86 4runner 22re never warms to op temp, no radiator flow, no heat regardless of load

#1

Registered User

Thread Starter

86 4runner 22re never warms to op temp, no radiator flow, no heat regardless of load

So, I recently acquired an 86 4runner DLX 5speed manual and while I knew there were some top end issues when I checked it out it seems the issues are far worse than I though... overall I still paid bellow market price out here in CA but the engine is having some cooling issues plus I think I've diagnosed a blown head gasket as well at cylinder 4.

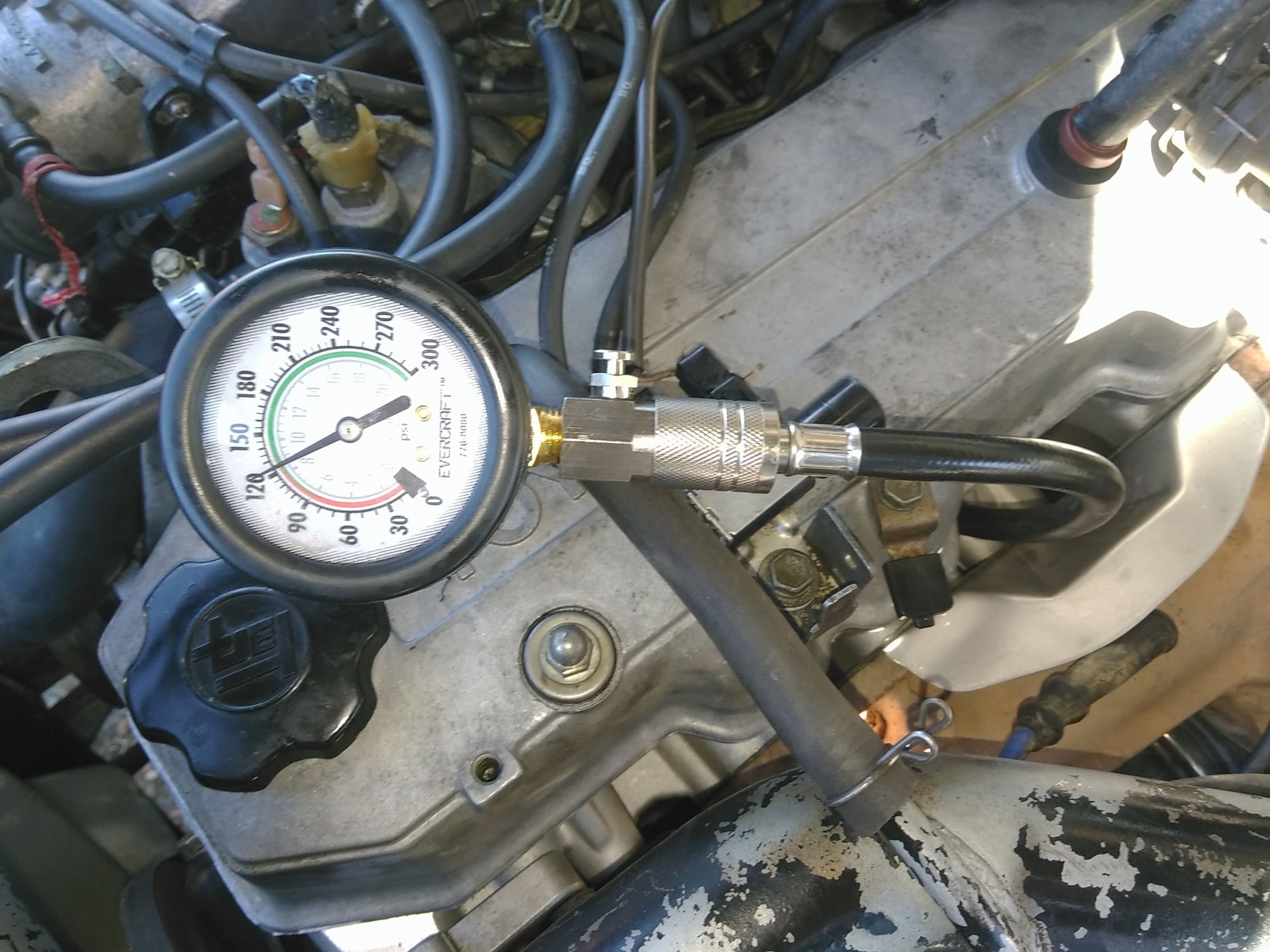

The first issue I've tried to dig into was the valve train noise which seems to be coming from the #4 cylinder. I've got a ton of exhaust pipe clap when I put a piece of paper up to the pipe so I figured I had a stuck exhaust valve. I ran a coompression test on all 4 cylinders and compression is within spec not factory New but not horrible

compression numbers:

cyl1 155psi

cyl2 155psi

cyl3 160psi

cyl4 158psi

the thing is even though compression was good in cylinder 4 the spark plug was totally clean and wet compared to the other cylinders which had tan carbons on the plugs and were dry. I've also got some serious smoking from the tail pipe that appears to be steam although it smells really rich and doesn't have a coolant smell to it. And the engine flutters bad like water in the combustion chamber or something.

Second issue is cooling system related as well The way I discovered this coolant issue was While I was running the engine to warm it up for the compression test I noticed the radiator never got even close to warm and the return hose at the top of the rad had no pressure and was also cold like the rad. I though great the thermostat is stuck closed so I pulled that and did the hot water test which resulted in the thermostat opening at 194 degrees (confirmed using a mercury lab thermometer) although spec for this thermostat is 180 it still opened within normal op temps . I also noticed the waterpump is leaking so it may have failed completely but I've also got almost no heat from the heater core and the gauge inside the cab reads 1/4 warm and was like that the entire 500 mile trip home. Thing that has me stumped is as far as I understand with no coolant flowing I should be running at overheating levels not sitting near the C most of the time and certainly not making a 500 mile trip without blowing up. What the heck could this be? I'm sure it's multiple issues but the no heat/cold coolant situation is stumping me... Clogged heater core?

