1986 4Runner 22RE rough idle, rich, no power

#1

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

1986 4Runner 22RE rough idle, rich, no power

I bought it a 3 weeks ago and drove it for 1 week and have been working on it since. It appeared to be getting terrible gas mileage. So I filled up with 89 octane and drove it about 30-40 miles. It ran good and smooth. the next morning it wouldn't idle and was puffing out black smoke and soot. Another problem maybe not related is the temp gauge when running was at 1/4 gauge.

PO replaced plugs, cap, rotor, fuel filter and cat for emmisions (since someone else removed it).

The first thing I did was check codes. The O2 code flashed. I replaced the O2, #2 temp sensor for the ECU next to thermo time switch for cold start injector and thermostat. All of that helped, but not much. I tried adjusting the idle screw, but wouldn't change at all.

I have a 89 4Runner that runs, not all parts are interchageable but i did swap some listed below.

Things that I have checked and swapped or replaced. I tried to type in order things were done, but might not be exact.

PO somewhere along the way spliced the 3 wires going to the igniter. Is that causing high resistance? Does it matter?

It does have the auxillary air valve. I clamped off the line going to the throttle body and it kills the engine. Don't know if that is a good check or not.

I'm thinking of swapping the 89 ECU and 89 MAF at same time and drive it tonight.

I checked the grounds at motor mount, intake, PS pump. All are tight. I read there is one on the back of the head that I need to check when I get home.

I'm thinking the ECU is bad, but can't confirm that. There are no codes with the 86 except code 11 which check code that is normal........right? the 89 ECU throws code 21 for O2. But the 89 has a 2 wire O2 and the 86 has a one wire O2. I believe that's why it's showing a code because the O2's are different. Not sure.

I'm sure there are some things that I haven't listed here that I have done or haven't done.

I'm a bodyman by trade and good around engines with out computers and emmisions. This is my first in depth trouble shooting on a engine with an ECU. I also struggle reading ohms at 20K reading. Just to let you know my limitations and experience.

About ready to strike a match

PO replaced plugs, cap, rotor, fuel filter and cat for emmisions (since someone else removed it).

The first thing I did was check codes. The O2 code flashed. I replaced the O2, #2 temp sensor for the ECU next to thermo time switch for cold start injector and thermostat. All of that helped, but not much. I tried adjusting the idle screw, but wouldn't change at all.

I have a 89 4Runner that runs, not all parts are interchageable but i did swap some listed below.

Things that I have checked and swapped or replaced. I tried to type in order things were done, but might not be exact.

- I sprayed brake cleaner around the intake and injectors- no change in RPM.

- Checked timing with jumper wire T-E1 5*BTDC

- Tested TPS-checked bad, replaced with new and adjusted with ohm meter

- Tested cold start injector. Sprays good and shuts off when de-energized with no seepage

- Swapped igniter/coil pack-no change

- Tested the voltages at ECU per 1987 Toyota service manual all within specs. Swapped the 89 ECU and in ran for about a minute then back to running rough.

- Swapped fuel pressure regulator and EGR from 89(since I had it off)-no change

- Test drive-No power and cat was glowing orange

- Replaced fuel injectors. When I removed the top half of the intake there was fuel puddled up in the #1&2 runners. It hadn't been ran in 24 hours. It actually ran pretty good after new injectors and intake gaskets. Idle was good and no RPM drop every 4 seconds when held at 2500-3000 rpm like before. But back fires thru intake on acceleration (parked).

- Cut exhaust off before cat thinking the exhaust was plugged.-no change installed straight pipe temporarily. Did another test drive, still no power in low RPM's but start pulling around 2500 rpm (no tach) but the pull wasn't steady.

- Swapped the distributor because the 86 pickup coil was 179 ohms the 89 was 145 ohms. Limit is 180 ohms

- Swapped the plug wires due too lower resistance-no change

- Swapped MAF -no change. Swapped back

- Swapped in 89 ECU again and it runs better with steadier idle. Still pops thru intake on acceleration (parked)

- Advanced timing to 12* runs a lot better

- Put 86 ECU back in and runs rough and black smoke out of exhuast. That's where it is now.

PO somewhere along the way spliced the 3 wires going to the igniter. Is that causing high resistance? Does it matter?

It does have the auxillary air valve. I clamped off the line going to the throttle body and it kills the engine. Don't know if that is a good check or not.

I'm thinking of swapping the 89 ECU and 89 MAF at same time and drive it tonight.

I checked the grounds at motor mount, intake, PS pump. All are tight. I read there is one on the back of the head that I need to check when I get home.

I'm thinking the ECU is bad, but can't confirm that. There are no codes with the 86 except code 11 which check code that is normal........right? the 89 ECU throws code 21 for O2. But the 89 has a 2 wire O2 and the 86 has a one wire O2. I believe that's why it's showing a code because the O2's are different. Not sure.

I'm sure there are some things that I haven't listed here that I have done or haven't done.

I'm a bodyman by trade and good around engines with out computers and emmisions. This is my first in depth trouble shooting on a engine with an ECU. I also struggle reading ohms at 20K reading. Just to let you know my limitations and experience.

