Headgasket 101 and discussion 22R/22RE

#21

Registered User

just an addition to this thread since you wanted experience with certain head gaskets.

6500 miles on my Rock Gasket no coolant loss, and not burning any oil that I can notice. Compression check at 6500 miles was 170 psi across the board. Block was shaved down a bit and a new head was used. 65 ft-lbs was used on brand new head bolts and anti-seize was used. Torqued at rebuild, re-torqued at 500 miles and re-torqued again at 1500 miles. Have not touched the headbolts since. This is about as by the book as I can get I guess.

I am sure although you were talking about shops that alot of people do not have the head checked for flatness/warping, nor the block. And also reuse their head bolts. And do not check or recheck the torque on those bolts as well as using the old numbers listed in the FSM. Cleaning out the bolt holes can also be tricky, I was not worried about those since the block was dipped 3 times during machining. Once before hand, once after boring and then again after decking. I am sure some people don't apply anti-sieze or oil on the head bolt thread prior to installing them.

All of these I am sure would play a factor in how long each manufactures headgaskets last.

6500 miles on my Rock Gasket no coolant loss, and not burning any oil that I can notice. Compression check at 6500 miles was 170 psi across the board. Block was shaved down a bit and a new head was used. 65 ft-lbs was used on brand new head bolts and anti-seize was used. Torqued at rebuild, re-torqued at 500 miles and re-torqued again at 1500 miles. Have not touched the headbolts since. This is about as by the book as I can get I guess.

I am sure although you were talking about shops that alot of people do not have the head checked for flatness/warping, nor the block. And also reuse their head bolts. And do not check or recheck the torque on those bolts as well as using the old numbers listed in the FSM. Cleaning out the bolt holes can also be tricky, I was not worried about those since the block was dipped 3 times during machining. Once before hand, once after boring and then again after decking. I am sure some people don't apply anti-sieze or oil on the head bolt thread prior to installing them.

All of these I am sure would play a factor in how long each manufactures headgaskets last.

#23

Registered User

yes they are, however, it's cheap insurance, but if they are reused, they should be put back into the same hole, which I am sure some do not do that either.

to me, as hard as it is to get some of those out and how many people have actually broken 1 or 2 of them taking them out (uh umm iamsuperbleeder comes to mind) I would much rather just replace them.

to me, as hard as it is to get some of those out and how many people have actually broken 1 or 2 of them taking them out (uh umm iamsuperbleeder comes to mind) I would much rather just replace them.

#24

Registered User

yes they are, however, it's cheap insurance, but if they are reused, they should be put back into the same hole, which I am sure some do not do that either.

to me, as hard as it is to get some of those out and how many people have actually broken 1 or 2 of them taking them out (uh umm iamsuperbleeder comes to mind) I would much rather just replace them.

to me, as hard as it is to get some of those out and how many people have actually broken 1 or 2 of them taking them out (uh umm iamsuperbleeder comes to mind) I would much rather just replace them.

well im sure some people dont even use a torque wrench, or even tighten them in sequence lol.

i reused them on the last few i rebuilt, but the were in good condition.

#25

Registered User

Not so sure I agree with the quality standard comment on the oem head bolts, but since I didn't have this truck since brand new and the fact is 20+ years old, I had no clue as to how many times they may have been removed so went with EB's head bolts. Now if I ever have to remove them to do a cam change or something I will reuse this set as I know the history on them.

#26

I have Rock HGs on my 3VZE now. And have ran them for ~11k with no issues. However, the fire ring is integral to the Slipperplate™, unlike the head gaskets shown in the previous posts.. There's also more interesting data on 22re HG failures due to poor/inaccurate HG design in my HG thread here. https://www.yotatech.com/forums/f123.../#post51227206

Notice the fire ring, or lack there of on these HGs for the 3VZE.

BTW, that Victor Reinz HG looks VERY much like the factory original that took 215k+ miles to blow on my 88 3VZE. No Slipperplate™ unlike the HGs installed during the HG recall campaign for the 3VZE. So it was highly likely the original, definitely never had the recall done atleast.

See. Fire rings on the older, pre-Slipperplate™, HG designs.

So you could be onto something there. I wonder if Victor makes HGs for the 3VZE like that anymore?

To the best of my knowledge NPR doesn't make pistons currently, nor have they ever. Prove me wrong there if you can.

Like you said...how is quench/piston to head clearance even directly measurable? It's not really, especially at operating temps anyway. It's a guessing game.

Furthermore the piston and head design of the 22RE is NOT actually of the quench type. To use that term for that particular engine is a misnomer.

