Fake/Upside Down 3VZE Head Gaskets!

#41

Registered User

Join Date: Dec 2009

Location: Columbia Tennessee...that's 10EC

Posts: 436

Likes: 0

Received 0 Likes

on

0 Posts

If you want pictures and a back story, you'll need to click on the link I provided and take a look at them in the reference. When I have formulated a good hypothesis that I feel is reasonably sound, I will post my conclusions in that thread.

#42

Registered User

Thread Starter

More fuel for the fire...

The latest addition to the story goes something like this...

Some time ago I asked myself the question "I wonder if anybody(specifically Victor Reinz) still makes the original style(w/o Slipperplate™/expanded bore grommet) 3VZ-E head gaskets?". I'd remembered reading about Victor Reinz still making some for the 22R-E previously. And that they'll supposedly still do the just job as well, or better, for 22R-Es(and/or potentially those originally on my 3VZ-E) than the Slipperplate™/expanded bore grommet type also being made for it(and the only type known to exist for 3VZ-Es). So...

I've eventually I've gotten around to doing a bit of the research to see if it's even possible they exist. Which, so far, does suggest the possiblility that Victor Reinz MAY actually make a similar style/type of HGs for the 3VZ-E. Since they do make some type of HGs for it. Exactly which type they are? With a Slipperplate™/expanded bore grommet, or not? We'll see I guess? Somebody will have to provide more than what I've found. But here's what I've got so far...

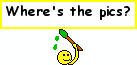

Victor Reinz #54186

Victor Reinz #54185

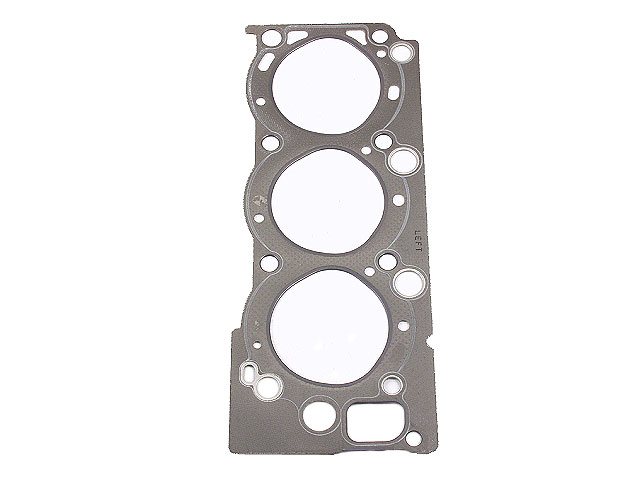

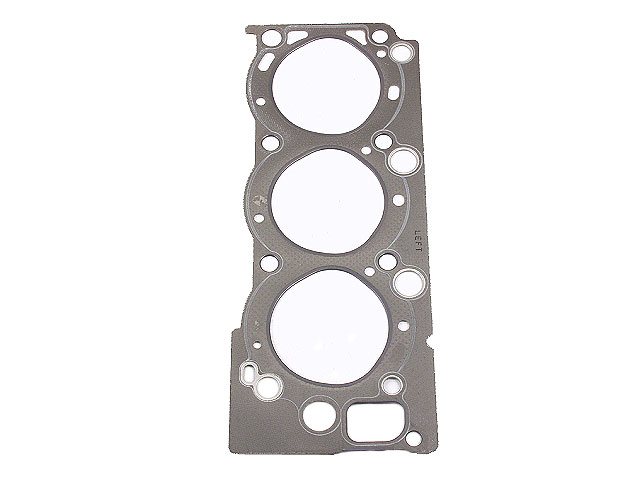

So...those must be either a type/style w/o Slipperplate™/expanded bore grommet(like the ones they make for the 22R-E). Or, if they do have a Slipperplate™/expanded bore grommet, it must be on the head facing sides of the gaskets. Because what is shown in the pics above are the block facing sides. Whichever type/style they are, the following has been stated regarding:

Victor Reinz Web Catalog

Some time ago I asked myself the question "I wonder if anybody(specifically Victor Reinz) still makes the original style(w/o Slipperplate™/expanded bore grommet) 3VZ-E head gaskets?". I'd remembered reading about Victor Reinz still making some for the 22R-E previously. And that they'll supposedly still do the just job as well, or better, for 22R-Es(and/or potentially those originally on my 3VZ-E) than the Slipperplate™/expanded bore grommet type also being made for it(and the only type known to exist for 3VZ-Es). So...

