Blazeland D.I.Y. weld up kit!

#41

Registered User

hey im looking at you kit and i like it but im just not sure what to do with the rear axle because obvs the front is going to be wider right? dont want to run wheel spacers, should i get rear steelies with a wider back spacing to basicly overcome using wheel spacers? i know this thread hasent been touched in a while but im concidering your full built kit lol if i was to buy your kit how much would it be for the t100 axles and basicaly everything so i could install it on a weekend and be able to drive it? my idea is to run your kit, my brandnew rear leafs, 33" km'2s, rear posi and then a 7mge around 230hp, and basicaly do some slow 4x4ing and also rip down some groomed trails haha. what do you think? im not gonna jump it really but i like the idea of the wider wheel base so i can corner like nuts haha

#42

O.k., I'm liking where this is headed so far.

But...I gotta ask though, is it possible to provide just the metal needed to fab the UCA brackets myself ? Hell I'd rather buy my own bolts for 'em too if it'd be cheaper for me.

Because if you could knock down the price for those UCA brackets by atleast 50%, then maybe we're talkin'.

But...I gotta ask though, is it possible to provide just the metal needed to fab the UCA brackets myself ? Hell I'd rather buy my own bolts for 'em too if it'd be cheaper for me.

Because if you could knock down the price for those UCA brackets by atleast 50%, then maybe we're talkin'.

#45

Registered User

not really a lift kit. Just a byproduct of a kit that gives you a longer travel on the independant front suspension (IFS). Otherwise called a long travel (LT) kit.

#47

Registered User

Thread Starter

Yeah, not really a lift kit! When you compress the suspension the height is the same as a stock. When you droop out the suspension the height will be about 4" higher...... before the wheels lift off the ground. You will gain about 4" of suspension travel over stock. The static ride height is adjustable but setting the ride height +3" higher than stock works best. So in those terms it would be a 3" lift!

#49

Registered User

Thread Starter

No I don't offer the weld up kit anymore. It turned out to be too difficult without the proper cutting and welding fixtures for the average DIY guy. There is some precise measuring then a calculated pre-stressing durring the welding process to compensate for warpage and to keep the arms parallel to each other. It took the professional fabricator I hired some time to get it dialed in. It took me a few trys to get it right when built the first prototypes. A DIY guy wouldn't be happy to have to do it over for each time he screw up!

If Blazeland offers the precut steel and the customer fabrication turns out sloppy then Blazeland looks bad. There may also be some liability involved if something goes wrong with a weld? The welding needs to be checked for proper welding specifications.

Building your own LT kit using the Blazeland concept may seem feasable but you will likely get stuck with getting the correct geometry between the UCA and LCA. They are not lengthened the same amount and the amount of drop for the BJ space needs to be considered because it effects a number of items. To build your own UCA Extension Brackets or LCA steel templates you need a cadd file and laser cutter. To machine your own Tie Rod Adjusting Sleeves you need custom taps and a lathe, even the jam nuts are custom machined. This isn't something the average DIY guy can do.

It would sure be nice to just sell the steel templates and other componants because having a professional do the welding, even at a volume rate, isn't cheap! You should also consider the core processing- I have the arms burned in an industrial oven and sand blasted to prep for fabrication. When all is done I have the arms professionally powdercoated. I even have all the bushing steel re-zinked. These proceedures a DIY guy cannot perform and if he had them done as a one off, rather than in a batch, the cost goes way up.

A admitt a DIY kit would remove much of the workload I am tiring of. The shipping, the inventory stocking, and the core exchange program is getting to be a hassle. It would also eliminate the bushing assembly which I am sick of. But to create the complete system and a high quality end product it is needed. It is a good deal more complicated than it would seem. My advice, set some money aside and just buy the complete kit. You will save yourself a big hassle.

If Blazeland offers the precut steel and the customer fabrication turns out sloppy then Blazeland looks bad. There may also be some liability involved if something goes wrong with a weld? The welding needs to be checked for proper welding specifications.

Building your own LT kit using the Blazeland concept may seem feasable but you will likely get stuck with getting the correct geometry between the UCA and LCA. They are not lengthened the same amount and the amount of drop for the BJ space needs to be considered because it effects a number of items. To build your own UCA Extension Brackets or LCA steel templates you need a cadd file and laser cutter. To machine your own Tie Rod Adjusting Sleeves you need custom taps and a lathe, even the jam nuts are custom machined. This isn't something the average DIY guy can do.

It would sure be nice to just sell the steel templates and other componants because having a professional do the welding, even at a volume rate, isn't cheap! You should also consider the core processing- I have the arms burned in an industrial oven and sand blasted to prep for fabrication. When all is done I have the arms professionally powdercoated. I even have all the bushing steel re-zinked. These proceedures a DIY guy cannot perform and if he had them done as a one off, rather than in a batch, the cost goes way up.

A admitt a DIY kit would remove much of the workload I am tiring of. The shipping, the inventory stocking, and the core exchange program is getting to be a hassle. It would also eliminate the bushing assembly which I am sick of. But to create the complete system and a high quality end product it is needed. It is a good deal more complicated than it would seem. My advice, set some money aside and just buy the complete kit. You will save yourself a big hassle.

