HELP!!! Burnt Valve issue

#1

Registered User

Thread Starter

Join Date: May 2008

Location: Provo Utah

Posts: 8

Likes: 0

Received 0 Likes

on

0 Posts

hi all. i'm new to the site so please don't flame me if this has been brought up a billion times. i performed a search but couldn't really find what i was looking for. i recently purchased an 89 ext cab with the 3.0 3vze. not knowing much about it i thought it ran decently and the guy i bought it from said there wasn't any wrong with it besides needing a new drivers side cv boot and the a/c didn't work.

well when i tried to get emissions done i found out there was something wrong and according to my mechanic (who i shoulda had check out the truck b4 i bought it) says i have a burnt valve.

i tried to call the guy i bought it from but he won't answer my calls so i'm guessing he knew it had more problems then he let on. ( BASTARD!!!!!)

BASTARD!!!!!)

any who... i can't afford $2200 to have a shop fix this when i only paid 2500 for the whole truck.

so here's my question (sorry for the lengthy intro)

(sorry for the lengthy intro)

how hard of a DIY job would this be? i'm fairly good with my hands and really want to learn. i've done all my own work on my car and have learned lots by working on it but i've never taken on something of this type.

any and all help would be much appreciated. also if there are any Utah members that would be willing to give me a hand i would really appreciate it. thanks

please no

well when i tried to get emissions done i found out there was something wrong and according to my mechanic (who i shoulda had check out the truck b4 i bought it) says i have a burnt valve.

i tried to call the guy i bought it from but he won't answer my calls so i'm guessing he knew it had more problems then he let on. (

BASTARD!!!!!)

BASTARD!!!!!)any who... i can't afford $2200 to have a shop fix this when i only paid 2500 for the whole truck.

so here's my question

(sorry for the lengthy intro)

(sorry for the lengthy intro)how hard of a DIY job would this be? i'm fairly good with my hands and really want to learn. i've done all my own work on my car and have learned lots by working on it but i've never taken on something of this type.

any and all help would be much appreciated. also if there are any Utah members that would be willing to give me a hand i would really appreciate it. thanks

please no

#2

I did a simplified write up of replacing burnt exhaust valves. You can find it here:

https://www.yotatech.com/forums/f2/1...valves-140030/

It is really a watered down version of the process, and it is a 3rzfe (2.7 4 cyl) instaed of a 3.0, but it will give you an idea of what you are up against. It is not an easy job, but it is doable. You may wish to have a machine shop rebuild your heads instead of just lapping in new valves yourself like I did, but it really depends on how confident you are making the repairs.