About ready to strike a match

#2

Registered User

That single, unidentified wire may be to the AAV. It goes to the back of it. Check it out.

In all of this, I think I'd run a compression test and/or check the valve adjustment.

I'd blame the ECU last. The fact that the timing appears to be good and that you can adjust it, and that the diagnostic function appears to be functioning is a good sign that the ECU is fine.

Can't comment on the three wires to the igniter unless I can see them in a pic. Nothing wrong with splicing them, though, if it was done well and they're routed correctly. The fact that the truck runs is a good sign, too.

As for the ECU and O2 sensor compatibility, in order for the emissions to work right......namely the sensor......you need to have the correct ECU to operate it. The '89 has a heater circuit whereas the '86 doesn't. I don't believe the voltage would be different, though. The feedback system might work differently, but not really sure on that. So, I'd stick with the '86 ECU for now. There's more I could comment on about what you're seeing in regards to the swapping you're doing, but I have to cut it short and take care of some things.

In all of this, I think I'd run a compression test and/or check the valve adjustment.

I'd blame the ECU last. The fact that the timing appears to be good and that you can adjust it, and that the diagnostic function appears to be functioning is a good sign that the ECU is fine.

Can't comment on the three wires to the igniter unless I can see them in a pic. Nothing wrong with splicing them, though, if it was done well and they're routed correctly. The fact that the truck runs is a good sign, too.

As for the ECU and O2 sensor compatibility, in order for the emissions to work right......namely the sensor......you need to have the correct ECU to operate it. The '89 has a heater circuit whereas the '86 doesn't. I don't believe the voltage would be different, though. The feedback system might work differently, but not really sure on that. So, I'd stick with the '86 ECU for now. There's more I could comment on about what you're seeing in regards to the swapping you're doing, but I have to cut it short and take care of some things.

#3

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

That single, unidentified wire may be to the AAV. It goes to the back of it. Check it out.

In all of this, I think I'd run a compression test and/or check the valve adjustment.

I'd blame the ECU last. The fact that the timing appears to be good and that you can adjust it, and that the diagnostic function appears to be functioning is a good sign that the ECU is fine.

Can't comment on the three wires to the igniter unless I can see them in a pic. Nothing wrong with splicing them, though, if it was done well and they're routed correctly. The fact that the truck runs is a good sign, too.

As for the ECU and O2 sensor compatibility, in order for the emissions to work right......namely the sensor......you need to have the correct ECU to operate it. The '89 has a heater circuit whereas the '86 doesn't. I don't believe the voltage would be different, though. The feedback system might work differently, but not really sure on that. So, I'd stick with the '86 ECU for now. There's more I could comment on about what you're seeing in regards to the swapping you're doing, but I have to cut it short and take care of some things.

In all of this, I think I'd run a compression test and/or check the valve adjustment.

I'd blame the ECU last. The fact that the timing appears to be good and that you can adjust it, and that the diagnostic function appears to be functioning is a good sign that the ECU is fine.

Can't comment on the three wires to the igniter unless I can see them in a pic. Nothing wrong with splicing them, though, if it was done well and they're routed correctly. The fact that the truck runs is a good sign, too.

As for the ECU and O2 sensor compatibility, in order for the emissions to work right......namely the sensor......you need to have the correct ECU to operate it. The '89 has a heater circuit whereas the '86 doesn't. I don't believe the voltage would be different, though. The feedback system might work differently, but not really sure on that. So, I'd stick with the '86 ECU for now. There's more I could comment on about what you're seeing in regards to the swapping you're doing, but I have to cut it short and take care of some things.

Thanks for the pointers. I will check on those tonight. I agree I don't want to replace the ECU until i can prove that is the cause.

I'm sorry i didn't post the compression check results from a few days ago on a warm engine.

#1=180

#2=170

#3=175

#4=180

Range in book says 142-171 with no more than 14 psi difference between cylinders.

I also replaced the exhaust manifold gasket and donuts right after I got it. I drove it for 3-4 days after replacement without any problems until this running rough issue showed it's head.

The valve train doesn't make any noise to speak of.

#4

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

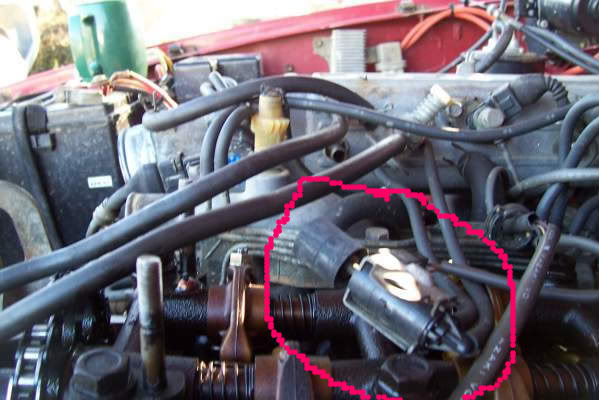

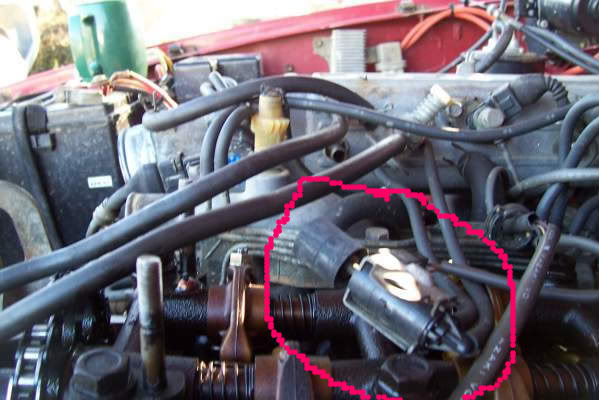

Here is a pic of the wire in question. It's green with a black stripe.

