how to tear into the L52 transmission

#1

Registered User

Thread Starter

how to tear into the L52 transmission

well i rebuilt (tore apart) 2 L52s last night to make one that worked.

most of these picts u can compare to yours for taking stuff apart.

first off the L52 is the first 5 speed they put into their us trucks. the L50 is basically the same but only a 4 speed.

-there are 2 different sized input bearing used in these trannies. butt the input/output/lower counter shafts are the same. but the housings, front bearing retainer and bearing are different and not interchangeable.

-some things i would like to point out are get a medium brass hammer and punch (u can hit the gears and they will not get messed up). snap ring pliers.

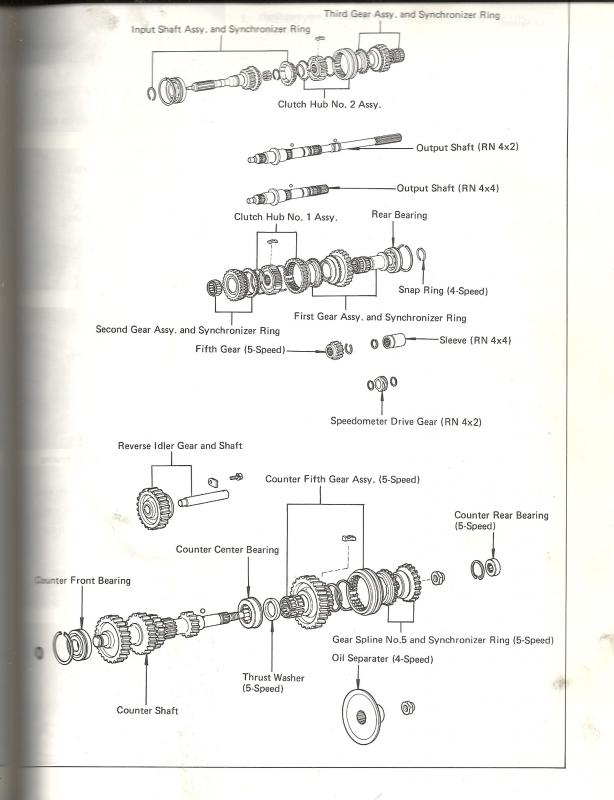

here are the pages from the fsm for the L52

i took these picts in reverse once i figured out how to take one apart.

i will try to do this in removal order from a complete tranny.

top view of transmission with the cover case/shift lever retainer removed

input shaft with bearing retainer on

-front bearing retainer off.

-you do not have to remove the snap rings on the in upper input shaft unless you are changing the bearing etc behind it.

-remove the lower 2 on the lower counter shaft end (the one below the input shaft with the splines).

-tail end of output shaft up top and lower counter shaft below with the shift fork.

-remove 4x4 sleeve off of upper output shaft. NOTE!!! when reinstalling this sleeve you MUST put it on with the line towards the front just like in this picture. if not your output splines will strip off and you will be screwed and need a new output shaft. notice in the last picture below you can see the splines that have been stripped off. someone else s screw up and my clean up.

-sleeve removed and the snap ring removed that was infront of it.

-also remove the other snap ring infront of the one that is removed. it is touching the 5th gear on the same shaft (output shaft) as the sleeve.

-with the sleeve and both snap rings removed from the output shaft. you do not have to remove these snap rings if you are not removing the bearing/gears.

-with counter shaft retaining nut removed and gear spline no. 5 and synch ring removed. also 1/2 of the bearing slid out (only for the picture).

-drive dowel pin out of the 5th gear shift fork/shaft

-shift fork and counter 5th gear assy off.

-thrust washer and detent ball still on shaft, remove them.

-remove thrust washer and detent ball.

-remove the 4, 12mm (head size) bolts with torx in the head, that secure the rear bearing retainer and remove bearing retainer.

-remove upper retaining ring off of output shaft bearing outer edge.

-remove counter center bearing off of the lower counter shaft output.

-also remove center front bearing and snap rings.

-with these bearings removed from the lower counter shaft drop it down in the housing like in the picture. with the front of the counter shaft dropped down this will allow for you to seporate the input shaft/bearing/gears from the output shaft.

-with the lower counter shaft dropped down this is the input shaft assy.pulled out only like 1 inch. you can see the snap ring (to the left of the brass synchro ring, on the splines down in there) that is pictured 2 pictures down, the one with the screwdriver pointing at it.

-pull input shaft out through the bellhousing side.