I've eventually I've gotten around to doing a bit of the research to see if it's even possible they exist. Which, so far, does suggest the possiblility that Victor Reinz MAY actually make a similar style/type of HGs for the 3VZ-E. Since they do make some type of HGs for it. Exactly which type they are? With a Slipperplate™/expanded bore grommet, or not? We'll see I guess? Somebody will have to provide more than what I've found. But here's what I've got so far...

Victor Reinz #54186

Victor Reinz #54185

So...those must be either a type/style w/o Slipperplate™/expanded bore grommet(like the ones they make for the 22R-E). Or, if they do have a Slipperplate™/expanded bore grommet, it must be on the head facing sides of the gaskets. Because what is shown in the pics above are the block facing sides. Whichever type/style they are, the following has been stated regarding:

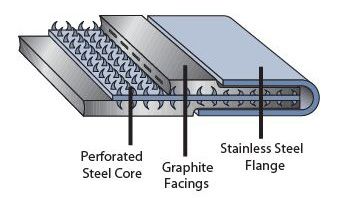

Gasket design: Fiber composite

Material: Nitroseal

• Stays cool at temperatures up to 1,800° F

• Doesn't know how to relax... no re-torque required

• Maximum heat transfer keeps your head (& manifold) straight

• Coolant, fuel and oil... no problem

• Designed to seal minor surface irregularities

Material: Nitroseal

• Stays cool at temperatures up to 1,800° F

• Doesn't know how to relax... no re-torque required

• Maximum heat transfer keeps your head (& manifold) straight

• Coolant, fuel and oil... no problem

• Designed to seal minor surface irregularities

Last edited by MudHippy; 12-07-2012 at 11:52 AM.

#43

Hey everyone! Ive been doing a lot of research on head gaskets, as I'm doing one in my 92 4Runner. One thing I've noticed in all threads related, from yotatech or other form sites is everyone has there own opinion on which aftermarket HG is the best to use. Also I've noticed that lots of people have a horror story of when they installed/had installed a new aftermarket HG that only went 10k, 15k, 30k, etc...

Whether the HG was from a reputable company, parts store or bought through eBay people have their horror stories....... All i can say is doing the HG is a finicky thing that takes time to do properly. More often then not people rush this job not follow every step from the FSM properly or even skipping steps!!! When re-surface the head check that it meets the specs for your specific HG (they change for HG to HG). Some HG's (depending on the material) need to be re-torqued after so many miles (this is often skipped as well).

Just remember not everything you hear is true. Its essayer to blame a faulty part then it is to blame a poorly done job.

(Please dont take this to heart, I just feel it something that never said but should be.)

Whether the HG was from a reputable company, parts store or bought through eBay people have their horror stories....... All i can say is doing the HG is a finicky thing that takes time to do properly. More often then not people rush this job not follow every step from the FSM properly or even skipping steps!!! When re-surface the head check that it meets the specs for your specific HG (they change for HG to HG). Some HG's (depending on the material) need to be re-torqued after so many miles (this is often skipped as well).

Just remember not everything you hear is true. Its essayer to blame a faulty part then it is to blame a poorly done job.

(Please dont take this to heart, I just feel it something that never said but should be.)

#44

Registered User

one should ALWAYS use OEM toyota gaskets when replacing things. Might cost more BUT you'll never have a problem. 3VZE complete gasket kit(v/c to pan) costs right under $300 BTW....

#48

I realize that this thread is pretty old, however, the DNJ Rock full gasket kit I opened yesterday for my 95 4Runner contained the upside-down head gaskets. I have received great products from them in the past and was quite surprised to find this. I will keep you posted how their customer plays out on this matter.

#49

Registered User

Thread Starter

I realize that this thread is pretty old, however, the DNJ Rock full gasket kit I opened yesterday for my 95 4Runner contained the upside-down head gaskets. I have received great products from them in the past and was quite surprised to find this. I will keep you posted how their customer plays out on this matter.

Which sucks. Since I won't use them. Or any that aren't of the older Rock or Ishino design. Wish me luck finding some. All other brands appear to have gone to the upside-down version now too. I may have to try the Victor Reinz(like OG OEM style found on my 88 possibly?)...if all else fails. My theory has pretty much evolved to "Toyota hasn't done anything right since 1988" anyways. Every design change they've made since then is/was just to cut corners IMO. Make it weaker for cheaper.