Thook

I used a mirror to look at the wire connector on the AAV. Is this the connector you are talking about?

More pics so you can see what I'm working with.

You can see the spliced wires to the coil/igniter in this pic below.

Thook

I used a mirror to look at the wire connector on the AAV. Is this the connector you are talking about?

More pics so you can see what I'm working with.

You can see the spliced wires to the coil/igniter in this pic below.

#5

Registered User

The splice looks legit from what I can see, though it's not close up for detail. But, as long as you're getting continuity and voltage (check with the meter at the ECU end) then you're golden.

Those compression readings are way too high in my opinion. Unless the motor was ever rebuilt and the head milled too much or the block was decked too much, then I'd blame valve adjustment. May not be making any appreciable noises, but again the compression's too high on all but #2. This could explain you're hot exhaust as well the other symptoms. But, I'll have to look at my '86 and see what that wire is for. I'm thinking it's just for the a/c idle up vacuum switching valve.........which appears to be missing from the top of your valve cover. Your AAV is hooked up just fine, though.

Those compression readings are way too high in my opinion. Unless the motor was ever rebuilt and the head milled too much or the block was decked too much, then I'd blame valve adjustment. May not be making any appreciable noises, but again the compression's too high on all but #2. This could explain you're hot exhaust as well the other symptoms. But, I'll have to look at my '86 and see what that wire is for. I'm thinking it's just for the a/c idle up vacuum switching valve.........which appears to be missing from the top of your valve cover. Your AAV is hooked up just fine, though.

Last edited by thook; 06-02-2010 at 03:10 PM.

#7

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

The splice looks legit from what I can see, though it's not close up for detail. But, as long as you're getting continuity and voltage (check with the meter at the ECU end) then you're golden.

Those compression readings are way too high in my opinion. Unless the motor was ever rebuilt and the head milled too much or the block was decked too much, then I'd blame valve adjustment. May not be making any appreciable noises, but again the compression's too high on all but #2. This could explain you're hot exhaust as well the other symptoms. But, I'll have to look at my '86 and see what that wire is for. I'm thinking it's just for the a/c idle up vacuum switching valve.........which appears to be missing from the top of your valve cover. Your AAV is hooked up just fine, though.

Those compression readings are way too high in my opinion. Unless the motor was ever rebuilt and the head milled too much or the block was decked too much, then I'd blame valve adjustment. May not be making any appreciable noises, but again the compression's too high on all but #2. This could explain you're hot exhaust as well the other symptoms. But, I'll have to look at my '86 and see what that wire is for. I'm thinking it's just for the a/c idle up vacuum switching valve.........which appears to be missing from the top of your valve cover. Your AAV is hooked up just fine, though.

</p>

</p>Here is the soot trail,

/p>

The cat that came out

Does anybody have an extra vac line assy. Mine is pinched on the top line. No airfow. Which reminds me what size vac hoses should I get? I need to bypass this hard line. I by passed it last week before the injector change. No noticeable change. So I put it back the way it was.

I know this has nothing to do with this problem, but is this the right setup for the throttle dampner?

Last edited by Alan's Classic; 06-02-2010 at 07:47 PM.

Trending Topics

#8

Registered User

I can't see a dern thing in that first pic.....lol! And, I can't watch the video. I just don't have sound at the moment.

4th pic.....I don't recall offhand what that line is for. EGR, maybe. I pulled the hard line assembly of my '86 a while back after removing the EGR system. So, I can't really comment on that. If you want to bypass, I'm sure you can. Just take a small piece of the soft line in to the parts store and have it matched up. That's what I'd do, but maybe someone else can actually give you the size.

The throttle dampener.....geez....I forget what that thing is actually called. Seems there's another name for it, but anyway.....it needs to be open to the atmosphere at the end. Not sure what you have it hooked it up to, but unhook it...hehe. Then, it's supposed to just dangle there a bit albeit in a somewhat secure way. On a stock set up, there's actually a clip to fasten it to a hose. Might just zip tie it to something and be done there.

That loose wire....it's not for the a/c switching valve. I do believe that's for the knock sensor! If so, you're going to need to fix that. That's the only single wire I can find on the top end of mine. The switching valves........a/c and fuel pressure up valves.....have two. But, what's your knock sensor looking like? It's between the plenum and valve cover right in the middle.

