Feeler: 3.4L TURBO manifold group buy?

#62

Originally Posted by node

Several of the board members are working with me to produce the kit. Once I have a prototype made up for the manifold, they will immediatly be available just like the 5VZ MR2 Turbo manifold is now. The "kit" will take a little more time. www.MR2Guru.com has agreed to distribute the 4runner, prerunner and T100 manifolds and kit once they are available. That way you guys can buy these parts from a respected, well established buissness. They are about to redo their website to include toyota trucks

oly884, you are correct, through gearing you dont need more power in 4L but if you are towing somthing big or just want to pass when going uphill the extra torque and horsepower will be VERY noticeable. We are even throwing around the idea of an electronic turbo enable switch so that you wont need to run premium unless you enguage the boost, very nifty. So basically when you need extra power for towing you could flip a switch that would enable the boost. Cool huh?

oly884, you are correct, through gearing you dont need more power in 4L but if you are towing somthing big or just want to pass when going uphill the extra torque and horsepower will be VERY noticeable. We are even throwing around the idea of an electronic turbo enable switch so that you wont need to run premium unless you enguage the boost, very nifty. So basically when you need extra power for towing you could flip a switch that would enable the boost. Cool huh?

As for passing, etc, bingo you nailed it. I forgot to mention the reason that people would buy a turbo or supercharger would be to have that extra power for towing, passing, and simply for fun.

#64

Registered User

Thread Starter

Join Date: Nov 2004

Location: Blue Ridge Mountains NC

Posts: 177

Likes: 0

Received 0 Likes

on

0 Posts

The 3.4L kit will have the stock boost set at 7psi and you can use a boost controller to raise the boost like you can with practically any turbo system. The 3.0 kit will probably have a 3 or 4 psi actuator. Again, you could use a boost controller to raise that to whatever you want once you do some fuel mods  .

.

The idea of a turbo dissable would basically be a solinoid to lock the wastegate open to improve gas mileage and keep the turbo from spooling. Thats just a possible additional thing for people who only want some extra kick once in a while. It may or may not be available bassed on the interest in that component.

The reason for the lower boost setting on the 3.0 kit is due to fueling issues. I have run 8 psi intercooled on my 5vz and I know the stock computer keeps everything under control but I have not used a turbo on the 3VZ yet. Several camry guys have done so with great success and very suprising power gains. I would like to verify what the stock ECU can handle before throwing a large amount of power at that engine.

.

. The idea of a turbo dissable would basically be a solinoid to lock the wastegate open to improve gas mileage and keep the turbo from spooling. Thats just a possible additional thing for people who only want some extra kick once in a while. It may or may not be available bassed on the interest in that component.

The reason for the lower boost setting on the 3.0 kit is due to fueling issues. I have run 8 psi intercooled on my 5vz and I know the stock computer keeps everything under control but I have not used a turbo on the 3VZ yet. Several camry guys have done so with great success and very suprising power gains. I would like to verify what the stock ECU can handle before throwing a large amount of power at that engine.

Last edited by node; 12-05-2005 at 08:00 PM.

#65

Registered User

Join Date: Jun 2003

Location: Vancouver, Canada

Posts: 943

Likes: 0

Received 0 Likes

on

0 Posts

the 3vz in your 4runner is a different breed  the 3.slow the headgaskets in these were the biggest issue thats what prevented any turbo kit development as far as i know.

the 3.slow the headgaskets in these were the biggest issue thats what prevented any turbo kit development as far as i know.

oh and i love your idea of locking wastegate open! You can have the little actuator controled by a piggyback or something too so when you swithc to map A you get boost and map b is economy mode

the 3.slow the headgaskets in these were the biggest issue thats what prevented any turbo kit development as far as i know.

the 3.slow the headgaskets in these were the biggest issue thats what prevented any turbo kit development as far as i know.oh and i love your idea of locking wastegate open! You can have the little actuator controled by a piggyback or something too so when you swithc to map A you get boost and map b is economy mode

#66

Contributing Member

Originally Posted by node

The reason for the lower boost setting on the 3.0 kit is due to fueling issues. I have run 8 psi intercooled on my 5vz and I know the stock computer keeps everything under control but I have not used a turbo on the 3VZ yet. Several camry guys have done so with great success and very suprising power gains. I would like to verify what the stock ECU can handle before throwing a large amount of power at that engine.

Mine is a 1996 so that is likely the worst case and I wanted to be sure the computer could handle the boost safely.

Very smart to keep the boost lower on the 3VZ, even a few psi will be VERY noticable, yet much safer on those motors.

Last edited by MTL_4runner; 12-06-2005 at 06:32 AM.

#67

Registered User

Join Date: Jun 2003

Location: Vancouver, Canada

Posts: 943

Likes: 0

Received 0 Likes

on

0 Posts

Jamie,

i would always use some sort of piggy back controler to get the safest power out of the engine. You can see a thread abou tthe smt6 here in yotatech about that unit. That is what i have used in my 96 Tacoma for over 3 years and 50k km now supercharged at 10psi.s

i would always use some sort of piggy back controler to get the safest power out of the engine. You can see a thread abou tthe smt6 here in yotatech about that unit. That is what i have used in my 96 Tacoma for over 3 years and 50k km now supercharged at 10psi.s

#68

Registered User

Thread Starter

Join Date: Nov 2004

Location: Blue Ridge Mountains NC

Posts: 177

Likes: 0

Received 0 Likes

on

0 Posts

Guys, I just wanted to let you see that we are actually working on this stuff. These are pics of one of the prototypes for the 5VZ-FE MR2 application. The welds are mig on the prototype but will be tig and much cleaner on the final product. As you can see the flanges are very clean. Those are the same flanges that will be used to produce the truck manifold.

Please excuse the dirty engine and car. It has been sitting outside awaiting a EMS, turbo etc..

Please excuse the dirty engine and car. It has been sitting outside awaiting a EMS, turbo etc..

Last edited by node; 12-06-2005 at 08:03 PM.

#69

Registered User

Originally Posted by marko3xl3

3" would be too much. You'd only want to go to 2.5". With 3" you wouldn't have any backpressure which would kill your "UMPH" and it is questionable if your high end would remain stable either.

The turbine in the hotside of the turbo gives your engine all the backpressure it could ever want (and then some) Once the exhuast passes by the turbine you will want the largest benificial downpipe you can get your hands on. The reason being it lowers EGTs That is reason enough - particularly for those of us playing around with 6+ Liters of turbo charged diesel power...

(this is why you see the duramaxx/cummins/powerstroke guys are dumping the stock 3"-3.5" exhausts for 5+" exhausts...

