How can you free up a sticky tranfer case actuator?

#1

Registered User

Thread Starter

How can you free up a sticky tranfer case actuator?

Is there anyway to get inside the transfer case actuator on 1996 Tacoma 4X4 Automatic to grease it up without removing it from the truck completely?

#2

Registered User

Thread Starter

Come on guys, I need some suggestions before the weekend gets here so I have a game plan on what to try with the actuator!!!! I want to have this fixed this weekend coming.

#3

Registered User

Thread Starter

Actuator

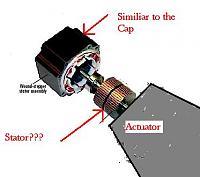

I have removed the plate on the actuator pictured here in the top right corner where you can see the orange gasket. Inside it is a cog with a hole in the middle of it where it looks like you could use a Torx socket, (except it is much finer, probably about 16 points) to turn the cog which is meshed with the shaft that engages the 4wd. If I could turn this cog, it would make the shaft engage and disengage possibly freeing up the actuator. (The plate must be there for some reason!!!) My questions is..... before turning the cog, do I have to remove the actuator motor on the other side? I am assuming I will because it has to be meshed with the shaft going to the cog!!!

I have removed the plate on the actuator pictured here in the top right corner where you can see the orange gasket. Inside it is a cog with a hole in the middle of it where it looks like you could use a Torx socket, (except it is much finer, probably about 16 points) to turn the cog which is meshed with the shaft that engages the 4wd. If I could turn this cog, it would make the shaft engage and disengage possibly freeing up the actuator. (The plate must be there for some reason!!!) My questions is..... before turning the cog, do I have to remove the actuator motor on the other side? I am assuming I will because it has to be meshed with the shaft going to the cog!!! Here is the actuator motor I think I need to remove..... What am I dealing with here, do I just take out the 3 screws and pull the motor off. There are no wires going to it so what makes this baby tick? I'm affraid to try and remove it in fear of not knowing what is inside it and how easy it will be to put back on!!! Any input on this would be greatly appreciated!!! Thanks!!!

Here is the actuator motor I think I need to remove..... What am I dealing with here, do I just take out the 3 screws and pull the motor off. There are no wires going to it so what makes this baby tick? I'm affraid to try and remove it in fear of not knowing what is inside it and how easy it will be to put back on!!! Any input on this would be greatly appreciated!!! Thanks!!!

The following users liked this post:

phx_4runner (08-13-2019)

#4

Registered User

Join Date: Feb 2007

Location: Pleasant Grove, Utah

Posts: 441

Likes: 0

Received 0 Likes

on

0 Posts

I hate to post without specific information, but it doesn't look like there's been much in the way of responses. Your best bet is probably to get a Chilton or Haynes manual and go that route (you may even find one at your local library if funds are the problem). It looks like a mess if you just dive right into the actuator, based on some other posts.

How is your actuator sticking? Mine was not shifting into 4wd, even though 2 months before, it had. I had no choice, so I just left the button clicked on the shifter and in a minute or two, I looked down, and it had locked in. It was slow switching in the first few times, but now it shifts right in. Good luck with everything, and please post up when you get your answer!

How is your actuator sticking? Mine was not shifting into 4wd, even though 2 months before, it had. I had no choice, so I just left the button clicked on the shifter and in a minute or two, I looked down, and it had locked in. It was slow switching in the first few times, but now it shifts right in. Good luck with everything, and please post up when you get your answer!

#5

Registered User

Thread Starter

I already have the Haynes manual and also found the Factory Service Manual online, but neither shows the take down of the actuator.... it is considered an unservicable part by toyota...go figure. My actuator is just clicking and after a alot of tapping with a hammer, I managed to get it into 4x4 2 or 3 times, but nothing consistant. I dont like to leave the button push for to long without the actuator engaging in fear of burning the motor up. While I was tapping the actuator, I had someone continually push the button....after about half hour the motor got really hot....over worked it I guess!!! I,m going to try and remove the position sensor and see if its sticking ..... if that doesnt work, I'm going to try and move the cog/shaft manually through the triangular plate on the side of the actuator.....and if that doesnt work I'm going to pull the motor off and take a look..... any other suggestions are welcomed. Thanks for your input!!!!

#6

That cap with no wires in it houses the magnets and a shaft bearing. The stator with the motor windings on it turns inside those magnets. If you pull the cap, the motor stator will stay in the main body of the actuator. The brushes for the motor (where the wires go to) are in the main body of the actuator, near the base of that cap. If you pull the cap off, you could check the magnets, clean out any gunk, free up that bearing and probably turn the stator to see what goes on through that other inspection plate you already have off. Another way to go about it could be to pull the vent hose and fill the thing with WD40 until it drips out, but this is sloppy, not long lasting, could cause another problem, and overall probably is not the best solution. At least you wouldn't have to take it apart. The actuator probably got water in it through that same vent hose.