4th pic.....I don't recall offhand what that line is for. EGR, maybe. I pulled the hard line assembly of my '86 a while back after removing the EGR system. So, I can't really comment on that. If you want to bypass, I'm sure you can. Just take a small piece of the soft line in to the parts store and have it matched up. That's what I'd do, but maybe someone else can actually give you the size.

The throttle dampener.....geez....I forget what that thing is actually called. Seems there's another name for it, but anyway.....it needs to be open to the atmosphere at the end. Not sure what you have it hooked it up to, but unhook it...hehe. Then, it's supposed to just dangle there a bit albeit in a somewhat secure way. On a stock set up, there's actually a clip to fasten it to a hose. Might just zip tie it to something and be done there.

That loose wire....it's not for the a/c switching valve. I do believe that's for the knock sensor! If so, you're going to need to fix that. That's the only single wire I can find on the top end of mine. The switching valves........a/c and fuel pressure up valves.....have two. But, what's your knock sensor looking like? It's between the plenum and valve cover right in the middle.

Last edited by thook; 06-02-2010 at 07:51 PM.

#9

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

I can't see a dern thing in that first pic.....lol!

4th pic.....I don't recall offhand what that line is for. EGR, maybe. I pulled the hard line assembly of my '86 a while back after removing the EGR system. So, I can't really comment on that. If you want to bypass, I'm sure you can. Just take a small piece of the soft line in to the parts store and have it matched up. That's what I'd do, but maybe someone else can actually give you the size.

The throttle dampener.....geez....I forget what that thing is actually called. Seems there's another name for it, but anyway.....it needs to be open to the atmosphere at the end. Not sure what you have it hooked it up to, but unhook it...hehe. Then, it's supposed to just dangle there a bit albeit in a somewhat secure way. On a stock set up, there's actually a clip to fasten it to a hose. Might just zip tie it to something and be done there.

That loose wire....it's not for the a/c switching valve. I do believe that's for the knock sensor! That's the only single wire I can find on the top end of mine. The switching valves........a/c and fuel pressure up valves.....have two. What's your knock sensor looking like? It's between the plenum and valve cover right in the middle.

4th pic.....I don't recall offhand what that line is for. EGR, maybe. I pulled the hard line assembly of my '86 a while back after removing the EGR system. So, I can't really comment on that. If you want to bypass, I'm sure you can. Just take a small piece of the soft line in to the parts store and have it matched up. That's what I'd do, but maybe someone else can actually give you the size.

The throttle dampener.....geez....I forget what that thing is actually called. Seems there's another name for it, but anyway.....it needs to be open to the atmosphere at the end. Not sure what you have it hooked it up to, but unhook it...hehe. Then, it's supposed to just dangle there a bit albeit in a somewhat secure way. On a stock set up, there's actually a clip to fasten it to a hose. Might just zip tie it to something and be done there.

That loose wire....it's not for the a/c switching valve. I do believe that's for the knock sensor! That's the only single wire I can find on the top end of mine. The switching valves........a/c and fuel pressure up valves.....have two. What's your knock sensor looking like? It's between the plenum and valve cover right in the middle.

The knock sensor has a wire running to it. When I had the intake off I unhooked it to get the harness out of the way. I'll try to get a pic of it as well.

I keep forgetting to grab a piece of vac hose when I go to the parts house. LOL

Thanks for the input.

#10

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

It's been mentioned tome several times to check the timing chain to make sure it's right.

Set it at 0* TDC #1 rvalves are closed.

This looks right to me. At least the dot is at 12 o clock. I also pulled the dizzy cap off and it was pointing to #1.

