Idle-Up vsv as thook mentioned. I doubt this is your problem, tho.

Unless I missed it, it sounds like you haven't yet tested fuel pressure. That would be good to eliminate. If the fuel return line were obstructed, you could have high fuel pressure. Also make sure that that the hose attached to the side of the regulator actually is the return line that goes to the tank. In older vehicles with multiple POs, you never know what was messed up by somebody in the past.

Another good thing to do is to measure the injector pulses. This requires a good automotive multimeter that can measure pulse width, and also you need to know what the pulse durations should be. I've read - but can't remember where - that during a cold start, injector pulses are at about 30 milliseconds. When motor is operating temp, I think they should be below 10 ms at idle. But the 22re fires all the injectors simultaneously, and does so once per revolution; in other words, twice per each ignition cycle. So should the pulse width be 15 ms instead of 30 during cold start?? IDK - maybe someone here can supply the specs. This is a pretty good thread on the question: https://www.yotatech.com/forums/f116...please-160477/ Which has this useful link: http://www.megamanual.com/index.html

Those splices in the igniter leads are really bad. Using barrel crimps will work ok at first, but soon the wires will corrode and resistance will go up. It looks from the pic you posted of the voltages at the ecu that you may have high resistance on the IGT lead - it has significantly low voltage at idle. How is the spark? Is it nice and bright blue? It should jump a half-inch gap or nearly so. If the low volt on IGT - which is the spark triggering signal from the ecu to the igniter - is causing the spark to misfire, those splices possibly could be causing your mixture trouble. Even if they aren't causing the rich running, they will prevent smooth running once you get your mixture issue sorted. Cleaning and soldering the wires, then coating with dielectric grease and then covering with heat shrink tubing is the way to go. Obviously, don't forget to get the heat shrink tubing over one of the wires before soldering (been there done that). This is a pretty good tutorial: http://www.mmxpress.com/technical/connections.htm

VS voltage (the air meter signal) at the ecu is a little high at idle, which is telling the computer that there is more air going in the motor than there actually is. Since the VS voltage is one of the main signals for mixture control, the computer will respond by making the mixture a little too rich at idle - probably not enough to cause your extreme rich problem, but it could be a contributing factor.

The high compression is probably coming from massive carbon deposits inside the combustion chamber. When you get the mixture issue taken care of, you'll need to feed about a gallon of water into the brake boost vacuum hose - VERY SLOWLY - like, take 20 minutes or so to prevent hydro-lock. See these:

http://www.toyotanation.com/forum/sh...70#post2946870

https://www.yotatech.com/forums/f116...l#post51124041

Yes, water really works: http://www.files.thinksitout.com/Alt...f%20engine.pdf

Always a good idea to check grounds. Make sure there is next to no resistance between motor & neg batt post, chassis & neg batt post, ecu terminal E1 & chassis ground, and E01/E02 & engine ground.

That's all that comes to mind, but I still have the niggling feeling that we're missing something. Good luck with it.

The coil and igniter also are different, and you will never get a motor running right by mismatching a new computer with older components, or vice-versa. You'll also get nothing worthwhile in terms of troubleshooting data. Swapping components is a good idea, but you have to use 88 or older components.

I see your THW (engine coolant temp sensor voltage) is good. If it were bad, the computer would run the motor in open loop with a lot more fuel, thinking it's a cold start situation. But seems like that is not an issue on your motor.

The 88 and earlier trucks as you mentioned use a one-wire O2 sensor. They rely on getting a good ground through the exhaust, which is crazy stupid. So one thing to test is the resistance between the metal body of the sensor and the neg batt post. There should be almost no resistance. If there is more than a few ohms, pinch a wire under one of the sensor mount nuts and run it to a good chassis ground.

Another thing that could mess with the O2 sensor readings is an exhaust leak, which could allow outside air to be drawn in, causing the O2 sensor to report more oxygen and so the computer would think it's running lean and would inject more fuel. But this would only affect the situation when the motor reached operating temp and began running in closed loop.

The 85 fsm wiring diagram shows the green wire with black stripe running from the ecu to a "Vacuum S/W" - a vsv. WHICH vsv, it doesn't say. Since you have a mixture issue, I would see if perhaps it should go to the fuel pressure vsv. Follow the vacuum tube from the top of the fuel pressure regulator back to the vsv to identify it. But it certainly could be the A/C Idle-Up vsv as thook mentioned. I doubt this is your problem, tho.