The 3VZE can be considered to be a quench type cylinder head/piston face design. Flat surfaces on both that coincide to form the quenching area of the combustion chamber when they are closest to each other.

I've been waiting to lay that one on you for awhile now.

Notice the fire ring, or lack there of on these HGs for the 3VZE.

BTW, that Victor Reinz HG looks VERY much like the factory original that took 215k+ miles to blow on my 88 3VZE. No Slipperplate™ unlike the HGs installed during the HG recall campaign for the 3VZE. So it was highly likely the original, definitely never had the recall done atleast.

See. Fire rings on the older, pre-Slipperplate™, HG designs.

So you could be onto something there. I wonder if Victor makes HGs for the 3VZE like that anymore?

...it seems that headgaskets of different brands have varying thicknesses, do they compress down to the same thickness, or do they vary once torqued down?...I have a new Toyota gasket at .053 thickness, and an ITM at .075 (this part # is advertised as oem replacement, they also make an .020 over thickness) why would they make a stock replacement thicker? One would think this would have a dramatic affect on quench and compression (many of you have probably seen my thread concerning these issues) I have searched high and low to find a true piston to head clearance spec because no matter how far your piston sticks up out of the block or not, the headgasket's compressed thickness enters another huge variable that will affect this area. If we're picking over the details of a few thousanth's of an inch and striving for piston to deck height of 0 to +.006 or so and we suddenly have a headgasket that's .010 or .020 different than stock, during a rebuild all the details that went into getting that piston to deck height "perfect" for the sake of compression, detonation, collision clearance etc. have all just gone out the window unless we know the optimal distance the piston should be away from the head at tdc. a piece of clay on a tiny wire through the sparkplug hole would be the only way I can think of to measure that.

Furthermore the piston and head design of the 22RE is NOT actually of the quench type. To use that term for that particular engine is a misnomer.

The 3VZE can be considered to be a quench type cylinder head/piston face design. Flat surfaces on both that coincide to form the quenching area of the combustion chamber when they are closest to each other.

I've been waiting to lay that one on you for awhile now.

Last edited by MudHippy; 04-14-2011 at 08:53 AM.

#27

Registered User

Join Date: Jul 2009

Location: Eastern NC

Posts: 832

Likes: 0

Received 0 Likes

on

0 Posts

Horse Power TV, did a segment on torque and lube used during the torque process. They used ARP head studs and many different types of oil, anti seize etc. What I found interesting, is every time the bolt was re-torque'd to the same spec, the pressure of the torque increased greatly. Kind of leads to the idea of using new head bolts each time.

Later

Later

#28

Registered User

Join Date: Apr 2004

Location: Leadville, CO

Posts: 154

Likes: 0

Received 0 Likes

on

0 Posts

Like you said...how is quench/piston to head clearance even measurable? It's not really.

Furthermore the piston and head design of the 22RE is NOT actually of the quench type. To use that term for that particular engine is a misnomer.

The 3VZE can be considered to be a quench type cylinder head/piston face design. Flat surfaces on both that coincide to form the quenching area of the combustion chamber when they are closest to each other.

I've been waiting to lay that one on you for awhile now.

Furthermore the piston and head design of the 22RE is NOT actually of the quench type. To use that term for that particular engine is a misnomer.

The 3VZE can be considered to be a quench type cylinder head/piston face design. Flat surfaces on both that coincide to form the quenching area of the combustion chamber when they are closest to each other.

I've been waiting to lay that one on you for awhile now.

I do see how the surface of the 3VZ-E's piston matches the combustion chamber in the head vs. the 22r with a symmetrical top surface meeting the head. So, thanks for clearing that up. I appreciate your point of view on your posts, as yours is generally the voice of reason here with speculation and assumption running wild. Thanks for laying it on me!

Nonetheless, my engine is assembled with the thinner Toyota HG and .022 destroked pistons running at .012 above deck height. It's installed and running smooth, quiet, snappy, and no pinging or audible detonation at proper timing, so I feel like there is a little more room to play than most have said. I guess we'll see where I'm at in 15,000 miles.

At this point the thread has been thouroughly hijacked, sorry trainwreck!

#29

I have had TWO Rock headgaskets fail in the last 3 years.

Both were on completely rebuilt 22RE's, with new head bolts torqued correctly, and no shortcuts taken whatsoever on the rebuilds. All machine work was professionaly done.

Both failures were with the slipper-plate design. The first completely blew out 7,000 miles after the rebuild, and the second just started pushing exhaust pressure into the cooling system with 13,000 miles on the engine.

I have since switched to Fel-Pro head gaskets, and have had ZERO issues.