I read a thread here with a guy with a similar problem and that was suggested as an issue but it didn't fix it for him and he never replied back with what was the fix.

I guess I should also mention there seems to be a knock for maybe 2-3 seconds on cold start up ... hard to tell if it's knock or timing chain clatter which I also started noticing at the top of 1st and 3rd gears when shifting. Seller said this thing was rebuilt 15k ago with a metal timing chain guide but the tchain clatter tells another story, although I won't be able to pull the valve cover to look until the weekend. Also after the truck has been sitting after running it has hard starting maybe 15 seconds before it fires ... I thought this might be the warm soak cold injector sensor issue I read about in a tech bulitin but now I suspect maybe coolant is getting in and sitting on the cylinder causing combustion issues? This thing runs like a Harley Davidson at the moment and I'd like to get a plan of attack in order so if anyone has any insight I'd really appreciate it. I'm not that experienced with wrenching on my own rig but this is why I bought this truck so I could learn. Any help would be appreciated.

I shot a couple of videos showing the top end noise and the smoking tail pipe see bellow. Thank you in advance.

Top end noise:

http://youtu.be/MdhRTKWbOJ4

tailpipe exhaust after idle dropped (was smoking more on startup before I filmed) https://youtu.be/oGbUKfrEp04

exhaust output when reved:

https://youtu.be/Y7dmV79S9cs

The first issue I've tried to dig into was the valve train noise which seems to be coming from the #4 cylinder. I've got a ton of exhaust pipe clap when I put a piece of paper up to the pipe so I figured I had a stuck exhaust valve. I ran a coompression test on all 4 cylinders and compression is within spec not factory New but not horrible

compression numbers:

cyl1 155psi

cyl2 155psi

cyl3 160psi

cyl4 158psi

the thing is even though compression was good in cylinder 4 the spark plug was totally clean and wet compared to the other cylinders which had tan carbons on the plugs and were dry. I've also got some serious smoking from the tail pipe that appears to be steam although it smells really rich and doesn't have a coolant smell to it. And the engine flutters bad like water in the combustion chamber or something.

