Headgasket 101 and discussion 22R/22RE

#1

Headgasket 101 and discussion 22R/22RE

I pulled a part an engine that I had installed into a customers truck.

Fully rebuilt with proper surface finishes for graphite type head gaskets. All threads tapped. Full D&J Rock Products kit

New ALTROM head bolts were used. The initial torque was set to 65 ftlbs. The customer brought the truck back for his initial oil change, head bolt re-torque, and valve adjust.

7 thousand miles later it sits in my shop after being swaped out to take care of an oil consumption issue.

When I pulled the head this is what I found.

The fire ring is one piece. Meaning it is "rolled" from front to back as one piece. When the gasket is crushed it is only supposed to pinch and stay intact.

Many times after years of service you will see a "split" head gasket, they often will still seal but it is definatly a precursor to blowing.

One of the fire rings had already split. One other rebuilt engine that I tore down had done this as well.

It's interesting this other issue is causing me to tear down engines that otherwise would never have been torn down. So a lot of R&D is going on here. It's interesting to see wear or issues that will become problems later in an engines life. Obviously most people don't tear down a freshly rebuilt engine.

Fully rebuilt with proper surface finishes for graphite type head gaskets. All threads tapped. Full D&J Rock Products kit

New ALTROM head bolts were used. The initial torque was set to 65 ftlbs. The customer brought the truck back for his initial oil change, head bolt re-torque, and valve adjust.

7 thousand miles later it sits in my shop after being swaped out to take care of an oil consumption issue.

When I pulled the head this is what I found.

The fire ring is one piece. Meaning it is "rolled" from front to back as one piece. When the gasket is crushed it is only supposed to pinch and stay intact.

Many times after years of service you will see a "split" head gasket, they often will still seal but it is definatly a precursor to blowing.

One of the fire rings had already split. One other rebuilt engine that I tore down had done this as well.

It's interesting this other issue is causing me to tear down engines that otherwise would never have been torn down. So a lot of R&D is going on here. It's interesting to see wear or issues that will become problems later in an engines life. Obviously most people don't tear down a freshly rebuilt engine.

Last edited by Trainwreckinseattle; 09-13-2010 at 07:28 PM.

#2

When a person goes in and talks to a shop they get answers about parts based off that persons likes and dislikes, hopefully experience based. And you just have to trust their judgement.

I was told by an engine rebuild company who ships quite a few 22R/22RE engines that he has seen many premature headgasket failures with most brands of headgaskets. Keep in mind this is a shop so we are talking about fully rebuilt engines. He said he seems to have solved 99.9 percent of these problems by going with a Victor gasket. There is always someone who reuses an old water pump we can't help those type of people when that pump causes an overheat and makes a gasket fail.

Anyways, what are your experiences? Anyone loose a headgasket shortly after a full rebuild?

it's common to loose a HG when people just are in there for a HG. It's hard to do it right unless it's fully torn down. But for the most part this isn't about those situations. I'm looking to try and narrow this down. So for the people who "did it right" by the book and still had one fail 4-10 K later. Please share your knowlege.