Unless I missed it, it sounds like you haven't yet tested fuel pressure. That would be good to eliminate. If the fuel return line were obstructed, you could have high fuel pressure. Also make sure that that the hose attached to the side of the regulator actually is the return line that goes to the tank. In older vehicles with multiple POs, you never know what was messed up by somebody in the past.

Another good thing to do is to measure the injector pulses. This requires a good automotive multimeter that can measure pulse width, and also you need to know what the pulse durations should be. I've read - but can't remember where - that during a cold start, injector pulses are at about 30 milliseconds. When motor is operating temp, I think they should be below 10 ms at idle. But the 22re fires all the injectors simultaneously, and does so once per revolution; in other words, twice per each ignition cycle. So should the pulse width be 15 ms instead of 30 during cold start?? IDK - maybe someone here can supply the specs. This is a pretty good thread on the question: https://www.yotatech.com/forums/f116...please-160477/ Which has this useful link: http://www.megamanual.com/index.html

Those splices in the igniter leads are really bad. Using barrel crimps will work ok at first, but soon the wires will corrode and resistance will go up. It looks from the pic you posted of the voltages at the ecu that you may have high resistance on the IGT lead - it has significantly low voltage at idle. How is the spark? Is it nice and bright blue? It should jump a half-inch gap or nearly so. If the low volt on IGT - which is the spark triggering signal from the ecu to the igniter - is causing the spark to misfire, those splices possibly could be causing your mixture trouble. Even if they aren't causing the rich running, they will prevent smooth running once you get your mixture issue sorted. Cleaning and soldering the wires, then coating with dielectric grease and then covering with heat shrink tubing is the way to go. Obviously, don't forget to get the heat shrink tubing over one of the wires before soldering (been there done that). This is a pretty good tutorial: http://www.mmxpress.com/technical/connections.htm

VS voltage (the air meter signal) at the ecu is a little high at idle, which is telling the computer that there is more air going in the motor than there actually is. Since the VS voltage is one of the main signals for mixture control, the computer will respond by making the mixture a little too rich at idle - probably not enough to cause your extreme rich problem, but it could be a contributing factor.

The high compression is probably coming from massive carbon deposits inside the combustion chamber. When you get the mixture issue taken care of, you'll need to feed about a gallon of water into the brake boost vacuum hose - VERY SLOWLY - like, take 20 minutes or so to prevent hydro-lock. See these:

http://www.toyotanation.com/forum/sh...70#post2946870

https://www.yotatech.com/forums/f116...l#post51124041

Yes, water really works: http://www.files.thinksitout.com/Alt...f%20engine.pdf

Always a good idea to check grounds. Make sure there is next to no resistance between motor & neg batt post, chassis & neg batt post, ecu terminal E1 & chassis ground, and E01/E02 & engine ground.

That's all that comes to mind, but I still have the niggling feeling that we're missing something. Good luck with it.

It's all good.

#32

Registered User

Oh yeah......it's all good. I'm just suspecting he's like some ancient yota zen master from prehistoric Densonesia reincarnated for the 1000th time. Of course, he'll deny it....

#33

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

I spent my shop time today on the 89. I was able to swap the igniter/coil back to the proper vehicle.

I was able to check the ground from the o2 to battery neg. Showed .5 ohms. I will post other results as I get them done.

I was able to check the ground from the o2 to battery neg. Showed .5 ohms. I will post other results as I get them done.

#34

Registered User

Join Date: Apr 2009

Location: Suisun City, California

Posts: 535

Likes: 0

Received 0 Likes

on

0 Posts

There are only 2 things that I know of that have not been covered.

The flapper in the air flow meter can be stuck open causing an incorrect signal to the ecu.

There may be a leak in the hose between the throttle body and the air flow meter. The part that connects to the throttle body is notorious for having cracks. This will also cause the air flow meter to send an incorrect signal to the ecu.

Also I did not read that you checked the timing or adjusted the valves as thook suggested. At least the chain guides are still there. From the picture I am assuming that there is not slack in the timing chain that may cause it to jump a tooth.

Hope you get it running better.

The flapper in the air flow meter can be stuck open causing an incorrect signal to the ecu.

There may be a leak in the hose between the throttle body and the air flow meter. The part that connects to the throttle body is notorious for having cracks. This will also cause the air flow meter to send an incorrect signal to the ecu.

Also I did not read that you checked the timing or adjusted the valves as thook suggested. At least the chain guides are still there. From the picture I am assuming that there is not slack in the timing chain that may cause it to jump a tooth.

Hope you get it running better.

#35

Registered User

iTrader: (5)

Wow, I'M FEELIN YER PAIN, BROTHA! lol....Been there, done that!