#7

Registered User

Thread Starter

Beto, this information is gold..... I just wish I understood the termonology a little better. I dont know what a stator is and exactly what to expect when I go to remove the cap. You explain it very well, but this is not my strong point. Will it be self explanitory when the cap is taken off or will things kind of drop out and be difficult to put back. What I guess I am asking is "will I be able to take it off and put it back on just as easy as it came off?" I have taken the end of a winch apart and had the brushes pop out of place on me leaving me a task of getting them back in.... it was a nuisence, but it was fixed!!! As far as the vent hose goes, I thought about the WD40 solution, but I wasnt sure if it was a good idea.... I think I will use that idea as a last resort before pulling the end completely off of the actuator itself!!! Thanks for the great information.... if you could give it one more go to explain it again, I think I will have the confidence to take it off!!! Thanks again!!!!

Trending Topics

#8

Registered User

Thread Starter

#9

It would be a little opposite to that. It should look a little more similar to this toy motor, but with more coils and more permanent magnets:

http://electronics.howstuffworks.com/motor3.htm

That motor that you posted is a variant of a "squirrel cage", it works by generating a magnetic field in the coils around the stator and the stator has several copper bars running along its length shorted at each end with a ring. The magnetic field generates a current in the copper bars, the flow of this current generating a magnetic field opposing the one applied by the coils. The net result is that the stator is repulsed away from the coils and turns. They are AC or Stepper motors and require something other than straight DC power to operate.

The motor that you should expect is a DC motor, it will have coils on the stator, and permanent magnets glued inside that cap. There will be a system of brushes (carbon blocks probably) and a ring on the stator that allows power to be transmitted to the coils on the stator. Different coils will be powered at different points during the rotation. The magnetic fields generated will push and pull the stator away from a permanent magnet and towards the next - these magnets are installed inside that cap.

http://electronics.howstuffworks.com/motor3.htm

That motor that you posted is a variant of a "squirrel cage", it works by generating a magnetic field in the coils around the stator and the stator has several copper bars running along its length shorted at each end with a ring. The magnetic field generates a current in the copper bars, the flow of this current generating a magnetic field opposing the one applied by the coils. The net result is that the stator is repulsed away from the coils and turns. They are AC or Stepper motors and require something other than straight DC power to operate.

The motor that you should expect is a DC motor, it will have coils on the stator, and permanent magnets glued inside that cap. There will be a system of brushes (carbon blocks probably) and a ring on the stator that allows power to be transmitted to the coils on the stator. Different coils will be powered at different points during the rotation. The magnetic fields generated will push and pull the stator away from a permanent magnet and towards the next - these magnets are installed inside that cap.

#10

Registered User

Thread Starter

Very good information as usual, one last quick question.... when the cap is removed, will the brushes eject themselves from the stator....will they push out or are they stationary and unable to come out of the stator? I dont want brushes and tiny springs coming out on the ground lol...Thanks again!!!

#11

The brushes will be housed in the actuator body and won't spring out unless the stator is removed. The brushes are not part of the stator, but rather deliver power to the stator by rubbing against contacts on the stator as it rotates. I don't think you'll be able to pull the stator out of the actuator body because it will have a worm gear on the shaft holding it into the actuator. Just to be safe, try not to pull on the stator as you remove the cap until you can see what is going on in there (the shaft might be a little stuck in the bearing in the top of the cap and might try to pull out). Like I said, it should be impossible to pull out because the other end will be attached to a gear mechanism of some sort. The ONLY thing in the cap should be a few (probably four) permanent magnets and the top bearing. You might find a loose magnet and it will have to be re-epoxied on with the original N-S orientation - be sure to determine this orientation before you glue it back. This isn't something to be overly worried about, if the magnet is already loose, there is nothing that can be done except take it apart and then through inspection of the left-over epoxy or testing with another magnet determine the proper orientation. Take pictures when you get it apart and post them so in the future this can be explained more easily.

#12

Registered User

Thread Starter

THEORY on the Position Sensor Switch and its workings!!

Beto, you sure know your stuff and it is greatly appreciated. I have a much better understanding of what I am about to tackle thanks to you. I am taking the day off work tomorrow so that I can tackle the project. I will definitely take some pictures of my progress and keep you informed on the outcome.