Thank you

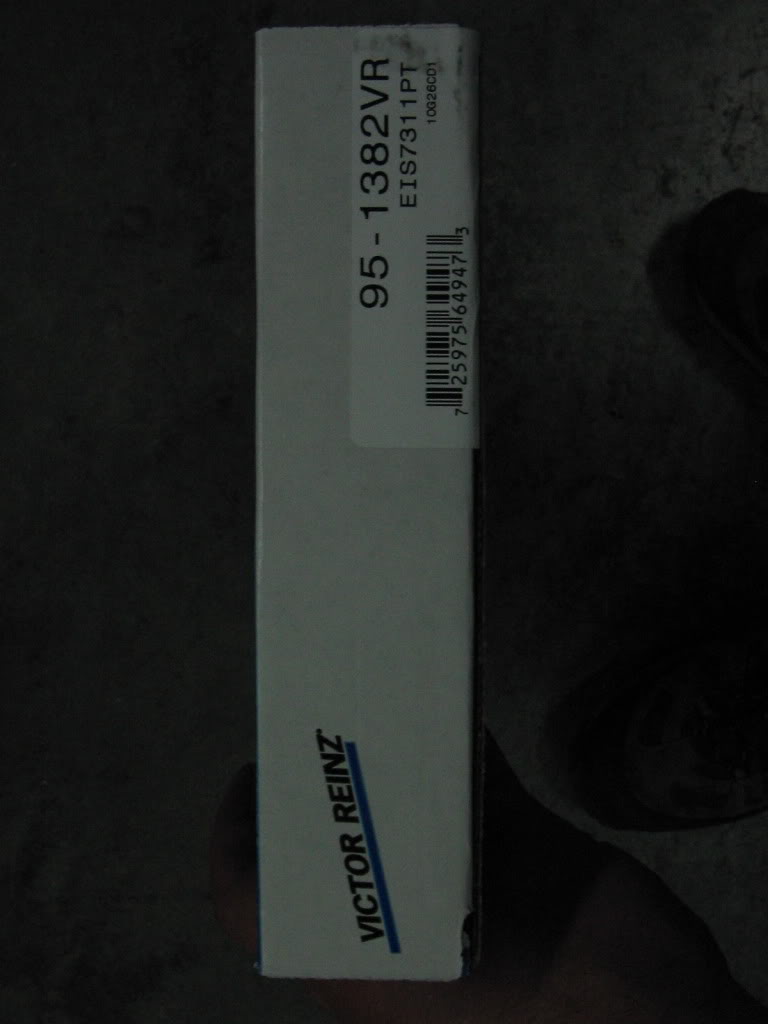

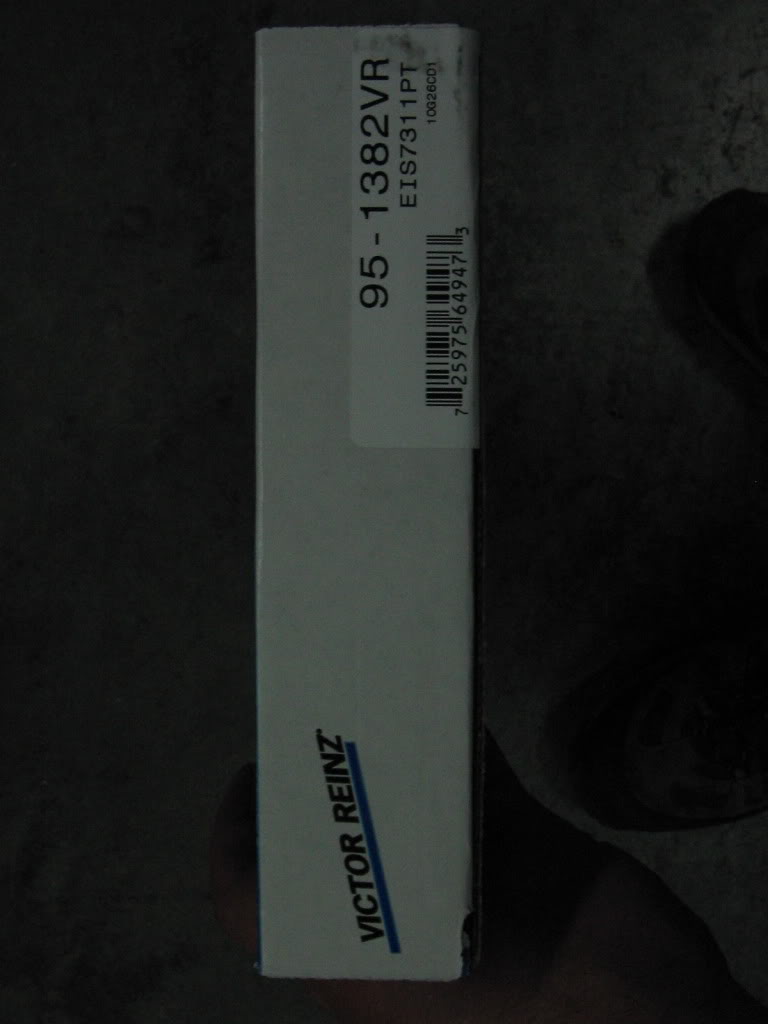

Some pictures: Notice the VERY different design from the Rock HG

I was told by an engine rebuild company who ships quite a few 22R/22RE engines that he has seen many premature headgasket failures with most brands of headgaskets. Keep in mind this is a shop so we are talking about fully rebuilt engines. He said he seems to have solved 99.9 percent of these problems by going with a Victor gasket. There is always someone who reuses an old water pump we can't help those type of people when that pump causes an overheat and makes a gasket fail.

