portable trail wirefeed welder ??

#1

portable trail wirefeed welder ??

I figure you guys get out on the trail more often than most of the other boards  ...and I bet you wish you had a welder sometimes.....a nice cheap one. A "Ready welder" can be had for about 600.

...and I bet you wish you had a welder sometimes.....a nice cheap one. A "Ready welder" can be had for about 600.

I researched using a spool gun as a "poor man's wirefeed welder" with google and nobody has ever documented ever never not in the least no-way using a spoolgun as a trail welder....so I tried it and I likey!!

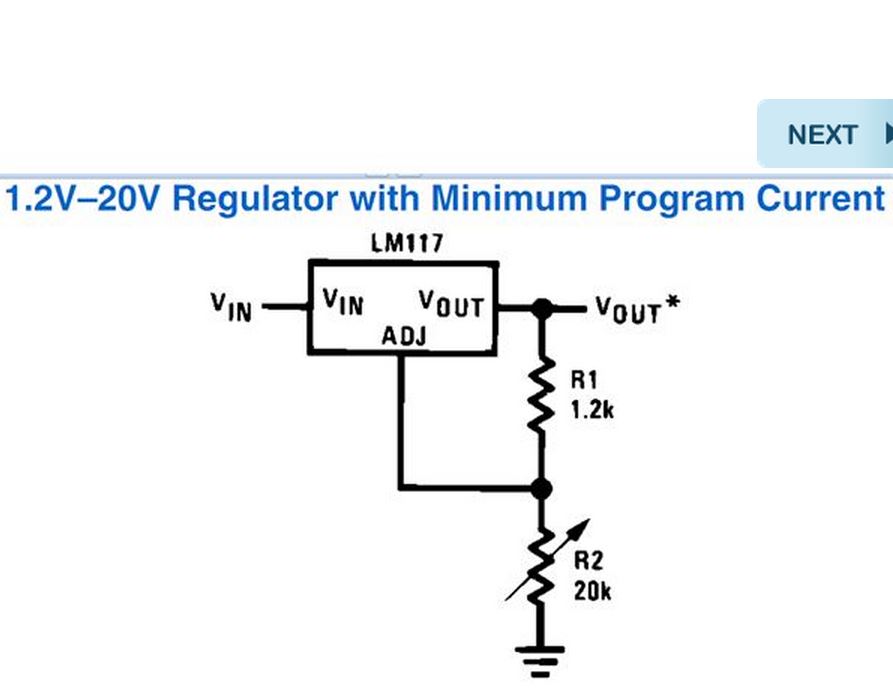

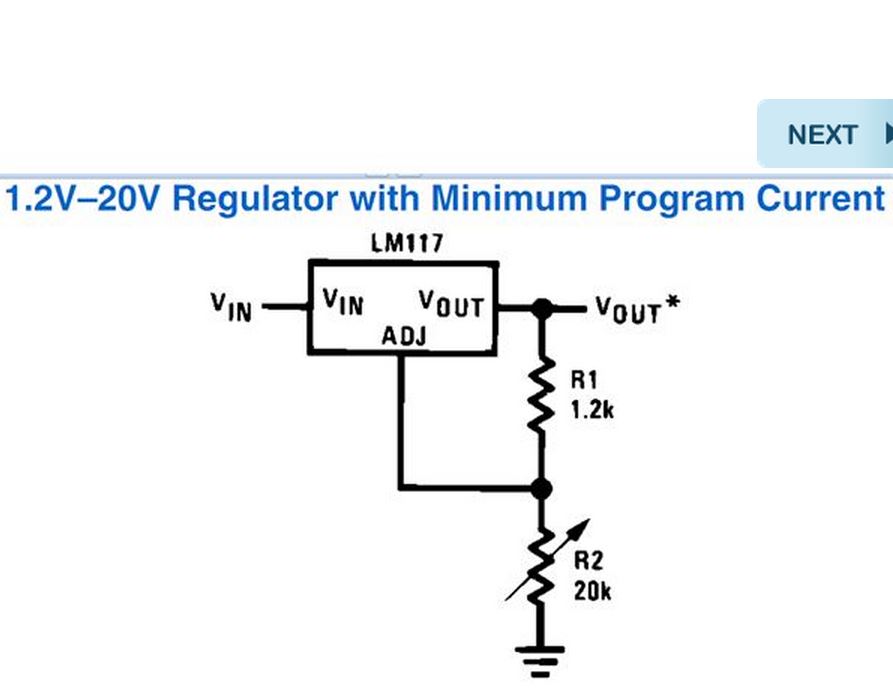

I bought the cheapest spoolgun I could find(about $120)....so the quality of the wirefeed mechanism might not be the best. The spoolguns make use of the wirefeed controller on the main welder....so something has to be done to get the right wirefeed voltage to the motor when used in the outback. I addressed that with simplicity. I show the LM317 integrated chip below but never mind that....not everybody is an engineer and I like to keep it as simple as possible even for my own use. see below.......

.

.

.

.

.

.

.

Planning on converting this spool gun for trail use. 030 flux core steel wire is the plan. Just have to make an LM317 IC the variable voltage

source for the wire feed controller. Preliminary tests (No wire, No load) indicate this wire feed motor operates in

the range of 3~9 volts dc and draws 160 milli-amps.

++++++++++++++++++++++++++++++++++++++++++++++++++ ++++++++++++++++++++++++++++++++++++++++++++++++++ ++++++++++++++++++++++++++++++++++++++++++++++++++ ++++++++++++++++++++++++++++++++++++++++++++++++++ +++++++++++++