WOW X 2 on that post that Thook so eloquently put as, ..."Toyota zen Master quotes" hahaha. WOW!

Well, one thing I was curious about, maybe you could clear it up....You said you pulled the Brake Booster Vacuum line....and it 'cleared up'??? Don't want to say anything until you clarify that, but I will ASK, 'say WHAT?' hahaha. I can't imagine the motor smoothing out with a GIGANTIC Vacuum leak, ...which is also something that could cause many of your symptoms. I recently went through, as you know, lol...several PAGES of searching for causes to my issue(which IS similar, like you said, but not identical).

Not sure if the Guru above mentioned, ...lemme look.....Ok, not that I can see. He mentioned 'swapping parts', and yes, that's ok for 'some' things, but as far as I know, the two AFM's are NOT the same. Every listing I've EVER seen for reman'd or used meters has been 84-88, PERIOD!(you can find out from any Toy dealer, Monday, k? Napa should also be able to tell you, they sell reman'd ones for about 200$ if you have a preferred card)...I have one from my 87 that I've swapped out with one I got on here. I'd gladly give it to you, but I'm not POSITIVE that it's not having issues of it's own, seeing as the Ambient Temp Reading came out a lil low. However, I can try mine and see if It's good, and you could try it out, ....I just don't 'like' the readings it gave. NOTHING like "THIS THING IS DEAD", ...but then 'goofy doesn't equal good ...just with an extra F" lol. The TPS, I believe, is also different, with different resistance according to the differing injectors, etc. Not REALLY sure on that, but PRETTY SURE. I went to get my TPS and my buddy at the dealer asked "What month in 87 is it? They are different according to early or late 87"...Soooo, lol. The ECU swap? Not sure that's a great idea, either, unless it was also a Pre-89 model, and even then, I believe 88 has differences from the 87(like mine). You'll have to ask a Guru for further info on that, as I'm learning, just like you! lol.

Not sure about that above post, regarding the Bosch O2....However, MINE WAS NOT working properly, even though it was OE. Popped in the OEM and it worked WAY better with my ECU(I can tell you how to get them cheaper from the dealer or online, OEM Denso). I've read FAR MORE posts from respected guys on here saying "OEM DENSO O2, PERIOD" than otherwise. Maybe I missed you clearing that up. Sorry if so. AFM, like Whokrz said can get 'sticky', and they do make AFM cleaner(BUT FOLLOW THE INSTRUCTIONS, lol.)

Press hard on your brakes to see if the idle drops A LOT....my booster was going out and gave no signs before finally perforating other than an occasional up and down idle, over and over for a few seconds. However, I'm pretty sure it's been a problem with 'dialing it in' for quite a while, now, for me.

I recommend Thook's(the other Guru here, lol) idea that he gave me, ...MAKE A TIGHT list of what you're SURE is good or not so sure. Start making sure ALL of your grounds are good, as well. Check timing, Gap, Wires, PLUG THAT EXHAUST lol, go Denso O2 if you can, Dealer-Cap-Rotor(and wires I'm told) if you can, but I AGREE, before buying anything else, MAKE SURE you don't have any vacuum leaks. A few lil ones can TOTALLY throw you off. Make sure you're getting GOOD Fuel Pressure. Make sure you're FPR is at least 'clicking away' when running(not likely, but possibly bad). Also, shouldn't that lil dimple in the CAM gear have the Bright link on it at 11:30 at TDC on the compression stroke....ALWAYS?

WOW X 2 on that post that Thook so eloquently put as, ..."Toyota zen Master quotes" hahaha. WOW!

Well, one thing I was curious about, maybe you could clear it up....You said you pulled the Brake Booster Vacuum line....and it 'cleared up'??? Don't want to say anything until you clarify that, but I will ASK, 'say WHAT?' hahaha. I can't imagine the motor smoothing out with a GIGANTIC Vacuum leak, ...which is also something that could cause many of your symptoms. I recently went through, as you know, lol...several PAGES of searching for causes to my issue(which IS similar, like you said, but not identical).

