Transmission coolers - low temps and bypass thermostats - Tests and results

#21

Contributing Member

I would be surprised if that was the case too.

#22

Registered User

Join Date: Feb 2011

Location: Raleigh NC

Posts: 41

Likes: 0

Received 0 Likes

on

0 Posts

I have a question about the mounting of the cooler, i just got the b&m 70264 just as fog recommended, my question is does it matter which way the cooler is mounted, does the outlets need to face up or down or sideways or does it matter??? My diagram has it with the inlet/outlet facing up. Just wondering because it seems i could use less tubing if i mounted it with i/o down. Any advice is apprecitated

#23

Contributing Member

I have a question about the mounting of the cooler, i just got the b&m 70264 just as fog recommended, my question is does it matter which way the cooler is mounted, does the outlets need to face up or down or sideways or does it matter??? My diagram has it with the inlet/outlet facing up. Just wondering because it seems i could use less tubing if i mounted it with i/o down. Any advice is apprecitated

Last edited by mt_goat; 03-04-2011 at 07:49 AM.

#25

Registered User

Join Date: Feb 2010

Location: Outer Banks, NC

Posts: 570

Likes: 0

Received 0 Likes

on

0 Posts

With my 70264 last summer in 100+ temps, my ATF was constantly at 167 degrees, peaking a couple of times at 172. This is running the B&m in line with but before the exchange cooler in the Koyo A1998.

Make sure to mount the B&M right up against the AC condenser or as close as possible to get good air flow from the fan to cool the ATF.

I have not seen Fogrunner on the board here lately. Those physics classes must have gotten the best of him.

Make sure to mount the B&M right up against the AC condenser or as close as possible to get good air flow from the fan to cool the ATF.

I have not seen Fogrunner on the board here lately. Those physics classes must have gotten the best of him.

#26

Some will say it doesn't matter as far as cooling, personally I like to over-think things and let gravity help out with the flow through the small tubes in the cooler. That means a side mount (inlet and outlet on the side) with the inlet at the top and outlet at the bottom would seem ideal. Confused yet?  I can provide pics.

I can provide pics.

I can provide pics.

I can provide pics.

#27

Contributing Member

I have mine mounted the other way (inlet bottom, outlet top). In all honesty, if it is always full of fluid, I don't think it makes a difference. The fluid takes the same path no matter what direction it goes, so gravity effects I think cancel themselves out. Take a pick, it'll work either way.

The main pressure drop in the system is the small passages in the cooler itself, so my theory is gravity helping the flow in that part if the system would be the most beneficial. Especially when there is a bypass tube involved.