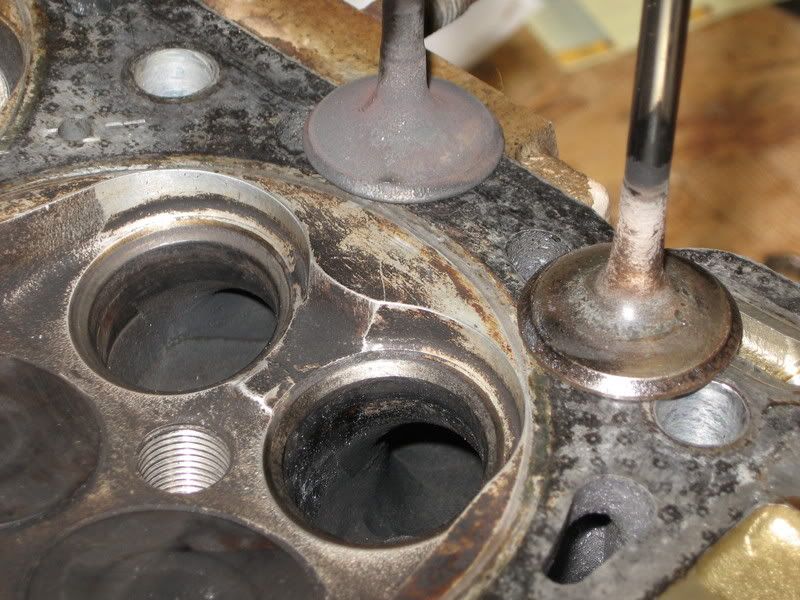

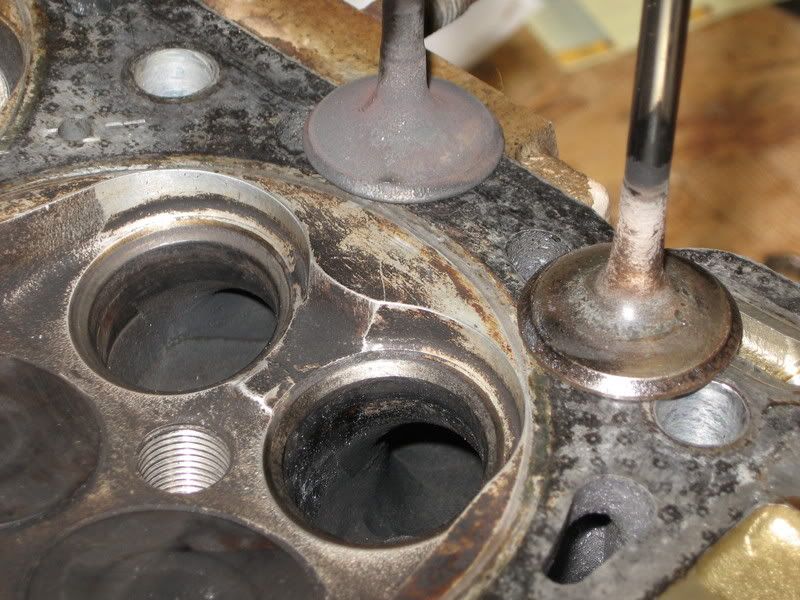

Here's what the valves I replaced looked like on teardown:

https://www.yotatech.com/forums/f2/1...valves-140030/

It is really a watered down version of the process, and it is a 3rzfe (2.7 4 cyl) instaed of a 3.0, but it will give you an idea of what you are up against. It is not an easy job, but it is doable. You may wish to have a machine shop rebuild your heads instead of just lapping in new valves yourself like I did, but it really depends on how confident you are making the repairs.

Here's what the valves I replaced looked like on teardown:

Last edited by zlathim; 05-07-2008 at 06:53 AM.

#5

Registered User

My recommendation would be to get that head off - that's where the vast majority of the labor is and the majority of the cost. IF you can get the head off and into a machine shop, you're probably looking at around $100-$150 to have the head put back into spec.

Note, while you're in there you might as well do the timing belt. Consider doing the water pump. It's likely that you'll need new shims / valve adjustment on the head that you have the work done on.

Note, while you're in there you might as well do the timing belt. Consider doing the water pump. It's likely that you'll need new shims / valve adjustment on the head that you have the work done on.

#6

Registered User

Join Date: Mar 2008

Location: Temecula Valley, CA

Posts: 12,723

Likes: 0

Received 4 Likes

on

4 Posts

It means applying lapping compound (which is a fine abrasive paste) to the head/valve seat where it seals with the valve then spinning the valve while pulling it gently against the valve seat. The lapping compound slightly grinds the valve and seat so that they have very round and matched mating surfaces.

#7

It means applying lapping compound (which is a fine abrasive paste) to the head/valve seat where it seals with the valve then spinning the valve while pulling it gently against the valve seat. The lapping compound slightly grinds the valve and seat so that they have very round and matched mating surfaces.

You can see that there were a couple of pits on the seat on the right after lapping, and maybe the contact area is a little wide, but it runs great.

Last edited by zlathim; 05-08-2008 at 05:40 AM.

Trending Topics

#8

Registered User

Join Date: Jul 2002

Location: Thurston County WA State

Posts: 977

Likes: 0

Received 0 Likes

on

0 Posts

I have a burnt valve on my 94 pickup as well. It has been that way for a while. No power, and poor fuel economy are some of the symptoms. I was going to get my 3.0 rebuilt but instead I am getting a 2RZ-FE swapped in along with an R151F Turbo tranny and a dual ultimate (2.28/4.7) crawler installed. Oh and by the way all that is less than getting the original 3.0 rebuilt.

#9

Contributing Member

I have a burnt valve on my 94 pickup as well. It has been that way for a while. No power, and poor fuel economy are some of the symptoms. I was going to get my 3.0 rebuilt but instead I am getting a 2RZ-FE swapped in along with an R151F Turbo tranny and a dual ultimate (2.28/4.7) crawler installed. Oh and by the way all that is less than getting the original 3.0 rebuilt.