I'll post some pics later of these newer DNJs. They look even worse quality than the Evergreens. Which I still have. I'll have to compare them side-by-side.

I wonder what would have happened if I hadn't gone and said anything/started this thread. Would there still be both styles available? Being as what I really proved in the end here(and decades after the fact to boot) was that the newest OEM style really are "upside-down"(compared to the previous OEM design). So why would anyone be trying NOT to imitate the latest OEM style? Now that I've gone and unveiled the truth about it FOR ALL TO SEE(26K+ views). Looks like I went and shot myself in the foot on this one. Nice!

BTW, how did that go for you? What did you do with them? What did they have to say about it?

it). Now, show me a graphite HG that clearly shows deterioration(better yet, having failed) from being in contact with oil during use(good luck with that!). And you DO NOT retorque the HGs on a 3VZ-E. You my friend have MUCH research to do still. Come back when you have a clue what you're talking about eh?

it). Now, show me a graphite HG that clearly shows deterioration(better yet, having failed) from being in contact with oil during use(good luck with that!). And you DO NOT retorque the HGs on a 3VZ-E. You my friend have MUCH research to do still. Come back when you have a clue what you're talking about eh?

Last edited by MudHippy; 12-28-2015 at 12:43 PM.

#50

Registered User

Thread Starter

On second thought, I'm thinking I'll probably run the damn things just to prove a point. What point? We'll see I guess. Is "upside-down" really worse? Better? Basically the same? Not even as good as the originals(with no Slipperplate™)? Who knows? Not me...not yet anyway. And I suspect I may never. Far too many miles for me to drive in what's left of my lifetime, most likely. Only got just over 20K on the old style Rocks I installed on my 88(whatever many years ago that was). At that rate, and/or unless they fail pretty quick, it don't look too promising. And whichever kind I put on my 90, that I'm gathering these parts to rebuild, will only take that much longer/many more miles to prove anything. One guy, two Toyota trucks. Can I wear either one out? Or will they both eventually wear me out? I dunno. But it sure sounds like fun!!!!

Anyhow...