#50

Registered User

Thread Starter

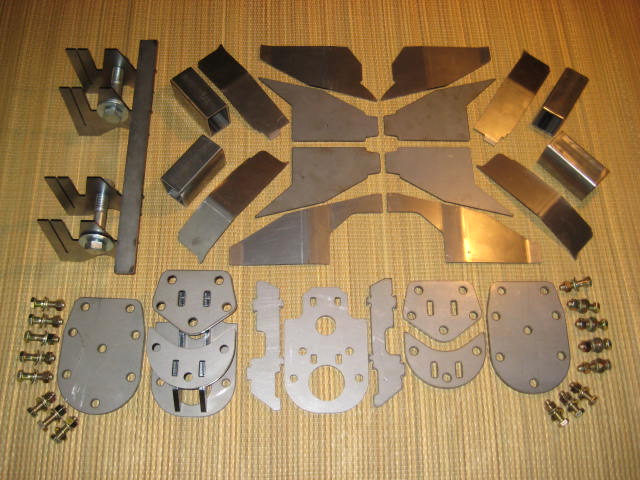

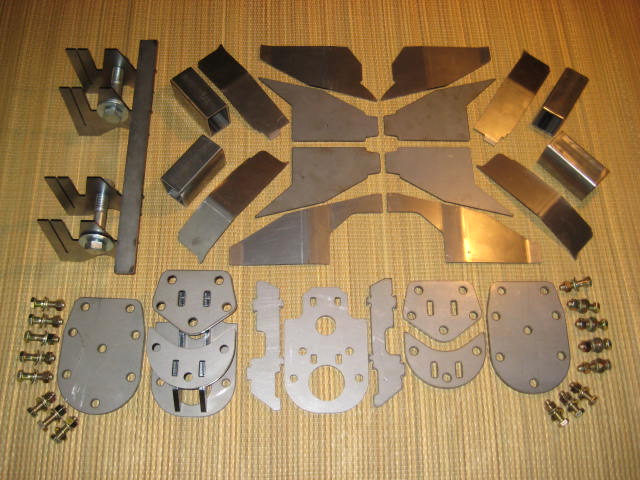

I'm bringing the weld up kit back! Actually, it never completely went away, it was just a special request thing. But now I am listing on the website under A La Carte!

#51

Registered User

Join Date: Mar 2010

Location: san diego

Posts: 8

Likes: 0

Received 0 Likes

on

0 Posts

It turned out to be too difficult without the proper cutting and welding fixtures for the average DIY guy. There is some precise measuring then a calculated pre-stressing durring the welding process to compensate for warpage and to keep the arms parallel to each other. It took the professional fabricator I hired some time to get it dialed in. It took me a few trys to get it right when built the first prototypes. A DIY guy wouldn't be happy to have to do it over for each time he screw up!

#52

Registered User

Thread Starter

I would but the folks who attempted are not giving me feed back. I think if you read over this thread you should get an idea of some of the difficulties. A lot of it has to do with the many steps to the process and the labor time. Turn key LCAs vs. DIY will only save about $200. Just the labor in welding the plating is worth that. The fab shop that does the plating charges me $120 per set of LCAs. I do all the prep work to the cores. Then I do the cutting lengthening and tack work so its just fitting and welding the plate. They do a little tweaking and trimming to fit. Then I have it media blasted and powder coated. I also install new HW and bushings. Its a ton of work.

#53

Registered User

Join Date: Aug 2013

Location: North Idaho

Posts: 45

Likes: 0

Received 0 Likes

on

0 Posts

I've kinda off and on looked at your kit for a few years...but never been too serious. I peeked through your website and noticed the DIY kit and thought hmm maybe that's an affordable option.

I can understand and appreciate the precision needed to piece together the lower control arm for proper geometry and function.

Reading through and looking at the picture of the currently offered DIY kit, the concern of the required pieces doesn't seem to big a deal as they look very well cut out and bent...my thought is the placement of the steel is the only concern.

So I guess to the point and my question LOL Is there a detailed measurement guide or a rough instructional when someone buys the DIY kit? I don't mean a hold my hand step by step, but a good descriptive and measurement points for placement of welding on pieces

I can understand and appreciate the precision needed to piece together the lower control arm for proper geometry and function.

Reading through and looking at the picture of the currently offered DIY kit, the concern of the required pieces doesn't seem to big a deal as they look very well cut out and bent...my thought is the placement of the steel is the only concern.

So I guess to the point and my question LOL Is there a detailed measurement guide or a rough instructional when someone buys the DIY kit? I don't mean a hold my hand step by step, but a good descriptive and measurement points for placement of welding on pieces

#55

Registered User

Thread Starter

When doing a search for "Blazeland" your probably coming up with hundreds of threads these days. I am creating keyword to threads that are pertinent to the subject. Type in "Blazelander2013" to see threads that actually have Blazeland related info.

Thread

Thread Starter

Forum

Replies

Last Post

FS[PacSouthWest]: 2- 8"3rd members:4.88 ratchet lockers,new setup kit, rear axle rebuild kit,diff armor

jerusry

Axles - Suspensions - Tires - Wheels

1

10-19-2015 05:28 PM

JookUpVandetti

86-95 Trucks & 4Runners (Build-Up Section)

7

09-10-2015 08:56 AM

Peevedkitten

86-95 Trucks & 4Runners (Build-Up Section)

11

08-31-2015 06:57 PM

crashburnoveride

86-95 Trucks & 4Runners

1

07-10-2015 06:39 AM