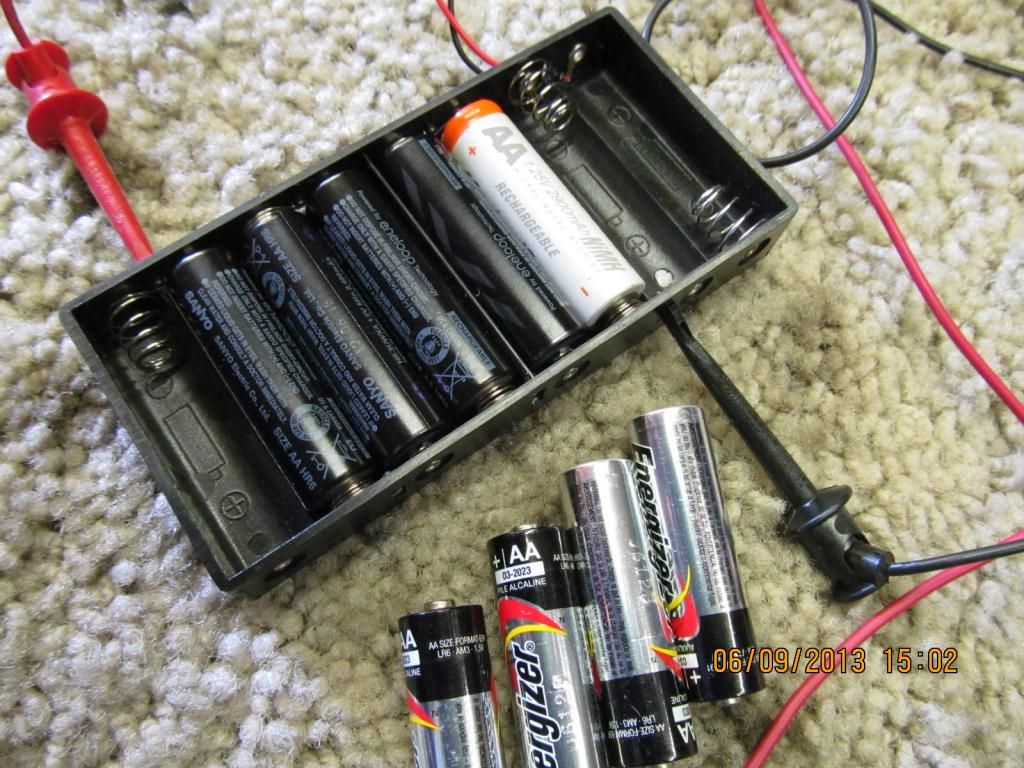

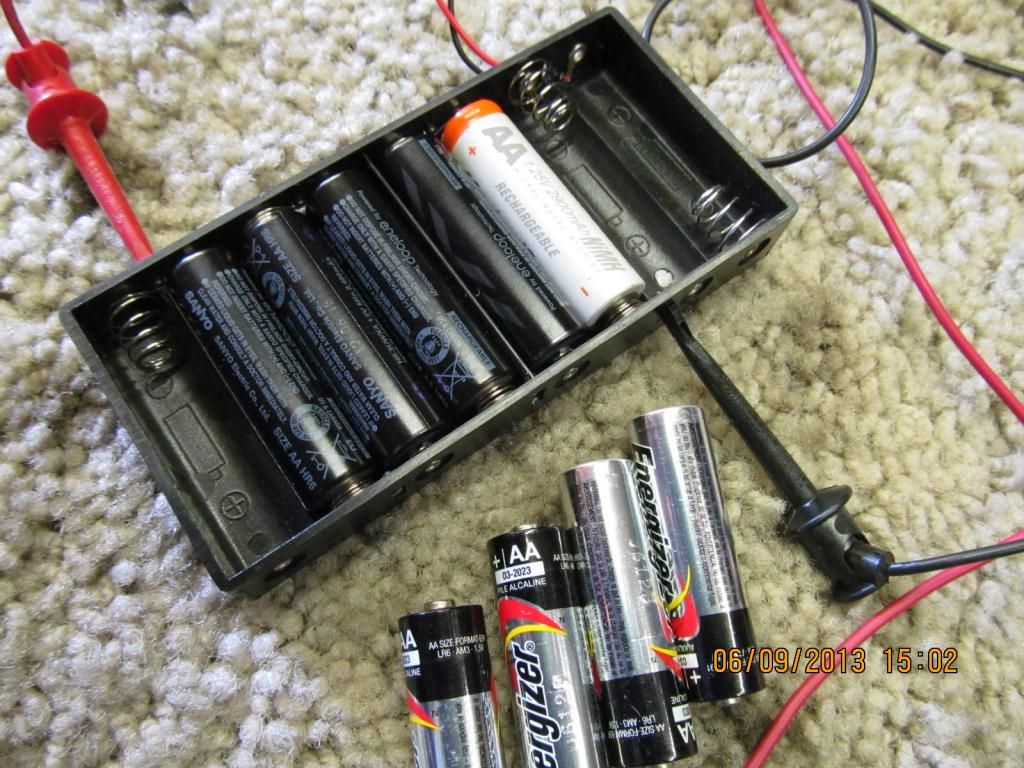

Looks like I have myself a $120 trail wirefeed welder The 24 volts is just fine for 1/8" to 1/4" mild steel. In the interests of simplicity, instead of the LM317 voltage chip for the wirefeed control, I chose to experiment with small AA batteries.... 4.5volt is too low.......6.0 volt is just about right.....7.5v is too fast....and this is for 030 flux core. So, this means no fancy variable voltage circuit is needed and I can see 4 c cells doing a nice job for. If using larger full sized truck batteries then that means the welding power goes up and 4 c cells is a little slow so 5 or 6 c's should more than do it. Buy a C cell battery holder....one that holds up to 6 cells and you're all set for all situations.

The 24 volts is just fine for 1/8" to 1/4" mild steel. In the interests of simplicity, instead of the LM317 voltage chip for the wirefeed control, I chose to experiment with small AA batteries.... 4.5volt is too low.......6.0 volt is just about right.....7.5v is too fast....and this is for 030 flux core. So, this means no fancy variable voltage circuit is needed and I can see 4 c cells doing a nice job for. If using larger full sized truck batteries then that means the welding power goes up and 4 c cells is a little slow so 5 or 6 c's should more than do it. Buy a C cell battery holder....one that holds up to 6 cells and you're all set for all situations.

Wire is loaded up.

I've had this 1/2 spool for 10 years now so it's time to use some of it.

This is fluxcore so positive ground.

the negative lead goes to the brass end.

Right side is the red attached to +......left side is the black negative of the battery cable jumper attached to -........middle is a jumper.

