My Turbo 3.4 4Runner

#1

Registered User

Thread Starter

Join Date: Feb 2007

Location: Santa Monica, Ca

Posts: 319

Likes: 0

Received 0 Likes

on

0 Posts

My Turbo 3.4 4Runner

Hi all, i havent been here in a while, but i'd thought i'd share my project with you. I'm currently turbo'ing my 2000 4runner 3.4. Its quite a bit of work, but when its all said and done it's gonna haul some azzz. I snapped a pic for all to see, but if you want to read thru the whole thread, its over on customtacos.com

I'll try to update here as i go along as well. Thx for looking.

Here is a link to the thread: http://www.customtacos.com/forum/sho...d.php?t=142621

I'll try to update here as i go along as well. Thx for looking.

Here is a link to the thread: http://www.customtacos.com/forum/sho...d.php?t=142621

#3

Registered User

Thread Starter

Join Date: Feb 2007

Location: Santa Monica, Ca

Posts: 319

Likes: 0

Received 0 Likes

on

0 Posts

ha, thx waldz. Yea, i have a problem acquiring 4runners - just cant have enough, right? Im itching to get this done - i see the end in sight now.

#4

Contributing Member

I think you should have put a flex coupling in the middle of your crossover. Think about how much that expands and contracts each warm up and cool down cycle and how much stress that puts on the manifold gaskets, studs, piping etc...just saying you could see cracking or gasket leaks in the near future.

Something like this is what I'm talking about:

Oh well too late now I guess, something to think about later if you have to take it off.

Very nice pipes BTW

Something like this is what I'm talking about:

Oh well too late now I guess, something to think about later if you have to take it off.

Very nice pipes BTW

Last edited by mt_goat; 03-24-2010 at 07:29 AM.

#5

Registered User

Thread Starter

Join Date: Feb 2007

Location: Santa Monica, Ca

Posts: 319

Likes: 0

Received 0 Likes

on

0 Posts

thx goat - i did actually (darn afterthoughts) after i had it ceramic coated - didnt get any pics after i fixed that - just a short 2" stainless flex. Thx for the recccomendation.

#6

Contributing Member

Oh good to hear that because those can be a PITA to get off later with the engine in place.

Could you explain the oiling system on that, like how does the oil get to the turbo. I saw the pic of the oil return to the valve cover already, so i guess its all part of the engine oiling system.

Any plans for an extra oil cooler?

Could you explain the oiling system on that, like how does the oil get to the turbo. I saw the pic of the oil return to the valve cover already, so i guess its all part of the engine oiling system.

Any plans for an extra oil cooler?

#7

Registered User

Join Date: Oct 2009

Location: Wheaton MO

Posts: 239

Likes: 0

Received 0 Likes

on

0 Posts

looking good man. have seen many turbos go on diesel (cause i put them there) but that looks good. wondering the same as Goat. were you going to run the oil from to get to your turbo? and i would consider a oil cooler!

Trending Topics

#8

Registered User

Thread Starter

Join Date: Feb 2007

Location: Santa Monica, Ca

Posts: 319

Likes: 0

Received 0 Likes

on

0 Posts

yea goat - it is all a royal PITA to install something like this when the motor is still in the bay - which is what i did. Looking back, i think it would have been a lot easier to pull the motor, install it all, then drop her back in. That way i could have torqued all the manifold nuts down a little better - space is Tight! I just have a really small garage and no space for an extraction right now.

