Another toyota turbo

#21

Registered User

DCG - you are right, stating that IS bad advice!

Norcalsvx - The amount of boost that can successfully be run with X compression is defined by a LOT of other variables. Rotating assembly's strenght, head design, fuel map, ignition map, and AIT's (AIT's to be determined by the turbo you run, the swept volume, pressure, your charge air cooler, etc) all play a very significant role in this. The LS1 has a 10.0:1 CR and people have zero issues running boost into them. 22re is a 9.5:1 cr, not 9.0:1, but that's still no bigge as your standard 5vz-fe (3.4L v6) has a 9.6:1 CR but TRD still came out with a supercharger for it....(roots no less...ugg) Done correctly its all good, but that build in the link makes me cry!

Norcalsvx - The amount of boost that can successfully be run with X compression is defined by a LOT of other variables. Rotating assembly's strenght, head design, fuel map, ignition map, and AIT's (AIT's to be determined by the turbo you run, the swept volume, pressure, your charge air cooler, etc) all play a very significant role in this. The LS1 has a 10.0:1 CR and people have zero issues running boost into them. 22re is a 9.5:1 cr, not 9.0:1, but that's still no bigge as your standard 5vz-fe (3.4L v6) has a 9.6:1 CR but TRD still came out with a supercharger for it....(roots no less...ugg) Done correctly its all good, but that build in the link makes me cry!

Last edited by Bumpin' Yota; 11-22-2006 at 03:22 PM.

#22

wow. ive been building turbo cars for a while and i can say, that truck is hideous. i just dont know about building something like that without a thorough resarch and development plan. i understand the 'budget' aspect, but mistakes in production will only yield a lot more expense later on.