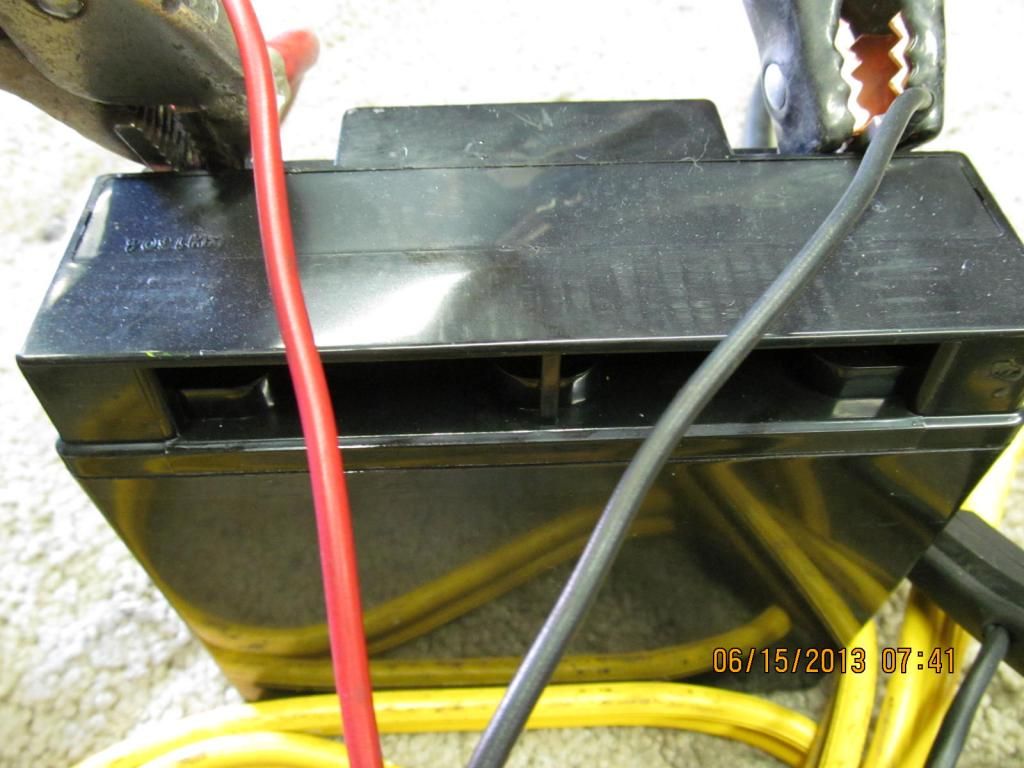

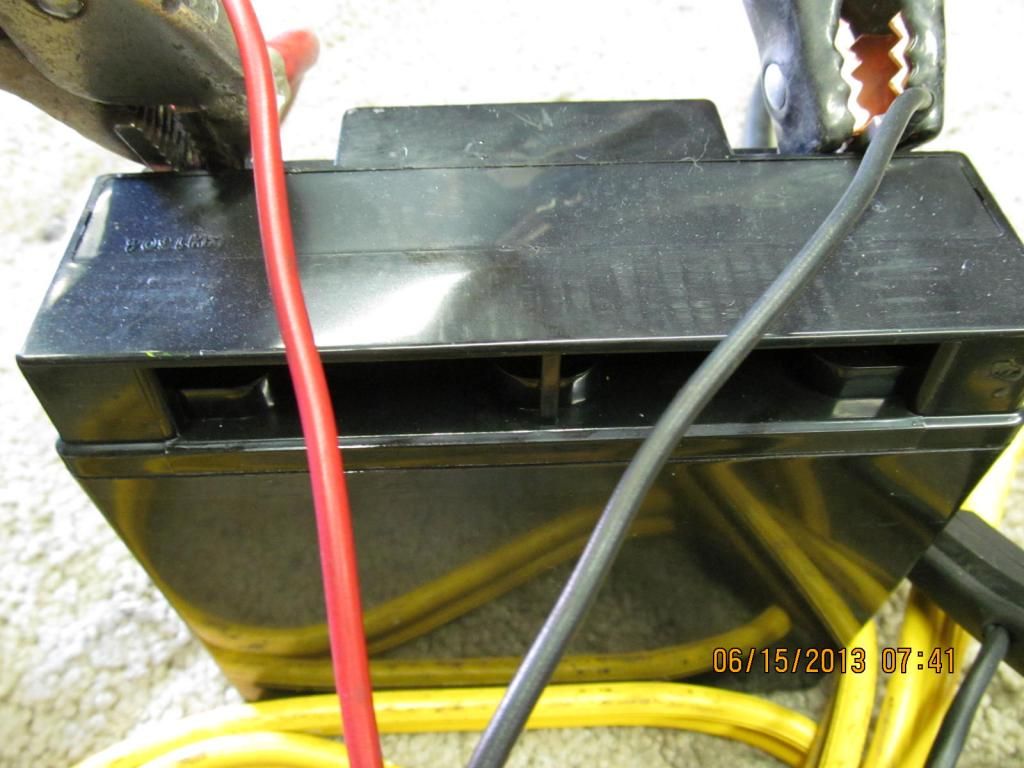

Got these online. 20 amp/hours is a long ways from car batteries but 3 times better than the old Harborfreight Century 131B portable welder with the 2 tiny internal batteries....if anyone knows what I am talking about.