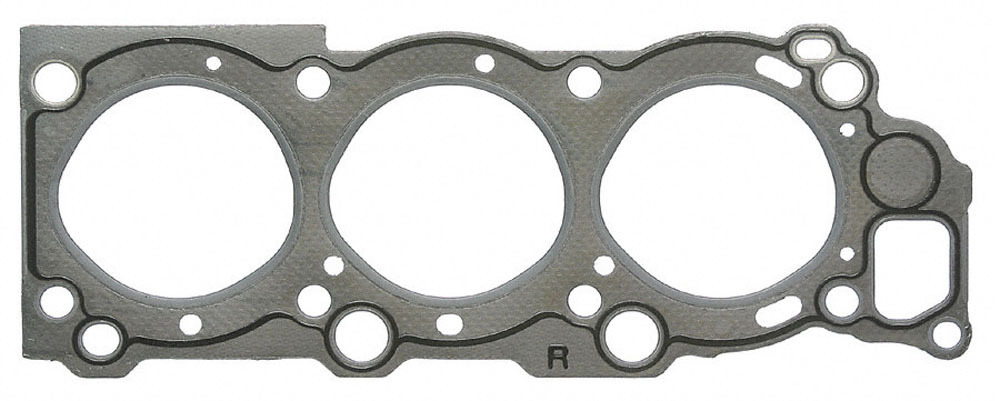

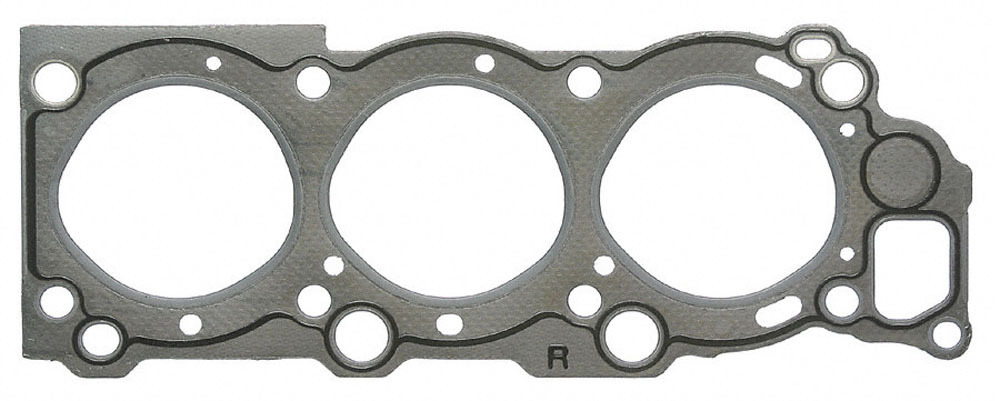

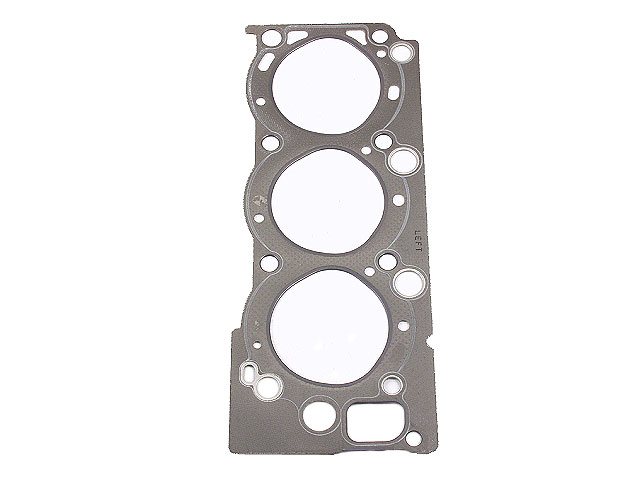

Here's the "new" DNJ Engine Components(no longer DNJ Rock) 3VZ-E HGs.

Man...I still don't know if I'm brave enough to try these though. It makes the most sense to me that the Slipperplate™ should face the best conditioned surface. Which, unless you're going to have the block resurfaced, is going to be the heads(resurfaced or not). And I don't like the idea of resurfacing a block. So far as I know it's bad idea entirely. I'm still not entirely sold on resurfacing the heads. Definitely no reason to if you're going to run HGs without the Slipperplate™ facing the heads. You could resurface the heads/block with a chainsaw, and the graphite-only side would still seal it. Which is why, I think, it should always face the block. If you're not following what I'm saying. Sorta confusing. Even more so the fact that either the heads or the block needing resurfaced is usually due to having used any kind of non-MLS HG previously. Which ALL do damage to the sealing/mating surfaces of either the block or the heads(or both) while in use. Like a thousand little needle marks strewn across the surface(s). If you've seen it...you know exactly what I'm talking about. It's not pretty.

and the graphite-only side would still seal it. Which is why, I think, it should always face the block. If you're not following what I'm saying. Sorta confusing. Even more so the fact that either the heads or the block needing resurfaced is usually due to having used any kind of non-MLS HG previously. Which ALL do damage to the sealing/mating surfaces of either the block or the heads(or both) while in use. Like a thousand little needle marks strewn across the surface(s). If you've seen it...you know exactly what I'm talking about. It's not pretty. And I want to do more of this because...?

And I want to do more of this because...?  Not like there's much choice I suppose.

Not like there's much choice I suppose.

Anyhow...

Here's the "new" DNJ Engine Components(no longer DNJ Rock) 3VZ-E HGs.

Man...I still don't know if I'm brave enough to try these though. It makes the most sense to me that the Slipperplate™ should face the best conditioned surface. Which, unless you're going to have the block resurfaced, is going to be the heads(resurfaced or not). And I don't like the idea of resurfacing a block. So far as I know it's bad idea entirely. I'm still not entirely sold on resurfacing the heads. Definitely no reason to if you're going to run HGs without the Slipperplate™ facing the heads. You could resurface the heads/block with a chainsaw,

and the graphite-only side would still seal it. Which is why, I think, it should always face the block. If you're not following what I'm saying. Sorta confusing. Even more so the fact that either the heads or the block needing resurfaced is usually due to having used any kind of non-MLS HG previously. Which ALL do damage to the sealing/mating surfaces of either the block or the heads(or both) while in use. Like a thousand little needle marks strewn across the surface(s). If you've seen it...you know exactly what I'm talking about. It's not pretty.

and the graphite-only side would still seal it. Which is why, I think, it should always face the block. If you're not following what I'm saying. Sorta confusing. Even more so the fact that either the heads or the block needing resurfaced is usually due to having used any kind of non-MLS HG previously. Which ALL do damage to the sealing/mating surfaces of either the block or the heads(or both) while in use. Like a thousand little needle marks strewn across the surface(s). If you've seen it...you know exactly what I'm talking about. It's not pretty. And I want to do more of this because...?