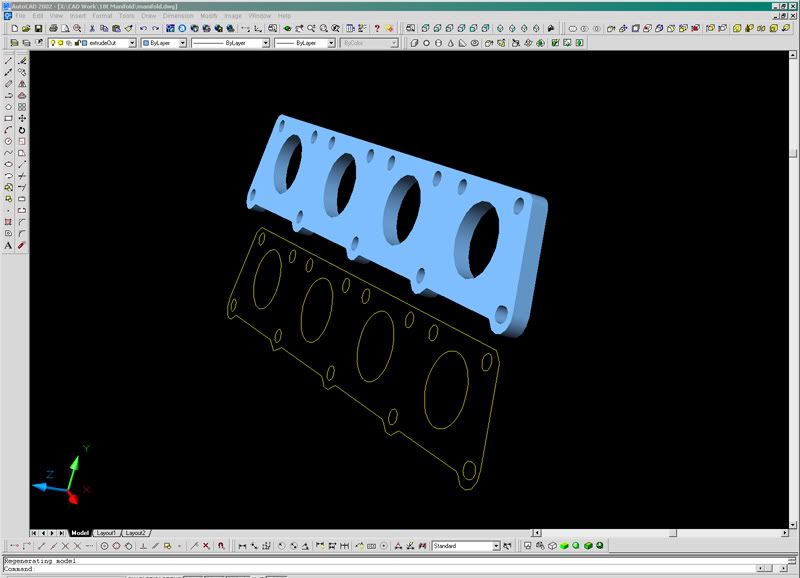

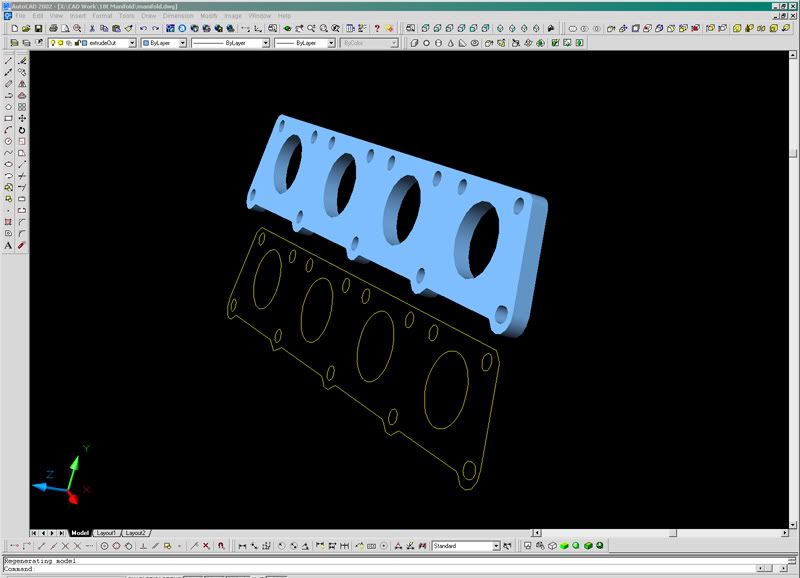

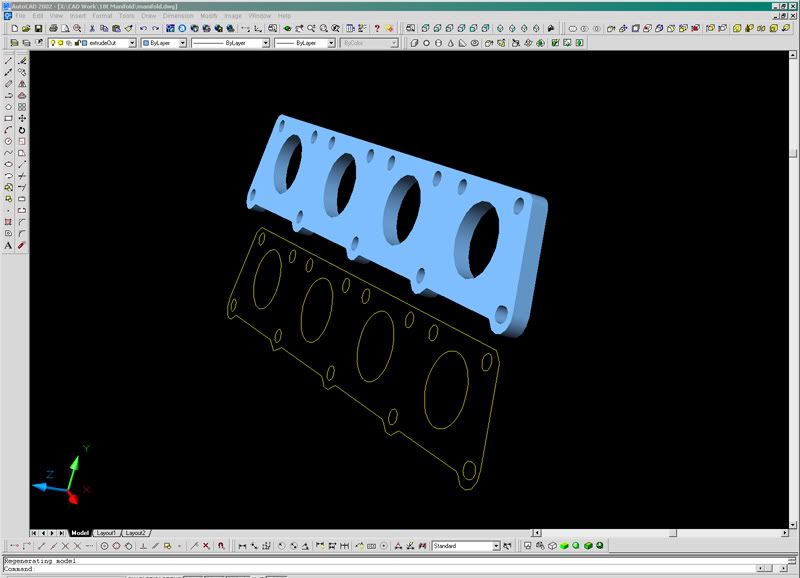

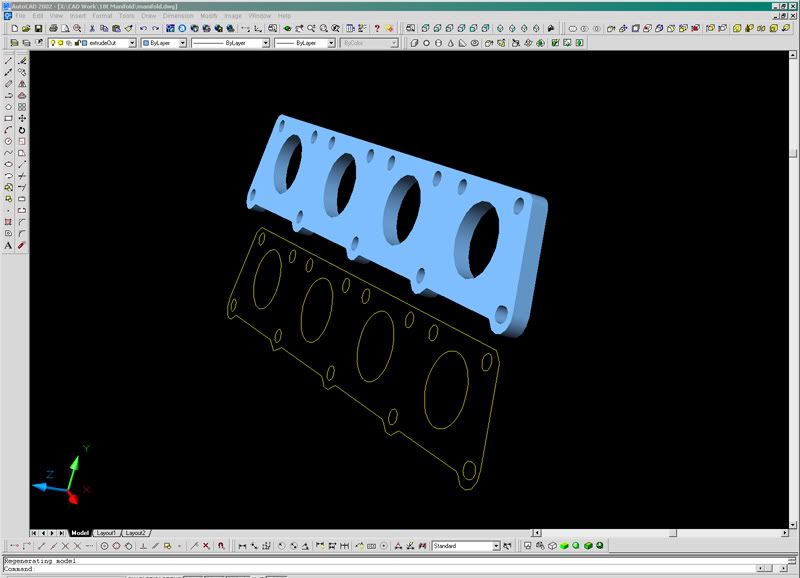

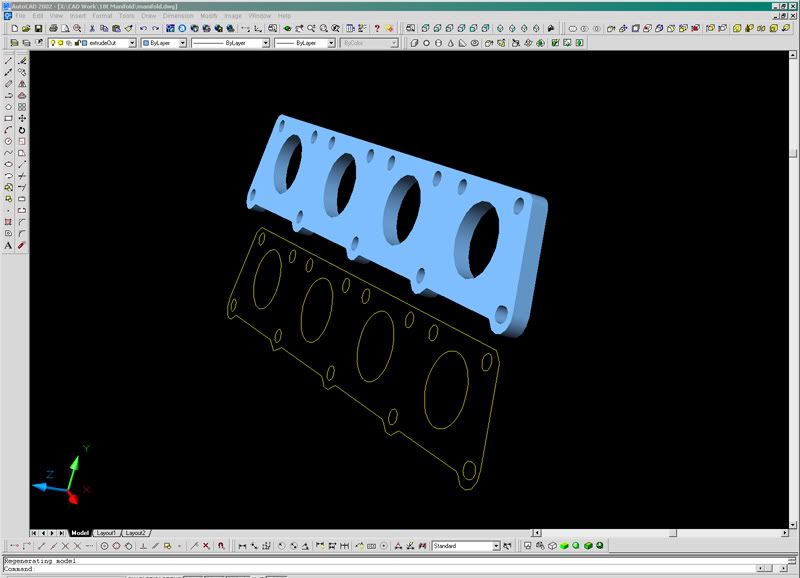

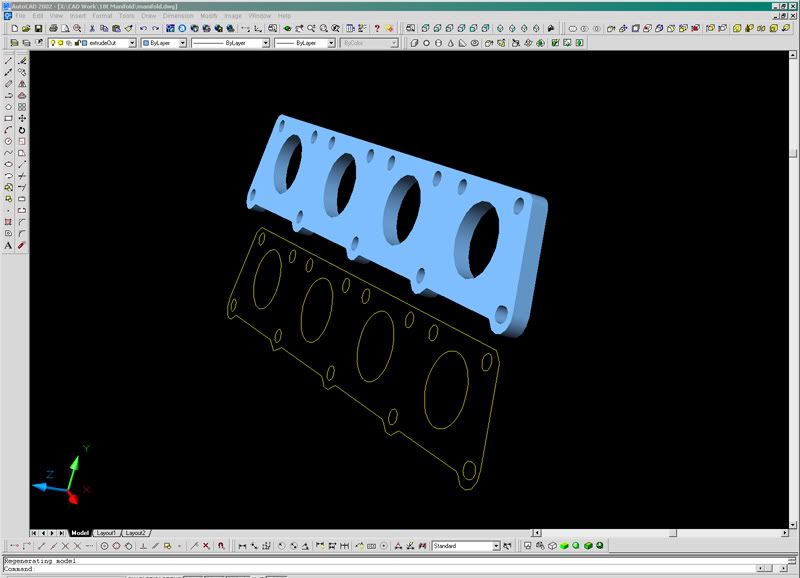

heres a sample of some of my work.... a turbo 'kit' i spec'd and designed for VW's.

heres a sample of some of my work.... a turbo 'kit' i spec'd and designed for VW's.

#23

Registered User

Join Date: Mar 2006

Location: Beaumont, Tx

Posts: 1,028

Likes: 0

Received 0 Likes

on

0 Posts

I am sorry, but there is no such thing as a "budget" turbo build up! If you are going to do the work to turbocharge an engine...you need to use quality parts to keep the engine running reliably.

I bet that PVC piping will blow up, and the fenceposts were a good way to ruin a perfectly good carb, the least he could have done, was have a muffler shop custom bend pipe for him...I mean seriously...It sounds like crap too!