Not sure if the Guru above mentioned, ...lemme look.....Ok, not that I can see. He mentioned 'swapping parts', and yes, that's ok for 'some' things, but as far as I know, the two AFM's are NOT the same. Every listing I've EVER seen for reman'd or used meters has been 84-88, PERIOD!(you can find out from any Toy dealer, Monday, k? Napa should also be able to tell you, they sell reman'd ones for about 200$ if you have a preferred card)...I have one from my 87 that I've swapped out with one I got on here. I'd gladly give it to you, but I'm not POSITIVE that it's not having issues of it's own, seeing as the Ambient Temp Reading came out a lil low. However, I can try mine and see if It's good, and you could try it out, ....I just don't 'like' the readings it gave. NOTHING like "THIS THING IS DEAD", ...but then 'goofy doesn't equal good ...just with an extra F" lol. The TPS, I believe, is also different, with different resistance according to the differing injectors, etc. Not REALLY sure on that, but PRETTY SURE. I went to get my TPS and my buddy at the dealer asked "What month in 87 is it? They are different according to early or late 87"...Soooo, lol. The ECU swap? Not sure that's a great idea, either, unless it was also a Pre-89 model, and even then, I believe 88 has differences from the 87(like mine). You'll have to ask a Guru for further info on that, as I'm learning, just like you! lol.

Not sure about that above post, regarding the Bosch O2....However, MINE WAS NOT working properly, even though it was OE. Popped in the OEM and it worked WAY better with my ECU(I can tell you how to get them cheaper from the dealer or online, OEM Denso). I've read FAR MORE posts from respected guys on here saying "OEM DENSO O2, PERIOD" than otherwise. Maybe I missed you clearing that up. Sorry if so. AFM, like Whokrz said can get 'sticky', and they do make AFM cleaner(BUT FOLLOW THE INSTRUCTIONS, lol.)

Press hard on your brakes to see if the idle drops A LOT....my booster was going out and gave no signs before finally perforating other than an occasional up and down idle, over and over for a few seconds. However, I'm pretty sure it's been a problem with 'dialing it in' for quite a while, now, for me.

I recommend Thook's(the other Guru here, lol) idea that he gave me, ...MAKE A TIGHT list of what you're SURE is good or not so sure. Start making sure ALL of your grounds are good, as well. Check timing, Gap, Wires, PLUG THAT EXHAUST lol, go Denso O2 if you can, Dealer-Cap-Rotor(and wires I'm told) if you can, but I AGREE, before buying anything else, MAKE SURE you don't have any vacuum leaks. A few lil ones can TOTALLY throw you off. Make sure you're getting GOOD Fuel Pressure. Make sure you're FPR is at least 'clicking away' when running(not likely, but possibly bad). Also, shouldn't that lil dimple in the CAM gear have the Bright link on it at 11:30 at TDC on the compression stroke....ALWAYS?

Last edited by ChefYota4x4; 06-13-2010 at 12:23 AM.

#36

Registered User

Join Date: Apr 2009

Location: Suisun City, California

Posts: 535

Likes: 0

Received 0 Likes

on

0 Posts

#37

Registered User

iTrader: (5)

Hey Whokrz,

No, what I meant was, ....When the #1 is on the compression stroke, the Bright Link should be at 11:30(11:42, whatever, lol) over the dimple in the CAM gear, with the Larger Mark(Hole, Indentation) at DEAD ON 12.

I know it takes what, 4 cranks of the crank pulley to get it to come around at times....but it SHOULD ALWAYS line up like I mentioned, when #1 hits the comp. stroke. But he has to verify he's got that the Other bright link on the Crank Gear Mark .......at 6'o'Clock, right? If you mean they don't always line up each time you bring it around 12hours...I know what you meant...Sorry. But otherwise, I'm not sure, cuz they should ALWAYS line up, eventually in the rotating of the crank.

Notch in the dizzy gear is right, Alan? Just left of the closest gear and lined up with #1 on the cap, etc? Sorry if that's been gone over, no disrespect...I'm just kinda popping in and out today really quickly.

I'm watching and best wishes.

Mark

No, what I meant was, ....When the #1 is on the compression stroke, the Bright Link should be at 11:30(11:42, whatever, lol) over the dimple in the CAM gear, with the Larger Mark(Hole, Indentation) at DEAD ON 12.

I know it takes what, 4 cranks of the crank pulley to get it to come around at times....but it SHOULD ALWAYS line up like I mentioned, when #1 hits the comp. stroke. But he has to verify he's got that the Other bright link on the Crank Gear Mark .......at 6'o'Clock, right? If you mean they don't always line up each time you bring it around 12hours...I know what you meant...Sorry. But otherwise, I'm not sure, cuz they should ALWAYS line up, eventually in the rotating of the crank.

Notch in the dizzy gear is right, Alan? Just left of the closest gear and lined up with #1 on the cap, etc? Sorry if that's been gone over, no disrespect...I'm just kinda popping in and out today really quickly.