Second issue is cooling system related as well The way I discovered this coolant issue was While I was running the engine to warm it up for the compression test I noticed the radiator never got even close to warm and the return hose at the top of the rad had no pressure and was also cold like the rad. I though great the thermostat is stuck closed so I pulled that and did the hot water test which resulted in the thermostat opening at 194 degrees (confirmed using a mercury lab thermometer) although spec for this thermostat is 180 it still opened within normal op temps . I also noticed the waterpump is leaking so it may have failed completely but I've also got almost no heat from the heater core and the gauge inside the cab reads 1/4 warm and was like that the entire 500 mile trip home. Thing that has me stumped is as far as I understand with no coolant flowing I should be running at overheating levels not sitting near the C most of the time and certainly not making a 500 mile trip without blowing up. What the heck could this be? I'm sure it's multiple issues but the no heat/cold coolant situation is stumping me... Clogged heater core?

I read a thread here with a guy with a similar problem and that was suggested as an issue but it didn't fix it for him and he never replied back with what was the fix.

I guess I should also mention there seems to be a knock for maybe 2-3 seconds on cold start up ... hard to tell if it's knock or timing chain clatter which I also started noticing at the top of 1st and 3rd gears when shifting. Seller said this thing was rebuilt 15k ago with a metal timing chain guide but the tchain clatter tells another story, although I won't be able to pull the valve cover to look until the weekend. Also after the truck has been sitting after running it has hard starting maybe 15 seconds before it fires ... I thought this might be the warm soak cold injector sensor issue I read about in a tech bulitin but now I suspect maybe coolant is getting in and sitting on the cylinder causing combustion issues? This thing runs like a Harley Davidson at the moment and I'd like to get a plan of attack in order so if anyone has any insight I'd really appreciate it. I'm not that experienced with wrenching on my own rig but this is why I bought this truck so I could learn. Any help would be appreciated.

I shot a couple of videos showing the top end noise and the smoking tail pipe see bellow. Thank you in advance.

Top end noise:

http://youtu.be/MdhRTKWbOJ4

tailpipe exhaust after idle dropped (was smoking more on startup before I filmed) https://youtu.be/oGbUKfrEp04

exhaust output when reved:

https://youtu.be/Y7dmV79S9cs

#2

Registered User

iTrader: (-1)

You need a stethoscope to find the noise, listen along both sides of the valve cover, listen along the lower intake to head junction. These are first generation injectors and they are pretty loud.

You definitely need a water pump once it starts leaking out the weep hole its done.

Put your hand in that exhaust, it will come out wet and likely smell of coolant. Your going to need atleast a head gasket, maybe worse.

You definitely need a water pump once it starts leaking out the weep hole its done.

Put your hand in that exhaust, it will come out wet and likely smell of coolant. Your going to need atleast a head gasket, maybe worse.

#3

Registered User

Thread Starter

You need a stethoscope to find the noise, listen along both sides of the valve cover, listen along the lower intake to head junction. These are first generation injectors and they are pretty loud.

You definitely need a water pump once it starts leaking out the weep hole its done.

Put your hand in that exhaust, it will come out wet and likely smell of coolant. Your going to need atleast a head gasket, maybe worse.

You definitely need a water pump once it starts leaking out the weep hole its done.

Put your hand in that exhaust, it will come out wet and likely smell of coolant. Your going to need atleast a head gasket, maybe worse.

guess its time for invasive surgery and a rebuild or replacement depending on what I find in there. Thanks again

Last edited by outdoorjunky; 02-26-2018 at 08:21 PM.

#4

there is a way fro coolant to get into cylinder 4 without the head gasket being involved.

The manifold gasket has a oolant chanel right between 3 and 4. Common problem, it leaks into the manifold and goes into cylinder 4 most often.