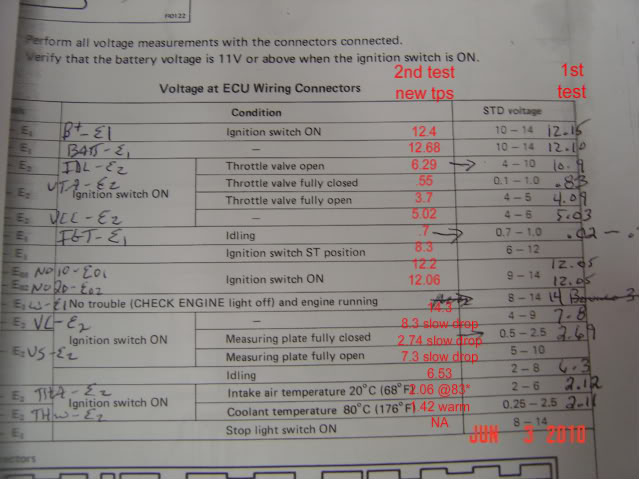

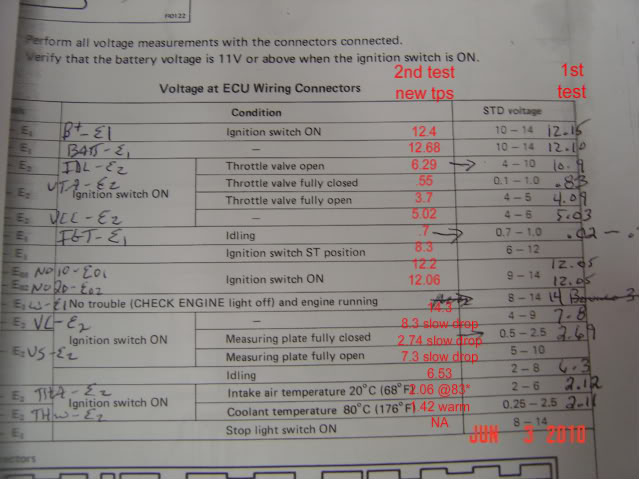

These are the voltage test I did last week prior to TPS and injector replacement. The arrows indicate out of range. Line 7 (idling) was measured when it would hardly idle. The voltage was bouncing all around the place. I figure the measuring plate (lines 12 & 13) is the throttle, but it mentions throttle on lines 3,4 & 5.

EDIT: the manual says the measuring plate is the MAF.

Set it at 0* TDC #1 rvalves are closed.

This looks right to me. At least the dot is at 12 o clock. I also pulled the dizzy cap off and it was pointing to #1.

These are the voltage test I did last week prior to TPS and injector replacement. The arrows indicate out of range. Line 7 (idling) was measured when it would hardly idle. The voltage was bouncing all around the place. I figure the measuring plate (lines 12 & 13) is the throttle, but it mentions throttle on lines 3,4 & 5.

EDIT: the manual says the measuring plate is the MAF.

Last edited by Alan's Classic; 06-03-2010 at 06:44 PM.

#11

Registered User

The timing looks right. The link's not going to stay in place after the motor's been run. It's only there for reference on installation.

I don't know what you have in store for more testing, but it looks like the throttle sensor is bad. Honestly, I've never tested one using voltage readings. I've always just used the ohm function on my meter directly at the sensor. And, if the sensor tested good, but I still suspect throttle sensor issues, I go to the ECU. Nevertheless, it seems to me you should see steady reading in voltages just the same as you would in ohms. For example, using the ohm function, one way to test the throttle angle (VTA circuit) along the entire track is with the probes hooked up to the VTA and E1 terminals, follow the meter/ohm readings as you slowly move the throttle plate from closed to wide open. There should be no dropouts (which seems to me is what you're seeing in terms of unsteady voltage) and a steady rise and then decline about midway of the throttle movement. Maybe you'd see it opposite in terms of voltage, ie a steady decline and then rise again midway? Haha....maybe you can tell me that? Anyway, what you're seeing could be a result of bad wiring or connections and not necessarily a bad sensor. You probably know that much, but thought I'd mention it. So, maybe test the sensor itself? If it still gives faulty readings, adjustment might correct it.

I'll look one more time for that wire on mine. No need for the pic I figure. If you have it hooked up, then it's kinda moot. Would save you the trouble, anyway.

I don't know what you have in store for more testing, but it looks like the throttle sensor is bad. Honestly, I've never tested one using voltage readings. I've always just used the ohm function on my meter directly at the sensor. And, if the sensor tested good, but I still suspect throttle sensor issues, I go to the ECU. Nevertheless, it seems to me you should see steady reading in voltages just the same as you would in ohms. For example, using the ohm function, one way to test the throttle angle (VTA circuit) along the entire track is with the probes hooked up to the VTA and E1 terminals, follow the meter/ohm readings as you slowly move the throttle plate from closed to wide open. There should be no dropouts (which seems to me is what you're seeing in terms of unsteady voltage) and a steady rise and then decline about midway of the throttle movement. Maybe you'd see it opposite in terms of voltage, ie a steady decline and then rise again midway? Haha....maybe you can tell me that? Anyway, what you're seeing could be a result of bad wiring or connections and not necessarily a bad sensor. You probably know that much, but thought I'd mention it. So, maybe test the sensor itself? If it still gives faulty readings, adjustment might correct it.

I'll look one more time for that wire on mine. No need for the pic I figure. If you have it hooked up, then it's kinda moot. Would save you the trouble, anyway.

#12

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

The timing looks right. The link's not going to stay in place after the motor's been run. It's only there for reference on installation.

I don't know what you have in store for more testing, but it looks like the throttle sensor is bad. Honestly, I've never tested one using voltage readings. I've always just used the ohm function on my meter directly at the sensor. And, if the sensor tested good, but I still suspect throttle sensor issues, I go to the ECU. Nevertheless, it seems to me you should see steady reading in voltages just the same as you would in ohms. For example, using the ohm function, one way to test the throttle angle (VTA circuit) along the entire track is with the probes hooked up to the VTA and E1 terminals, follow the meter/ohm readings as you slowly move the throttle plate from closed to wide open. There should be no dropouts (which seems to me is what you're seeing in terms of unsteady voltage) and a steady rise and then decline about midway of the throttle movement. Maybe you'd see it opposite in terms of voltage, ie a steady decline and then rise again midway? Haha....maybe you can tell me that? Anyway, what you're seeing could be a result of bad wiring or connections and not necessarily a bad sensor. You probably know that much, but thought I'd mention it. So, maybe test the sensor itself? If it still gives faulty readings, adjustment might correct it.