(this is why you see the duramaxx/cummins/powerstroke guys are dumping the stock 3"-3.5" exhausts for 5+" exhausts...Anyhoo, this REALLY excites me, but at the same time makes me sad... My 3vze has 268,000 on the clock and ive maintained her meticulously but I have also driven her hard.... I want to do a kit like this, but honestly Im afraid to. I think Ill have to have the 3vze rebuilt or rebuild it myself first...unless I could get a kit and detune (deboost?) so that it only generates say 50 additional hp?

Last edited by Bumpin' Yota; 12-07-2005 at 09:13 AM.

#71

Registered User

hahahaa if I swap it's getting a 383 with a 671 blower and a 4L80e, shift kit, 3000stall, and a moser 12bolt, 4link, with 4:55 gears!!

oh wait I havent won the lotto...damn nevermind..lol

oh wait I havent won the lotto...damn nevermind..lol

Last edited by Bumpin' Yota; 12-07-2005 at 05:07 PM.

#72

Registered User

Join Date: Nov 2004

Location: Mona, Utah

Posts: 119

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Bumpin' Yota

hahahaa if I swap it's getting a 383 with a 671 blower and a 4L80e, shift kit, 3000stall, and a moser 12bolt, 4link, with 4:55 gears!!

oh wait I havent won the lotto...damn nevermind..lol

oh wait I havent won the lotto...damn nevermind..lol

#73

Registered User

Join Date: Jun 2003

Location: Vancouver, Canada

Posts: 943

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Bumpin' Yota

I know you nipped this in the bud Node, but I'd also like to address this.

The turbine in the hotside of the turbo gives your engine all the backpressure it could ever want (and then some) Once the exhuast passes by the turbine you will want the largest benificial downpipe you can get your hands on. The reason being it lowers EGTs That is reason enough - particularly for those of us playing around with 6+ Liters of turbo charged diesel power... (this is why you see the duramaxx/cummins/powerstroke guys are dumping the stock 3"-3.5" exhausts for 5+" exhausts...

(this is why you see the duramaxx/cummins/powerstroke guys are dumping the stock 3"-3.5" exhausts for 5+" exhausts...

The turbine in the hotside of the turbo gives your engine all the backpressure it could ever want (and then some) Once the exhuast passes by the turbine you will want the largest benificial downpipe you can get your hands on. The reason being it lowers EGTs That is reason enough - particularly for those of us playing around with 6+ Liters of turbo charged diesel power...

(this is why you see the duramaxx/cummins/powerstroke guys are dumping the stock 3"-3.5" exhausts for 5+" exhausts...

(this is why you see the duramaxx/cummins/powerstroke guys are dumping the stock 3"-3.5" exhausts for 5+" exhausts... Timing control affects EGTs.....and believ it or not Water injection.

Timing control affects EGTs.....and believ it or not Water injection.I doubt this 3" DP would create a HUGE enough effect at the boost its going to put out that you may really thing. Considering your looking at around 7-10psi...hell stock exhaust collectors and stock exhaust with 10psi supercharged really hits home too

But i moniter things with EGT gauge.

But i moniter things with EGT gauge.

Last edited by Weasy2k; 12-07-2005 at 09:40 PM.

#74

Registered User

Join Date: Jun 2003

Location: Vancouver, Canada

Posts: 943

Likes: 0

Received 0 Likes

on

0 Posts

And here is some input from toysrme......always there for some good information!

Gotta be split into 2....

[quote=Toysrme]

OK gonna hit on a bunch of things here in one post. It's long, so deal with it!

The best exhaust...... Is always no exhaust... The next best exhaust for a turbocharged vehicle is still no exhaust. The next best one for an N/A vehicle is one incorporating a tuned resonance chamber (Tuned pipe), where at a very small portion of an RPM range, a resonance will be created & who's pressure waves will help pull exhaust from the chamber.

Backpressure has some effect on EGT's, but your main concern with them is going to be the quality of your combustion in the chambers (a mix of fuel ratio, ignition, cam timing).

Let's all remember that anything 2.5" & bigger from the downpipe back is gonna be "big enough" for the most part. Anything more is candy. The less post turbine restriction, the better. Now... Start playing with your merge & uppipe size, and you can make some real interesting stuff happen!

The 3vz-e compression ratio is only 9:1 (Compared to the 9.6 on VZ block FE heads). Using a CT-26 off a Mark3 Supra (stock wastegate 5psi). The peak effective compression ratio is only going come up to 9.58:1 compression ratio! That's only the stock vz-fe compression ratio! (9.6:1)

(For comparison, a 3vz-e with heads warped out of spec that are milled back to flat is going to get a bump to around 9.6:1!)

10psi would result in an 11.5:1 CR.

(The math I used: Assuming the 3vz-e has a peak volumetric efficiency of 80%. Worse case, if the peak VE is 85%, the CR bumps to 10:1 for 5psi, 12.5:1CR @ 10psi. It's not normal for SOHC 2 valve engines to be more than 80% efficient stock, but there's the result if you're interested.

With concerning blowing head gaskets, the big thing under boost is how much the effective compression ratio rises. At these boost levels on that engine, there really isn't a problem to worry over. Such a minor bump in CR wouldn't hurt anything that's in good shape to begin with. (Remember psi doesn't make power! The mass of the charge does! A larger turbo @ low psi will be able to kill a small one @ high psi, at the expensive of response! Because the chosen CT-26's are not small turbos & not huge - they can provide lots of power, quickly, at relatively low psi.)

In my opinion, if a compression test shows 155psi on the lowest cylinder, the rings, valves & valve timing are all up to a turbo. Down past 150 would be OK, but I'd want to find out where the compression is going. Put some oil in the cylinder & retest. (If pressure goes up bigtime, the rings have some wear, otherwise leakage @ the valves. Obviously, abnormally low compression between cylinders, or on a single cylinder normally spells a head gasket problem!)

Toyota specs:

Normal 171psi

Low 142psi

No more than 14psi difference

********************

The boost controller idea for 0 boost I would avoid. The turbine & compressor wheel can be large restrictions in flow when they're not "pulling their own weight". Keep in mind that even tho a turbo is not making "positive" psig, that doesn't mean it's not doing anything. Letting the turbo spool around is a good thing for economy. Tho their airflow is exponentially better as the RPM rises (& it normally takes a few ten thousand rpm to make good positive psi), that's not the whole story. Where you may be making 8-5inHG ov vacuum just cruising down the highway N/A, with a turbo it may go on up to 0inHg & kick into positive with a light load (like going up a hill).

If they're not allowed to pay for themselves like that, you're going to wind up with worse mileage with the turbo. Being able to partly spool (& decrease vacuum, or go ahead & spool into a few psi under an engine load - at light-medium throttle) is what ensures that a turbo will provide the same economy, if not a bit more under certain conditions!

ENd of first half

Gotta be split into 2....

[quote=Toysrme]

OK gonna hit on a bunch of things here in one post. It's long, so deal with it!