Coincidence that the water pump is also borked. maybe

Those compression figures are god and u had no heat. A breached compression chamber to coolant jacket usually results in heat being transfered into the coolant as combustion gas and that makes its way everywhere in the cooling system.

Id check the manifold gasket first.

The manifold gasket has a oolant chanel right between 3 and 4. Common problem, it leaks into the manifold and goes into cylinder 4 most often.

Coincidence that the water pump is also borked. maybe

Those compression figures are god and u had no heat. A breached compression chamber to coolant jacket usually results in heat being transfered into the coolant as combustion gas and that makes its way everywhere in the cooling system.

Id check the manifold gasket first.

#6

Registered User

I agree with TT. Those compression numbers suggest your head gasket is ok. If you drove this thing 500 miles home, the problem would have worsened, you would have been on the side of the road. In the video I hear valve clatter and probably an exhaust leak.

The heat in these vehicles is not great, even when working correctly. Put a laser thermometer right above the thermostat housing for an accurate engine temp.

The heat in these vehicles is not great, even when working correctly. Put a laser thermometer right above the thermostat housing for an accurate engine temp.

#7

Registered User

iTrader: (-1)

What you see above is a one way leak from coolant to combustion in number two. No measurable loss of compression.

Plenty of water in that exhaust..

Not really sure what thomo is talking about there not being a water jacket on the back end, maybe a typo. There are not only cylinder water jacket but the egr coolant passage is supplied from there.

Not a bad idea to check the intake however, if you find water here seal it and button it back up and see if it goes away.

A leaking water pump (out the shaft, or weep hole) needs replacing no if and or but, once that seal goes it is pushing water into the bearing.

Trending Topics

#8

Registered User

OK CO 94 PU, good data. perhaps I may change my opinion. But how many miles did you drive the truck like that? 500?

In my experience my failed head gaskets have lasted about 20 miles.

In my experience my failed head gaskets have lasted about 20 miles.

#9

Registered User

Thread Starter

Thank you guys this gives me a little more hope for this engine. I can see a weld spot on the y pipe so this must had had an exhaust leak before that they patched but I'll look around for other exhaust leaks ... strange that the seller produced a valid smog certificate from earlier in the day (the day I bought it) in CA it shouldn't have passed with exhaust leaks or how rich it's running. I'm thinking he put some liquid sealer crap in to sell it to me and all that crap gave way on the trip home.

Anyway thanks for the suggestions I'll check the manifold and get back with results.

Anyway thanks for the suggestions I'll check the manifold and get back with results.

Last edited by outdoorjunky; 02-27-2018 at 11:34 AM.

#10

Registered User

iTrader: (-1)

When I lost the water pump on the 2wd, about six miles straight to the part store, but maybe ten before I noticed. Again from "old man" memory, better details are somewhere in the build threads.

There are tales here of people driving with blown head gaskets for a long time. It really depends on what is leaking. Untill it mixes water into the oil or hydro locks while the engine is running you can go as far as you are willing and able to keep filling the radiator.

The "big" point of my post was don't trust a compression test as your only source. You need to inspect the oil, check the compression, and check cooling system.

PS. I see what TT was saying now, it was the "fro" typo throwing my brain for loops I guess

#12

Registered User

Thread Starter

yeah sorry it looks like a y coming off the manifold probably part of it ... looks like it continues on to the cat. I tried tracking down a digital version of the 86 FSM but links are dead ... plenty of 87 fsm available will that work or are there drastic changes between years?

About the one way leak I was thinking that too since my plug in cylinder 4 is totally clean compared to the others and I read it is possible to have a headgasket failure but not lose compression. Would a leakdown test give confirmation on a failed head gasket even if a compression test was good?

the oil looks fine as far as I can tell but I don't know if there is water sitting in the pan ... but there is not milkyness in the oil or foaming on the cap. The radiator looks like ˟˟˟˟ though it is filled with that green crap for one and also I see rust particles but I'm not sure there is oil in there ... guess I can get my hands on a hydrocarbon tester to see if exhaust gasses are entering the cooling system. A cooling system pressure test won't help me with all the leaks I've got though right?

do you guys think my heater issues are related to all the breaches in my cooling system allowing air in?