I'll look one more time for that wire on mine. No need for the pic I figure. If you have it hooked up, then it's kinda moot. Would save you the trouble, anyway.

I don't know what you have in store for more testing, but it looks like the throttle sensor is bad. Honestly, I've never tested one using voltage readings. I've always just used the ohm function on my meter directly at the sensor. And, if the sensor tested good, but I still suspect throttle sensor issues, I go to the ECU. Nevertheless, it seems to me you should see steady reading in voltages just the same as you would in ohms. For example, using the ohm function, one way to test the throttle angle (VTA circuit) along the entire track is with the probes hooked up to the VTA and E1 terminals, follow the meter/ohm readings as you slowly move the throttle plate from closed to wide open. There should be no dropouts (which seems to me is what you're seeing in terms of unsteady voltage) and a steady rise and then decline about midway of the throttle movement. Maybe you'd see it opposite in terms of voltage, ie a steady decline and then rise again midway? Haha....maybe you can tell me that? Anyway, what you're seeing could be a result of bad wiring or connections and not necessarily a bad sensor. You probably know that much, but thought I'd mention it. So, maybe test the sensor itself? If it still gives faulty readings, adjustment might correct it.

I'll look one more time for that wire on mine. No need for the pic I figure. If you have it hooked up, then it's kinda moot. Would save you the trouble, anyway.

The voltages listed were before the TPS change. I adjusted the TPS with an OHM meter, but it wouldn't be a bad idea to retest that circuit you mentioned. The further testing was a mistake on my part. I was thumbing thru the manual and saw a bunch of different circuits getting tested, but it was flow charts on the test I had already done. :-)

Bad wiring has been in the back of my mind, just can't prove it yet. I did check the grounds all 4 on the engine. Going out to test that circuit right now. Thanks again for the help and patience.

#14

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

I can give you one of these if you figure this out. I'll buy you a beer the next time you come over here. ;-)

I checked it on 20K. It had a steady climb and decent.

Idle=.7 which =700 ohms correct?

About 1/2" of pedal travel from WOT it= 1.74 then it falls off

WOT=1.45

Just for giggles I went from E1 to chassis ground =0.00 which shows no resistance. Check good.

I'm curious if the new O2 I put in is any good. I checked for codes and it flashed 1. System normal.

I checked it on 20K. It had a steady climb and decent.

Idle=.7 which =700 ohms correct?

About 1/2" of pedal travel from WOT it= 1.74 then it falls off

WOT=1.45

Just for giggles I went from E1 to chassis ground =0.00 which shows no resistance. Check good.

I'm curious if the new O2 I put in is any good. I checked for codes and it flashed 1. System normal.

#15

Registered User

Just letting you know I've read your post and will comment later tonight. I've been juggling the wife's station wagon, my own Toyota project, and the daily chores.

Next time I'm in Georgia.....well, one never knows. I might have to make a trip to Florida at some point and I do believe Northern Georgia would be on the way there.....if an airplane's not involved....haha.

Next time I'm in Georgia.....well, one never knows. I might have to make a trip to Florida at some point and I do believe Northern Georgia would be on the way there.....if an airplane's not involved....haha.

#16

Registered User

Okay....I believe this may be what that wire is for. I forgot to look at my vehicle again last night, so I went through some pics of mine and found this:

Ignore the circle. That's the vacuum switching valve for the a/c. But, look behind it at the temp switch on the thermostat. I forget what exactly that's for, and I seriously doubt it has anything to do with your issue, and I'll have to actually verify it's a single wire unit when I get home from work, but!! I think that's it. Your missing that switch from the top of your thermo housing, anyway. As well, I started and/or participated in a thread a while back discussing what that switch is for. I'll find it and report back.

Anyway.....here's an idea because I think your TPS wiring is bad. Unplug the bugger and see how the truck runs. Theory is the ECU will run in default mode relying on other sensor input to control injector pulse and timing. If the truck runs better, this is a good indication the TPS is giving faulty input......in your case from wiring. Remove offending input and the ECU theoretically balances out. I say theoretically because I don't rememeber all the facts behind this experiment, though I do know people have been able to effectively diagnose TPS troubles this way. I learned this from another thread I started a long time ago discussing my 3vze issues. Try it and see.

Sorry to keep you waiting....

Oh......what brand of O2 sensor is in it?

Ignore the circle. That's the vacuum switching valve for the a/c. But, look behind it at the temp switch on the thermostat. I forget what exactly that's for, and I seriously doubt it has anything to do with your issue, and I'll have to actually verify it's a single wire unit when I get home from work, but!! I think that's it. Your missing that switch from the top of your thermo housing, anyway. As well, I started and/or participated in a thread a while back discussing what that switch is for. I'll find it and report back.

Anyway.....here's an idea because I think your TPS wiring is bad. Unplug the bugger and see how the truck runs. Theory is the ECU will run in default mode relying on other sensor input to control injector pulse and timing. If the truck runs better, this is a good indication the TPS is giving faulty input......in your case from wiring. Remove offending input and the ECU theoretically balances out. I say theoretically because I don't rememeber all the facts behind this experiment, though I do know people have been able to effectively diagnose TPS troubles this way. I learned this from another thread I started a long time ago discussing my 3vze issues. Try it and see.

