85 22R - Not your typical Crank Pulley Bolt Question!

#1

Registered User

Thread Starter

85 22R - Not your typical Crank Pulley Bolt Question!

I'm back! With my third 80s Toyota. Will have to start a build thread soon..

Wife actually found this one on CL and I jumped on it before the 13 other people that called. Was in a front end accident in the 90s, but it appears they bead blasted the whole truck and repainted at the time - effectively removing the bondo from the fenders in the box (exposing the spot welds), which actually has preserved the truck from prematurely rusting. Pretty awesome. Truck is completely rust free.

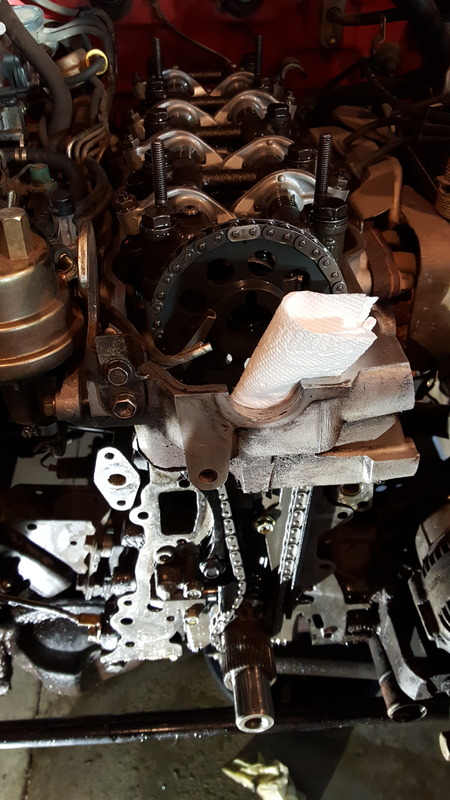

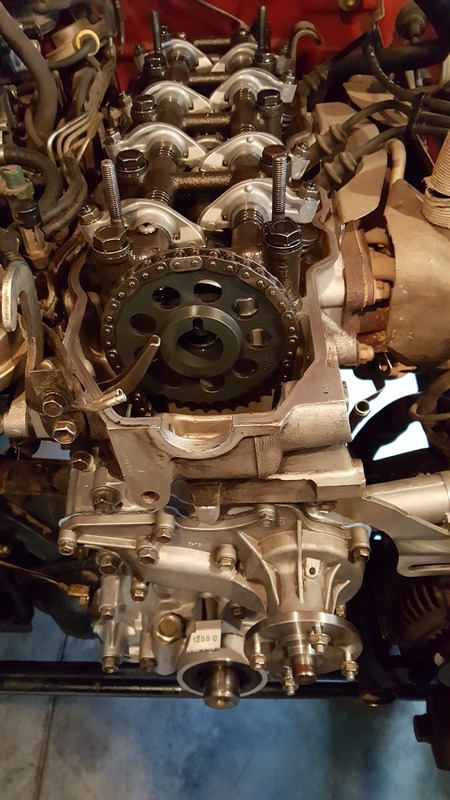

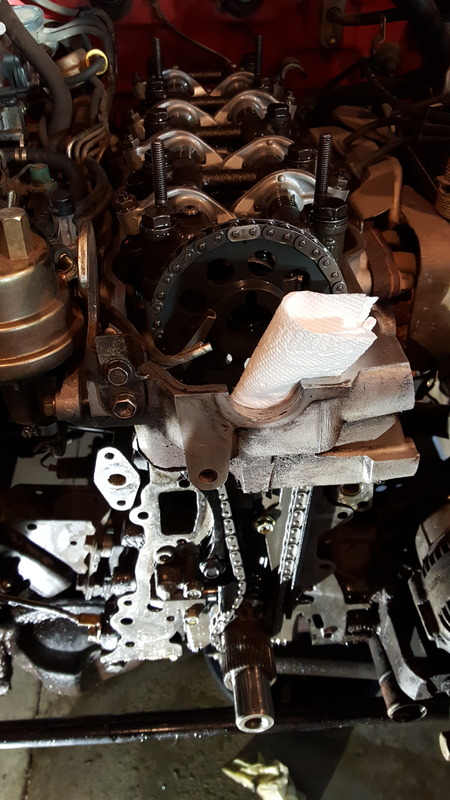

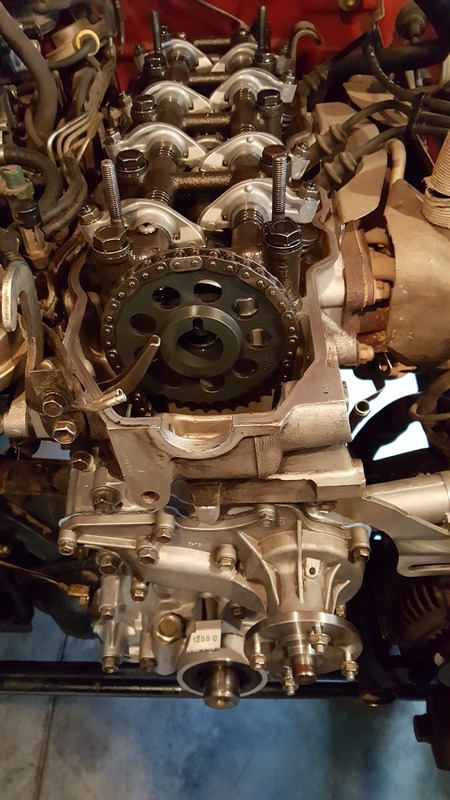

Long story short, the PO rebuilt the motor "10k ago", and doesn't have a lot of mechanical experience. Really handy guy, but his neighbor, and a renowned mountain biker helped him with this project. I failed to ask why the motor was rebuilt at 160k.. They did replace the chain, guides and sprockets which is nice, and it runs well.

I've had a:

- 3VZ-E, which ran well, intermittent psudo knock sensor engine fault code

- 20R Run into the dirt, brought back to life then eventually needed a head gasket

- Now, a 22R.

He mentioned it had a small timing chain cover leak when I purchased. I figured, no big deal will get to it at some point. Now we're up to speed, about 4k miles later. Two weeks ago it started SPEWING oil from said leak. A lot of research later I can see why, and it also seems pretty common. Probably 2 drips per second while running, next to nothing while parked. This was also the same time I did an oil change and checked the RAD. Uh oh. Coolant and oil are mixing. Luckily the truck got me through the 6ft of snow we got in December and January..