According to Napaonline, Fel-Pro has improved their head gasket design for the 22RE. It has a graphite facing with a perforated steel core.

Both were on completely rebuilt 22RE's, with new head bolts torqued correctly, and no shortcuts taken whatsoever on the rebuilds. All machine work was professionaly done.

Both failures were with the slipper-plate design. The first completely blew out 7,000 miles after the rebuild, and the second just started pushing exhaust pressure into the cooling system with 13,000 miles on the engine.

I have since switched to Fel-Pro head gaskets, and have had ZERO issues.

According to Napaonline, Fel-Pro has improved their head gasket design for the 22RE. It has a graphite facing with a perforated steel core.

#30

Registered User

Join Date: Oct 2009

Location: Northwest Oregon

Posts: 119

Likes: 0

Received 0 Likes

on

0 Posts

i just finished a front/top end rebuild on my 22re. i bought the Japan Made Nippon Reinz (JMNR) head gasket kit. it was twice the price, but i had it next to the Rock. the difference was more than noticable in the quality. every gasket fit like a glove. i used the rock on my brother in laws 22re. it seemed ok, but for piece of mind the extra couple bucks is worth it.

#31

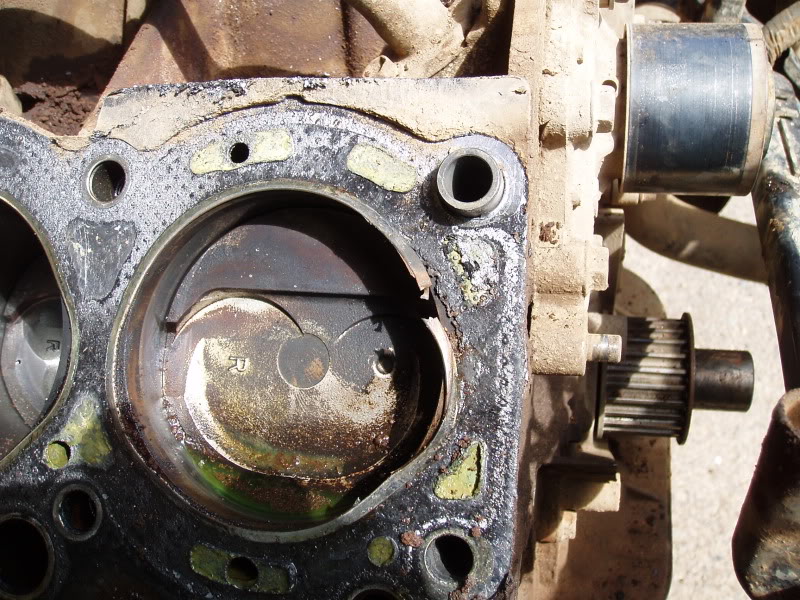

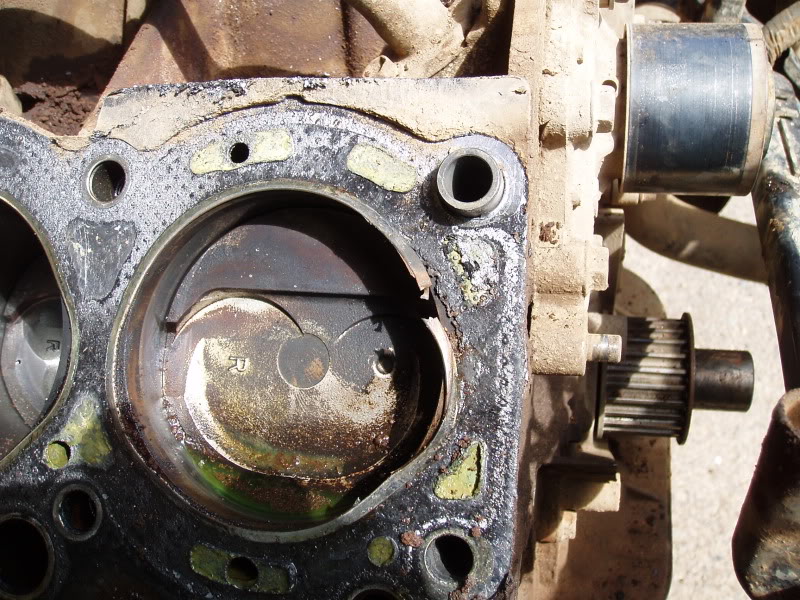

+1 on the nippon gasket made in japan. Just seems better quality. The thing I always see is the layers of the HG coming apart. Have you guys seen alot of coolant intrusion into the cylinder??? and if so, was there alot of material missing from that result??? when I took off my HG, i could see where it had blown, and tried to smooth it out with the snap on 3m pad and a die grinder. didnt do much honestly. Also , does anyone believe in using the shellac compound (the indian gasket sealer stuff or the copper gasket spray) on the gasket just before you install it????