Sorry to keep you waiting....

Oh......what brand of O2 sensor is in it?

Last edited by thook; 06-05-2010 at 09:52 AM.

#17

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

Thanks Thook

My thermostat housing doesn't have that sensor. There aren't any holes for one. Still wandering what this engine came out of.

I unplugged the TPS while running and no change.

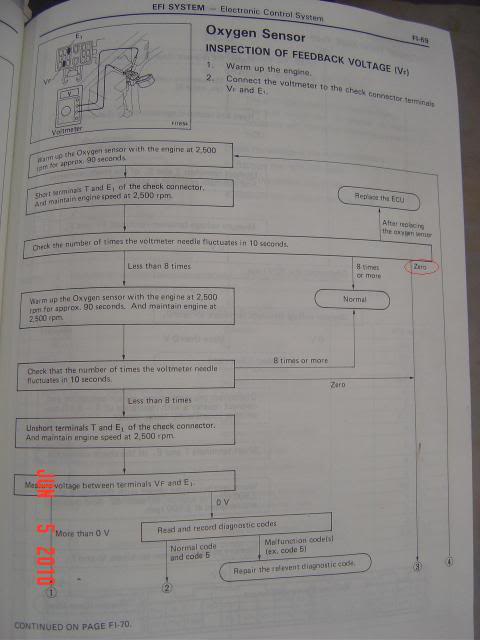

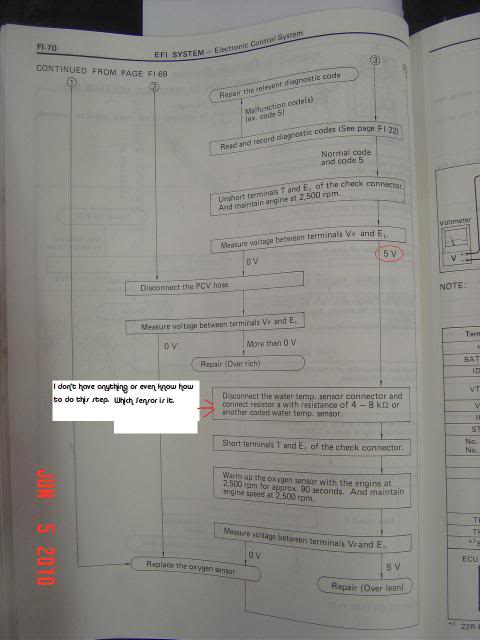

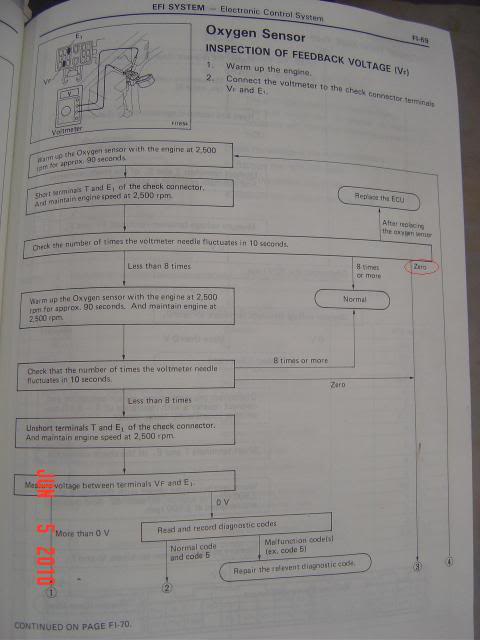

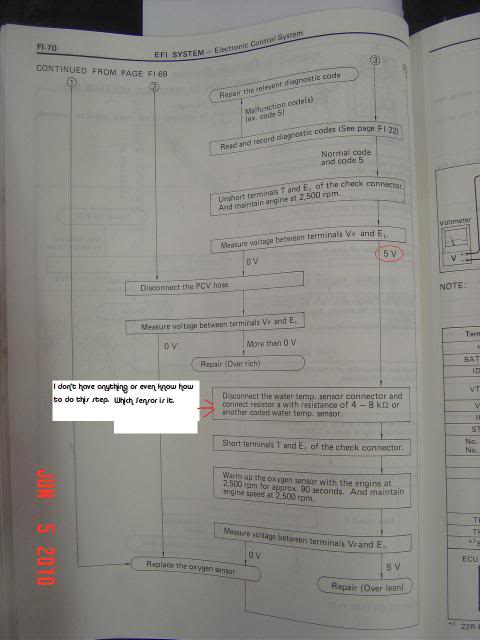

Here are the flow charts in the manual for testing the O2. I tested both the new one and put the old one back in. Both read the same. There a series of steps I couldn't do due to limited components and know how. I notated the ones I couldn't do. There is no movement at all on the meter at 2500. I have hooked up a temp tach for the time being. It's not looking good for the O2, but since I can't perform the last set of test I can't confirm. In the last result it has an option either bad O2 or lean condition. I know it is not lean. Too much soot and if I unhooked the PCV and creat a major vac leak it runs really good since it is leaning it out. The new O2 is a Bosch.