Anyways, what are your experiences? Anyone loose a headgasket shortly after a full rebuild?

it's common to loose a HG when people just are in there for a HG. It's hard to do it right unless it's fully torn down. But for the most part this isn't about those situations. I'm looking to try and narrow this down. So for the people who "did it right" by the book and still had one fail 4-10 K later. Please share your knowlege.

Thank you

Some pictures: Notice the VERY different design from the Rock HG

Last edited by Trainwreckinseattle; 09-13-2010 at 07:39 PM.

#4

Registered User

ive seen a number of rebuilt engines have problems with rock products.

a few that were fully rebuilt, and done right have had hg failure before 5k miles. a few that just had been "freshened up" had the coating on the rod/main bearings disintegrate along with hg failure. those were all assembled by experienced mechanics(though they weren't dedicated yota mechanics).. i have also seen about the same amount of engines get rebuilt with rock products and have no problems.

because of those horror stories, i use this kit when i rebuild them. http://www.22re.com/main/toy/complete_22r_kit.htm i have had no problems at all. though i just rebuild them for myself, friends, and friends of friends, so i have only rebuilt 5. but, i have all the machine work done at a quality machine shop and cut no corners.

im very intersted to see what you come up with!

subscribed!

a few that were fully rebuilt, and done right have had hg failure before 5k miles. a few that just had been "freshened up" had the coating on the rod/main bearings disintegrate along with hg failure. those were all assembled by experienced mechanics(though they weren't dedicated yota mechanics).. i have also seen about the same amount of engines get rebuilt with rock products and have no problems.

because of those horror stories, i use this kit when i rebuild them. http://www.22re.com/main/toy/complete_22r_kit.htm i have had no problems at all. though i just rebuild them for myself, friends, and friends of friends, so i have only rebuilt 5. but, i have all the machine work done at a quality machine shop and cut no corners.

im very intersted to see what you come up with!

subscribed!

#6

Registered User

#7

58 lbs is the original torque. The first few years had hg problems so they bumped it to 61

Every shop I've ever talked to says to torque to 65lbs.

Last edited by Trainwreckinseattle; 09-13-2010 at 09:46 PM.

Trending Topics

#8

As people who are also following my other threads may already know I do have doubts. And am changing a bunch of stuff.

It all boils down to money. Nobody is willing to pay 3,200 for a rebuilt long block. Everyone has beaten down the price to about 1,100 - 1,200. It can be achieved with kits from the likes of Rock. But you get what you pay for.

Factory parts are expensive, very expensive and there can be good quality alternitives that come close to or match the quality for much less.

So it all boils down to a happy medium. Keep costs down but deliver a motor that lasts as long as possible. That fine line can be hard to achieve sometimes.

As for gaskets, does anyone have any experience with these Victors? They are somewhat expensive compaired to Rock and some others.

#9

ive seen a number of rebuilt engines have problems with rock products.

a few that were fully rebuilt, and done right have had hg failure before 5k miles. a few that just had been "freshened up" had the coating on the rod/main bearings disintegrate along with hg failure. those were all assembled by experienced mechanics(though they weren't dedicated yota mechanics).. i have also seen about the same amount of engines get rebuilt with rock products and have no problems.

because of those horror stories, i use this kit when i rebuild them. http://www.22re.com/main/toy/complete_22r_kit.htm i have had no problems at all. though i just rebuild them for myself, friends, and friends of friends, so i have only rebuilt 5. but, i have all the machine work done at a quality machine shop and cut no corners.

im very intersted to see what you come up with!

subscribed!

a few that were fully rebuilt, and done right have had hg failure before 5k miles. a few that just had been "freshened up" had the coating on the rod/main bearings disintegrate along with hg failure. those were all assembled by experienced mechanics(though they weren't dedicated yota mechanics).. i have also seen about the same amount of engines get rebuilt with rock products and have no problems.

because of those horror stories, i use this kit when i rebuild them. http://www.22re.com/main/toy/complete_22r_kit.htm i have had no problems at all. though i just rebuild them for myself, friends, and friends of friends, so i have only rebuilt 5. but, i have all the machine work done at a quality machine shop and cut no corners.

im very intersted to see what you come up with!

subscribed!