#10

Registered User

Join Date: May 2008

Location: Auburn, WA

Posts: 31

Likes: 0

Received 0 Likes

on

0 Posts

out of curiousity, where is a good place to buy new valves for the 3vze? I'm guessing i will probably end up needing to when i rebuild as my compression is basically non-existent in 2 cyl

#11

Do a cylinder leakdown test before teardown to make sure it is the valves. I bought the 3rz valves at the dealership. They were kinda spendy, I think about $22 a piece. If you find a better outlet, let us know.

#12

Registered User

Join Date: May 2008

Location: Auburn, WA

Posts: 31

Likes: 0

Received 0 Likes

on

0 Posts

any advice on doing a leak down test on the 3vze? never actually done one yet. i do have a compressor, so that shouldn't be a problem.

i assume you just used a socket on the crankshaft pulley to rotate the engine around to check for gouges in the cylinder walls...?

i assume you just used a socket on the crankshaft pulley to rotate the engine around to check for gouges in the cylinder walls...?

#13

Pull the rad cap and look for bubbles, listen for a hiss at the intake, the tail pipe, and the dipstick tube with the dipstick removed. Any air escaping from these areas indicate HG leak, intake valve leak, exhaust valve leak, and piston rings respectively.

Last edited by zlathim; 05-08-2008 at 10:37 AM.

#14

Registered User

Join Date: May 2008

Location: Auburn, WA

Posts: 31

Likes: 0

Received 0 Likes

on

0 Posts

lol i guess that makes sense, i hadn't thought about the fact that the valves would move when the engine is turned (DUH!)

what PSI do you typically run the compressor at to do this? i would assume it doesn't matter a whole lot on mine cause i'm only getting 30 psi on #6 and 0 psi on #4. Also, what is your method for making sure each cyl is at TDC when you test each one?

Also, when doing the leak down test, i am guessing that i will have to have a helper either listen or hold the crankshaft in place so the engine doesn't turn from the compressed air?

what PSI do you typically run the compressor at to do this? i would assume it doesn't matter a whole lot on mine cause i'm only getting 30 psi on #6 and 0 psi on #4. Also, what is your method for making sure each cyl is at TDC when you test each one?

Also, when doing the leak down test, i am guessing that i will have to have a helper either listen or hold the crankshaft in place so the engine doesn't turn from the compressed air?

Last edited by devinwwu; 05-08-2008 at 11:18 AM.

#15

Registered User

Thread Starter

Join Date: May 2008

Location: Provo Utah

Posts: 8

Likes: 0

Received 0 Likes

on

0 Posts

thanks so far for the replies guys. does anyone have the part # for the valves? if so i can probably get them at 1sttoyotaparts.com for pretty cheap.

i'm thinking about just rebuilding from the head up to save on future heartache.

i also found a cheap 89 pickup that i'm contemplating buying, swapping the motor then selling the rest for parts. it needs a new clutch and the body isn't in very good condition and he's asking 700 for it. depending on the miles on the truck that just might be the route i take

i'm thinking about just rebuilding from the head up to save on future heartache.

i also found a cheap 89 pickup that i'm contemplating buying, swapping the motor then selling the rest for parts. it needs a new clutch and the body isn't in very good condition and he's asking 700 for it. depending on the miles on the truck that just might be the route i take

#17

Contributing Member

Not sure how much you like this truck, or how much you're willing to spend but you could make lemon aid out of this lemon with a 3.4 swap.

If interested check out the 3.4 swap section here:

https://www.yotatech.com/forums/f160/

If interested check out the 3.4 swap section here:

https://www.yotatech.com/forums/f160/

#18

lol i guess that makes sense, i hadn't thought about the fact that the valves would move when the engine is turned (DUH!)

what PSI do you typically run the compressor at to do this? i would assume it doesn't matter a whole lot on mine cause i'm only getting 30 psi on #6 and 0 psi on #4. I have one of those harbor freight leakdown testers, and I think it says not to run above 90 psi, but I think that is specific to the tester. I am guessing that 90-100 would be okAlso, what is your method for making sure each cyl is at TDC when you test each one?the easiest method is to have the valve cover removed and visually confirm that both valves are closed on the cylinder that you are currently testing

Also, when doing the leak down test, i am guessing that i will have to have a helper either listen or hold the crankshaft in place so the engine doesn't turn from the compressed air?I've not had a problem with the crank turning, as long as the cylinder being tested is at TDC. I am usually working alone, so it is a matter of airing up the cylinder, then scurrying around to listen for leaks. A helper would be nice though...