#33

Contributing Member

Interesting I did not see this thread earlier.

The previous owner had just replaced a HG, done by a mechanic, LAST year. He told me he had bought "Rock" products. I didn't know what that was. I was having overheating issues, and some other issues which made me change the HG just last month. I'm fairly certain the HG did the same thing as in the first post by Trainwreck, and I'm 90% sure he got the HG from Enginebuilder. Weird!

The previous owner had just replaced a HG, done by a mechanic, LAST year. He told me he had bought "Rock" products. I didn't know what that was. I was having overheating issues, and some other issues which made me change the HG just last month. I'm fairly certain the HG did the same thing as in the first post by Trainwreck, and I'm 90% sure he got the HG from Enginebuilder. Weird!

#34

Registered User

Join Date: Apr 2008

Location: Glendale AZ

Posts: 292

Likes: 0

Received 0 Likes

on

0 Posts

I just installed a new Street RV head back in February with Rock gaskets from Engbldr, I wasn't aware that the new torque spec is 65ft Ibs. I also didn't know that you have to "re-torque".

I torque the new head bolts to factory specs, I think 58ft Ibs and haven't touched it since, I now have over 4K with no problems, engine runs great. Should I re-torque and torque to 65 ft Ibs. ???

I torque the new head bolts to factory specs, I think 58ft Ibs and haven't touched it since, I now have over 4K with no problems, engine runs great. Should I re-torque and torque to 65 ft Ibs. ???

#35

We use click-style torque wrenches in aviation. They're calibrated regularly, though.

#36

Registered User

iTrader: (5)

I just installed a new Street RV head back in February with Rock gaskets from Engbldr, I wasn't aware that the new torque spec is 65ft Ibs. I also didn't know that you have to "re-torque".

I torque the new head bolts to factory specs, I think 58ft Ibs and haven't touched it since, I now have over 4K with no problems, engine runs great. Should I re-torque and torque to 65 ft Ibs. ???

I torque the new head bolts to factory specs, I think 58ft Ibs and haven't touched it since, I now have over 4K with no problems, engine runs great. Should I re-torque and torque to 65 ft Ibs. ???

Since I'm dealing with Engnbldr CAM install(1000 after the full rebuild.... I KNOW, tell the dang machinist! lol).. and all new head components, head bolts, etc.... I went back in at 500 miles after the cam install and went to 63Lbs.(Recommended by Tod and Ted at engnbldr. as a "Meet them a lil over half way" type trial and error they've found effective.... Remember, they do this all day long, 24/7-365, lol). I actually replaced the cam w/out removing the head.... No leaks, no ticking and no problems.

Note; I sapped up all the oil out of the holes and cleaned the holes very well before dropping back in the head bolts... Can't be a bad idea, especially if it's a block that's not been chased out or otherwise rebuilt, etc.

#37

Registered User

Join Date: Apr 2008

Location: Glendale AZ

Posts: 292

Likes: 0

Received 0 Likes

on

0 Posts

ChefYota4x4,

I had always wondered if you could change the cam with out pulling the head. I was under the impression that once you remove the head bolts you should use a new gasket because it's a crush type gasket. I guess i can retorque but it's working great. I wonder if I leave it the way it is I'll continue to not have problems? I guess I should ask Ted too.

I had always wondered if you could change the cam with out pulling the head. I was under the impression that once you remove the head bolts you should use a new gasket because it's a crush type gasket. I guess i can retorque but it's working great. I wonder if I leave it the way it is I'll continue to not have problems? I guess I should ask Ted too.

#38

Registered User

iTrader: (5)

Hey Hilux.....

Yes, YOU CAN do so, but many will tell you not to do so, lol.(change the cam w/out replacing the HG). If you go through my Build thread, in red, below... you'll see(just before the pics of my trip to the Sierras) an explanation of the CAM install. In my troubleshooting thread, you'll see why I had no choice but replace it, and I figured...why not try, eh? Strapped down the rear of the head on both sides with HD straps to about 40# and left the front hidden bolt in.....worked fine. I think it didn't hurt that it was a new head and engine, etc., ya know? MAJOR THING; Have to be VERY careful to not even nudge the head, once the bolts start coming out, ya know?

Ted will probably tell ya to do it just to be sure. Actually, 4 of the 8 bolts I re-checked had loosened around 3# or so. I guess that's more common when everything is new? lol.