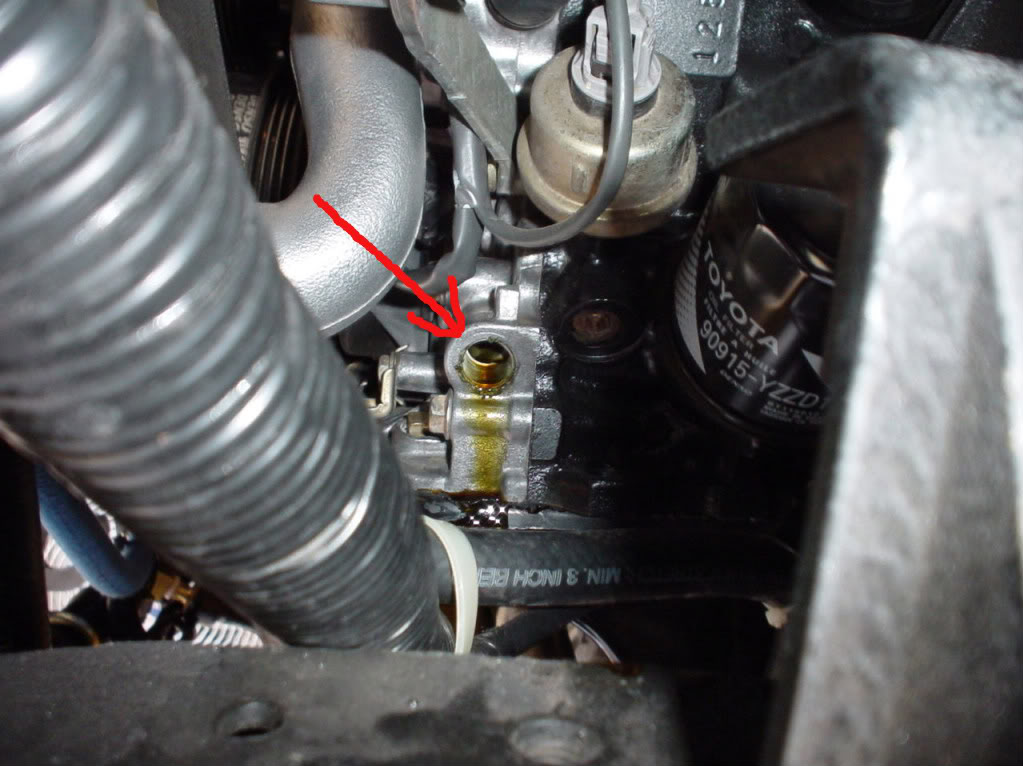

There is a tapped plug near the oil filter that can be used. So i just ran a SS braided line from there to the top of the turbo, then it drains into the valve cover. Some opt to drain it straight to the pan, but i didnt want to jack the engine up/take the steering rack off to remove the pan, weld a bung, then re install it all. My buddy has been running his turbo setup like this way for over 50k miles with no issues.

Thx broncrider - No plans for an oil cooler - just doesnt seem necessary on this application and most who turbo the 3.4 have'nt put one on - at least that i know of.

There is a tapped plug near the oil filter that can be used. So i just ran a SS braided line from there to the top of the turbo, then it drains into the valve cover. Some opt to drain it straight to the pan, but i didnt want to jack the engine up/take the steering rack off to remove the pan, weld a bung, then re install it all. My buddy has been running his turbo setup like this way for over 50k miles with no issues.

Thx broncrider - No plans for an oil cooler - just doesnt seem necessary on this application and most who turbo the 3.4 have'nt put one on - at least that i know of.

#9

Contributing Member

#10

Contributing Member

That is kind of scary, because that adds another bypass for the oil pump. All the flow through the turbo oiling system has completely bypassed the engine's lubrication system, oil cooler and oil filter. I wouldn't have wanted to be the first one to try this LOL.

I'd definitely check the oil temps with that setup, my oil temps got up to 260* F running 10 psi of boost before I added an extra oil cooler. Oil temp taken at that hole in the pic above (oil pump discharge port). That location could be as much as 50* cooler than the hotter parts of the engine so figure 310* F possibly.

I'd also run a little test measuring the oil flow through the turbo. Let me know if you'd like details on how to do that. It would be important to know because that flow is what is stolen from your engine's oil pressure and flow.

I'd definitely check the oil temps with that setup, my oil temps got up to 260* F running 10 psi of boost before I added an extra oil cooler. Oil temp taken at that hole in the pic above (oil pump discharge port). That location could be as much as 50* cooler than the hotter parts of the engine so figure 310* F possibly.

I'd also run a little test measuring the oil flow through the turbo. Let me know if you'd like details on how to do that. It would be important to know because that flow is what is stolen from your engine's oil pressure and flow.

Last edited by mt_goat; 03-24-2010 at 02:27 PM.