I bet that PVC piping will blow up, and the fenceposts were a good way to ruin a perfectly good carb, the least he could have done, was have a muffler shop custom bend pipe for him...I mean seriously...It sounds like crap too!

#25

Using PVC is weird but great for mockup and testing, Its rated at 200-400 psi depending on the schedule so I dont really see any worries of detonation from it.

The problem with PVC is, It doesnt like heat, You can mold and bend it after its been sitting in the sunlight.

Marvulous stuff.

The problem with PVC is, It doesnt like heat, You can mold and bend it after its been sitting in the sunlight.

Marvulous stuff.

#26

Registered User

Precisely! PVC melts at 175*F or so, turbo outlet temps can get WELL over 300*F if you get outside of a turbo's efficiency range.....(Like a Borg Warner GM4 on a 6.5 pushing 18psi....outlet temps are around 275*F)

#27

Registered User

wow. ive been building turbo cars for a while and i can say, that truck is hideous. i just dont know about building something like that without a thorough resarch and development plan. i understand the 'budget' aspect, but mistakes in production will only yield a lot more expense later on.

heres a sample of some of my work.... a turbo 'kit' i spec'd and designed for VW's.

heres a sample of some of my work.... a turbo 'kit' i spec'd and designed for VW's.

Good looking setup you have there, and VERY well built turbo manifold! Whats the firing order of the cylinders and have you tried a divided entry hotside? Theoretically it would reduce your spool up time.

I also like how the WG can vent all cylinders equally

I also like how the WG can vent all cylinders equally

What is the flange made out of?

#28

Contributing Member

wow. ive been building turbo cars for a while and i can say, that truck is hideous. i just dont know about building something like that without a thorough resarch and development plan. i understand the 'budget' aspect, but mistakes in production will only yield a lot more expense later on.

heres a sample of some of my work.... a turbo 'kit' i spec'd and designed for VW's.

heres a sample of some of my work.... a turbo 'kit' i spec'd and designed for VW's.

#30

hey bumpin, the inlet isnt divided....it would have caused the collector to be too long to fit under the hood. since it was a top-mount setup it wouldnt have worked. FO= 1-4-3-2 (if i remember correctly)

all compnents are 304SS....manifold piping is all sched40. flange is 304SS

laser cutter was used for the flanges.

all compnents are 304SS....manifold piping is all sched40. flange is 304SS

laser cutter was used for the flanges.

#31

Registered User

Join Date: Nov 2005

Location: Las Vegas, NV

Posts: 48

Likes: 0

Received 0 Likes

on

0 Posts

Darin, your exactly right. The timing and fuel curves do a complete 180 to keep my truck in tune, if I remember correctly under full boost total timing only ends up being 12 degrees, with AFR's in the low 11's on pump gas.

I did find out something else pretty cool that I thought some Toyota guys outta know, it seems a bigger throttle body left us with....one choice from LCE which is what 3mm bigger? (59mm) and is rediculous in price. With the addition of a stand alone ECU a Ford throttle body has been used, and I had a 4.6L Mustang TB in stock and opened it up to find that the mount flange itself is alot smaller than the 5.0L TB's and it has the same throttle cable hook-up as a Toyota, so your stock throttle cable will slip right on without mods. The only bad thing is the 4.6L Stangs have a different IAC it is not on the TB itself, but I have another solution for that, I'll have to e-mail you some pics. the 4.6L TB is alot smaller looking for a cleaner look and the one I have is a 70mm which can be bought new for under $200. The first adapter I made was on the water jet cutter, but I'm making some more with the CNC.

I did find some vids I had made of my truck during some "shake-down" passes on the street, they sound pretty cool, I'm going to do some editing and get them downloaded to my server so you guys can hear and see the wrath of boosting a bone stock 22RE!

Later

Thread

Thread Starter

Forum

Replies

Last Post

GreatLakesGuy

The Classifieds GraveYard

8

09-04-2015 09:27 AM

And he even used ct couplings.

And he even used ct couplings.