I'm watching and best wishes.

Mark

#38

Registered User

Join Date: Apr 2009

Location: Suisun City, California

Posts: 535

Likes: 0

Received 0 Likes

on

0 Posts

I know when you install the timing chain the marks on the gears need to line up to the bright links and the engine needs to be TDC. When I rebuilt my engine I got the timing chain on to spec and then rotated the engine by hand to make sure everything was functioning smoothly. after a few turns I noticed that the links no longer lined up at TDC. It really freaked me out. I reversed the engine a few turns and then they lined up again. I do not know how may rotations it takes going forward to get them to line up.

Also as ChefYota4x4 stated making sure the distributer is lined up properly would be good to check if you have not already done so.

Also as ChefYota4x4 stated making sure the distributer is lined up properly would be good to check if you have not already done so.

#39

Registered User

iTrader: (5)

Just wanted to throw in here, Alan;

1. CODES, CODES, CODES....yeah, and I know, when you have NO CODES, other than the obvious one that you're working on,....and it seems to STILL DOG, ...."GRRR", lol. However, one thing to consider, NOT SAYING TO GO BUY ONE, is that Flecker and I messed with this thing for 9-10 hours, STRAIGHT, ....NO CODES, a few funny readings, and after adjusting everything back to 'SPEC', .....CRAPOLA! HOWEVER-2;, lol.... When replacing my ECU with the one Flecker brought over? 2 CODES, IMMEDIATELY! Not to mention, the ECU I HAD WAS NOT PROPERLY relaying signal to certain sensors, most likely, after misreading or improperly sending signal to the NEXT SENSOR, etc. BAD ECU= OFTEN THROWS NO CODES! ....From what I've been reading lately.

2. This replacement ECU is throwing an O2 Code on mine........BUT IT'S BRAND NEW! However, hehehe; The PO had torn back the shielded wire that it comes with, factory, to just simply connect up the 'SINGLE WIRE' to the New O2 he must have put in.(Great job for a 20 year ASE Toyota Mechanic, eh?...that wasn't the all of it, either, trust me!lol) From what Flecker is telling me, THAT WIRE NEEDS TO BE SHIELDED! Why? Because,(excuse my crude explanation), it's not filtering out noise between the ECU-Power supply- and O2, thus creating a mis-reading by the ECU that "WE NEED TO GO BACK INTO OPEN LOOP". This COULD be why I'm not having as much power....but still running MUCH smoother.

3. My old ECU, for whatever reason, had either 'GIVEN UP' on that Sensor, burned out the section of the board that reads 02 readings, or, ....well, ....just finally crapped out on me! lol. You really need to do what Thook suggested and MAKE SURE that your ECU readings at the TPS connections, AFM connections, O2 Connections, are reading properly and similar. If not, I'M ONLY GUESSING, but I would imagine that can wreak GREAT havoc. The readings you get from the AFM and TPS, etc., when Unplugged, can only tell you one thing...."This Sensor is good, goofy or 'not great but ok' ". You also need to be 100% SURE that the 89 ECU is compatible, for #1, .....WORKING PROPERLY, #2.

4. Recheck all your grounds and wiring that's not too difficult to inspect, and basically......the only place to see how some of that is being read, ....again, ...at the ECU.

5. The dizzy gear notch can ALSO wreak havoc....Just ask Philbert or, I believe, 92 Toy. Bad pickups in that dizzy can also cause HUGE problems, and it's possible that mine are giving me trouble as well....Have to test it later when I figure out how! lol.

6. A single bad wire, plug wire, cap connection, Rotor quality, fuel pressure regulator, IACV, VSV, .....ANY of them could cause some of the problems you're having, but obviously not ALL of them. So, like Thook said, "LIST, LIST, LIST", double check everything and then make a plan of attack. IT'S CRUCIAL. Swapping can help, but if it's not the right part, or the part you're swapping is not 100%, or you've not cleared the ECU each time(or it's not even reading-regulating properly), etc., etc., ...they can cause you to rule something out that, technically, you should not be ruling out.

I'll keep an eye, and like I said, "i'm just throwing this out there", but they are things that DID cause me problems, so MAKE SURE you're reading the meter right, ...then start checking down a VERY LONG and laborious list, lol.