22RE.com uses Altrom parts.

I used to have an Altrom account, untill Napa purchased them outright. They then closed all smaller accounts. My cost on the full Altrom kit was around 220.00

I had few if any problems.

So I switched to Rock, I can't eat enough advil do deal with the headaches that has brought me.

#10

Registered User

yea they do, though the timing set and is o.s.k and the oil pump is toyota. bearings are koyo? valve stem seals are viton. i think the only thing altrom in that kit are the piston/ rings and maybe the gasket set?

whats your thoughts on altrom??

yea, those dj kits i call the rock knock lol.

whats your thoughts on altrom??

yea, those dj kits i call the rock knock lol.

#12

yea they do, though the timing set and is o.s.k and the oil pump is toyota. bearings are koyo? valve stem seals are viton. i think the only thing altrom in that kit are the piston/ rings and maybe the gasket set?

whats your thoughts on altrom??

yea, those dj kits i call the rock knock lol.

whats your thoughts on altrom??

yea, those dj kits i call the rock knock lol.

Altrom is like Rock and many other companies. They just sell other peoples stuff.

Only thing with Altrom is they import stuff direct from JAPAN. So yeah their oil pump IS a Toyota pump with "Toyota" ground off since it is copyrited. The entire chain kit is OSK not just the tensioner. ETC........

I like Altrom..... I just wish NAPA hadn't have purchased them, closed my and many other peoples accounts and then jacked the prices up when you order through napa.

I have learned my lesson about "Cheep" parts not always is it a good idea to buy the cheepest parts out there.

#13

Registered User

Altrom is like Rock and many other companies. They just sell other peoples stuff.

Only thing with Altrom is they import stuff direct from JAPAN. So yeah their oil pump IS a Toyota pump with "Toyota" ground off since it is copyrited. The entire chain kit is OSK not just the tensioner. ETC........

I like Altrom..... I just wish NAPA hadn't have purchased them, closed my and many other peoples accounts and then jacked the prices up when you order through napa.

I have learned my lesson about "Cheep" parts not always is it a good idea to buy the cheepest parts out there.

Only thing with Altrom is they import stuff direct from JAPAN. So yeah their oil pump IS a Toyota pump with "Toyota" ground off since it is copyrited. The entire chain kit is OSK not just the tensioner. ETC........

I like Altrom..... I just wish NAPA hadn't have purchased them, closed my and many other peoples accounts and then jacked the prices up when you order through napa.

I have learned my lesson about "Cheep" parts not always is it a good idea to buy the cheepest parts out there.

better than taiwaneese lol. 299 for a full kit isnt that bad.. what did you pay before for a kit?

how much did you pay for the rock knock kit?

#14

Registered User

I only have one question, so only a brief hijack, if you will.

I'm willing to bet when I rebuilt my 22re 2yrs ago, I torqued the head bolts to the "recommended" 58ft/lbs. Would it be advisable to torque them again to 65? I reused my original headbolts as they were fine shape. Don't know if that's a mitigating factor in anything, but figured I'd mention it.

I'm willing to bet when I rebuilt my 22re 2yrs ago, I torqued the head bolts to the "recommended" 58ft/lbs. Would it be advisable to torque them again to 65? I reused my original headbolts as they were fine shape. Don't know if that's a mitigating factor in anything, but figured I'd mention it.

#15

With my old Altrom Account I paid 220.00 for a kit.

Actual NPR pistons and rings

Rod, Main and thrust bearings

Full OSK T-chain set, including chain and rails. All parts made in Japan.

OE Toyota Oil pump. Still says "Aisin" but where it should say "toyota", it's ground off by hand.