I cut off the black interface jack and will solder on my own alligator clips in the near future.

Red and white are plus and minus for the wirefeed motor....yellow and green come from the trigger. Connecting up my 6 volts as shown lets me use the trigger to start/stop the wire. Picture is hard to see but 6v positve goes to the red wire....negative goes to the YELLOW.....green and white just get twisted together. This is how you can use the trigger to interrupt the voltage to the wirefeed motor. Very easy. I really like the KISS principle.

Here's my way under-powered wirefeed battery juice set-up....Wire feed rate might speed up/slow down based on how much of a birds nest my 4 pound spool is. Imagine the smoother feed with 4 C cells....or a BIG 6 volt motorcycle battery similar to the two 12 volters I have for electrode power. Here, I am using 5 re-chargeables....5 times 1.2volts....or I could use 4 alkalines.....4 times 1.5volts...same effect.

Here, I am going to run a vertical down weld.

wow, sure has a nice quiet hissy sound unlike the BUZZZZ of a 120vac garage unit. I'm not doing a steady vertical feed....I'm weaving it back and forth similar to C's. Feels real good.

Here, I am doing a horizontal weld.....doing C's.

Here's the un-retouched vertical weld....flux-core leaves a light coating of slag similar to stick. Sure looks ugly here with all that yellow/brown burnt smokey crap.

Here's the horizontal weld....ugly as hell untouched.

Vertical weld cleaned up........

horiz weld cleaned up. This "spoolgun" is going in my trucks toolbox for those trail rides ......

.

.

.

.

.

.

.

.

.

.

.

.

...and I bet you wish you had a welder sometimes.....a nice cheap one. A "Ready welder" can be had for about 600.

...and I bet you wish you had a welder sometimes.....a nice cheap one. A "Ready welder" can be had for about 600.I researched using a spool gun as a "poor man's wirefeed welder" with google and nobody has ever documented ever never not in the least no-way using a spoolgun as a trail welder....so I tried it and I likey!!

I bought the cheapest spoolgun I could find(about $120)....so the quality of the wirefeed mechanism might not be the best. The spoolguns make use of the wirefeed controller on the main welder....so something has to be done to get the right wirefeed voltage to the motor when used in the outback. I addressed that with simplicity. I show the LM317 integrated chip below but never mind that....not everybody is an engineer and I like to keep it as simple as possible even for my own use. see below.......

.

.

.

.

.

.

.

Planning on converting this spool gun for trail use. 030 flux core steel wire is the plan. Just have to make an LM317 IC the variable voltage

source for the wire feed controller. Preliminary tests (No wire, No load) indicate this wire feed motor operates in

the range of 3~9 volts dc and draws 160 milli-amps.

++++++++++++++++++++++++++++++++++++++++++++++++++ ++++++++++++++++++++++++++++++++++++++++++++++++++ ++++++++++++++++++++++++++++++++++++++++++++++++++ ++++++++++++++++++++++++++++++++++++++++++++++++++ +++++++++++++

Looks like I have myself a $120 trail wirefeed welder

The 24 volts is just fine for 1/8" to 1/4" mild steel. In the interests of simplicity, instead of the LM317 voltage chip for the wirefeed control, I chose to experiment with small AA batteries.... 4.5volt is too low.......6.0 volt is just about right.....7.5v is too fast....and this is for 030 flux core. So, this means no fancy variable voltage circuit is needed and I can see 4 c cells doing a nice job for. If using larger full sized truck batteries then that means the welding power goes up and 4 c cells is a little slow so 5 or 6 c's should more than do it. Buy a C cell battery holder....one that holds up to 6 cells and you're all set for all situations.