Again, Best Wishes,

Mark

1. CODES, CODES, CODES....yeah, and I know, when you have NO CODES, other than the obvious one that you're working on,....and it seems to STILL DOG, ...."GRRR", lol. However, one thing to consider, NOT SAYING TO GO BUY ONE, is that Flecker and I messed with this thing for 9-10 hours, STRAIGHT, ....NO CODES, a few funny readings, and after adjusting everything back to 'SPEC', .....CRAPOLA! HOWEVER-2;, lol.... When replacing my ECU with the one Flecker brought over? 2 CODES, IMMEDIATELY! Not to mention, the ECU I HAD WAS NOT PROPERLY relaying signal to certain sensors, most likely, after misreading or improperly sending signal to the NEXT SENSOR, etc. BAD ECU= OFTEN THROWS NO CODES! ....From what I've been reading lately.

2. This replacement ECU is throwing an O2 Code on mine........BUT IT'S BRAND NEW! However, hehehe; The PO had torn back the shielded wire that it comes with, factory, to just simply connect up the 'SINGLE WIRE' to the New O2 he must have put in.(Great job for a 20 year ASE Toyota Mechanic, eh?...that wasn't the all of it, either, trust me!lol) From what Flecker is telling me, THAT WIRE NEEDS TO BE SHIELDED! Why? Because,(excuse my crude explanation), it's not filtering out noise between the ECU-Power supply- and O2, thus creating a mis-reading by the ECU that "WE NEED TO GO BACK INTO OPEN LOOP". This COULD be why I'm not having as much power....but still running MUCH smoother.

3. My old ECU, for whatever reason, had either 'GIVEN UP' on that Sensor, burned out the section of the board that reads 02 readings, or, ....well, ....just finally crapped out on me! lol. You really need to do what Thook suggested and MAKE SURE that your ECU readings at the TPS connections, AFM connections, O2 Connections, are reading properly and similar. If not, I'M ONLY GUESSING, but I would imagine that can wreak GREAT havoc. The readings you get from the AFM and TPS, etc., when Unplugged, can only tell you one thing...."This Sensor is good, goofy or 'not great but ok' ". You also need to be 100% SURE that the 89 ECU is compatible, for #1, .....WORKING PROPERLY, #2.

4. Recheck all your grounds and wiring that's not too difficult to inspect, and basically......the only place to see how some of that is being read, ....again, ...at the ECU.

5. The dizzy gear notch can ALSO wreak havoc....Just ask Philbert or, I believe, 92 Toy. Bad pickups in that dizzy can also cause HUGE problems, and it's possible that mine are giving me trouble as well....Have to test it later when I figure out how! lol.

6. A single bad wire, plug wire, cap connection, Rotor quality, fuel pressure regulator, IACV, VSV, .....ANY of them could cause some of the problems you're having, but obviously not ALL of them. So, like Thook said, "LIST, LIST, LIST", double check everything and then make a plan of attack. IT'S CRUCIAL. Swapping can help, but if it's not the right part, or the part you're swapping is not 100%, or you've not cleared the ECU each time(or it's not even reading-regulating properly), etc., etc., ...they can cause you to rule something out that, technically, you should not be ruling out.

I'll keep an eye, and like I said, "i'm just throwing this out there", but they are things that DID cause me problems, so MAKE SURE you're reading the meter right, ...then start checking down a VERY LONG and laborious list, lol.

Again, Best Wishes,

Mark

#40

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

Thanks guys again for your info and help.

I did this today. Pics will show what I found.

This is where the vac line from the top of the FPR ends up on the 86 (problem child).

This is the 89. It goes to this valve first then over to the thingy on the intake. I put the 89 pic in here for referrence.

Still have to do the fuel pressure.

The flapper in the AFM moves freely and the timing is at 5*BTDC. I haven't checked the valve adjustment yet. That's something else that needs to go on the to-do list.

It's running so rich so when I enduce a major vac leak it leans the mixture out. Thanks for the offer on the AFM. I will keep that in mind. Don't worry I'm not going to use any more 89 parts to swap out. I still need to put a few things back in their original place. My O2 sensor is a new Bosch and it doesn't have any protective coating on the wire. Sorry this post is so jumpy. I'm trying to condense my replies so y'all don't have to read a novel. LOL. I will work on the list tonight, because I am loosing track of what I have done and what needs to be done with results.

Mark, my responses are in red above. I will print out this whole thread and make my list from what has been done and what needs to be done.

sb5walker...Follow the vacuum tube from the top of the fuel pressure regulator back to the vsv to identify it. But it certainly could be the A/C Idle-Up vsv as thook mentioned. I doubt this is your problem, tho.

This is where the vac line from the top of the FPR ends up on the 86 (problem child).

This is the 89. It goes to this valve first then over to the thingy on the intake. I put the 89 pic in here for referrence.