-top view with input shaft assy. removed

-front snap ring on output shaft. remove

-removing clutch hub keys (there are 3 total) on clutch hub assy. no.2

-clutch gear removal

-clutch slider removed up through top opening.

-third gear assy., bearing and synch ring sliding off through the bellhousing hole.

-third gear assy/clutch hub no. 2 held inline removed from output shaft.

-here is how the rings on the inside of the clutch hub have to line up. note how each keyway has the ring covering the gap. the 2 ends stop just past each of the keyways. if the rings are not installed like this on both sides the little keys will not be supported.make sure they are pushed all the way against the hub wall. like in the picture

-slide the output shaft towards the front and stick the front of the output shaft out the input shaft bearing hole into the bellhousing. then lift up the output- output splined end up and out.

-input and output shafts removed

-lower counter shaft in bottom and reverse gear on lower shaft in upper left of housing. above that the 5th gear shift lever with the ball and pin coming up out of it above the reverse shaft.

-outside of the housing on the bottom is the output shaft with the bad output splines from having the 4x4 sleeve put on backwards.

-removal of counter shaft. slide out back side bearing hole and lift out the top cover hole.

-counter shaft out and reverse gear slider/shaft and 5th gearshaft

take your time and label everything. once the counter shaft and input/output shafts are back in put the rear bearing retainer on before you put back onthe counter 5th gear assy. good luck and if i forgot anything please chime in. or message me, because i know i forgot a bunch of stuff

most of these picts u can compare to yours for taking stuff apart.

first off the L52 is the first 5 speed they put into their us trucks. the L50 is basically the same but only a 4 speed.

-there are 2 different sized input bearing used in these trannies. butt the input/output/lower counter shafts are the same. but the housings, front bearing retainer and bearing are different and not interchangeable.

-some things i would like to point out are get a medium brass hammer and punch (u can hit the gears and they will not get messed up). snap ring pliers.

here are the pages from the fsm for the L52

i took these picts in reverse once i figured out how to take one apart.

i will try to do this in removal order from a complete tranny.

top view of transmission with the cover case/shift lever retainer removed

input shaft with bearing retainer on

-front bearing retainer off.

-you do not have to remove the snap rings on the in upper input shaft unless you are changing the bearing etc behind it.

-remove the lower 2 on the lower counter shaft end (the one below the input shaft with the splines).

-tail end of output shaft up top and lower counter shaft below with the shift fork.

-remove 4x4 sleeve off of upper output shaft. NOTE!!! when reinstalling this sleeve you MUST put it on with the line towards the front just like in this picture. if not your output splines will strip off and you will be screwed and need a new output shaft. notice in the last picture below you can see the splines that have been stripped off. someone else s screw up and my clean up.

-sleeve removed and the snap ring removed that was infront of it.

-also remove the other snap ring infront of the one that is removed. it is touching the 5th gear on the same shaft (output shaft) as the sleeve.

-with the sleeve and both snap rings removed from the output shaft. you do not have to remove these snap rings if you are not removing the bearing/gears.

-with counter shaft retaining nut removed and gear spline no. 5 and synch ring removed. also 1/2 of the bearing slid out (only for the picture).

-drive dowel pin out of the 5th gear shift fork/shaft

-shift fork and counter 5th gear assy off.

-thrust washer and detent ball still on shaft, remove them.

-remove thrust washer and detent ball.

-remove the 4, 12mm (head size) bolts with torx in the head, that secure the rear bearing retainer and remove bearing retainer.

-remove upper retaining ring off of output shaft bearing outer edge.

-remove counter center bearing off of the lower counter shaft output.

-also remove center front bearing and snap rings.

-with these bearings removed from the lower counter shaft drop it down in the housing like in the picture. with the front of the counter shaft dropped down this will allow for you to seporate the input shaft/bearing/gears from the output shaft.

-with the lower counter shaft dropped down this is the input shaft assy.pulled out only like 1 inch. you can see the snap ring (to the left of the brass synchro ring, on the splines down in there) that is pictured 2 pictures down, the one with the screwdriver pointing at it.

-pull input shaft out through the bellhousing side.

-top view with input shaft assy. removed

-front snap ring on output shaft. remove

-removing clutch hub keys (there are 3 total) on clutch hub assy. no.2

-clutch gear removal

-clutch slider removed up through top opening.

-third gear assy., bearing and synch ring sliding off through the bellhousing hole.

-third gear assy/clutch hub no. 2 held inline removed from output shaft.