I've been talking to a Toyota Tech and he doesn't have a lot of experience with the 22RE, but there are some old timers there that have experience. They mentioned that I should use an analog meter and measure the OX signal at the check connector and should see a steady swing there as well.

I have circled in red my values.

My thermostat housing doesn't have that sensor. There aren't any holes for one. Still wandering what this engine came out of.

I unplugged the TPS while running and no change.

Here are the flow charts in the manual for testing the O2. I tested both the new one and put the old one back in. Both read the same. There a series of steps I couldn't do due to limited components and know how. I notated the ones I couldn't do. There is no movement at all on the meter at 2500. I have hooked up a temp tach for the time being. It's not looking good for the O2, but since I can't perform the last set of test I can't confirm. In the last result it has an option either bad O2 or lean condition. I know it is not lean. Too much soot and if I unhooked the PCV and creat a major vac leak it runs really good since it is leaning it out. The new O2 is a Bosch.

I've been talking to a Toyota Tech and he doesn't have a lot of experience with the 22RE, but there are some old timers there that have experience. They mentioned that I should use an analog meter and measure the OX signal at the check connector and should see a steady swing there as well.

I have circled in red my values.

Last edited by Alan's Classic; 06-05-2010 at 12:58 PM.

#18

Registered User

iTrader: (1)

You may have multiple gremlins going on.

engine sounds like it is getting unmetered air in to it, check vacuum lines and the handy line someone attach to the throttle dampener and intake. this would also explain the glowing cat and rough idle and O2 code.

The EGR may also be contributing as they can get stuck open. Easy check take an empty beer or coke can and make your self a block off plate to fit in between egr and intake. I don't favor running it this way but it will let you eliminate it. Can cause weird idle surges and o2 code

pull the TPS and check the return spring, the electric values may all be in range but the return spring may have gone weak. can cause the that drop in rpms when gas is let off and o2 code.

Are your plug wires in right position. 1342 going clockwise?

engine sounds like it is getting unmetered air in to it, check vacuum lines and the handy line someone attach to the throttle dampener and intake. this would also explain the glowing cat and rough idle and O2 code.

The EGR may also be contributing as they can get stuck open. Easy check take an empty beer or coke can and make your self a block off plate to fit in between egr and intake. I don't favor running it this way but it will let you eliminate it. Can cause weird idle surges and o2 code

pull the TPS and check the return spring, the electric values may all be in range but the return spring may have gone weak. can cause the that drop in rpms when gas is let off and o2 code.

Are your plug wires in right position. 1342 going clockwise?

#19

Registered User

iTrader: (1)

The data plate you were referring to doesn't really say anything but rather is about the same sizes and shape as the EGR/intake gasket and is located sightly behind and above the driver side motor mount/brackets.

if you don't have the warm temp switch on the thermostat housing it is no big deal. 2wd versions did not have that. Mines been disconnected because the connector broke for almost 4 yrs with no issues. Was thinking of using the hole for electric fan sensor.

if you don't have the warm temp switch on the thermostat housing it is no big deal. 2wd versions did not have that. Mines been disconnected because the connector broke for almost 4 yrs with no issues. Was thinking of using the hole for electric fan sensor.

#20

Registered User

Thread Starter

Join Date: Jun 2010

Location: North Georgia

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

You may have multiple gremlins going on.

engine sounds like it is getting unmetered air in to it, check vacuum lines and the handy line someone attach to the throttle dampener and intake. this would also explain the glowing cat and rough idle and O2 code.

The EGR may also be contributing as they can get stuck open. Easy check take an empty beer or coke can and make your self a block off plate to fit in between egr and intake. I don't favor running it this way but it will let you eliminate it. Can cause weird idle surges and o2 code

pull the TPS and check the return spring, the electric values may all be in range but the return spring may have gone weak. can cause the that drop in rpms when gas is let off and o2 code.

Are your plug wires in right position. 1342 going clockwise?

engine sounds like it is getting unmetered air in to it, check vacuum lines and the handy line someone attach to the throttle dampener and intake. this would also explain the glowing cat and rough idle and O2 code.

The EGR may also be contributing as they can get stuck open. Easy check take an empty beer or coke can and make your self a block off plate to fit in between egr and intake. I don't favor running it this way but it will let you eliminate it. Can cause weird idle surges and o2 code

pull the TPS and check the return spring, the electric values may all be in range but the return spring may have gone weak. can cause the that drop in rpms when gas is let off and o2 code.

Are your plug wires in right position. 1342 going clockwise?

If the EGR was leaking that is the same as a vac leak correct? It runs really well when I enduce a major vac leak like disconnecting the brake booster hose. It leans it out.

That's a good trick for the EGR block off.

The TPS is new and the spring feels really good. The old one didn't return to idle.

Firing order correct. I've read at different places that after market O2 sensors aren't a good option. Is that true? Should I go with an OE? I'm getting the same readings with the old O2 and the new Bosch. Either their both good (which I doubt), or they are both bad. I'm confident with the test on the O2 except for those last few steps.