Last edited by outdoorjunky; 02-27-2018 at 08:30 AM.

#13

Registered User

I am thinking if you drained the water out of the cooling system, or maybe even opened the radiator cap and tried the comp test again it wouldn't give the same result.

#14

Registered User

iTrader: (-1)

Ah, Toyota calls that one the intermediate pipe, forgot about that one, it is a y pipe.

A coolant system pressure test will show that kind of leak. That is a way to check that lower intake gasket on the head also, just pull the upper intake pressurize the coolant then run a swab/towel down the runners and see if you have leaks.

A coolant system pressure test will show that kind of leak. That is a way to check that lower intake gasket on the head also, just pull the upper intake pressurize the coolant then run a swab/towel down the runners and see if you have leaks.

#15

Registered User

iTrader: (-1)

That reminds me of a point I meant to make. Air under either the thermostat or temp guage sender will not transfer heat well. You'll get a low reading on the dash. Thermostat will fail to open. A "stuck" thermostat will put pressure on the water pump seal.

#16

Registered User

Thread Starter

Bad valve, clogged core, dirty air vanes, air lock is also possible..

That reminds me of a point I meant to make. Air under either the thermostat or temp guage sender will not transfer heat well. You'll get a low reading on the dash. Thermostat will fail to open. A "stuck" thermostat will put pressure on the water pump seal.

That reminds me of a point I meant to make. Air under either the thermostat or temp guage sender will not transfer heat well. You'll get a low reading on the dash. Thermostat will fail to open. A "stuck" thermostat will put pressure on the water pump seal.

#17

Registered User

Thread Starter

good idea I'll try another compression test with the radiator cap open and see what happens... my compression tester instructions state to turn the engine over until the needle stops gaining pressure so it's possible there is a breach into the cooling system that was being pressurized and giving me a false reading right?

#18

Registered User

Thread Starter

good idea I'll try another compression test with the radiator cap open and see what happens... my compression tester instructions state to turn the engine over until the needle stops gaining pressure so it's possible there is a breach into the cooling system that was being pressurized and giving me a false reading right?

#19

Registered User

iTrader: (-1)

For example cylinder one pumps up to 150psi and takes 5 cycles, cylinder two pumps up to 150psi but takes 10 cycles. Without knowing how many times the needle pulses (compression strokes) these look like a good compression test.

A few strokes either way won't typically be a big issue but you want the cranking time reasonably equal....

#20

Registered User

Thread Starter

This method can give errors in cylinder balance.

For example cylinder one pumps up to 150psi and takes 5 cycles, cylinder two pumps up to 150psi but takes 10 cycles. Without knowing how many times the needle pulses (compression strokes) these look like a good compression test.

A few strokes either way won't typically be a big issue but you want the cranking time reasonably equal....

For example cylinder one pumps up to 150psi and takes 5 cycles, cylinder two pumps up to 150psi but takes 10 cycles. Without knowing how many times the needle pulses (compression strokes) these look like a good compression test.

A few strokes either way won't typically be a big issue but you want the cranking time reasonably equal....

Cold test numbers:

Cyl 1 140psi 21 cranks

Cyl2 145psi 22 cranks

Cyl3. 140psi 22 cranks

Cyl4. 135psi 26 cranks

This is about as scientific as I can get with a harbor freight tester (I guess?) but it doesn't tell me a whole lot except that cyl4 is not in as good of shape as the other 3 cylinders... (again I guess). keep in mind I just bought this as a quick indication of uniformity between cylinders but obviously I didn't consider the deviation in number of crank revolutions throwing a wrench in the accuracy of the test. It would probably help to know if others with these Pittsburg compression testers need to crank their engine over that many times to get a reading, otherwise I've really got no baseline to work from.

Last edited by outdoorjunky; 02-28-2018 at 06:58 PM.