The best exhaust...... Is always no exhaust... The next best exhaust for a turbocharged vehicle is still no exhaust. The next best one for an N/A vehicle is one incorporating a tuned resonance chamber (Tuned pipe), where at a very small portion of an RPM range, a resonance will be created & who's pressure waves will help pull exhaust from the chamber.

Backpressure has some effect on EGT's, but your main concern with them is going to be the quality of your combustion in the chambers (a mix of fuel ratio, ignition, cam timing).

Let's all remember that anything 2.5" & bigger from the downpipe back is gonna be "big enough" for the most part. Anything more is candy. The less post turbine restriction, the better. Now... Start playing with your merge & uppipe size, and you can make some real interesting stuff happen!

The 3vz-e compression ratio is only 9:1 (Compared to the 9.6 on VZ block FE heads). Using a CT-26 off a Mark3 Supra (stock wastegate 5psi). The peak effective compression ratio is only going come up to 9.58:1 compression ratio! That's only the stock vz-fe compression ratio! (9.6:1)

(For comparison, a 3vz-e with heads warped out of spec that are milled back to flat is going to get a bump to around 9.6:1!)

10psi would result in an 11.5:1 CR.

(The math I used: Assuming the 3vz-e has a peak volumetric efficiency of 80%. Worse case, if the peak VE is 85%, the CR bumps to 10:1 for 5psi, 12.5:1CR @ 10psi. It's not normal for SOHC 2 valve engines to be more than 80% efficient stock, but there's the result if you're interested.

With concerning blowing head gaskets, the big thing under boost is how much the effective compression ratio rises. At these boost levels on that engine, there really isn't a problem to worry over. Such a minor bump in CR wouldn't hurt anything that's in good shape to begin with. (Remember psi doesn't make power! The mass of the charge does! A larger turbo @ low psi will be able to kill a small one @ high psi, at the expensive of response! Because the chosen CT-26's are not small turbos & not huge - they can provide lots of power, quickly, at relatively low psi.)

In my opinion, if a compression test shows 155psi on the lowest cylinder, the rings, valves & valve timing are all up to a turbo. Down past 150 would be OK, but I'd want to find out where the compression is going. Put some oil in the cylinder & retest. (If pressure goes up bigtime, the rings have some wear, otherwise leakage @ the valves. Obviously, abnormally low compression between cylinders, or on a single cylinder normally spells a head gasket problem!)

Toyota specs:

Normal 171psi

Low 142psi

No more than 14psi difference

********************

The boost controller idea for 0 boost I would avoid. The turbine & compressor wheel can be large restrictions in flow when they're not "pulling their own weight". Keep in mind that even tho a turbo is not making "positive" psig, that doesn't mean it's not doing anything. Letting the turbo spool around is a good thing for economy. Tho their airflow is exponentially better as the RPM rises (& it normally takes a few ten thousand rpm to make good positive psi), that's not the whole story. Where you may be making 8-5inHG ov vacuum just cruising down the highway N/A, with a turbo it may go on up to 0inHg & kick into positive with a light load (like going up a hill).

If they're not allowed to pay for themselves like that, you're going to wind up with worse mileage with the turbo. Being able to partly spool (& decrease vacuum, or go ahead & spool into a few psi under an engine load - at light-medium throttle) is what ensures that a turbo will provide the same economy, if not a bit more under certain conditions!

ENd of first half

Last edited by Weasy2k; 12-07-2005 at 09:55 PM.

#75

Registered User

Join Date: Jun 2003

Location: Vancouver, Canada

Posts: 943

Likes: 0

Received 0 Likes

on

0 Posts

********************

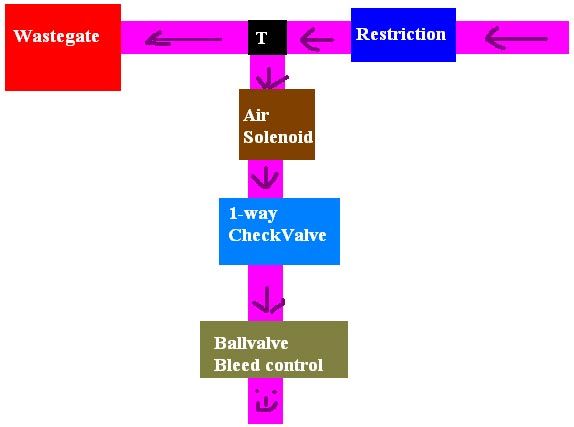

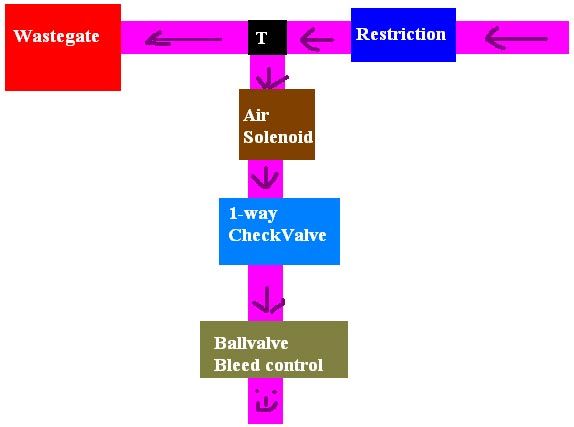

Personally, if it's imperative to run lower than stock wastegate settings, I think it would be better to simply lower boost (remaining positive, not 0psi) - then use a ball valve restrictor & solenoid to vent boost to make whatever higher psi you want.

1) Modify the wastegate actuator rod to be smaller. The best example is to run the rod through a die so it's threaded. Then use a nuts & washers to hold the spring, and thus hold the wastegate rod under tension.

This in turn will lower boost for pennies!!!

(You can see in the example pics how it works.)

2) You can get very complex combinations of a ballvalve, pop valve (To keep pressure from the wastegate at all until it reaches a level - eleminating wastegate creep & cutting spool time down) & solenoids to make complex boost controls for semi-cheap. Or make one that's really cheap & just has two settings. Low & high psi.

Here is how I do it. (It's the common way.)

It's pretty obvious how it works. The restrictor lowers the size of the bleed you need to control boost. The solenoid is opened or closed electrically, saving people from routing boost hoses & such into the cab. The check valve is just for safety incase the solenoid leaks a little bit under vacuum. The ball valve controls how much boost is bleed off - controlling the your boost!

Variations:

You can have a basic electronic control using a boost pressure switch to control the solenoid - keep in mind it's gonna vary a bit from one way to another.

You can add more solenoid/restrictor loops to varry boost further.

Whatever.

Anyway, you could fairly easily adjust it to have say 3psi & 7psi. Obviously do whatever you want.

********************

I really see no problem running the stock 5psi wastegate & a ct-26 from a Supra on a 3vz-e. The mr2's turbo is going to choke off quickly on the v6. The only good reason to use it would be the twin entry housing & smaller A/R to spool faster.