-here is how the rings on the inside of the clutch hub have to line up. note how each keyway has the ring covering the gap. the 2 ends stop just past each of the keyways. if the rings are not installed like this on both sides the little keys will not be supported.make sure they are pushed all the way against the hub wall. like in the picture

-slide the output shaft towards the front and stick the front of the output shaft out the input shaft bearing hole into the bellhousing. then lift up the output- output splined end up and out.

-input and output shafts removed

-lower counter shaft in bottom and reverse gear on lower shaft in upper left of housing. above that the 5th gear shift lever with the ball and pin coming up out of it above the reverse shaft.

-outside of the housing on the bottom is the output shaft with the bad output splines from having the 4x4 sleeve put on backwards.

-removal of counter shaft. slide out back side bearing hole and lift out the top cover hole.

-counter shaft out and reverse gear slider/shaft and 5th gearshaft

take your time and label everything. once the counter shaft and input/output shafts are back in put the rear bearing retainer on before you put back onthe counter 5th gear assy. good luck and if i forgot anything please chime in. or message me, because i know i forgot a bunch of stuff

Last edited by INFINITY; 09-14-2011 at 08:23 PM.

#2

Registered User

That's a good write up! Thanks a lot for that. I sometimes plan to do a good tutorial like that...then I get caught up just getting the job done and don't take pictures.

Reminds me of rebuilding my t-case...except way more complicated...

Reminds me of rebuilding my t-case...except way more complicated...

#3

Registered User

Join Date: Sep 2011

Location: Virgilina, VA

Posts: 5

Likes: 0

Received 0 Likes

on

0 Posts

Can the early model 4wd trannys internal parts be interchanged

My reasoning in asking is that I have a L42 i believe, side loader trans, where my gears are in good shape but the side cover is bent and it doesn't seal correctly and i was wondering if I could take those gears and put them in my L50 or 52 trans, top loader 4 speed?

Oh and I'm new so it may take a lil while to get used to you guys form of posting

Oh and I'm new so it may take a lil while to get used to you guys form of posting

#4

82 toyota diesel pickup 2wd L52

I just got back the L52 from autozone from having it rebuilt and the tranny is stuck in reverse. But the shifter is in neutral. I called the outfit in Minnesota who rebuilt it and they said there is a plug on the driver's side of the tranny and I have to stick a screwdriver in it to get it out of reverse. My question is what plug do I do this too. from what I can see there are three plugs. One is obviously the fill plug. The second one is above the fill plug that has a small spring in it and there is another one that has a screw in it to adjust something on the same side but higher up on the tranny.

#5

Registered User

Start your own thread. This is off topic to this one and is buried way down where people might not see it.

Also, for questions about the inner workings of transmissions, you'll get a lot more response over on the Marlin Crawler forum.

Also, for questions about the inner workings of transmissions, you'll get a lot more response over on the Marlin Crawler forum.

Trending Topics

#8

Infinity,

Sounds like your comfortable w/tearing transmissions apart, i built the trans {L52} in my '82 but ran into a snag when assembly time arrived..i didn't have the factory press that does inner/outer races at the same time..Ended up having a local rebuilder doing that part and assembled the rest myself..My question{s} to you are; does the W56{?} require a inner/outer bearing press too,on the w56 , the removable b-housing=are there different versions that adapt the trans to a V6 and I4 and finally is there a "most" desirable year/version to build? I'm a machinest and can fab. a new crossmember and move/patch the floor to accept differnt shifters..Thanks in advance for the imput.

Randy

Sounds like your comfortable w/tearing transmissions apart, i built the trans {L52} in my '82 but ran into a snag when assembly time arrived..i didn't have the factory press that does inner/outer races at the same time..Ended up having a local rebuilder doing that part and assembled the rest myself..My question{s} to you are; does the W56{?} require a inner/outer bearing press too,on the w56 , the removable b-housing=are there different versions that adapt the trans to a V6 and I4 and finally is there a "most" desirable year/version to build? I'm a machinest and can fab. a new crossmember and move/patch the floor to accept differnt shifters..Thanks in advance for the imput.

Randy

#9

Registered User

Thread Starter

Infinity,

Sounds like your comfortable w/tearing transmissions apart, i built the trans {L52} in my '82 but ran into a snag when assembly time arrived..i didn't have the factory press that does inner/outer races at the same time..Ended up having a local rebuilder doing that part and assembled the rest myself..My question{s} to you are; does the W56{?} require a inner/outer bearing press too,on the w56 , the removable b-housing=are there different versions that adapt the trans to a V6 and I4 and finally is there a "most" desirable year/version to build? I'm a machinest and can fab. a new crossmember and move/patch the floor to accept differnt shifters..Thanks in advance for the imput.