what PSI do you typically run the compressor at to do this? i would assume it doesn't matter a whole lot on mine cause i'm only getting 30 psi on #6 and 0 psi on #4. I have one of those harbor freight leakdown testers, and I think it says not to run above 90 psi, but I think that is specific to the tester. I am guessing that 90-100 would be okAlso, what is your method for making sure each cyl is at TDC when you test each one?the easiest method is to have the valve cover removed and visually confirm that both valves are closed on the cylinder that you are currently testing

Also, when doing the leak down test, i am guessing that i will have to have a helper either listen or hold the crankshaft in place so the engine doesn't turn from the compressed air?I've not had a problem with the crank turning, as long as the cylinder being tested is at TDC. I am usually working alone, so it is a matter of airing up the cylinder, then scurrying around to listen for leaks. A helper would be nice though...

#19

Registered User

Thread Starter

Join Date: May 2008

Location: Provo Utah

Posts: 8

Likes: 0

Received 0 Likes

on

0 Posts

Not sure how much you like this truck, or how much you're willing to spend but you could make lemon aid out of this lemon with a 3.4 swap.

If interested check out the 3.4 swap section here:

https://www.yotatech.com/forums/f160/

If interested check out the 3.4 swap section here:

https://www.yotatech.com/forums/f160/

i'm thinking about just replacing everything from the head up. seems to be the most cost effective right now. where would be the best place to get the parts from though? i found this on ebay. is there a better place i can get it for about the same price if not cheaper? would it be better to just do it myself? i'm very much a newb when it comes to motor work to be completely honest. i do have a haynes manual that i will be reading and browsing through so i can get a feel of the work ahead of me.

now just as an effort to save myself some unnecessary work, do think you guys if i ran some seafoam through it that it might help? also i don't have a check engine light on either. at this point i don't want to do all this work just to find out it was misdiagnosed. i do realize this is a common problem with this motor but still. i want to make sure all my other possibilities are ruled out b4 i do anything too drastic.

thanks again for all the help provided so far.

Last edited by goferris; 05-09-2008 at 07:46 AM.

#20

Contributing Member

i would love to do a swap but i just don't have the $$$ or the know how. now if there was someone nearby that could help me with it i would but i just don't have the tools or knowledge necessary.

i'm thinking about just replacing everything from the head up. seems to be the most cost effective right now. where would be the best place to get the parts from though? i found this on ebay. is there a better place i can get it for about the same price if not cheaper? would it be better to just do it myself? i'm very much a newb when it comes to motor work to be completely honest. i do have a haynes manual that i will be reading and browsing through so i can get a feel of the work ahead of me.

now just as an effort to save myself some unnecessary work, do think you guys if i ran some seafoam through it that it might help? also i don't have a check engine light on either. at this point i don't want to do all this work just to find out it was misdiagnosed. i do realize this is a common problem with this motor but still. i want to make sure all my other possibilities are ruled out b4 i do anything too drastic.

thanks again for all the help provided so far.

i'm thinking about just replacing everything from the head up. seems to be the most cost effective right now. where would be the best place to get the parts from though? i found this on ebay. is there a better place i can get it for about the same price if not cheaper? would it be better to just do it myself? i'm very much a newb when it comes to motor work to be completely honest. i do have a haynes manual that i will be reading and browsing through so i can get a feel of the work ahead of me.

now just as an effort to save myself some unnecessary work, do think you guys if i ran some seafoam through it that it might help? also i don't have a check engine light on either. at this point i don't want to do all this work just to find out it was misdiagnosed. i do realize this is a common problem with this motor but still. i want to make sure all my other possibilities are ruled out b4 i do anything too drastic.

thanks again for all the help provided so far.

There will be a few differences between the 89 and 93 though.

There will be a few differences between the 89 and 93 though.I don't know anything about that ebay seller, but I know EB is a good one:

http://www.engnbldr.com/ His oversized valves are very popular, don't know for sure if he sells standard sizes or not. Can't go wrong with EBs stuff.

And no he doesn't pay me to say that LOL**

And no he doesn't pay me to say that LOL****Although I'm open to the idea hehe

Last edited by mt_goat; 05-09-2008 at 08:07 AM.