Still have to do the fuel pressure.

whokrz.....There are only 2 things that I know of that have not been covered.

The flapper in the air flow meter can be stuck open causing an incorrect signal to the ecu.

There may be a leak in the hose between the throttle body and the air flow meter. The part that connects to the throttle body is notorious for having cracks. This will also cause the air flow meter to send an incorrect signal to the ecu.

Also I did not read that you checked the timing or adjusted the valves as thook suggested. At least the chain guides are still there. From the picture I am assuming that there is not slack in the timing chain that may cause it to jump a tooth.

The flapper in the air flow meter can be stuck open causing an incorrect signal to the ecu.

There may be a leak in the hose between the throttle body and the air flow meter. The part that connects to the throttle body is notorious for having cracks. This will also cause the air flow meter to send an incorrect signal to the ecu.

Also I did not read that you checked the timing or adjusted the valves as thook suggested. At least the chain guides are still there. From the picture I am assuming that there is not slack in the timing chain that may cause it to jump a tooth.

Chefyota4X4.......Well, one thing I was curious about, maybe you could clear it up....You said you pulled the Brake Booster Vacuum line....and it 'cleared up'??? Don't want to say anything until you clarify that, but I will ASK, 'say WHAT?' hahaha. I can't imagine the motor smoothing out with a GIGANTIC Vacuum leak, ...which is also something that could cause many of your symptoms. I recently went through, as you know, lol...several PAGES of searching for causes to my issue(which IS similar, like you said, but not identical).

Chefyota4X4....Just wanted to throw in here, Alan;

1. CODES, CODES, CODES....yeah, and I know, when you have NO CODES, other than the obvious one that you're working on,....and it seems to STILL DOG, ...."GRRR", lol. However, one thing to consider, NOT SAYING TO GO BUY ONE, is that Flecker and I messed with this thing for 9-10 hours, STRAIGHT, ....NO CODES, a few funny readings, and after adjusting everything back to 'SPEC', .....CRAPOLA! HOWEVER-2;, lol.... When replacing my ECU with the one Flecker brought over? 2 CODES, IMMEDIATELY! Not to mention, the ECU I HAD WAS NOT PROPERLY relaying signal to certain sensors, most likely, after misreading or improperly sending signal to the NEXT SENSOR, etc. BAD ECU= OFTEN THROWS NO CODES! ....From what I've been reading lately.

No codes right now.

2. This replacement ECU is throwing an O2 Code on mine........BUT IT'S BRAND NEW! However, hehehe; The PO had torn back the shielded wire that it comes with, factory, to just simply connect up the 'SINGLE WIRE' to the New O2 he must have put in.(Great job for a 20 year ASE Toyota Mechanic, eh?...that wasn't the all of it, either, trust me!lol) From what Flecker is telling me, THAT WIRE NEEDS TO BE SHIELDED! Why? Because,(excuse my crude explanation), it's not filtering out noise between the ECU-Power supply- and O2, thus creating a mis-reading by the ECU that "WE NEED TO GO BACK INTO OPEN LOOP". This COULD be why I'm not having as much power....but still running MUCH smoother.

My new Bosch O2 doesn't have the shield on the wire.

3. My old ECU, for whatever reason, had either 'GIVEN UP' on that Sensor, burned out the section of the board that reads 02 readings, or, ....well, ....just finally crapped out on me! lol. You really need to do what Thook suggested and MAKE SURE that your ECU readings at the TPS connections, AFM connections, O2 Connections, are reading properly and similar. If not, I'M ONLY GUESSING, but I would imagine that can wreak GREAT havoc. The readings you get from the AFM and TPS, etc., when Unplugged, can only tell you one thing...."This Sensor is good, goofy or 'not great but ok' ". You also need to be 100% SURE that the 89 ECU is compatible, for #1, .....WORKING PROPERLY, #2.

4. Recheck all your grounds and wiring that's not too difficult to inspect, and basically......the only place to see how some of that is being read, ....again, ...at the ECU.

No matter where I touch the engine with an ohm meter it shows .5 ohms. I wiggled the 4 grounds on the engine and all seem secure.

5. The dizzy gear notch can ALSO wreak havoc....Just ask Philbert or, I believe, 92 Toy. Bad pickups in that dizzy can also cause HUGE problems, and it's possible that mine are giving me trouble as well....Have to test it later when I figure out how! lol.

What and where is the notch on the dizzy gear? I sit the dizzy in with the engine at TDC #1 valves closed and rotor pointing to #1.