I purchased everything I need for HG and TC Cover jobs. The timing cover was so bad, that I'm crossing my fingers that's where the oil and coolant were mixing. I'll address HG later; hoping to get the truck up and running tonight.

Liquid Gaskets for Timing Chain Cover, WP, Oil Pump, Oil Pan are all currently in the curing phase since last night. I'm just now buttoning up everything and waiting till tonight to fill the oil and coolant.

FINALLY, here's the question!

The Crank pulley bolt is effed. Pretty typical I'm assuming after a few uses. You know you live in a small town where there's never the spare part you need, when you need it....

Options:

1. Button it all up and deal with potentially stripped bolt next time around

2. Bike to hardware store, purchase a spare 19mm impact socket, bike to welder and have them weld it on, then button it all up. (I have all day today so I could do this).

3. New nut comes in to Toyota dealership tomorrow, but I won't be able to pick it up till Saturday most likely, so: Bike in the rain to work and back this week, and fix the yota with the new nut next weekend?

4. Preventative grinding on partially stripped bolt NOW, grind it down to a 17/18mm, for future removal needs?

Look forward to hearing everyone's opinion!

Wife actually found this one on CL and I jumped on it before the 13 other people that called. Was in a front end accident in the 90s, but it appears they bead blasted the whole truck and repainted at the time - effectively removing the bondo from the fenders in the box (exposing the spot welds), which actually has preserved the truck from prematurely rusting. Pretty awesome. Truck is completely rust free.