Randy

Sounds like your comfortable w/tearing transmissions apart, i built the trans {L52} in my '82 but ran into a snag when assembly time arrived..i didn't have the factory press that does inner/outer races at the same time..Ended up having a local rebuilder doing that part and assembled the rest myself..My question{s} to you are; does the W56{?} require a inner/outer bearing press too,on the w56 , the removable b-housing=are there different versions that adapt the trans to a V6 and I4 and finally is there a "most" desirable year/version to build? I'm a machinest and can fab. a new crossmember and move/patch the floor to accept differnt shifters..Thanks in advance for the imput.

Randy

so i really cant answer any of your questions, sorry. people use the r154 tranny out a 22ret as a stronger tranny behind the 22r, etc...

i mainly did this write up because there was only a few picts of these transmissions on the internet. and i was tearing down one so i figured it could help someone else out.

they did not produce these trannys except for like 1.5 years or so. but it is a direct drop in for a 80-83 pickup from a 4 speed to a 5 speed. any later year tranny and you have to move the x-member back.

#10

Registered User

I know this thread is a year old, but only one i've found with useful info.

I've got an 81 with a 5 speed, i think that means its an l50, but i am not sure. the input bearing really started to howl on the freeway the other day.

To replace the input bearing do i just drop the transmission and pull the bearing retainer plate, that i see in the diagram. I've never messed with a transmission before, so bear with me haha, no pun intended.

I've got an 81 with a 5 speed, i think that means its an l50, but i am not sure. the input bearing really started to howl on the freeway the other day.

To replace the input bearing do i just drop the transmission and pull the bearing retainer plate, that i see in the diagram. I've never messed with a transmission before, so bear with me haha, no pun intended.

#14

Registered User

iTrader: (1)

I know this thread is a year old, but only one i've found with useful info.

I've got an 81 with a 5 speed, i think that means its an l50, but i am not sure. the input bearing really started to howl on the freeway the other day.

To replace the input bearing do i just drop the transmission and pull the bearing retainer plate, that i see in the diagram. I've never messed with a transmission before, so bear with me haha, no pun intended.

I've got an 81 with a 5 speed, i think that means its an l50, but i am not sure. the input bearing really started to howl on the freeway the other day.

To replace the input bearing do i just drop the transmission and pull the bearing retainer plate, that i see in the diagram. I've never messed with a transmission before, so bear with me haha, no pun intended.

Last edited by cman1; 01-21-2013 at 04:24 PM.

#15

Registered User

Join Date: Jun 2006

Location: Teays Valley, WV

Posts: 296

Likes: 0

Received 0 Likes

on

0 Posts

I'm right there with ya. Have mine laying in the garage floor right now doing the clutch and I notice (just like you) that there is quite a bit of wobble and up/down/left/right play in the input shaft. Feels tight in/out (axial?) though. REALLY don't wanna tear into the whole thing but looks like you have to go pretty far in just to get that input shaft bearing out.

#17

Registered User

Join Date: Jun 2006

Location: Teays Valley, WV

Posts: 296

Likes: 0

Received 0 Likes

on

0 Posts

I did have some sporadic whining about a year ago but it went away. At the time I thought it may have been the throw-out bearing whining. But now that I have the trans out and have inspected the input shaft, I'm pretty sure it was the input shaft bearing that was whining.

#18

Registered User

iTrader: (1)

bringing this thread back up, I'm tearing down an l45 to grab the front input shaft to fix my l52, I want to know what tools and methods you used to remove the front and rear input, output and counter shaft bearings, I'm having a really hard time, They need to be removed to pull the shafts out of the transmission.

#20

Registered User

Join Date: Feb 2014

Location: 40 miles North of Atlanta

Posts: 250

Likes: 0

Received 0 Likes

on

0 Posts

bringing this thread back up, I'm tearing down an l45 to grab the front input shaft to fix my l52, I want to know what tools and methods you used to remove the front and rear input, output and counter shaft bearings, I'm having a really hard time, They need to be removed to pull the shafts out of the transmission.

Hey bud how did you end up getting these bearing out? I'm in the same spot. Need to know what puller to buy without spending a fortune on a bad arse snap on set.

There are some decent videos on youtube for ford top loader 5speeds. the mechanics are the same from what I can tell.