6. A single bad wire, plug wire, cap connection, Rotor quality, fuel pressure regulator, IACV, VSV, .....ANY of them could cause some of the problems you're having, but obviously not ALL of them. So, like Thook said, "LIST, LIST, LIST", double check everything and then make a plan of attack. IT'S CRUCIAL. Swapping can help, but if it's not the right part, or the part you're swapping is not 100%, or you've not cleared the ECU each time(or it's not even reading-regulating properly), etc., etc., ...they can cause you to rule something out that, technically, you should not be ruling out.

The list is my priority tonight.

I'll keep an eye, and like I said, "i'm just throwing this out there", but they are things that DID cause me problems, so MAKE SURE you're reading the meter right, ...then start checking down a VERY LONG and laborious list, lol.

Again, Best Wishes,

Mark

1. CODES, CODES, CODES....yeah, and I know, when you have NO CODES, other than the obvious one that you're working on,....and it seems to STILL DOG, ...."GRRR", lol. However, one thing to consider, NOT SAYING TO GO BUY ONE, is that Flecker and I messed with this thing for 9-10 hours, STRAIGHT, ....NO CODES, a few funny readings, and after adjusting everything back to 'SPEC', .....CRAPOLA! HOWEVER-2;, lol.... When replacing my ECU with the one Flecker brought over? 2 CODES, IMMEDIATELY! Not to mention, the ECU I HAD WAS NOT PROPERLY relaying signal to certain sensors, most likely, after misreading or improperly sending signal to the NEXT SENSOR, etc. BAD ECU= OFTEN THROWS NO CODES! ....From what I've been reading lately.

No codes right now.

2. This replacement ECU is throwing an O2 Code on mine........BUT IT'S BRAND NEW! However, hehehe; The PO had torn back the shielded wire that it comes with, factory, to just simply connect up the 'SINGLE WIRE' to the New O2 he must have put in.(Great job for a 20 year ASE Toyota Mechanic, eh?...that wasn't the all of it, either, trust me!lol) From what Flecker is telling me, THAT WIRE NEEDS TO BE SHIELDED! Why? Because,(excuse my crude explanation), it's not filtering out noise between the ECU-Power supply- and O2, thus creating a mis-reading by the ECU that "WE NEED TO GO BACK INTO OPEN LOOP". This COULD be why I'm not having as much power....but still running MUCH smoother.

My new Bosch O2 doesn't have the shield on the wire.

3. My old ECU, for whatever reason, had either 'GIVEN UP' on that Sensor, burned out the section of the board that reads 02 readings, or, ....well, ....just finally crapped out on me! lol. You really need to do what Thook suggested and MAKE SURE that your ECU readings at the TPS connections, AFM connections, O2 Connections, are reading properly and similar. If not, I'M ONLY GUESSING, but I would imagine that can wreak GREAT havoc. The readings you get from the AFM and TPS, etc., when Unplugged, can only tell you one thing...."This Sensor is good, goofy or 'not great but ok' ". You also need to be 100% SURE that the 89 ECU is compatible, for #1, .....WORKING PROPERLY, #2.

4. Recheck all your grounds and wiring that's not too difficult to inspect, and basically......the only place to see how some of that is being read, ....again, ...at the ECU.

No matter where I touch the engine with an ohm meter it shows .5 ohms. I wiggled the 4 grounds on the engine and all seem secure.

5. The dizzy gear notch can ALSO wreak havoc....Just ask Philbert or, I believe, 92 Toy. Bad pickups in that dizzy can also cause HUGE problems, and it's possible that mine are giving me trouble as well....Have to test it later when I figure out how! lol.

What and where is the notch on the dizzy gear? I sit the dizzy in with the engine at TDC #1 valves closed and rotor pointing to #1.

6. A single bad wire, plug wire, cap connection, Rotor quality, fuel pressure regulator, IACV, VSV, .....ANY of them could cause some of the problems you're having, but obviously not ALL of them. So, like Thook said, "LIST, LIST, LIST", double check everything and then make a plan of attack. IT'S CRUCIAL. Swapping can help, but if it's not the right part, or the part you're swapping is not 100%, or you've not cleared the ECU each time(or it's not even reading-regulating properly), etc., etc., ...they can cause you to rule something out that, technically, you should not be ruling out.

The list is my priority tonight.

I'll keep an eye, and like I said, "i'm just throwing this out there", but they are things that DID cause me problems, so MAKE SURE you're reading the meter right, ...then start checking down a VERY LONG and laborious list, lol.

Again, Best Wishes,

Mark