But like stated several times, any medium sized turbo is going to spool instantly - as soon as you hit the gas, (or a big load hits the engine) count a couple tenths of a second & you've got positive manifold pressure.

Also, to make good power on the mr2 turbo, that means running more psi - which is the main concern of the 3vz-e crowd (Honestly, the main concern of anyone without the revised Metal Head Gaskets - i.e. early 5vz-fe owners also fall into that bunch!!!). While the supra ct26 will make plenty of power & lower psi levels - much safer for the head gaskets.

A 3vz-e @ a 12:1 A/F ratio is going to want 33lb/m to make roughly 280bhp.

38lb/m will make about 320bhp. A CT-26 off a supra flows about 33lb/m @ just 5psi.

I would expect anywhere between 280 & 300bhp on a 3vz-e+Supra CT-26. That's perfect!!! 3vz-e parts are not the strongest of the v6s, but they're far stronger than 3s-fe parts. The parts are plenty fine for atleast 350bhp before there is much chance of random catastrophic failures & 350 is a little conservative guesstimate.

In short, there is not going to be a more perfect marriage than the 3vz-e with the Supra's CT-26 @ the stock 5psi! It's going to be heaven between [b]zero]/b] lag, little spool time, huge torque & horsepower powerbands, lots of peak power, & pleanty of headroom for later.

********************

Fueling OBD-I is way easy because closed-loop doesn't tune as much & any closed loop changes don't carry over to open-loop.

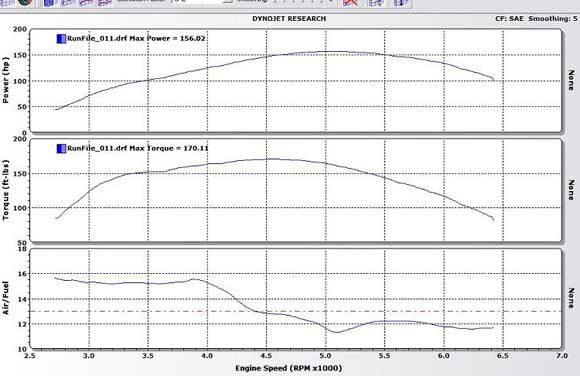

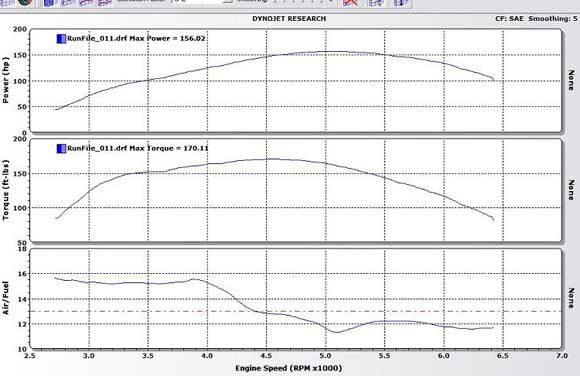

Most of the time, you wind up with a "hole" before an engine goes into open loop mode. This is because you can have power without being in open-loop. Ask anyone with an N/A supercharger, or a turbo that can spool below 4000rpm. If you see an A/F graph against a dyno plot, barring very, very good tuning (The kind NOT achieved at your local dyno shop, because:

1) They normally suck at tuning - yes... I said it & it's TRUE!!!

2) A dyno is not a great representation of what happens when driving.

You almost always wind up with atleast 1000, maybe 1500rpm+ of boost - without additional fuel!

The perfect example of both points I just made & that OBD-II is nasty! An OBD-II 5s-fte. (3s-gte manifold & turbo on a 5s-fe) tuned with an SAFC II by a tuning shop - on a dyno.

The turbo is spooling under 3000rpm (Don't forget it has a torque convertor!).

Yet fueling for boost doesn't come down to cracking 12's until long after throttle transition & boost have occurred! About 1500rpm of the engine having a load, having bosot & higher than normal power output.

This would be OK to drive around on, but any amount of flogging over time is going to lead in melting pistons, or rings. They just can't take that!

The problem, is having to balance when you add fuel. Too early & the ECU corrects for it (& OBD-II will carry corrections into open loop, making the whole thing lean). Too late & you're simply running lean! Conditions are also always changing & never the same! it can be a difficult problem.

With OBD-I it's no big deal! By simply using a boost pressure switch (Or an output linked to manifold pressure on a piggyback) set at say 2psi (3psi if you boost while cruising alot). Have it trigger a STDP relay that feeds the TPS supply voltage back to the ECU.

This get's the ECU into open-loop mode anytime boost is present, with side affects of:

Throttle transition = slightly enriching the mixture (on it's own), adding a couple steps of timing for a short amount of timing (DO NOT WORRYECU steps are normally in .25, or .5 * of crankshaft rotation, not 1 full degree!)

Transmission shift logic operates as if the throttle is all the way down.

Nothing but good comes from this & the TPS signal won't be read "out of spec" because the voltage is wildly too high.

Now that open-loop is present anytime enough boost is present to requiring fueling - you simply map your piggyback to fuel for the amount of boost -WITHOUT worrying about the RPM, or TPS signal being too low & having a tuning hole!

I will say, this makes very, very short work of fuel tuning for boost on OBD-I. With an SMT6, you can simply leave the stock setup intact & run extra injector<s>, tuned only via boost (MAP sensor, or if you're really cheap ass... A few BPS's @ different psi.) have ignition retard via boost. Then you've got a choice. Use the analog screen to tune the AFM some, OR use it to tune the lambda sensor<s>. While the AFM would be "traditional", changing the lambda sensors would be so slick it's crazy.

Regardless of the map you run, (Because remember we're tuning fuel based on boost! It's not a static correction!!!) You could lean out the engine some, then have closed loop tuning richen up for getting into boost. Possible combinations & neat-o applications are nearly endless!

Fuel correction for a 3vz-e is easy. This is how I did it & do it on 3vz-fe's.

The 3vz-e comes with injectors rated for 200cc @ 41psi. The stock fueling - like most Toyota's, runs between low & high 30's.

1) Walbro 190

2) Fuel pressure regulator setting pressure base pressure to 60psi. (A cheapie off ebay that just raises base fuel pressure, & a 1:1 ratio under boost works good.)

3) Piggyback capable of GOOD TUNING. SMT-7's E-Manage Gold & new unichips are nice, but not required.

Bare minimum for a good setup is going to be buying an SMT-6, or an upgraded E-Manage. (Otherwise you get into buying lots of separate hardware. SAFC + MSD6 + blah blah blah & still NOT have the amount of options) SMT-6 is a little harder to use than an E-Manage, but does a lot more & you don't have to waste money buying "upgrades". SMT-6 does everything it can do out of the box.(I'm not a fan of FTC's. They don't live tune, They only do two things, they're hella expensive. They loose from every angle you look at them - so I don't like them compared to their competition. That does [b]NOT[.b] mean they don't work well - The competition is just better & better for the money.)