Long story short, the PO rebuilt the motor "10k ago", and doesn't have a lot of mechanical experience. Really handy guy, but his neighbor, and a renowned mountain biker helped him with this project. I failed to ask why the motor was rebuilt at 160k.. They did replace the chain, guides and sprockets which is nice, and it runs well.

I've had a:

- 3VZ-E, which ran well, intermittent psudo knock sensor engine fault code

- 20R Run into the dirt, brought back to life then eventually needed a head gasket

- Now, a 22R.

He mentioned it had a small timing chain cover leak when I purchased. I figured, no big deal will get to it at some point. Now we're up to speed, about 4k miles later. Two weeks ago it started SPEWING oil from said leak. A lot of research later I can see why, and it also seems pretty common. Probably 2 drips per second while running, next to nothing while parked. This was also the same time I did an oil change and checked the RAD. Uh oh. Coolant and oil are mixing. Luckily the truck got me through the 6ft of snow we got in December and January..

I purchased everything I need for HG and TC Cover jobs. The timing cover was so bad, that I'm crossing my fingers that's where the oil and coolant were mixing. I'll address HG later; hoping to get the truck up and running tonight.

Liquid Gaskets for Timing Chain Cover, WP, Oil Pump, Oil Pan are all currently in the curing phase since last night. I'm just now buttoning up everything and waiting till tonight to fill the oil and coolant.

FINALLY, here's the question!

The Crank pulley bolt is effed. Pretty typical I'm assuming after a few uses. You know you live in a small town where there's never the spare part you need, when you need it....

Options:

1. Button it all up and deal with potentially stripped bolt next time around

2. Bike to hardware store, purchase a spare 19mm impact socket, bike to welder and have them weld it on, then button it all up. (I have all day today so I could do this).

3. New nut comes in to Toyota dealership tomorrow, but I won't be able to pick it up till Saturday most likely, so: Bike in the rain to work and back this week, and fix the yota with the new nut next weekend?

4. Preventative grinding on partially stripped bolt NOW, grind it down to a 17/18mm, for future removal needs?

Look forward to hearing everyone's opinion!

Last edited by neockder; 02-13-2017 at 10:14 AM.

#2

Registered User

Thread Starter

I chose option A! Will have the new bolt ready,. if and when need be! If anyone is planning on doing any front end work, i would recommend having one on hand just in case..

#4

Registered User

I would go with 4. It seems fairly simple and you won't have to bike in the rain even though that might provide for additional "interesting" posts.

You can still do option 1 and/or 2 if it doesn't work out well.

My 2 cents worth - I do accept Paypal

P.S. Nice lookin truck

You can still do option 1 and/or 2 if it doesn't work out well.

My 2 cents worth - I do accept Paypal

P.S. Nice lookin truck

#5

Registered User

Thread Starter

I would go with 4. It seems fairly simple and you won't have to bike in the rain even though that might provide for additional "interesting" posts.

You can still do option 1 and/or 2 if it doesn't work out well.

My 2 cents worth - I do accept Paypal

P.S. Nice lookin truck

You can still do option 1 and/or 2 if it doesn't work out well.

My 2 cents worth - I do accept Paypal

P.S. Nice lookin truck

I put about 80ft/lbs on the current nut. There's still enough meat to get it off i think. I made sure I would be able to get a bar on there with the fan and rad installed. I'll pick it up the new nut tomorrow and wrench this one on. I was too anxious not to button everything up tonight and test the system. So far so good! A few spatters, i think from crank seal that i greased.. we'll see how its holding in the coming weeks and if the HG still needs to be done. Good news so far is the heat is working awesome, and prior I was hearing a 'whooshing' through the heater core as if the coolant was never fully bleeding. No wooshing anymore..

#6

Registered User

iTrader: (1)

Hope that does it for you. I would order a new bolt and have it in my box waiting for the head gasket. Then if you can't get your current one to spin off when it's time get a sacrificial socket and JB weld it on to the rounded bolt and either throw it away or keep it as a trophy. Then install new bolt and your good to go. Being that rounded it looks like it was hammered on by a loose socket and or a 12pt 19mm socket. I have never had one round and have R&Red one 4 times on the same rig before, (don't ask).