And I want to do more of this because...?  Not like there's much choice I suppose.

Not like there's much choice I suppose.

Last edited by MudHippy; 12-28-2015 at 04:16 PM.

#51

Registered User

I am currently building a a 22RE.

Both the head and the block deck are freshly surfaced.

I have a graphite with slipper plate type head gasket- pedigree unknown; it might be a cheapy Evergreen, I don't remember for sure.

Slipper plate is on top-toward the aluminum head.

The Ishino-Stone gasket set I bought came with a graphite gasket with no slipper plate.

I have used many plain graphite type head gaskets on Ford/Mazda and on other similar aluminum on steel engines with long lasting success, so I'm leaning towards installing the plain Stone graphite gasket on my fresh engine.

Any comments, or contrary suggestions from anyone????

Both the head and the block deck are freshly surfaced.

I have a graphite with slipper plate type head gasket- pedigree unknown; it might be a cheapy Evergreen, I don't remember for sure.

Slipper plate is on top-toward the aluminum head.

The Ishino-Stone gasket set I bought came with a graphite gasket with no slipper plate.

I have used many plain graphite type head gaskets on Ford/Mazda and on other similar aluminum on steel engines with long lasting success, so I'm leaning towards installing the plain Stone graphite gasket on my fresh engine.

Any comments, or contrary suggestions from anyone????

Last edited by millball; 12-28-2015 at 05:30 PM.

#52

Registered User

The slipper plate style head gasket was Toyotas answer to the friction caused on the gasket by two metals expanding and contracting at two different rates. The 22re doesn't have as much issues as the 3VZ-E, but it still could pose a problem.

Why not go with the Toyota head gasket. It's pretty cheap and proven?

Why not go with the Toyota head gasket. It's pretty cheap and proven?

#53

Registered User

Thread Starter

I am currently building a a 22RE.

Both the head and the block deck are freshly surfaced.

I have a graphite with slipper plate type head gasket- pedigree unknown; it might be a cheapy Evergreen, I don't remember for sure.

Slipper plate is on top-toward the aluminum head.

The Ishino-Stone gasket set I bought came with a graphite gasket with no slipper plate.

I have used many plain graphite type head gaskets on Ford/Mazda and on other similar aluminum on steel engines with long lasting success, so I'm leaning towards installing the plain Stone graphite gasket on my fresh engine.

Any comments, or contrary suggestions from anyone????

Both the head and the block deck are freshly surfaced.

I have a graphite with slipper plate type head gasket- pedigree unknown; it might be a cheapy Evergreen, I don't remember for sure.

Slipper plate is on top-toward the aluminum head.

The Ishino-Stone gasket set I bought came with a graphite gasket with no slipper plate.

I have used many plain graphite type head gaskets on Ford/Mazda and on other similar aluminum on steel engines with long lasting success, so I'm leaning towards installing the plain Stone graphite gasket on my fresh engine.

Any comments, or contrary suggestions from anyone????

I should also add that I have no proof that the Ishino HGs for the 3VZ-E do indeed have the Sliiperplate™/expanded bore grommet. They might not. From the pics, it either faces the head, or doesn't exist. It's been difficult for me to find much info on them. Just the pics, and this little snippet.

The 3VZE engine is experiencing possible "head gasket" problems. The dealer has been covering the first repair up to 100,000 miles driven, but they are not covering the second head gasket repair. From 061705 our head gaskets are of the latest design change, containing the OE Sanwa made head gaskets, 11115-65033 and 11116-65033. But the actual problem is with the head design. Prior to 061705, our head gaskets, were made by Ishino, and were designed based on the 11115-65031/2 and 11116-65031/2, which will work just fine.

http://www.autohausaz.com/pn/1111665031

The slipper plate style head gasket was Toyotas answer to the friction caused on the gasket by two metals expanding and contracting at two different rates. The 22re doesn't have as much issues as the 3VZ-E, but it still could pose a problem.

Why not go with the Toyota head gasket. It's pretty cheap and proven?

Why not go with the Toyota head gasket. It's pretty cheap and proven?

1. It wasn't Toyota's answer. They stole the idea(I proved that earlier in this thread).

2. The 22R(E) is the engine with the major HG issue. The 3VZ-E HG issue is a myth. The Slipperplate™ was originally designed for the 22R(E), to solve said issue.