Yes, YOU CAN do so, but many will tell you not to do so, lol.(change the cam w/out replacing the HG). If you go through my Build thread, in red, below... you'll see(just before the pics of my trip to the Sierras) an explanation of the CAM install. In my troubleshooting thread, you'll see why I had no choice but replace it, and I figured...why not try, eh? Strapped down the rear of the head on both sides with HD straps to about 40# and left the front hidden bolt in.....worked fine. I think it didn't hurt that it was a new head and engine, etc., ya know? MAJOR THING; Have to be VERY careful to not even nudge the head, once the bolts start coming out, ya know?

Ted will probably tell ya to do it just to be sure. Actually, 4 of the 8 bolts I re-checked had loosened around 3# or so. I guess that's more common when everything is new? lol.

#39

Registered User

I think ted in one of his articles had mentioned when you go to re-torque those head bolts to do it one by one in normal order but to loosen them and then re-tighten not to just "check" the torque. But I could be wrong. After re-torquing the head you should recheck and adjust if necc. the valve lash.

#40

Registered User

Join Date: Apr 2008

Location: Glendale AZ

Posts: 292

Likes: 0

Received 0 Likes

on

0 Posts

Just got this email back from Ted...

To: Ted Stanwood

Sent: Thursday, October 21, 2010 11:09 AM

Subject: Re: 22RE Parts

Hello,

Just had a quick question about some parts I bought earlier this year. I installed the street RV head and 268c cam and master gasket set back in Feb and now have 4k+ miles on my 22RE with no problems. Engine runs great! I torque the new head bolts to my factory manual spec, i think 58 ft Ibs. My question is do I have to re-torque? I just saw a thread today on yotatech that a member is saying to initially torque to 63ft Ibs., he was told by Ted and Todd.

I haven't touched the engine since the new head. Should I re-torque to 63ft Ibs.?

From: Ted Stanwood <engnbldr@engnbldr.com>

To:

Sent: Thu, October 21, 2010 11:26:06 AM

Subject: Re: 22RE Parts

Hi!

We do reset them as a final to 63-64# ourselves but you obviously did a good uniform job and that is far more important than the final torque number.

At 4000 miles she is fully set, so I would just retorque as part of the annual tuneup, we always suggest doing that anyway.

I wouldn't be too worried about it, just use the 58# setting, that works for the factory..

Thanks again,

Ted

----- Original Message -----

From:

To: Ted Stanwood

Sent: Thursday, October 21, 2010 12:50 PM

Subject: Re: 22RE Parts

Thanks for the quick reply Ted,

One more thing, when I do re-torque at the annual tune-up interval should I completely loosen a head bolt and then re-torque or just re-torque on top of what they are torqued to now?

Thanks again,

From: Ted Stanwood <engnbldr@engnbldr.com>

We just set the wrench and give them a pull, be sure to follow the sequence, start at the center and work your way out.

Ted

To: Ted Stanwood

Sent: Thursday, October 21, 2010 11:09 AM

Subject: Re: 22RE Parts

Hello,

Just had a quick question about some parts I bought earlier this year. I installed the street RV head and 268c cam and master gasket set back in Feb and now have 4k+ miles on my 22RE with no problems. Engine runs great! I torque the new head bolts to my factory manual spec, i think 58 ft Ibs. My question is do I have to re-torque? I just saw a thread today on yotatech that a member is saying to initially torque to 63ft Ibs., he was told by Ted and Todd.

I haven't touched the engine since the new head. Should I re-torque to 63ft Ibs.?

From: Ted Stanwood <engnbldr@engnbldr.com>

To:

Sent: Thu, October 21, 2010 11:26:06 AM

Subject: Re: 22RE Parts

Hi!

We do reset them as a final to 63-64# ourselves but you obviously did a good uniform job and that is far more important than the final torque number.

At 4000 miles she is fully set, so I would just retorque as part of the annual tuneup, we always suggest doing that anyway.

I wouldn't be too worried about it, just use the 58# setting, that works for the factory..

Thanks again,

Ted

----- Original Message -----

From:

To: Ted Stanwood

Sent: Thursday, October 21, 2010 12:50 PM

Subject: Re: 22RE Parts

Thanks for the quick reply Ted,

One more thing, when I do re-torque at the annual tune-up interval should I completely loosen a head bolt and then re-torque or just re-torque on top of what they are torqued to now?

Thanks again,

From: Ted Stanwood <engnbldr@engnbldr.com>

We just set the wrench and give them a pull, be sure to follow the sequence, start at the center and work your way out.

Ted