4) Extra injector<s>. Best to have low imp.

*The stock pumps suck - like all stock wide spread N/A Toyota pumps. They just don't flow enough & die at high pressure. A 225+ is nice, but a 190 is all you need to make 400bhp+. A 255 is a waste of $10 & causes that much more re-tuning.

*The 200cc injectors become 240cc injectors @ 60psi.

*A good piggyback handles ignition retard under boost, along with any fuel tuning.

Quick fuel math 'cause you can learn to do the "real math" on your own time & this is normally accurate to within a few percent in the worst case. (Normally less than 1.5%.)

Injector flow /5 = horsepower capable of flowing * # of injectors

Then take 90% of that because you don't want to run an injector @ 100% duration.

200/5*6*.9= 216bhp worth of fuel. Stock

240/5*6*.9= 259bhp worth of fuel @ 60psi

I would go with 1 550, or 2 300'ish cc injectors.

550cc @ 60psi = 649cc, 649/5*.9 = 116bhp

300cc @ 60psi = 360cc, 300/5*.9 = 54bhp (times 2)

259bhp+116bhp = 375bhp worth of fuel. That's pleeeeeeeeanty of overhead for a CT-26 @ 5psi!

Let's turn around & say you only get 210bhp of fueling from the stock system, You've still got over 320bhp worth of fuel left. Nothing another 5psi of base fuel pressure & some minor piggyback tweaking can't take care of.

Now I'd like to throw something else out there... I love doing this trick I'm gonna sharing for two reasons:

1) Safety.

2) It works regardless of anything else.

Get on ebay & buy a boost pressure switch, AND a cold-start injector off a 3vz. (If you're doing the TPS trick I shared earlier, you've already got a BPS set at 2-3psi & you don't need to buy anything else!) Anytime there is much boost, you'll get either 18bhp worth of fuel (75cc @ 60psi, CSI's have 100% duration), or 36bhp worth of fuel (150cc @ 60psi).

This adds a measure of safety against leaning out while tuning, leaning out if there is some other screw-up & adds even more head room above & beyond anything else.

You can also have the BPS fire the stock cold-start injector (I think yall 3vz-e's have them too, I don't remember). Keep in mind, that the distribution from the stock CSI is highly uneven because of it's location & orientation.

Also, when adding injectors, they never spray towards a wall. Either fire them at an angle with the air stream, or better yet fire them INTO the incoming air stream.

Adding injectors is not complicated. CSI's are just drill your hole, take a couple of sheet metal screws & put dabs of silicon sealer (RTV) on them & go at it. (Works on both metal & rubber!)

Regular injectors can be trickier, but there is no reason to make them out to be hard to install. You can easily drill out a plate (or scrap of wood - please seal the wood with something first!) & epoxy / JB Weld it to the injector. Then use the same method to secure it (Drill the hole for the injector out, then use sheet metal screws t secure it - sealing it with RTV before finishing).

Anywho, That's what I think, & if I were doing another 3vz-te tomorrow, that's exactly how I'd set it up. SMT-6, extra injectors & ignition tuned off a MAP sensor (It can be just a 2bar.), BPS triggering open loop (via TPS) & firing a CSI @ low psi, and tuning LAMBDA (You can use the AFM cog to tweak the stock injectors if needed), how the fuel strategy would work.

& the components (CT-26 off a supra).

[/quote]

THat is all

Personally, if it's imperative to run lower than stock wastegate settings, I think it would be better to simply lower boost (remaining positive, not 0psi) - then use a ball valve restrictor & solenoid to vent boost to make whatever higher psi you want.

1) Modify the wastegate actuator rod to be smaller. The best example is to run the rod through a die so it's threaded. Then use a nuts & washers to hold the spring, and thus hold the wastegate rod under tension.

This in turn will lower boost for pennies!!!

(You can see in the example pics how it works.)

2) You can get very complex combinations of a ballvalve, pop valve (To keep pressure from the wastegate at all until it reaches a level - eleminating wastegate creep & cutting spool time down) & solenoids to make complex boost controls for semi-cheap. Or make one that's really cheap & just has two settings. Low & high psi.

Here is how I do it. (It's the common way.)

It's pretty obvious how it works. The restrictor lowers the size of the bleed you need to control boost. The solenoid is opened or closed electrically, saving people from routing boost hoses & such into the cab. The check valve is just for safety incase the solenoid leaks a little bit under vacuum. The ball valve controls how much boost is bleed off - controlling the your boost!

Variations:

You can have a basic electronic control using a boost pressure switch to control the solenoid - keep in mind it's gonna vary a bit from one way to another.

You can add more solenoid/restrictor loops to varry boost further.

Whatever.

Anyway, you could fairly easily adjust it to have say 3psi & 7psi. Obviously do whatever you want.

********************

I really see no problem running the stock 5psi wastegate & a ct-26 from a Supra on a 3vz-e. The mr2's turbo is going to choke off quickly on the v6. The only good reason to use it would be the twin entry housing & smaller A/R to spool faster.

But like stated several times, any medium sized turbo is going to spool instantly - as soon as you hit the gas, (or a big load hits the engine) count a couple tenths of a second & you've got positive manifold pressure.

Also, to make good power on the mr2 turbo, that means running more psi - which is the main concern of the 3vz-e crowd (Honestly, the main concern of anyone without the revised Metal Head Gaskets - i.e. early 5vz-fe owners also fall into that bunch!!!). While the supra ct26 will make plenty of power & lower psi levels - much safer for the head gaskets.

A 3vz-e @ a 12:1 A/F ratio is going to want 33lb/m to make roughly 280bhp.

38lb/m will make about 320bhp. A CT-26 off a supra flows about 33lb/m @ just 5psi.

I would expect anywhere between 280 & 300bhp on a 3vz-e+Supra CT-26. That's perfect!!! 3vz-e parts are not the strongest of the v6s, but they're far stronger than 3s-fe parts. The parts are plenty fine for atleast 350bhp before there is much chance of random catastrophic failures & 350 is a little conservative guesstimate.

In short, there is not going to be a more perfect marriage than the 3vz-e with the Supra's CT-26 @ the stock 5psi! It's going to be heaven between [b]zero]/b] lag, little spool time, huge torque & horsepower powerbands, lots of peak power, & pleanty of headroom for later.

********************

Fueling OBD-I is way easy because closed-loop doesn't tune as much & any closed loop changes don't carry over to open-loop.