OE Toyota Front cover. "Toyota" is ground off by hand

Premium Gasket set

Freeze plug set

Head bolt set

*****Altrom does not supply NPR pistons anymore. I'm not sure who's pistons they are but they look totally different now. But the Rings are still for sure NPR.

The Rock kit costs 180.00

Stamped "Rock" pistons

Stamped "Rock" Rings (Ted says made to Rock spec by NPR)

Stamped "Rock" main, rod, and thrust bearings

Stamped "Rock" oil pump

Gasket set, "Rock" is imprinted into the Headgasket

**This means "ROCK" the name is acually stamped into these parts, so they are not re-boxes of anyones parts. These parts are made For Rock, as Rock's parts only, by manufacturers. Who know by who for sure.

Aftermarket front cover. For sure it's the same as at least a few other re-boxed company brands.

Timing chain set with OSK Tensioner only. Other parts including chain and rails are not OSK.

Freeze plugs

Rod pin bushing set

#16

I only have one question, so only a brief hijack, if you will.

I'm willing to bet when I rebuilt my 22re 2yrs ago, I torqued the head bolts to the "recommended" 58ft/lbs. Would it be advisable to torque them again to 65? I reused my original headbolts as they were fine shape. Don't know if that's a mitigating factor in anything, but figured I'd mention it.

I'm willing to bet when I rebuilt my 22re 2yrs ago, I torqued the head bolts to the "recommended" 58ft/lbs. Would it be advisable to torque them again to 65? I reused my original headbolts as they were fine shape. Don't know if that's a mitigating factor in anything, but figured I'd mention it.

The 22R/22RE engine had a couple "Recalls" over the years.

They had "Piston slap" issues

They had "Head Gasket" Issues

They had "Rocker arm spacer" issues

Originally the torque spec was 58ft/lbs which was revised to 61ft/lbs

Most engine rebuild companies that I have had contact with call out for a 65ft/lb final torque spec.

I don't know if this is an attempt to solve "head gasket issues" steming from poor quality gaskets. Or if there is actual science or R&D behind this change. I have so far simply "trusted" other peoples word on this update.

My personal belief is that IF a person uses a quality gasket and mating surface R/A (surface texture) the 58 probably would work fine, 61, or 65 is hardly a large increase however. More to the point, click style torque wrenches that most people use are actually fairly inaccurate.

Hopefully that confuses you enough?

#17

Registered User

Oh yes, quite discombobulated.....thank you. I'm going to hang upside down, now.

Actually, you answered the question well enough. I used an engnbldr complete front end/timing kit, but I don't recall if I got the headgasket from them or not. So, it could be a Rock gasket or a FelPro. I'll have to dig through my records..... if I even kept documents. Then again, many use Rock and never have problems. So, I might be fine either way. I'm just a little concerned is all. I did use a clicker wrench, but the fellow I borrowed it from has it calibrated regular like. Next time I have the cover off, I might hit the bolts with my regular, needle style torque wrench........or whatever you call it.

Actually, you answered the question well enough. I used an engnbldr complete front end/timing kit, but I don't recall if I got the headgasket from them or not. So, it could be a Rock gasket or a FelPro. I'll have to dig through my records..... if I even kept documents. Then again, many use Rock and never have problems. So, I might be fine either way. I'm just a little concerned is all. I did use a clicker wrench, but the fellow I borrowed it from has it calibrated regular like. Next time I have the cover off, I might hit the bolts with my regular, needle style torque wrench........or whatever you call it.

#18

That HG looks goofy. Semi-crush, semi-(ML)Steel. I would NOT trust that thing to crush uniformly and seal correctly.

My belief is Rock is the same crap you get from the cheap chinese kits on Ebay.

I've compared the eBay special timing cover + timing kit with the Rock crap side by side, in my hands, and they are the same thing.

That gasket looks eriely familiar to this one doesnt it?

http://cgi.ebay.com/ebaymotors/1985-...Q5fAccessories

$32 shipped isnt bad if you are just in it for the other gaskets and seals.