People have just assumed it would be good for a 3VZ-E too.

3. Toyota has no clue when it comes to HGs. All they do is keep changing their minds. 4 different 3VZ-E HG part numbers? I mean come on. They're clueless.

Last edited by MudHippy; 12-29-2015 at 06:34 AM.

#54

Registered User

I like the way you think. For the most part. My main worry with resurfacing blocks is the potiential need to use a shim/spacer to gain piston to head clearance. They tend to get pretty beat up(compared to heads). The ones I've seen would need a lot of material removed. Which could be the case with the heads too. But removing enough material from either, or both, to need a shim/spacer just adds another component to possibly fail IMO. Since using them gives you 4 more additional surfaces to seal.

I am trying my best to build my engine as carefully as Toyota did.

#55

Registered User

I like the way you think. For the most part. My main worry with resurfacing blocks is the potiential need to use a shim/spacer to gain piston to head clearance. They tend to get pretty beat up(compared to heads). The ones I've seen would need a lot of material removed. Which could be the case with the heads too. But removing enough material from either, or both, to need a shim/spacer just adds another component to possibly fail IMO. Since using them gives you 4 more additional surfaces to seal.

I should also add that I have no proof that the Ishino HGs for the 3VZ-E do indeed have the Sliiperplate™/expanded bore grommet. They might not. From the pics, it either faces the head, or doesn't exist. It's been difficult for me to find much info on them. Just the pics, and this little snippet.

Hold on, I just found this too. Which supposedly shows "Stone 11116-65031", the same part # as the Ishino HGs. Which is of the other side(not previously shown in this thread) of the Left HG. And it appears to confirm that they(Ishino/Stone HGs for the 3VZ-E) DO NOT have a Slipperplate™/expanded bore grommet. As I previously assumed they did.

http://www.autohausaz.com/pn/1111665031

I beg to differ.

1. It wasn't Toyota's answer. They stole the idea(I proved that earlier in this thread).

2. The 22R(E) is the engine with the major HG issue. The 3VZ-E HG issue is a myth. The Slipperplate™ was originally designed for the 22R(E), to solve said issue.

People have just assumed it would be good for a 3VZ-E too.

3. Toyota has no clue when it comes to HGs. All they do is keep changing their minds. 4 different 3VZ-E HG part numbers? I mean come on. They're clueless.

I should also add that I have no proof that the Ishino HGs for the 3VZ-E do indeed have the Sliiperplate™/expanded bore grommet. They might not. From the pics, it either faces the head, or doesn't exist. It's been difficult for me to find much info on them. Just the pics, and this little snippet.

Hold on, I just found this too. Which supposedly shows "Stone 11116-65031", the same part # as the Ishino HGs. Which is of the other side(not previously shown in this thread) of the Left HG. And it appears to confirm that they(Ishino/Stone HGs for the 3VZ-E) DO NOT have a Slipperplate™/expanded bore grommet. As I previously assumed they did.

http://www.autohausaz.com/pn/1111665031

I beg to differ.

1. It wasn't Toyota's answer. They stole the idea(I proved that earlier in this thread).

2. The 22R(E) is the engine with the major HG issue. The 3VZ-E HG issue is a myth. The Slipperplate™ was originally designed for the 22R(E), to solve said issue.

People have just assumed it would be good for a 3VZ-E too.

3. Toyota has no clue when it comes to HGs. All they do is keep changing their minds. 4 different 3VZ-E HG part numbers? I mean come on. They're clueless.

I also beg to differ the 22re had head gasket issues. They had timing chain issues that led to head gasket issues. The 22r with the double row timing chain never had head gasket issues because they never timing chain issues. Many see the correlation between the two, but never understood the causation. Antifreeze contaminating the oil is what killed the head gaskets.

#56

Registered User

Thread Starter

2. Beg all you want. But it's not even debateable. Search this site for "22R-E head gasket failure" threads. Then "3VZ-E head gasket failure" threads. Wonder why there's several hundred more of one than the other? I don't!

I just emailed engnbldr today about this. Here's how that played out:

Hey, can you guys get me some 3VZ-E head gaskets with the Slipperplate facing the heads? The whole world, including DNJ Rock(or whoever the hell they are now) has gone bassackwards on me since the last time I needed some. Now I don't know where to get them, if anybody still makes/has them, or what I should use instead. I didn't know I was supposed to stock up before they vanished off the face of the Earth. Or I would have.