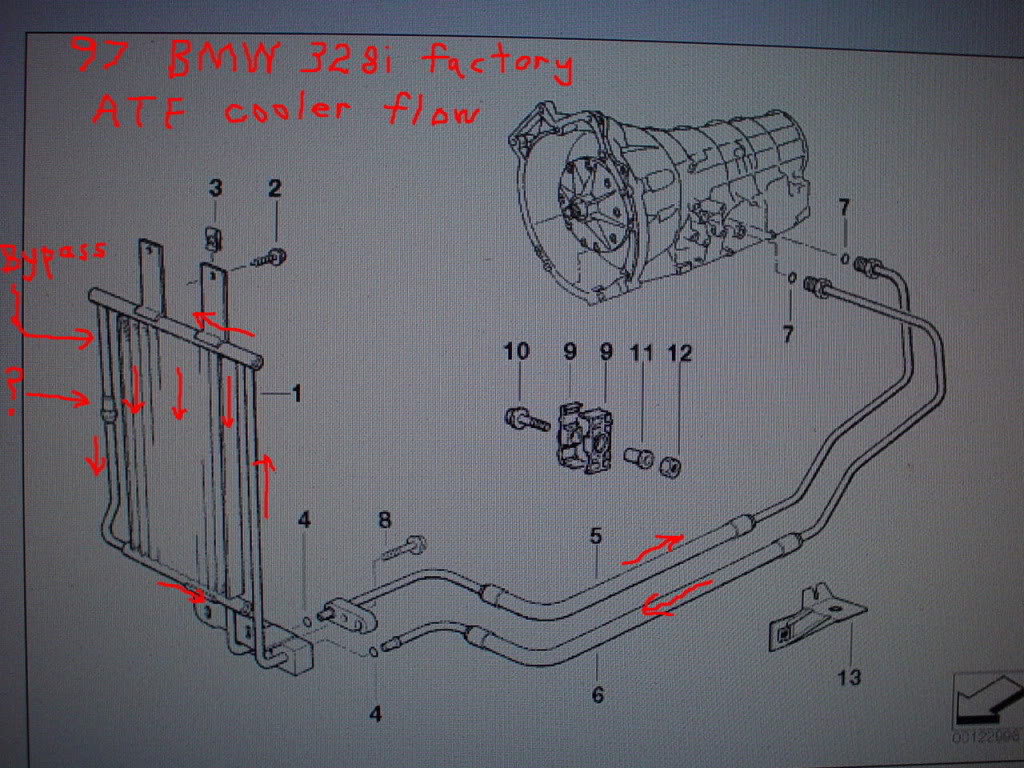

The main pressure drop in the system is the small passages in the cooler itself, so my theory is gravity helping the flow in that part if the system would be the most beneficial. Especially when there is a bypass tube involved. I also noticed the factory cooler in my BMW runs the same way:

Last edited by mt_goat; 03-03-2011 at 10:43 AM.

#28

It is debatable but I'll just add one more point or 2.  The main pressure drop in the system is the small passages in the cooler itself, so my theory is gravity helping the flow in that part if the system would be the most beneficial. Especially when there is a bypass tube involved.

The main pressure drop in the system is the small passages in the cooler itself, so my theory is gravity helping the flow in that part if the system would be the most beneficial. Especially when there is a bypass tube involved.

I also noticed the factory cooler in my BMW runs the same way:]

The main pressure drop in the system is the small passages in the cooler itself, so my theory is gravity helping the flow in that part if the system would be the most beneficial. Especially when there is a bypass tube involved.

The main pressure drop in the system is the small passages in the cooler itself, so my theory is gravity helping the flow in that part if the system would be the most beneficial. Especially when there is a bypass tube involved. I also noticed the factory cooler in my BMW runs the same way:]

http://www.jk-forum.com/showthread.p...mission-Cooler

If I'd found this before I installed mine, I might have been less arbitrary about the way I installed mine. Either way, it is easy enough to swap the tubes.

EDIT: I guess the reason for this is having the outlet on top helps air to leave the cooler.

Last edited by Nelsonmd; 03-03-2011 at 11:12 AM.

#29

Contributing Member

I can see the trapped air argument too though, just not sure if its a real problem or not. I need more R&D funds to investigate farther

#30

Would you consider it a closed loop with a bypass involved? I guess my main point is that more flow would be through the cooler and less through the bypass.

I can see the trapped air argument too though, just not sure if its a real problem or not. I need more R&D funds to investigate farther

I can see the trapped air argument too though, just not sure if its a real problem or not. I need more R&D funds to investigate farther

Anyway, it's kind of irrelevant because that effect is likely very small compared to other factors, like air pockets etc.

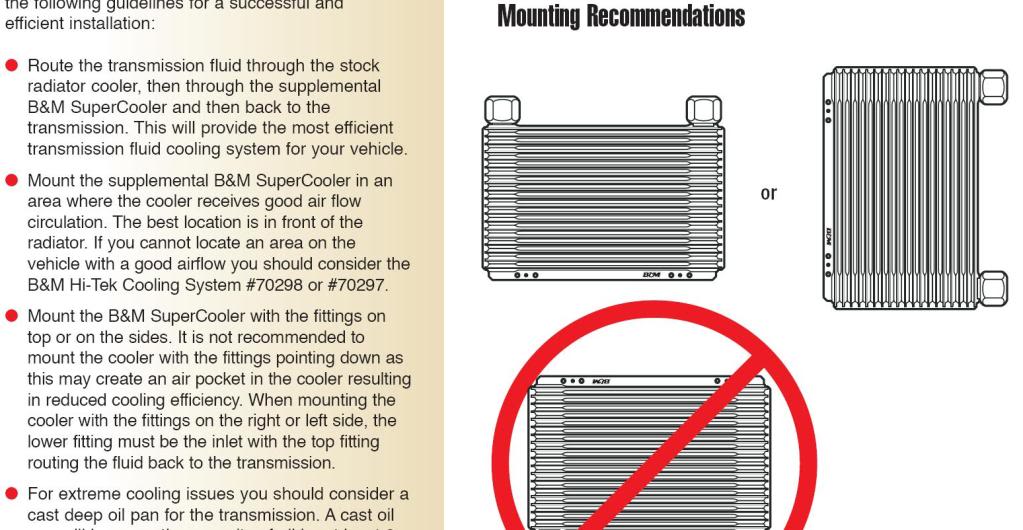

I just looked up their website to see if they had more details on the bypass, and I found that they recommend mounting inlet on bottom, outlet at top.

http://www.bmracing.com/bmracing/ima...er_techdoc.pdf

So SHAWNB, there you go, it's already in B&M's instructions.