Most of the time, you wind up with a "hole" before an engine goes into open loop mode. This is because you can have power without being in open-loop. Ask anyone with an N/A supercharger, or a turbo that can spool below 4000rpm. If you see an A/F graph against a dyno plot, barring very, very good tuning (The kind NOT achieved at your local dyno shop, because:

1) They normally suck at tuning - yes... I said it & it's TRUE!!!

2) A dyno is not a great representation of what happens when driving.

You almost always wind up with atleast 1000, maybe 1500rpm+ of boost - without additional fuel!

The perfect example of both points I just made & that OBD-II is nasty! An OBD-II 5s-fte. (3s-gte manifold & turbo on a 5s-fe) tuned with an SAFC II by a tuning shop - on a dyno.

The turbo is spooling under 3000rpm (Don't forget it has a torque convertor!).

Yet fueling for boost doesn't come down to cracking 12's until long after throttle transition & boost have occurred! About 1500rpm of the engine having a load, having bosot & higher than normal power output.

This would be OK to drive around on, but any amount of flogging over time is going to lead in melting pistons, or rings. They just can't take that!

The problem, is having to balance when you add fuel. Too early & the ECU corrects for it (& OBD-II will carry corrections into open loop, making the whole thing lean). Too late & you're simply running lean! Conditions are also always changing & never the same! it can be a difficult problem.

With OBD-I it's no big deal! By simply using a boost pressure switch (Or an output linked to manifold pressure on a piggyback) set at say 2psi (3psi if you boost while cruising alot). Have it trigger a STDP relay that feeds the TPS supply voltage back to the ECU.

This get's the ECU into open-loop mode anytime boost is present, with side affects of:

Throttle transition = slightly enriching the mixture (on it's own), adding a couple steps of timing for a short amount of timing (DO NOT WORRYECU steps are normally in .25, or .5 * of crankshaft rotation, not 1 full degree!)

Transmission shift logic operates as if the throttle is all the way down.

Nothing but good comes from this & the TPS signal won't be read "out of spec" because the voltage is wildly too high.

Now that open-loop is present anytime enough boost is present to requiring fueling - you simply map your piggyback to fuel for the amount of boost -WITHOUT worrying about the RPM, or TPS signal being too low & having a tuning hole!

I will say, this makes very, very short work of fuel tuning for boost on OBD-I. With an SMT6, you can simply leave the stock setup intact & run extra injector<s>, tuned only via boost (MAP sensor, or if you're really cheap ass... A few BPS's @ different psi.) have ignition retard via boost. Then you've got a choice. Use the analog screen to tune the AFM some, OR use it to tune the lambda sensor<s>. While the AFM would be "traditional", changing the lambda sensors would be so slick it's crazy.

Regardless of the map you run, (Because remember we're tuning fuel based on boost! It's not a static correction!!!) You could lean out the engine some, then have closed loop tuning richen up for getting into boost. Possible combinations & neat-o applications are nearly endless!

Fuel correction for a 3vz-e is easy. This is how I did it & do it on 3vz-fe's.

The 3vz-e comes with injectors rated for 200cc @ 41psi. The stock fueling - like most Toyota's, runs between low & high 30's.

1) Walbro 190

2) Fuel pressure regulator setting pressure base pressure to 60psi. (A cheapie off ebay that just raises base fuel pressure, & a 1:1 ratio under boost works good.)

3) Piggyback capable of GOOD TUNING. SMT-7's E-Manage Gold & new unichips are nice, but not required.

Bare minimum for a good setup is going to be buying an SMT-6, or an upgraded E-Manage. (Otherwise you get into buying lots of separate hardware. SAFC + MSD6 + blah blah blah & still NOT have the amount of options) SMT-6 is a little harder to use than an E-Manage, but does a lot more & you don't have to waste money buying "upgrades". SMT-6 does everything it can do out of the box.(I'm not a fan of FTC's. They don't live tune, They only do two things, they're hella expensive. They loose from every angle you look at them - so I don't like them compared to their competition. That does [b]NOT[.b] mean they don't work well - The competition is just better & better for the money.)

4) Extra injector<s>. Best to have low imp.

*The stock pumps suck - like all stock wide spread N/A Toyota pumps. They just don't flow enough & die at high pressure. A 225+ is nice, but a 190 is all you need to make 400bhp+. A 255 is a waste of $10 & causes that much more re-tuning.

*The 200cc injectors become 240cc injectors @ 60psi.

*A good piggyback handles ignition retard under boost, along with any fuel tuning.

Quick fuel math 'cause you can learn to do the "real math" on your own time & this is normally accurate to within a few percent in the worst case. (Normally less than 1.5%.)

Injector flow /5 = horsepower capable of flowing * # of injectors

Then take 90% of that because you don't want to run an injector @ 100% duration.

200/5*6*.9= 216bhp worth of fuel. Stock

240/5*6*.9= 259bhp worth of fuel @ 60psi

I would go with 1 550, or 2 300'ish cc injectors.

550cc @ 60psi = 649cc, 649/5*.9 = 116bhp

300cc @ 60psi = 360cc, 300/5*.9 = 54bhp (times 2)

259bhp+116bhp = 375bhp worth of fuel. That's pleeeeeeeeanty of overhead for a CT-26 @ 5psi!

Let's turn around & say you only get 210bhp of fueling from the stock system, You've still got over 320bhp worth of fuel left. Nothing another 5psi of base fuel pressure & some minor piggyback tweaking can't take care of.

Now I'd like to throw something else out there... I love doing this trick I'm gonna sharing for two reasons:

1) Safety.

2) It works regardless of anything else.

Get on ebay & buy a boost pressure switch, AND a cold-start injector off a 3vz. (If you're doing the TPS trick I shared earlier, you've already got a BPS set at 2-3psi & you don't need to buy anything else!) Anytime there is much boost, you'll get either 18bhp worth of fuel (75cc @ 60psi, CSI's have 100% duration), or 36bhp worth of fuel (150cc @ 60psi).

This adds a measure of safety against leaning out while tuning, leaning out if there is some other screw-up & adds even more head room above & beyond anything else.

You can also have the BPS fire the stock cold-start injector (I think yall 3vz-e's have them too, I don't remember). Keep in mind, that the distribution from the stock CSI is highly uneven because of it's location & orientation.

Also, when adding injectors, they never spray towards a wall. Either fire them at an angle with the air stream, or better yet fire them INTO the incoming air stream.

Adding injectors is not complicated. CSI's are just drill your hole, take a couple of sheet metal screws & put dabs of silicon sealer (RTV) on them & go at it. (Works on both metal & rubber!)

Regular injectors can be trickier, but there is no reason to make them out to be hard to install. You can easily drill out a plate (or scrap of wood - please seal the wood with something first!) & epoxy / JB Weld it to the injector. Then use the same method to secure it (Drill the hole for the injector out, then use sheet metal screws t secure it - sealing it with RTV before finishing).