Help me Obi-Wan Kenobi...you're my only hope!

Help me Obi-Wan Kenobi...you're my only hope!

Hi.

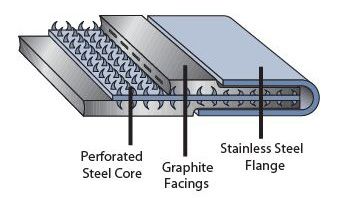

I wish I could since the last most recent update on the design, no one makes them the old way any more. Of course the “Slipperplate” design was my own, that applies to the 22R/RE head gasket.

The idea is that during thermal expansion, the steel facing allows the metal to expand and slip.

Engineering says the only reason for steel on the 3VZE since the aluminum is a different metalurgy and does not expand the same is to retain the gasket integrity.

Less costly to do them all one way is the current theory, so far it seems to work all right.

Sorry, no source here, either, kind of wish I did, I could sell the dickens out of them.

Ted

I wish I could since the last most recent update on the design, no one makes them the old way any more. Of course the “Slipperplate” design was my own, that applies to the 22R/RE head gasket.

The idea is that during thermal expansion, the steel facing allows the metal to expand and slip.

Engineering says the only reason for steel on the 3VZE since the aluminum is a different metalurgy and does not expand the same is to retain the gasket integrity.

Less costly to do them all one way is the current theory, so far it seems to work all right.

Sorry, no source here, either, kind of wish I did, I could sell the dickens out of them.

Ted

I'm still thinking it's a total disaster in the making. Might just have to go to MLS afterall. What a nightmare...

Last edited by MudHippy; 12-30-2015 at 05:14 PM.

#57

Registered User

Thread Starter

I'm going to try a couple other possibilities. Just to be sure where we're at here. I found some from a couple different sources that look like they might be what I'm after. Both have graphite sides towards the block at least. So there's a 50/50 chance there might be a Slipperplate on the other. And they're a lot cheaper than the Victor Reinz. Now I just have to order some and find out.

We'll see if I turn any up....no pun intended.

We'll see if I turn any up....no pun intended.

Last edited by MudHippy; 01-10-2016 at 07:15 AM.

#58

Registered User

Thread Starter

I did manage to find some with the Slipperplate™ towards the head. Could be one of the last remaining sets of their type and brand too. It looks like there's another set available if you know which 2 sites to go to. One site has the L and the other site has the R.

They're Apex brand. And are nearly identical to the original Rock design. Structural/design wise they're totally identical. In fact I believe they actually are rebranded original style Rocks.

Anyhow, I think I might be saving them for later and going with the Evergreens or the new Rocks on my next rebuild. Just to prove a point.

There's still some of another brand/design on ebay that I haven't seen both sides of yet. They might have the Slipperplate™ towards the head too. And there's a couple guys selling them. So there's quite a few of them to be had. Thing is you have to buy the whole rest of the set they come in. Since they don't sell them separately. The set is cheap enough that the rest of the gaskets in it could be considered freebies though. IOW, it's the same price as a cheap set of head gaskets anywhere else.

Here's those.

They're Apex brand. And are nearly identical to the original Rock design. Structural/design wise they're totally identical. In fact I believe they actually are rebranded original style Rocks.

Anyhow, I think I might be saving them for later and going with the Evergreens or the new Rocks on my next rebuild. Just to prove a point.

There's still some of another brand/design on ebay that I haven't seen both sides of yet. They might have the Slipperplate™ towards the head too. And there's a couple guys selling them. So there's quite a few of them to be had. Thing is you have to buy the whole rest of the set they come in. Since they don't sell them separately. The set is cheap enough that the rest of the gaskets in it could be considered freebies though. IOW, it's the same price as a cheap set of head gaskets anywhere else.

Here's those.

Last edited by MudHippy; 03-01-2016 at 06:44 AM.

#60

Registered User

Thread Starter

You're welcome. I'm not sure for what. Good luck with whichever path you choose. But you probably won't need it. Since though there may be many different brands/types, there doesn't seem to be much substantial evidence showing one brand/type is any better/worse than another. Which may be because they're all relatively good variations of the design. Or, as I've said time and time again, because the 3VZ-E doesn't really have any major problem related to head gaskets anyway. It's one of the biggest internet myths ever propagated. So any head gasket you put in it will probably work just fine.