Stick with known brands if you are going to rebuild your engine. How much is your time worth taking everything apart to replace that sh-tty rear main seal, clutch, headgasket, valve stem seals, or bearings because it was cheaper initially? How about a snapped timing chain that destroyed your head and you're stuck 25 miles into the trail?

I'm just a weekend wrencher and have had way too many horrible experiences with people bringing me crap parts when they drop off their car. The last one was a guy wanting me to put a clutch in his 240SX and be brought me some garbage Duralast kit. I installed it and started bleeding the clutch when the slave cylinder just blew out. I suspected a shorter pressure plate or throwout. He brought me an Exedy next weekend and when I compared the garbage vs. Exedy, the garbage pressure plate and throwout bearing were shorter. Autozone confirmed part #'s were correct. I changed the clutch twice for the same price because I'm just nice like that. You get what you pay for, Lesson learned

My belief is Rock is the same crap you get from the cheap chinese kits on Ebay.

I've compared the eBay special timing cover + timing kit with the Rock crap side by side, in my hands, and they are the same thing.

That gasket looks eriely familiar to this one doesnt it?

http://cgi.ebay.com/ebaymotors/1985-...Q5fAccessories

$32 shipped isnt bad if you are just in it for the other gaskets and seals.

Stick with known brands if you are going to rebuild your engine. How much is your time worth taking everything apart to replace that sh-tty rear main seal, clutch, headgasket, valve stem seals, or bearings because it was cheaper initially? How about a snapped timing chain that destroyed your head and you're stuck 25 miles into the trail?

I'm just a weekend wrencher and have had way too many horrible experiences with people bringing me crap parts when they drop off their car. The last one was a guy wanting me to put a clutch in his 240SX and be brought me some garbage Duralast kit. I installed it and started bleeding the clutch when the slave cylinder just blew out. I suspected a shorter pressure plate or throwout. He brought me an Exedy next weekend and when I compared the garbage vs. Exedy, the garbage pressure plate and throwout bearing were shorter. Autozone confirmed part #'s were correct. I changed the clutch twice for the same price because I'm just nice like that. You get what you pay for, Lesson learned

Last edited by hnugen; 09-16-2010 at 09:58 AM.

#19

Registered User

Join Date: Apr 2004

Location: Leadville, CO

Posts: 154

Likes: 0

Received 0 Likes

on

0 Posts

another headgasket subject I'd like to open up here(if it's not considered a hijack), it seems that headgaskets of different brands have varying thicknesses, do they compress down to the same thickness, or do they vary once torqued down?...I have a new Toyota gasket at .053 thickness, and an ITM at .075 (this part # is advertised as oem replacement, they also make an .020 over thickness) why would they make a stock replacement thicker? One would think this would have a dramatic affect on quench and compression (many of you have probably seen my thread concerning these issues) I have searched high and low to find a true piston to head clearance spec because no matter how far your piston sticks up out of the block or not, the headgasket's compressed thickness enters another huge variable that will affect this area. If we're picking over the details of a few thousanth's of an inch and striving for piston to deck height of 0 to +.006 or so and we suddenly have a headgasket that's .010 or .020 different than stock, during a rebuild all the details that went into getting that piston to deck height "perfect" for the sake of compression, detonation, collision clearance etc. have all just gone out the window unless we know the optimal distance the piston should be away from the head at tdc. a piece of clay on a tiny wire through the sparkplug hole would be the only way I can think of to measure that.

Last edited by yotafreakshow; 09-17-2010 at 07:02 AM.

#20

Thats a long ways down the rabbit hole my friend. LOL

Yes I would say the only way to achieve "Original OEM" specs is to use OEM parts.

Beyond that "I think" many people only care that it runs good, and hopefully lasts a while. You can fudge numbers a little here and there and still achieve this. Same with your average rebuild shop, they see price, and a 12,000 mile warranty, not exact tolerance. Some are better than others

Yes I would say the only way to achieve "Original OEM" specs is to use OEM parts.

Beyond that "I think" many people only care that it runs good, and hopefully lasts a while. You can fudge numbers a little here and there and still achieve this. Same with your average rebuild shop, they see price, and a 12,000 mile warranty, not exact tolerance. Some are better than others