Anywho, That's what I think, & if I were doing another 3vz-te tomorrow, that's exactly how I'd set it up. SMT-6, extra injectors & ignition tuned off a MAP sensor (It can be just a 2bar.), BPS triggering open loop (via TPS) & firing a CSI @ low psi, and tuning LAMBDA (You can use the AFM cog to tweak the stock injectors if needed), how the fuel strategy would work.

& the components (CT-26 off a supra).

[/quote]

THat is all

#76

Registered User

Join Date: Jun 2003

Location: Vancouver, Canada

Posts: 943

Likes: 0

Received 0 Likes

on

0 Posts

I would also like to add to help some confusion im noticing:

3vz-e

3.0L V6

Single OHC 16V (1 cam and 8v per side) engine

9.0:1 CR

Horrible Cooling problems in the head causing valve problems.

These came in the PU and 4runners that we know and love so much....

3vz-Fe

Quad Cam 24v

9.6:1 CR

Completly redeisnged head and internals...the ONLY thing that is the same as the truck engine is the block casting

Came in Lexi ES300 and Toyota Camery (im sure others as well)

People dont expect HUGE gains with a turbo on a 3vz-E engine this is a good way of helping give it that grunt it OH so needs! but dont try to push 300+ or else carry the approprate tools to replace HG's and exhaust valves!

3vz-e

3.0L V6

Single OHC 16V (1 cam and 8v per side) engine

9.0:1 CR

Horrible Cooling problems in the head causing valve problems.

These came in the PU and 4runners that we know and love so much....

3vz-Fe

Quad Cam 24v

9.6:1 CR

Completly redeisnged head and internals...the ONLY thing that is the same as the truck engine is the block casting

Came in Lexi ES300 and Toyota Camery (im sure others as well)

People dont expect HUGE gains with a turbo on a 3vz-E engine this is a good way of helping give it that grunt it OH so needs! but dont try to push 300+ or else carry the approprate tools to replace HG's and exhaust valves!

#79

Weasy

While it is true that there is a advantage to using OBD-I instead of OBD-II ecu's due to their inherent ability to correct for fuel shortage-- there is a way around it and its still better than messing with the old junk. OBD-II is much better at controlling fuel trim than the older computers due to the newer smog regulations and increased demand for efficiency from consumers.

All one has to do to take advantage of the ECU's ability to even out fuel curves is place a precision op-amp in the signal chain between the sensor and the ecu. We all know that supercharged engines need a lower a/f ratio than an NA engine, but the ecu will not let any aftermarket device alter the ratio forever-- it has been tried with many band-aid approaches and still won't work. The trick is to make the ECU think that it is doing what it is supposed to and not what the designer intended. If you modify the voltage from the pre and post 02 sensors to keep the same proportion of signal but at a lower voltage, then the ECU will in fact do all the tuning for you because it is interpreting the lower voltage as a lean condition and will increase the fuel pulse width to increase the voltage on the sensor to bring the signal up to engineered standards. What this will do is enable anyone to run any injectors just by creating different voltage differentials between the desired A/f ratio and the NA ratio.

Maybe one day I will actually assemble this device it really easy to build--only needs 3 precision op amps and the support components. (but if someone starts selling these-- all the aftermarket ECU companies will be out of business )

it really easy to build--only needs 3 precision op amps and the support components. (but if someone starts selling these-- all the aftermarket ECU companies will be out of business )

T

While it is true that there is a advantage to using OBD-I instead of OBD-II ecu's due to their inherent ability to correct for fuel shortage-- there is a way around it and its still better than messing with the old junk. OBD-II is much better at controlling fuel trim than the older computers due to the newer smog regulations and increased demand for efficiency from consumers.

All one has to do to take advantage of the ECU's ability to even out fuel curves is place a precision op-amp in the signal chain between the sensor and the ecu. We all know that supercharged engines need a lower a/f ratio than an NA engine, but the ecu will not let any aftermarket device alter the ratio forever-- it has been tried with many band-aid approaches and still won't work. The trick is to make the ECU think that it is doing what it is supposed to and not what the designer intended. If you modify the voltage from the pre and post 02 sensors to keep the same proportion of signal but at a lower voltage, then the ECU will in fact do all the tuning for you because it is interpreting the lower voltage as a lean condition and will increase the fuel pulse width to increase the voltage on the sensor to bring the signal up to engineered standards. What this will do is enable anyone to run any injectors just by creating different voltage differentials between the desired A/f ratio and the NA ratio.

Maybe one day I will actually assemble this device

it really easy to build--only needs 3 precision op amps and the support components. (but if someone starts selling these-- all the aftermarket ECU companies will be out of business )

it really easy to build--only needs 3 precision op amps and the support components. (but if someone starts selling these-- all the aftermarket ECU companies will be out of business )T

#80

Registered User

Join Date: Jun 2003

Location: Vancouver, Canada

Posts: 943

Likes: 0

Received 0 Likes

on

0 Posts

Yo duffdog....that LONG 2 posts was not from me but from toysrme, he will be posting soon, for some reason he is on a temp ban from a previous thing on this forum.

but in response i can talk about what you just said

While this is true in a good economical sense.....think of it from a tuning sense...what hes trying to say is that by tuning with ODB-I is easier because you don't have th ecu fighting with you as much as you wold the OBDII system due to the fact its very picky.

Now if you were a guy who wants more safe power from your engine...say 10psi TRD S/C MOST tuners know to not stick around 14.7 too long even at 70% throttle, this leads to overheating of the cyls/detonation. Now to correct this you normally with a piggyback add more fuel to the area....no problem right?....wrong...the stock ecu goes..."Wtfomgbbq something is not le right here" and proceeds to REMOVE fuel again because the 02 sensor is reading richer then 14.7.....so now your back where you started. Now you decide to try and fight it more....the OBDII system wins again by firing off a check engine light...yay....

A way to correct this is to have the ECU tricked into thinking it is at WOT above a given psi so that way you can tune to a proper AFR...this has been done using a SMT6 piggyback (i believe midiwall was the guy who did this...i still have his original post LONG time ago in the LARGE smt6 thread ), this works well for a 5spd but i haven't found out nor had the time to try to test this on the auto tranny just because the ecu will start sending erratic signals to the solenoids which will cause odd shifting patterns at moderate throttle (due to the ecu thinking its at WOT all the time).

), this works well for a 5spd but i haven't found out nor had the time to try to test this on the auto tranny just because the ecu will start sending erratic signals to the solenoids which will cause odd shifting patterns at moderate throttle (due to the ecu thinking its at WOT all the time).

With OBD-1...you can get away with more then 50% of the throttle! so all the above is not needed to be done SImple...

SImple...