#11

Registered User

Join Date: Oct 2009

Location: Wheaton MO

Posts: 239

Likes: 0

Received 0 Likes

on

0 Posts

i agree at least a pressure gauge also so you know what your running. but it should be ok. i know that on the diesels it comes off the top of the oil filter then straight to the turbo then it drains back down into the oil pan.

#12

Contributing Member

Good idea about the pressure gauge, IIRC you want about 10 psi min for each 1000 rpms.

Last edited by mt_goat; 03-24-2010 at 01:58 PM.

#13

Registered User

Thread Starter

Join Date: Feb 2007

Location: Santa Monica, Ca

Posts: 319

Likes: 0

Received 0 Likes

on

0 Posts

Actually no, i put a T fitting where that sensor is off the block. You took it off the aluminum port - not sure what that's for. On my buddy's turbo tacoma 3.4 - he took his from where i did (see pic) and has a oil pressure gauge hooked up to it and has been full pressure all the time.

#14

Contributing Member

#15

Registered User

Join Date: Oct 2009

Location: Wheaton MO

Posts: 239

Likes: 0

Received 0 Likes

on

0 Posts

no not that i am aware of. and a lot of times the tubro can only take so much oil at on time through that hole. dont think its going to drop his pressure enough to make a difference now that i think about it. the biggest problem is if the return line has to much of a kink in it. the oil will not flow right. will have to look in my books from school but i believe you dont want any more then 35* of an angle.

#16

Contributing Member

Ok, I did a little reading and some questions came up. What type bearings does the turbo have, ball bearing or journal? What size oil line did you use and does it have a restrictor?

#18

Contributing Member

Does my turbo require an oil restrictor?

Oil requirements depend on the turbo's bearing system type. Garrett has two types of bearing systems; traditional journal bearing; and ball bearing.

The journal bearing system in a turbo functions very similarly to the rod or crank bearings in an engine. These bearings require enough oil pressure to keep the components separated by a hydrodynamic film. If the oil pressure is too low, the metal components will come in contact causing premature wear and ultimately failure. If the oil pressure is too high, leakage may occur from the turbocharger seals. With that as background, an oil restrictor is generally not needed for a journal-bearing turbocharger except for those applications with oil-pressure-induced seal leakage. Remember to address all other potential causes of leakage first (e.g., inadequate/improper oil drain out of the turbocharger, excessive crankcase pressure, turbocharger past its useful service life, etc.) and use a restrictor as a last resort. Garrett distributors can tell you the recommended range of acceptable oil pressures for your particular turbo. Restrictor size will always depend on how much oil pressure your engine is generating-there is no single restrictor size suited for all engines.

Ball-bearing turbochargers can benefit from the addition of an oil restrictor, as most engines deliver more pressure than a ball bearing turbo requires. The benefit is seen in improved boost response due to less windage of oil in the bearing. In addition, lower oil flow further reduces the risk of oil leakage compared to journal-bearing turbochargers. Oil pressure entering a ball-bearing turbocharger needs to be between 40 psi and 45 psi at the maximum engine operating speed. For many common passenger vehicle engines, this generally translates into a restrictor with a minimum of 0.040" diameter orifice upstream of the oil inlet on the turbocharger center section. Again, it is imperative that the restrictor be sized according to the oil pressure characteristics of the engine to which the turbo is attached. Always verify that the appropriate oil pressure is reaching the turbo.

The use of an oil restrictor can (but not always) help ensure that you have the proper oil flow/pressure entering the turbocharger, as well as extract the maximum performance.

Oil requirements depend on the turbo's bearing system type. Garrett has two types of bearing systems; traditional journal bearing; and ball bearing.

The journal bearing system in a turbo functions very similarly to the rod or crank bearings in an engine. These bearings require enough oil pressure to keep the components separated by a hydrodynamic film. If the oil pressure is too low, the metal components will come in contact causing premature wear and ultimately failure. If the oil pressure is too high, leakage may occur from the turbocharger seals. With that as background, an oil restrictor is generally not needed for a journal-bearing turbocharger except for those applications with oil-pressure-induced seal leakage. Remember to address all other potential causes of leakage first (e.g., inadequate/improper oil drain out of the turbocharger, excessive crankcase pressure, turbocharger past its useful service life, etc.) and use a restrictor as a last resort. Garrett distributors can tell you the recommended range of acceptable oil pressures for your particular turbo. Restrictor size will always depend on how much oil pressure your engine is generating-there is no single restrictor size suited for all engines.