The 24 volts is just fine for 1/8" to 1/4" mild steel. In the interests of simplicity, instead of the LM317 voltage chip for the wirefeed control, I chose to experiment with small AA batteries.... 4.5volt is too low.......6.0 volt is just about right.....7.5v is too fast....and this is for 030 flux core. So, this means no fancy variable voltage circuit is needed and I can see 4 c cells doing a nice job for. If using larger full sized truck batteries then that means the welding power goes up and 4 c cells is a little slow so 5 or 6 c's should more than do it. Buy a C cell battery holder....one that holds up to 6 cells and you're all set for all situations.

Wire is loaded up.

I've had this 1/2 spool for 10 years now so it's time to use some of it.

This is fluxcore so positive ground.

the negative lead goes to the brass end.

Right side is the red attached to +......left side is the black negative of the battery cable jumper attached to -........middle is a jumper.

Got these online. 20 amp/hours is a long ways from car batteries but 3 times better than the old Harborfreight Century 131B portable welder with the 2 tiny internal batteries....if anyone knows what I am talking about.

I cut off the black interface jack and will solder on my own alligator clips in the near future.

Red and white are plus and minus for the wirefeed motor....yellow and green come from the trigger. Connecting up my 6 volts as shown lets me use the trigger to start/stop the wire. Picture is hard to see but 6v positve goes to the red wire....negative goes to the YELLOW.....green and white just get twisted together. This is how you can use the trigger to interrupt the voltage to the wirefeed motor. Very easy. I really like the KISS principle.

Here's my way under-powered wirefeed battery juice set-up....Wire feed rate might speed up/slow down based on how much of a birds nest my 4 pound spool is. Imagine the smoother feed with 4 C cells....or a BIG 6 volt motorcycle battery similar to the two 12 volters I have for electrode power. Here, I am using 5 re-chargeables....5 times 1.2volts....or I could use 4 alkalines.....4 times 1.5volts...same effect.

Here, I am going to run a vertical down weld.

wow, sure has a nice quiet hissy sound unlike the BUZZZZ of a 120vac garage unit. I'm not doing a steady vertical feed....I'm weaving it back and forth similar to C's. Feels real good.

Here, I am doing a horizontal weld.....doing C's.

Here's the un-retouched vertical weld....flux-core leaves a light coating of slag similar to stick. Sure looks ugly here with all that yellow/brown burnt smokey crap.

Here's the horizontal weld....ugly as hell untouched.

Vertical weld cleaned up........

horiz weld cleaned up. This "spoolgun" is going in my trucks toolbox for those trail rides ......

.

.

.

.

.

.

.

.

.

.

.

.

Last edited by ZUK; 06-09-2013 at 04:06 PM.

#7

Registered User

Join Date: May 2013

Location: Vancouver, Wa

Posts: 78

Likes: 0

Received 0 Likes

on

0 Posts

That. Is. Awesome!

Instruction only goes so far. There is no replacement for hood time.

Thats the only way you will be able to "see" whats actually going on.

Weldingtipsandtricks.com is a good place to start though. He does alot more TIG welding than anything, but you can find awesome info on there. Youtube as well.

Instruction only goes so far. There is no replacement for hood time.

Thats the only way you will be able to "see" whats actually going on.

Weldingtipsandtricks.com is a good place to start though. He does alot more TIG welding than anything, but you can find awesome info on there. Youtube as well.

Trending Topics

#8

Registered User

Join Date: Oct 2009

Location: NW Phoenix

Posts: 134

Likes: 0

Received 0 Likes

on

0 Posts

ZUK,

Instead of the "other" batteries to control the speed, could I just tap off my own variable controller off of one of the welding batteries? You know, a potientiometer to "dial adjust" the speed, as needed?

Instead of the "other" batteries to control the speed, could I just tap off my own variable controller off of one of the welding batteries? You know, a potientiometer to "dial adjust" the speed, as needed?

#10

Stace-

You crack me up.

Actually, using a variable resistor(pot)....or fixed resistor is worth a try.

Assume tapping into one of the 12 volt batteries....160ma going thru a resistor that is sucking up to 6 volts cross it means 1 watt of heat across that resistor(pot).

P=IE.... .160 x 6......1 watt

E=IR......