That is why OBDII is a disadvantage for us people who want more power, but awsome for regular guys who just keep there trucks stock

Wat can be done that is very similar to your idea is using the SMT6 LAMBDA mode in which it takes your O2 sensor reading into the smt6 and you have all the play inthe world....add fuel and the smt6 will send a leaner signal to the ecu just enough to richen it a bit until the O2 sensor sends a little bit of a richer signal at which point the smt6 sends a signal to the stock ecu that its 14.7:1 when its really 13.2:1 or something.

The problem with this tho is that the smt6 can modify the o2 signal or the maf signal not both at same time which sucks...or you can take the 2 for one offer and get 2 smt6's

which sucks...or you can take the 2 for one offer and get 2 smt6's

But by running the smt6 to modify the maf signal (which really matters) and proper tuning with some tricks you can get the engine running fine...much like mine...10psi s/c 91 or 94 octane with a flip of a switch...been this way for 50k km

OK so i will run your little thing through a test here in my mind and what the ecu would do

YOu set your O2 sensor device to say 15.7 all the time so now your ecu will go and start adding fuel....and more fuel and more fuel until the trim reading is above 25% at which point your A) at 9:1afr because the ecu continues to add fuel B) that god damn check engine light will come back on again! DAMNIT stupid thing Why? because it sees that its adding more and more fuel but it still isnt getting a reading as its supposed to....fuel trim above 25% error

Why? because it sees that its adding more and more fuel but it still isnt getting a reading as its supposed to....fuel trim above 25% error

SECONDLY to this...when you go WOT your ecu SHUTS down its reading from o2 sensors and instead reads INCOMING air from the MAF sensor and adds fuel accordingly....now with stock injectors...fine this will work alright....but add 370cc injectors like i have in my 96 taco and holy ลลลล black smoke out the tail pipe

Why? MAF reads 20lbs of air coming in.....ECU puts out Xms cycle to the injectors...it doesn't kow what injectors you have in there...so it will hold those 370cc injectors OPEN for just the same amount of time as the 248cc stokers...which = allot of black smoke and again 9:1 afr....pooooooor running conditions.

I'm sure if that was easy.....then every single company would have done this

but in response i can talk about what you just said

While it is true that there is a advantage to using OBD-I instead of OBD-II ecu's due to their inherent ability to correct for fuel shortage-- there is a way around it and its still better than messing with the old junk. OBD-II is much better at controlling fuel trim than the older computers due to the newer smog regulations and increased demand for efficiency from consumers.

Now if you were a guy who wants more safe power from your engine...say 10psi TRD S/C MOST tuners know to not stick around 14.7 too long even at 70% throttle, this leads to overheating of the cyls/detonation. Now to correct this you normally with a piggyback add more fuel to the area....no problem right?....wrong...the stock ecu goes..."Wtfomgbbq something is not le right here" and proceeds to REMOVE fuel again because the 02 sensor is reading richer then 14.7.....so now your back where you started. Now you decide to try and fight it more....the OBDII system wins again by firing off a check engine light...yay....

A way to correct this is to have the ECU tricked into thinking it is at WOT above a given psi so that way you can tune to a proper AFR...this has been done using a SMT6 piggyback (i believe midiwall was the guy who did this...i still have his original post LONG time ago in the LARGE smt6 thread

), this works well for a 5spd but i haven't found out nor had the time to try to test this on the auto tranny just because the ecu will start sending erratic signals to the solenoids which will cause odd shifting patterns at moderate throttle (due to the ecu thinking its at WOT all the time).

), this works well for a 5spd but i haven't found out nor had the time to try to test this on the auto tranny just because the ecu will start sending erratic signals to the solenoids which will cause odd shifting patterns at moderate throttle (due to the ecu thinking its at WOT all the time).With OBD-1...you can get away with more then 50% of the throttle! so all the above is not needed to be done

SImple...

SImple...That is why OBDII is a disadvantage for us people who want more power, but awsome for regular guys who just keep there trucks stock

Wat can be done that is very similar to your idea is using the SMT6 LAMBDA mode in which it takes your O2 sensor reading into the smt6 and you have all the play inthe world....add fuel and the smt6 will send a leaner signal to the ecu just enough to richen it a bit until the O2 sensor sends a little bit of a richer signal at which point the smt6 sends a signal to the stock ecu that its 14.7:1 when its really 13.2:1 or something.

The problem with this tho is that the smt6 can modify the o2 signal or the maf signal not both at same time

which sucks...or you can take the 2 for one offer and get 2 smt6's

which sucks...or you can take the 2 for one offer and get 2 smt6's

But by running the smt6 to modify the maf signal (which really matters) and proper tuning with some tricks you can get the engine running fine...much like mine...10psi s/c 91 or 94 octane with a flip of a switch...been this way for 50k km

All one has to do to take advantage of the ECU's ability to even out fuel curves is place a precision op-amp in the signal chain between the sensor and the ecu. We all know that supercharged engines need a lower a/f ratio than an NA engine, but the ecu will not let any aftermarket device alter the ratio forever-- it has been tried with many band-aid approaches and still won't work. The trick is to make the ECU think that it is doing what it is supposed to and not what the designer intended. If you modify the voltage from the pre and post 02 sensors to keep the same proportion of signal but at a lower voltage, then the ECU will in fact do all the tuning for you because it is interpreting the lower voltage as a lean condition and will increase the fuel pulse width to increase the voltage on the sensor to bring the signal up to engineered standards. What this will do is enable anyone to run any injectors just by creating different voltage differentials between the desired A/f ratio and the NA ratio.

YOu set your O2 sensor device to say 15.7 all the time so now your ecu will go and start adding fuel....and more fuel and more fuel until the trim reading is above 25% at which point your A) at 9:1afr because the ecu continues to add fuel B) that god damn check engine light will come back on again! DAMNIT stupid thing

Why? because it sees that its adding more and more fuel but it still isnt getting a reading as its supposed to....fuel trim above 25% error

Why? because it sees that its adding more and more fuel but it still isnt getting a reading as its supposed to....fuel trim above 25% error

SECONDLY to this...when you go WOT your ecu SHUTS down its reading from o2 sensors and instead reads INCOMING air from the MAF sensor and adds fuel accordingly....now with stock injectors...fine this will work alright....but add 370cc injectors like i have in my 96 taco and holy ลลลล black smoke out the tail pipe

Why? MAF reads 20lbs of air coming in.....ECU puts out Xms cycle to the injectors...it doesn't kow what injectors you have in there...so it will hold those 370cc injectors OPEN for just the same amount of time as the 248cc stokers...which = allot of black smoke and again 9:1 afr....pooooooor running conditions.

Maybe one day I will actually assemble this device it really easy to build--only needs 3 precision op amps and the support components. (but if someone starts selling these-- all the aftermarket ECU companies will be out of business )

Last edited by Weasy2k; 12-08-2005 at 10:50 PM. Reason: spell check