#31

Contributing Member

Well B&M and I agree on 2 things:

Actually my ATF cooler now is mounted with both up, but at a 45 deg angle off vertical. Mainly because my cooler is lower than the transmission.

Last edited by mt_goat; 03-03-2011 at 01:20 PM.

#34

Registered User

Join Date: Feb 2010

Location: Outer Banks, NC

Posts: 570

Likes: 0

Received 0 Likes

on

0 Posts

The B&M instructions I received with my 70264 were so old, they mentioned Ford's infamous A4LD in them. My B&M begins to open at 170, and does a fantastic job at keeping the ATF cool. I do little offroading, so I have never seen the need to install a Spal fan or the like.

I've always run my ATF aftermarket external coolers before the radiator ATF cooler or heat exchanger, and have never seen any ill effects from doing such in 15+ years. Both of my Ford Broncos had OEM (Hayden) ATF external coolers and came with both fittings from the cooler pointed down from the factory so I turned them upside down and mounted them right up against the condenser. Today each Bronco has more than 200,000 miles on each tranny, plus 285,000 on my dad's first generation A4LD Explorer. My Tundra has an external OEM cooler, mounted sideways close to the condenser, with both fittings next to each other. I am not sure if it has a LPD or not.

Cool and clean ATF fluid is the way to go IMHO for long tranny life.

I've always run my ATF aftermarket external coolers before the radiator ATF cooler or heat exchanger, and have never seen any ill effects from doing such in 15+ years. Both of my Ford Broncos had OEM (Hayden) ATF external coolers and came with both fittings from the cooler pointed down from the factory so I turned them upside down and mounted them right up against the condenser. Today each Bronco has more than 200,000 miles on each tranny, plus 285,000 on my dad's first generation A4LD Explorer. My Tundra has an external OEM cooler, mounted sideways close to the condenser, with both fittings next to each other. I am not sure if it has a LPD or not.

Cool and clean ATF fluid is the way to go IMHO for long tranny life.

#35

B&M's side mounting requirements seem odd to me. Input on bottom, output on top? I've mounted both my B&M installations the opposite of that (in/top, out/bottom). Just seemed logical to me. Maybe when I upgrade from my 70268 to a 70264 this spring, I'll run the lines that way.

#36

Contributing Member

But with a bypass design like the "worst" pic above I definitely could see air getting trapped in the top half or 1/4 of the cooler forcing the ATF to flow more through the bypass.

But with a bypass design like the "worst" pic above I definitely could see air getting trapped in the top half or 1/4 of the cooler forcing the ATF to flow more through the bypass.If you see good temps don't worry about it.

Last edited by mt_goat; 03-04-2011 at 05:29 AM.

#37

I do find it interesting that the Ford coolers mentioned (and a couple older walkthrough's I found) show the install with both fittings facing down. The bypass would make a big difference if the cooler is mostly filled with air and the only flow is through the bottom portion of the cooler. But with or without a bypass, we agree that that is the worst way to mount it; a bypass just makes it even worse.

SHAWNB is the guys installing his this weekend that had the question about which way to hook it up. You quoted him.

Nice!! That is really funny.

#38

Contributing Member

#39

#40

Contributing Member

You are talking about getting the highest flow rate through the cooler, and it seems (at least from the research I have now done) that the biggest factor for flow rate is fully filling the cooler and not allowing air to block flow (meaning achieving the lowest resistance/greatest cross sectional area of flow through the cooler). I mean, take this for what it's worth, I just did a bit of internet research and checked that with my fluids/thermo knowledge from college so I am by no means an expert, and in the end, this is just an internet discussion, but I haven't seen any evidence to suggest there is an advantage to flow down, but there are distinct advantages to flow up...

But I have had good temps running that way in the past, although now I have both inlet and outlet up (BTW I don't see better or worse temps but its hard to compare since the location changed too).

But I have had good temps running that way in the past, although now I have both inlet and outlet up (BTW I don't see better or worse temps but its hard to compare since the location changed too). I too have had a semester of fluids and thermo I & II, BSME here. There was one project I was working on for Dana Corp redesigning a water jacket for a water cooled brake. We had previously done some testing with a clear plexiglass cover over the water jacket to see the flow. So I've been trying to think of a way to do some visual testing with the atf flow. Hmmm....anyway thanks for the info.

Last edited by mt_goat; 03-04-2011 at 07:53 AM.