R=E/I......6v/.160.....36 ohm for 6 volts to motor

R=E/I......5v/.160.....30 ohm for 7 volts to motor

I'll try it out and see how it works.

You crack me up.

Actually, using a variable resistor(pot)....or fixed resistor is worth a try.

Assume tapping into one of the 12 volt batteries....160ma going thru a resistor that is sucking up to 6 volts cross it means 1 watt of heat across that resistor(pot).

P=IE.... .160 x 6......1 watt

E=IR......

R=E/I......6v/.160.....36 ohm for 6 volts to motor

R=E/I......5v/.160.....30 ohm for 7 volts to motor

I'll try it out and see how it works.

Last edited by ZUK; 06-13-2013 at 07:44 AM. Reason: spelling and arithmetik

#14

Hey Stetson....just get a 6~9 ohm 2~3 watt rated carbon resistor and go for it. That's all it really takes.

Stace----The pot worked aok....basically, I introduced about 6 ohms resistance

and it slowed the wire feed just enough

to do a great job for most any use. Here's some pics......

Here's the rheostat (pot) I'm gonna say that a 10 ohm variable pot is about perfect....but I also bet a fixed 6~9 ohm resistor will work aok....keep it simple and stupid.

To hook up the pot with power to the wire feed motor I first run a couple of small guage jumpers to to either battery.

The + red from the battery goes to the left here to the red for the motor....the jumper on the far right now goes to the pot. White is the - for the motor.....remember that green and yellow go to the trigger and short together when the trigger is squeezed so now run a jumper on the far right to the pot.

I connected it to the middle and the bottom one simply goes back to the - on the 12v battery. Path is now complete. Just squeeze the trigger and things start turning.

So, I grabbed some 1/8" scrap....going to run a vertical weld first and then another horizontal.

I ran about 1 inch of vertical weld and I thought the speed was a little fast so I slowed the feed down a little and finished the weld.

Just knocked the light slag coating off.....

Amazing how the real weld looks with a little clean-up from the high speed wire wheel. Notice the top 1 inch at the faster speed seems about right....good flow and fill. Then I slowed the feed down and you can see the change. Should have left it running a little faster.

Here's the horizontal weld from left to right.....not bad.

Stace----The pot worked aok....basically, I introduced about 6 ohms resistance

and it slowed the wire feed just enough

to do a great job for most any use. Here's some pics......

Here's the rheostat (pot) I'm gonna say that a 10 ohm variable pot is about perfect....but I also bet a fixed 6~9 ohm resistor will work aok....keep it simple and stupid.

To hook up the pot with power to the wire feed motor I first run a couple of small guage jumpers to to either battery.

The + red from the battery goes to the left here to the red for the motor....the jumper on the far right now goes to the pot. White is the - for the motor.....remember that green and yellow go to the trigger and short together when the trigger is squeezed so now run a jumper on the far right to the pot.

I connected it to the middle and the bottom one simply goes back to the - on the 12v battery. Path is now complete. Just squeeze the trigger and things start turning.

So, I grabbed some 1/8" scrap....going to run a vertical weld first and then another horizontal.

I ran about 1 inch of vertical weld and I thought the speed was a little fast so I slowed the feed down a little and finished the weld.

Just knocked the light slag coating off.....

Amazing how the real weld looks with a little clean-up from the high speed wire wheel. Notice the top 1 inch at the faster speed seems about right....good flow and fill. Then I slowed the feed down and you can see the change. Should have left it running a little faster.

Here's the horizontal weld from left to right.....not bad.

Last edited by ZUK; 06-15-2013 at 08:18 AM.

#15

Update.....best to use a pair of truck batteries. I noted my 18 amp/hour rated batteries were mostly dis-charged on the last bit of welding I did (11.7 volts each). Obviously, the size of the truck batteries will last much longer.

Last edited by ZUK; 06-15-2013 at 11:15 AM.

Thread

Thread Starter

Forum

Replies

Last Post

TheBFA

Solid Axle Swaps, All Years

8

02-15-2020 06:55 AM

primordialbeast117

86-95 Trucks & 4Runners

11

12-19-2015 12:23 PM

83yotastockR

86-95 Trucks & 4Runners (Build-Up Section)

11

11-10-2015 06:54 AM

Toys4parts

86-95 Trucks & 4Runners (Build-Up Section)

2

09-26-2015 01:56 PM