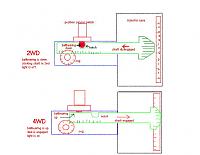

I also plan on taking out the Postion Sensor Switch to make sure the ballbearing at the end isn't sticking. Here is a drawing that I completely made up....I don't even know if this is how it works... its just a theory I have...... does it seem to make sense. If the ballbearing is stuck extended all the way out, it wouldn't let the shaft move, the truck engage into 4wd or the dash light come on. (I have the notch in the shaft exaggerated to make my theory easier to understand... naturally the notch would be more like a dimple on the shaft). Take a look and see!!!

I also plan on taking out the Postion Sensor Switch to make sure the ballbearing at the end isn't sticking. Here is a drawing that I completely made up....I don't even know if this is how it works... its just a theory I have...... does it seem to make sense. If the ballbearing is stuck extended all the way out, it wouldn't let the shaft move, the truck engage into 4wd or the dash light come on. (I have the notch in the shaft exaggerated to make my theory easier to understand... naturally the notch would be more like a dimple on the shaft). Take a look and see!!!

I also plan on taking out the Postion Sensor Switch to make sure the ballbearing at the end isn't sticking. Here is a drawing that I completely made up....I don't even know if this is how it works... its just a theory I have...... does it seem to make sense. If the ballbearing is stuck extended all the way out, it wouldn't let the shaft move, the truck engage into 4wd or the dash light come on. (I have the notch in the shaft exaggerated to make my theory easier to understand... naturally the notch would be more like a dimple on the shaft). Take a look and see!!!

I also plan on taking out the Postion Sensor Switch to make sure the ballbearing at the end isn't sticking. Here is a drawing that I completely made up....I don't even know if this is how it works... its just a theory I have...... does it seem to make sense. If the ballbearing is stuck extended all the way out, it wouldn't let the shaft move, the truck engage into 4wd or the dash light come on. (I have the notch in the shaft exaggerated to make my theory easier to understand... naturally the notch would be more like a dimple on the shaft). Take a look and see!!!

Last edited by kennyyoung; 11-05-2009 at 09:13 AM.

#13

Makes sense to me but I really don't know exactly what's in there. I remember the cog on the end of the motor shaft engaging a worm gear - vaguely - this is opposite to the rear diff lock actuator which has the worm gear part on the motor shaft. As far as that ball bearing it could very well work like that. The one question I would have is how does the actuator know when to stop actuating when engaging 4WD? It would have to have some separate mechanism to remove power from the motor once it is fully engaged. It should be pretty logical in there, I don't think you are opening a can of worms unless you find something damaged, then you need to fabricate your own replacement part or replace the whole thing. The chances of it springing apart into a million unidentifiable pieces is very remote. If it were sort of working right now I'd be more cautious because you'd risk making it not work at all. That is not your situation, you either take it apart and make it work, or find out that it can't be repaired - either way you still haven't lost anything.

#14

Registered User

Thread Starter

Right you are, I can't thank you enough for all the time and energy you have been putting into explaining this to me. It is very much appreciated!!!! I will tackle this tomorrow and let you know the results forsure!!! Fingers crossed...lol!!!!

Last edited by kennyyoung; 11-05-2009 at 11:04 AM.

#15

Registered User

Thread Starter

Hey Beto, I just came in from under the truck. The first thing I did was to remove the Position Sensor to see if the ballbearing was sticking....it was perfectly fine!!! What I noticed though, was when I had the position sensor out, I plugged it back in and pushed the ballbearing up into the sensor. As I expected, the dash light came on with each push of the ballbearing..... but what I didnt expect, was to hear the front actuator engaging and the stubby front drive shaft lock as if the truck is in 4x4 with every push of the button. So what the heck is the point of the transfer case actuator anyway... if I bypass the actuator by just putting a toggle swith in place of the position sensor.... that would allow me to push a button, lock the stubby shaft and have the dash light come on. As long as that stubby shaft is locked, isnt it in 4x4? I couldnt get the motor cap off, the 3 screws are to rusted for a star screwdriver to even fit into them anymore. The only way for me to get them out is remove the actuator from the transfer case. So as my last resort, I took the wd40 and filled the bugger through that vent hose. Still not working yet, but im not giving up. Problem is, I took the day off to do the work and I wake up this morning to a snowstorm..... I tried anyway!!!! What do you think about bypassing the sensor?

#16

No, my old taco had a mod on that system. The ADD (automatic differential disconnect) system engages the front diff after the transfer confirms engagement of 4WD. The ADD system needs the front driveshaft and front axles to be turning at the same speed before it engages as it has no syncro's. The transfer has a syncro that spins the front driveshaft up to speed as it engages.