Ball-bearing turbochargers can benefit from the addition of an oil restrictor, as most engines deliver more pressure than a ball bearing turbo requires. The benefit is seen in improved boost response due to less windage of oil in the bearing. In addition, lower oil flow further reduces the risk of oil leakage compared to journal-bearing turbochargers. Oil pressure entering a ball-bearing turbocharger needs to be between 40 psi and 45 psi at the maximum engine operating speed. For many common passenger vehicle engines, this generally translates into a restrictor with a minimum of 0.040" diameter orifice upstream of the oil inlet on the turbocharger center section. Again, it is imperative that the restrictor be sized according to the oil pressure characteristics of the engine to which the turbo is attached. Always verify that the appropriate oil pressure is reaching the turbo.

The use of an oil restrictor can (but not always) help ensure that you have the proper oil flow/pressure entering the turbocharger, as well as extract the maximum performance.

#19

Contributing Member

This is a pretty good page too: http://www.turbobygarrett.com/turbob...imization.html

Note the gauges they recommend near the bottom:

I have 1,2,3,4 & 7 on my rig plus a boost gauge, although my oil pressure gauge is just the factory gauge (doesn't provide hard numbers). I would suggest you get a real one since you'll be stealing oil pressure from the engine for the turbo. The OBDII also provides more info. Just some things to think about.

I saw where you were going to use the URD turbo injector manifold, that looks sweet! http://www.urdusa.com/product_info.p..._id=1260518481 12 injectors should do a great job of providing fuel.

More from the garrett page:

Note the gauges they recommend near the bottom:

Monitoring

The turbo system in your car should be monitored to insure that every aspect is

functioning properly to give you trouble-free performance.

Instrumentation used to monitor / optimize system

1. Oil Pressure (Required to monitor engine operation)

2. Oil Temperature (Required to monitor engine operation)

3. Water Temperature (Required to monitor engine operation)

4. A/F Ratio (such as a wideband sensor; required to monitor engine operation)

5. Manifold Pressure

6. Turbine Inlet Pressure

7. Exhaust Gas Temperature

8. Turbo Speed Sensor

The turbo system in your car should be monitored to insure that every aspect is

functioning properly to give you trouble-free performance.

Instrumentation used to monitor / optimize system

1. Oil Pressure (Required to monitor engine operation)

2. Oil Temperature (Required to monitor engine operation)

3. Water Temperature (Required to monitor engine operation)

4. A/F Ratio (such as a wideband sensor; required to monitor engine operation)

5. Manifold Pressure

6. Turbine Inlet Pressure

7. Exhaust Gas Temperature

8. Turbo Speed Sensor

I saw where you were going to use the URD turbo injector manifold, that looks sweet! http://www.urdusa.com/product_info.p..._id=1260518481 12 injectors should do a great job of providing fuel.

More from the garrett page:

Oil Supply & Drainage

Journal Bearing Turbo

Journal Bearing Turbo Journal-bearings function similarly to rod or crank bearings in an engine - oil pressure is required to keep components separated. An oil restrictor is generally not needed except for oil-pressure-induced leakage. The recommended oil feed for journal bearing turbochargers is -4AN or hose/tubing with an ID of approximately 0.25.

Be sure to use an oil filter that meets or exceeds the OEM specifications.

Journal Bearing Turbo

Journal Bearing Turbo Journal-bearings function similarly to rod or crank bearings in an engine - oil pressure is required to keep components separated. An oil restrictor is generally not needed except for oil-pressure-induced leakage. The recommended oil feed for journal bearing turbochargers is -4AN or hose/tubing with an ID of approximately 0.25.

Be sure to use an oil filter that meets or exceeds the OEM specifications.

Last edited by mt_goat; 03-27-2010 at 08:26 AM.

Thread

Thread Starter

Forum

Replies

Last Post

XtraCab

Solid Axle Swaps, All Years

18

04-12-2020 05:25 AM

TokyoD23

95.5-2004 Tacomas & 96-2002 4Runners

4

07-12-2015 06:01 AM