The purpose behind this system is to save fuel and wear and tear on the front drive components by having only the front axles turning, not the diff and front driveshaft.

I know this very well because I blew that syncro in my taco and had a mod to lock and unlock the ADD system manually. With it locked, the front driveshaft spins with the front axle but you are definitely not in 4WD, the transfer does not engage until the transfer actuator moves. My mod allowed me not to worry about that blown syncro by keeping the driveshaft spinning if I wanted. It also opened up "LOW2" possibility - handy for stop and go when you have a touchy stage II clutch.

If you do what you say in your post and are driving over a couple of miles per hour/kilometers per hour when you let ADD engage without the transfer, you will have a large "bang" coming from the front end. I never tried this over 2 or 3 KPH, but by the sound of it, I'd have dropped the front end out of the truck if I flipped that switch at speed.

And you are in CANADA - try a Robertson screwdriver bit. the biggest one that you can force into the head of those screws, and tap it with a hammer. I have used this trick several times, If you have enough room, try holding the robertson screwdriver with a pair of vice grips and turning while you are tapping the end of the handle with a hammer - this keeps it seated, and could be worth a shot.

The purpose behind this system is to save fuel and wear and tear on the front drive components by having only the front axles turning, not the diff and front driveshaft.

I know this very well because I blew that syncro in my taco and had a mod to lock and unlock the ADD system manually. With it locked, the front driveshaft spins with the front axle but you are definitely not in 4WD, the transfer does not engage until the transfer actuator moves. My mod allowed me not to worry about that blown syncro by keeping the driveshaft spinning if I wanted. It also opened up "LOW2" possibility - handy for stop and go when you have a touchy stage II clutch.

If you do what you say in your post and are driving over a couple of miles per hour/kilometers per hour when you let ADD engage without the transfer, you will have a large "bang" coming from the front end. I never tried this over 2 or 3 KPH, but by the sound of it, I'd have dropped the front end out of the truck if I flipped that switch at speed.

And you are in CANADA - try a Robertson screwdriver bit. the biggest one that you can force into the head of those screws, and tap it with a hammer. I have used this trick several times, If you have enough room, try holding the robertson screwdriver with a pair of vice grips and turning while you are tapping the end of the handle with a hammer - this keeps it seated, and could be worth a shot.

Last edited by Beto; 11-06-2009 at 07:19 AM.

#17

Registered User

Thread Starter

So at least I know my front actuator is working properly.....right? If I bypass that position sensor switch, get the the front actuator to engage and the stubby to lock, drive the truck a few yards...... would that turn the gears in the transfer case actuator to possibly get them freed up? Never mind......Im going to answer my own question here..... No, there are no splines on that shaft going into the transfer case, its just a smooth shaft..... isnt it? Im gonna have to take the entire back off the transfer case, just to get that actuator off ....I can see it coming!!!! Its easy to get into the internals of the main body of the actuator .... even while its on the truck....how complicated are the internals to take out, clean up and put back? Oh yeah, the screws on the motor cap.... the only way I could try a screwdriver and a hammer is in a vise on a bench.... its looking that way more and more.

Last edited by kennyyoung; 11-06-2009 at 08:02 AM.

#18

Nope. The front propeller shaft will just spin unengaged with the transfer, you'd be doing the same thing if you unlocked your front diff and spun the driveshaft by hand. BTW, just in case it happens, and to save you more confusion, you might notice that the front actuator stops working after a while without the engine running - it is vacuum actuated - there are two solenoids on the drivers fender well red and blue or red and black if I remember right.

Have you checked the electrical connections and voltages at the motor? You said before it was getting hot, so I assume it's getting power.

What was it I said about a can of worms?

Have you checked the electrical connections and voltages at the motor? You said before it was getting hot, so I assume it's getting power.

What was it I said about a can of worms?

#19

Registered User

Thread Starter

Yeah I realize how the vacuumm works on the front actuator.... truck must be running for the most part. The motor gets hot due to repeatedly pushing the button over and over again....yeah its getting power. I am now thinking its the intrenals of the actuator body itself....I hope the half can of wd40 in the breather hose decides to work over time. So, I guess by the can of worms remark .... I got a tough job on my hands if I open the actuator...thats what you are saying right? Any other ideas....lol?

#20

I don't think the actuator inside will be that bad, depending on what's seized up. I just meant that you've stripped those three screws on the motor cap, now getting into it the easy way is, well, not easy. I think if you could get that cap off, you'd be able to turn the stator by hand and apply more torque than the electric motor could on it's own, possibly freeing something up.

Last edited by Beto; 11-06-2009 at 08:24 AM.